Thingiverse

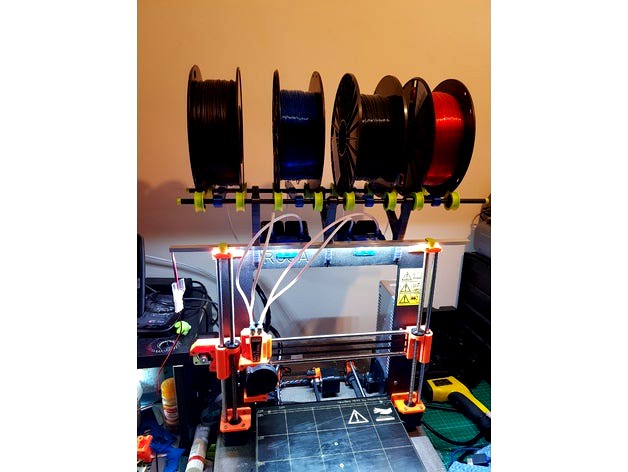

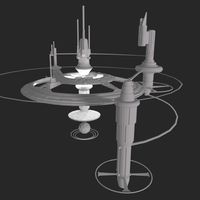

Prusa i3 Mk2s MMU Frame Spool Support (4 Spools) Space Saver by MonkeyTurnip

by Thingiverse

Last crawled date: 3 years, 1 month ago

Space is a premium for me, so i wanted to create a 4 spool holder that attached to the top of the frame, and also gave a easier way to feed the filament in to the extruder, than trying to feed in into the bottom of the extruder.

I have been testing this for the last couple of months, and with some tweaks (what the files are now) i have something i am happy with. printing at speeds of upto 70mm/s get no noticeable vibrations/rocking, and print quality has been unaffected. I am aware that some clone printer with a plastic frame can experience the frame bending with weight added to it, which affects the print quality. But with the Original Prusa i3 MK2s frame being metal, i haven't noticed it.

i normally print PETG at 20-40mm/s and its rock solid.

inbetween the supports and you can upto 100mm wide spools on the rollers, but if you stagger over the supports you could get wider. but most spools i have, seem to be less than 100mm wide.

the bend in the PTFE tube is higher than the highest point the nozzle can go, so it wont interfere with tall prints.

Parts List:

2 Prusa i3 Mk2s MMU Modified Extruder For Bowden Style Input

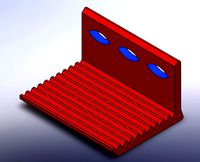

3 Spool Frame Supports

4 Filament Guides

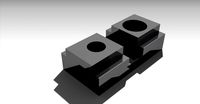

16 Bearing housings

4 end Caps

4 250mm long 4mm OD 2mm id PTFE tube

4 M5 x 7mm brass inserts

4 Festo QSM-M5-4 Push-in Fittings

16 Bearings from the Prusa MMU Filament Rollers

2 500mm long 8mm OD 6mm id Carbon Fibre rods

3 160 x 2.6mm Zip Ties (same ones supplied by Prusa)

I used M5 x 7mm brass inserts that i found on Ebay. loads available for not allot of money. i tried to match what Prusa used, by they worked out very expensive in comparison.

I used Festo QSM-M5-4 Push Fittings i purchased from RS Online. These are the same as the ones Prusa inlcuded with the MMU

https://uk.rs-online.com/web/p/pneumatic-straight-threaded-to-tube-adaptors/1216037/

Slightly modified Bearing housing/Wheel, i modified the design from this design https://www.thingiverse.com/thing:1832235. My design has slightly higher sides.

I modified the Prusa Extruder to take a 4mm OD PTFE Tube from the Filament Guide.https://www.thingiverse.com/thing:2822229

The Bearings are from the MMU Spool holders. saves having to buy some.

the Rods are 500mm long 8mm OD 6mm ID Carbon Fibre rods. i bought these because Carbon Fibre is cool. the inside Diameter of the Bearings are 8mm, and because of that are too tight for the 8mm rod. i sanded to rod to be slightly thinner, and to allow the bearings to slide along the length with out friction.

the Holes for the brass insers are 7.2mm diameter, to allow for material expansion, making the hole smaller. i press fit these in cold, but you could use a little heat if you wanted, to make the plastic plyable.

the fillament guides are designed to have a little bit of flex, to allow them to snap over the rods. they can also slide freely, so they can be position where best for the filament roll you have

The Supports have a internal channel to allow the zip ties to tie round the frame. this is a must, as the weight of the filament and the over hang pull the support over. the zip tie is fed in from the back, it comes out the bottom of the front leg, is wrapped around the frame, and goes into the bottom of the rear leg. through the locking part of the zip tie and it comes out of the top of the support, if you pull it tight with pliers, then wrap it round the pliers jaw and twist (as shown in the photos) you will get a couple extra "clicks" and the zip tie will be very tight. this is important to stop any vibrations/rocking/failing of the support.

the end caps are to stop the end bearings falling off, and to highlight the ends of the rods to make them more visible.

When cutting PTFE DO NOT use side cutters, it crushes the tube before cutting and makes it oval, which makes it harder for the filament to push through. Use a sharp craft knife and it stays round.

The Light that is in the photo is this one https://www.thingiverse.com/thing:2791701

I have been testing this for the last couple of months, and with some tweaks (what the files are now) i have something i am happy with. printing at speeds of upto 70mm/s get no noticeable vibrations/rocking, and print quality has been unaffected. I am aware that some clone printer with a plastic frame can experience the frame bending with weight added to it, which affects the print quality. But with the Original Prusa i3 MK2s frame being metal, i haven't noticed it.

i normally print PETG at 20-40mm/s and its rock solid.

inbetween the supports and you can upto 100mm wide spools on the rollers, but if you stagger over the supports you could get wider. but most spools i have, seem to be less than 100mm wide.

the bend in the PTFE tube is higher than the highest point the nozzle can go, so it wont interfere with tall prints.

Parts List:

2 Prusa i3 Mk2s MMU Modified Extruder For Bowden Style Input

3 Spool Frame Supports

4 Filament Guides

16 Bearing housings

4 end Caps

4 250mm long 4mm OD 2mm id PTFE tube

4 M5 x 7mm brass inserts

4 Festo QSM-M5-4 Push-in Fittings

16 Bearings from the Prusa MMU Filament Rollers

2 500mm long 8mm OD 6mm id Carbon Fibre rods

3 160 x 2.6mm Zip Ties (same ones supplied by Prusa)

I used M5 x 7mm brass inserts that i found on Ebay. loads available for not allot of money. i tried to match what Prusa used, by they worked out very expensive in comparison.

I used Festo QSM-M5-4 Push Fittings i purchased from RS Online. These are the same as the ones Prusa inlcuded with the MMU

https://uk.rs-online.com/web/p/pneumatic-straight-threaded-to-tube-adaptors/1216037/

Slightly modified Bearing housing/Wheel, i modified the design from this design https://www.thingiverse.com/thing:1832235. My design has slightly higher sides.

I modified the Prusa Extruder to take a 4mm OD PTFE Tube from the Filament Guide.https://www.thingiverse.com/thing:2822229

The Bearings are from the MMU Spool holders. saves having to buy some.

the Rods are 500mm long 8mm OD 6mm ID Carbon Fibre rods. i bought these because Carbon Fibre is cool. the inside Diameter of the Bearings are 8mm, and because of that are too tight for the 8mm rod. i sanded to rod to be slightly thinner, and to allow the bearings to slide along the length with out friction.

the Holes for the brass insers are 7.2mm diameter, to allow for material expansion, making the hole smaller. i press fit these in cold, but you could use a little heat if you wanted, to make the plastic plyable.

the fillament guides are designed to have a little bit of flex, to allow them to snap over the rods. they can also slide freely, so they can be position where best for the filament roll you have

The Supports have a internal channel to allow the zip ties to tie round the frame. this is a must, as the weight of the filament and the over hang pull the support over. the zip tie is fed in from the back, it comes out the bottom of the front leg, is wrapped around the frame, and goes into the bottom of the rear leg. through the locking part of the zip tie and it comes out of the top of the support, if you pull it tight with pliers, then wrap it round the pliers jaw and twist (as shown in the photos) you will get a couple extra "clicks" and the zip tie will be very tight. this is important to stop any vibrations/rocking/failing of the support.

the end caps are to stop the end bearings falling off, and to highlight the ends of the rods to make them more visible.

When cutting PTFE DO NOT use side cutters, it crushes the tube before cutting and makes it oval, which makes it harder for the filament to push through. Use a sharp craft knife and it stays round.

The Light that is in the photo is this one https://www.thingiverse.com/thing:2791701

Similar models

thingiverse

free

Prusa i3 Mk2s MMU Modified Extruder For Bowden Style Input by MonkeyTurnip

...re cutting and makes it oval, which makes it harder for the filament to push through. use a sharp craft knife and it stays round.

thingiverse

free

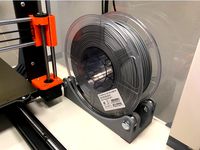

Prusa MMU spool holder PTFE tube attachment

...ttle snap-on thing to attach ptfe tubes to the stock prusa mmu filament holders.

one m3x10 screw required for fastening the tube.

thingiverse

free

PTFE Filament Guide for the Original Prusa i3 MK2 by sunbart

...t from prusa 3d themselves which adds an endpoint for a regular ptfe bowden tube at the top of the printer frame, above the psu.

thingiverse

free

Prusa i3 MK2 MMU Dust Guard by skate15e

... tube supplied with the mmu kit)

filter foam (i cut a piece from a cheap foam brush)

please let me know how i can make it better.

thingiverse

free

Compacto Extruder by Srek

...ment stability during transport even more.

to make the ptfe tube stick you have to thread the output end of the extruder with m4.

thingiverse

free

Prusa i3 MK2/S/3 Filament Spool Holder ClipOn by Area51

...tyle design: prusa i3 spool holder, single side clipon

update:

added holder for 22mm od tubes.

added holder for m8 threaded rod.

thingiverse

free

![[Updated] Tom's easy spool holder with 8mm rod for Prusa i3 MK2 (or Plus) V3 by tomulinek](/t/8829690.jpg)

[Updated] Tom's easy spool holder with 8mm rod for Prusa i3 MK2 (or Plus) V3 by tomulinek

...l, faster print) and filament guide (v3a) for full spools where filament tends to slide aside. all is printable without supports.

thingiverse

free

Prusa Mk2 Enclosure Plug by lukeksywalkerhq

... to have a ptfe tube fit inside it, for reduced friction. i printed it with pteg to resist any high temps that it may experience.

thingiverse

free

608ZZ Bearing Filiment Spool Holder with PTFE tube holder by Darak_Chen

...holderhttps://www.thingiverse.com/thing:3067909

layer height: 0.2mm

infill: 20%

infill type: grid

support: n/a

filiment type: pla

thingiverse

free

Prusa i3 MK2 Spool holder by Kals

...changing rolls quick and easy. requires m5-16 screws or similar as well as 4x 625zz bearings. note! there is...

Monkeyturnip

thingiverse

free

1.75mm Filament 200mm long - Printed wow by MonkeyTurnip

...tual advice, dont do thisis a joke design for when people ask what to print. i am annoyed that i have to type this disclaimer tbh

thingiverse

free

40mm to 50mm Fan Adaptor for 50 mm Heavy Duty Layer Fan duct - FLASHFORGE Creator X (MakerBot Replicator Dual, CTC and more) by MonkeyTurnip

...er designs, where a 40mm fan is to be fitted in a 50mm fan hole.

its tight enough for no need of screws to fit, compression fit.

thingiverse

free

Prusa i3 Mk2 MMU LED Strip Light Bracket for Hexagon Hole by MonkeyTurnip

...igid-led-strip-aluminium-profile/291652042409?sspagename=strk%3amebidx%3ait&var=590685936585&_trksid=p2057872.m2749.l2649

thingiverse

free

Prusa i3 Mk2s MMU Modified Extruder For Bowden Style Input by MonkeyTurnip

...re cutting and makes it oval, which makes it harder for the filament to push through. use a sharp craft knife and it stays round.

thingiverse

free

CTC Replicator Clone Cooling Fan duct by Tempy111

...i use a 40mm standard, so just print out monkeyturnip's 40mm to 50mm adaptor (https://www.thingiverse.com/thing:2424908) slip it into to...

Mmu

3d_export

$129

NASA MMU Astronaut with backpack 3D Model

...ipment space nasa astronaut apollo scifi sf mmu backpack back pack

nasa mmu astronaut with backpack 3d model squir 85316 3dexport

cg_studio

$129

NASA MMU Astronaut with backpack3d model

....fbx .lwo .max .obj - nasa mmu astronaut with backpack 3d model, royalty free license available, instant download after purchase.

cg_studio

$199

NASA Astronaut with MMU backpack rigged for Maya3d model

....mb - nasa astronaut with mmu backpack rigged for maya 3d model, royalty free license available, instant download after purchase.

3d_export

$199

NASA Astronaut with MMU backpack rigged for Maya 3D Model

...a astronaut with mmu backpack rigged for maya 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl squir 111622 3dexport

3dfindit

free

MMU

...mmu

3dfind.it

catalog: wiska

3dfindit

free

MMU EMV

...mmu emv

3dfind.it

catalog: wiska

thingiverse

free

Tesla Coaster MMU by muddymaker

...tesla coaster mmu by muddymaker

thingiverse

tesla coaster mmu

thingiverse

free

Steelers Coaster for MMU by BanditBBS

...steelers coaster for mmu by banditbbs

thingiverse

modified original print to be used on mmu and be flat!

thingiverse

free

MMU Christmas Tree

...it can not be printed and glued together. please post makes and remakes. they really push me to make more things.

happy holidays

thingiverse

free

MMU Turkey by Zachery124

...er. for palette printers read instructions below. please post makes and remixes as it really inspires me to do more cool things.

Saver

turbosquid

$20

Robot-saver

...y free 3d model robot-saver for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1468253)

turbosquid

$15

Life Saver Ring

...id

royalty free 3d model life saver ring for download as c4d on turbosquid: 3d models for games, architecture, videos. (1625086)

turbosquid

$3

ROOM ENERGY SAVER

... 3d model room energy saver for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370383)

turbosquid

$10

Parking Spot Saver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Energy Saver Light Bulbs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Sound And Light Saver Pack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$15

Light bulb (Energy saver)

...hting lighting luminance zluminance

detailed light bulb with rendering studio included. rendered with vray. hq hdri map included!

3d_export

$30

Energy Saver Light Bulbs 3D Model

...hilips fluorescent energy saver architecture rhinoceros 3dm vray vismat

energy saver light bulbs 3d model blacks3d 35292 3dexport

turbosquid

$5

Energy Saver Classic Light Bulb

...r classic light bulb for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1428208)

3d_ocean

$6

Energy Saver Tubular Light Bulb

... nurbs setup

generic fluorescent light bulb in spiral, high precision model, render setup, textures and necessary files included.

Mk2S

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Spools

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Space

3ddd

free

Space

... space , вытяжка

вытяжка elica space, производство elica evolution

3d_ocean

$19

Space station

...space station

3docean

space station

space station

3d_ocean

$7

Space Fighter

...space fighter

3docean

fighter space

space fighter

turbosquid

$5

space

...e

turbosquid

royalty free 3d model space for download as max on turbosquid: 3d models for games, architecture, videos. (1184221)

turbosquid

$2

Space

...turbosquid

royalty free 3d model space for download as blend on turbosquid: 3d models for games, architecture, videos. (1660625)

3d_ocean

$4

Space Station

...space station

3docean

habitat low poly ship space space ship space station vehicle

space station low poly modelled, not textured.

turbosquid

$2

Space

...royalty free 3d model space for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1644726)

turbosquid

$8

Space

...ty free 3d model space for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1521166)

turbosquid

$160

space

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Space

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Support

turbosquid

$5

Support

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Support 3D Model

...support 3d model

3dexport

support cantilever console

support 3d model tasal 73900 3dexport

3d_export

$5

phone support

...phone support

3dexport

phone

turbosquid

$12

Support bars

...squid

royalty free 3d model support bars for download as max on turbosquid: 3d models for games, architecture, videos. (1411542)

turbosquid

$8

support weights

...id

royalty free 3d model support weights for download as max on turbosquid: 3d models for games, architecture, videos. (1411538)

turbosquid

$2

headphone support

...royalty free 3d model headphone support for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357583)

turbosquid

$2

Support for flowers

...royalty free 3d model support for flowers for download as max on turbosquid: 3d models for games, architecture, videos. (1463543)

turbosquid

$14

Flower Support

...alty free 3d model flower support for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1497066)

turbosquid

$5

serum support

...yalty free 3d model serum support for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1551267)

3d_export

$10

spyro joystick support

...spyro joystick support

3dexport

joystick support of spyro dragon

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

turbosquid

$1

re 4-4 electric locomotive

... free 3d model re 4 4 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707845)

3ddd

$1

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло