Thingiverse

Prusa MK2 filament guide by kwijatkowski

by Thingiverse

Last crawled date: 4 years, 4 months ago

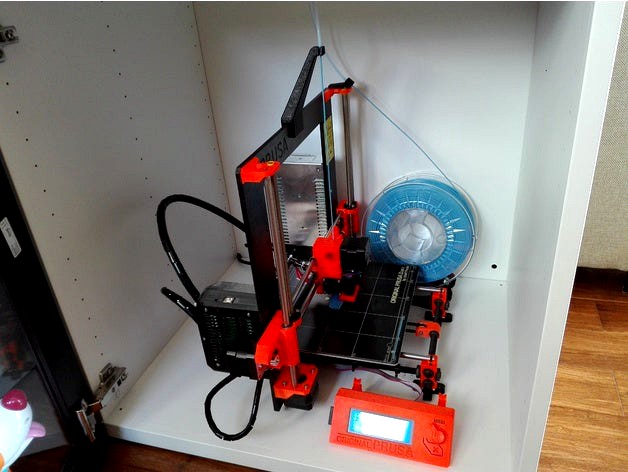

This is a simple filement guide which I designed for my Prusa. It is super simple to juse. Just use hexagon hole on the Prusa z rod mount to attach small part, and slide bigger one on the frame center. You will also need 35cm of ptfe tube. To have complete system you will also need spool holder (I use this one http://www.thingiverse.com/thing:1806139 )

There is NO negative effect on print quality. If you push your ptfe all way into the hole, there is very little additional drag (just make sure filament is not grinding any edges). If you compare it to stock prusa spool holder, it is even easier to pull filament from the spool. As a proof photo of green benchy :)

I keep this one as in progress, because I want feedback regarding tolerances. Everything is tight fit and works great on my side, but want other people to comment.

If you made it, please share photo. It is always nice to see one :)

edit 14.05.2017:

Frame center.stl replaced with Frame center_large.stl. Geometry is almost the same - I added one radius at the end of tube, to make sure filament is not touching it even at extreme extruding positions

Added Frame center_small.stl. It is 20mm shorter. It comes in handy when you have paver tile in your enclosure - then with shorter arm tube is not touching the enclosure.

edit 28.02.2017:

Modified both shorter and longer center fram element to make it fit frame tighter. Now it is 6mm wide instead previous 6.4mm

There is NO negative effect on print quality. If you push your ptfe all way into the hole, there is very little additional drag (just make sure filament is not grinding any edges). If you compare it to stock prusa spool holder, it is even easier to pull filament from the spool. As a proof photo of green benchy :)

I keep this one as in progress, because I want feedback regarding tolerances. Everything is tight fit and works great on my side, but want other people to comment.

If you made it, please share photo. It is always nice to see one :)

edit 14.05.2017:

Frame center.stl replaced with Frame center_large.stl. Geometry is almost the same - I added one radius at the end of tube, to make sure filament is not touching it even at extreme extruding positions

Added Frame center_small.stl. It is 20mm shorter. It comes in handy when you have paver tile in your enclosure - then with shorter arm tube is not touching the enclosure.

edit 28.02.2017:

Modified both shorter and longer center fram element to make it fit frame tighter. Now it is 6mm wide instead previous 6.4mm