Thingiverse

Prusa i3 Mk2 / Mk2S / Mk2.5 PSU spacer by triplepoint

by Thingiverse

Last crawled date: 3 years ago

I have a Prusa i3 MK2 kit (shipped Feb/2017), which has since been upgraded to a Mk2S (Oct/2017), and then a Mk2.5 (Apr/2018).

Judging by the bed-leveling search pattern, the vertical frame on this printer has always seemed a few millimeters too far back on the Y-axis threaded rods. This has resulted in sporadic XYZ failure-to-calibrate issues.

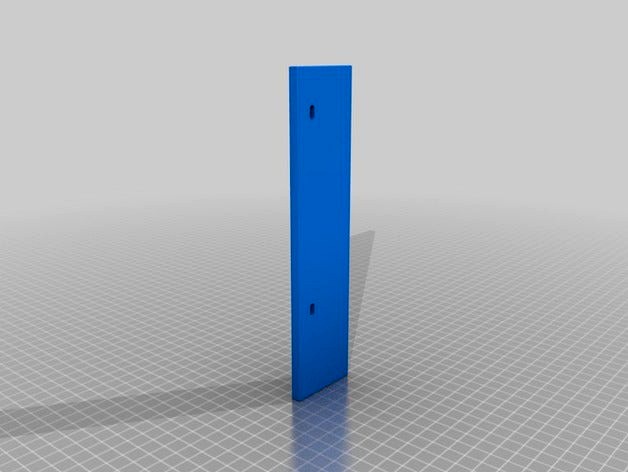

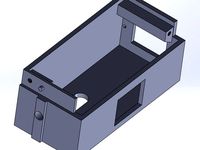

One solution proposed by others with this issue was to unbolt the power supply unit (PSU) from the back-right corner of the Y-frame (first picture), allowing the vertical frame to be moved forward the required amount. This worked, but it leads to a reduction in stiffness in the frame.

My solution here is to print a spacer to go between the PSU and the vertical frame (2nd and 3rd pictures). This allows the vertical frame to shift forward on the y-axis, while still being securely bolted to the back-right corner.

To determine the thickness (6.88 mm), I unbolted the PSU from the vertical frame, reattached it to the back right corner of the y-axis foot, and moved the z-axis frame further forward on the y-axis's threaded rods, until the bed-leveling search algorithm was centered in the y-axis on the marker points on the heated bed. Then I could simply measure the gap between the vertical frame and the PSU, and print the part accordingly.

See a more complete description of the issue here:https://github.com/prusa3d/Prusa-Firmware/issues/616#issuecomment-385211047

Judging by the bed-leveling search pattern, the vertical frame on this printer has always seemed a few millimeters too far back on the Y-axis threaded rods. This has resulted in sporadic XYZ failure-to-calibrate issues.

One solution proposed by others with this issue was to unbolt the power supply unit (PSU) from the back-right corner of the Y-frame (first picture), allowing the vertical frame to be moved forward the required amount. This worked, but it leads to a reduction in stiffness in the frame.

My solution here is to print a spacer to go between the PSU and the vertical frame (2nd and 3rd pictures). This allows the vertical frame to shift forward on the y-axis, while still being securely bolted to the back-right corner.

To determine the thickness (6.88 mm), I unbolted the PSU from the vertical frame, reattached it to the back right corner of the y-axis foot, and moved the z-axis frame further forward on the y-axis's threaded rods, until the bed-leveling search algorithm was centered in the y-axis on the marker points on the heated bed. Then I could simply measure the gap between the vertical frame and the PSU, and print the part accordingly.

See a more complete description of the issue here:https://github.com/prusa3d/Prusa-Firmware/issues/616#issuecomment-385211047

Similar models

thingiverse

free

PRUSA I3 MK2(S) & MK2.5 Y AXIS UPGRADE FEET

...mp; mk2.5 y axis upgrade feet

thingiverse

feet for prusa i3 mk2(s) & mk2.5 y axis upgrade.

www.thingiverse.com/thing:2836470

thingiverse

free

Prusa I3 Mk2 Y motor spacer by fpikus

... far, the cable must not get pinched between the motor and the spacer) and let go of the motor, it will hold the spacer in place.

thingiverse

free

Parametric Prusa i3 Frame Stabilizer kit by projunk

...(2x) (back)

m10 threaded rod 394 mm (2x) (y-axis)

m10 threaded rod 385 mm (2x) (sloping)

m10 nuts (46x)

m10 washers (46x)

thingiverse

free

Anet A6 Y axis stabilising spacer by BrienAllison

...pacer to be squashed into the frame making it very rigid. repeat with the other threaded rod and re-assemble the y-axis assembly.

thingiverse

free

Prusa i3 Z support lower Y corner mount M8 rod by wayne69x

...prusa i3 z support lower y corner mount m8 rod by wayne69x

thingiverse

y axis corner for z brace - all m8 threaded rod

thingiverse

free

Frame stiffener Prusa i3 MK2s by AristoDesign

...les on y axis). you might need to print additional interface for original threaded rods.

designed to be printed without supports.

thingiverse

free

Original Prusa i3 Mk2 X-Brace by jasonsnyder01

...o ensure the m10 threaded rods are completely parallel on my original prusa i3's y-axis

i print this laying flat on the bed.

thingiverse

free

CTC Prusa i3 Pro B Z-Axis Bracket(Remix) by davethecomputerdoc

...are free to move forward, back, left, or right. this effectively eliminates the z-axis wobble on the ctc prusa i3 pro b printer.

thingiverse

free

Prusa i3 Y-Corner 10 mm by Draman

...prusa i3 y-corner 10 mm by draman

thingiverse

y-corner for 10mm threaded rod (front)

and 10mm/8mm (back)

thingiverse

free

Prusa i3 y endstop mount by flow

...frame for the side rods (m10 threaded rod and m8 smooth rod) of my y-axis. the distance between the clamps is approximately 38mm.

Triplepoint

thingiverse

free

Test Coins by triplepoint

... printer's default 150 micron layer settings. i found these coins really useful for dialing in the z-axis offset adjustment.

thingiverse

free

8 Card Wallet by triplepoint

... edges of the piece create a thin wall that eventually split. i'll redesign this and address this issue in the next version.

Psu

3d_ocean

$17

Computer Case

...3docean atx case computer corsair full game gaming pc psu full tower-like computer case model with 113946...

cg_studio

$9

Power Supply Unit PSU3d model

...d .fbx .lwo .ma .max .obj .xsi - power supply unit psu 3d model, royalty free license available, instant download after purchase.

thingiverse

free

PSU cover for 12v 30A PSU by Salti

...

cover for the "dangerous" end of a standard led psu

230v input, 2 x 12v outputs

supports psu width 11cm and height 5cm

thingiverse

free

psu holder by sta8atos

...psu holder by sta8atos

thingiverse

psu holder

thingiverse

free

psu stamp by astorck

...psu stamp by astorck

thingiverse

psu stamp

thingiverse

free

PSU Cover by Shojo

...psu cover by shojo

thingiverse

psu cover

thingiverse

free

PSU cover by chroja

...psu cover by chroja

thingiverse

psu cover

thingiverse

free

PSU Cover for 9,9 cm PSU Anet A8 by Wolverine_DH

...a8 by wolverine_dh

thingiverse

psu cover for 9.9sm psu optimal high for anet a8 screw holes, more side holes for diffrend psus.

thingiverse

free

Anet A8 PSU Fan (2017 PSU)

...coarse threaded fan screws. additionally 2 x m3x8mm machine screws needed to attach fan mount to psu. do not use long than 8mm.

thingiverse

free

SFX PSU to ATX PSU adapter by Kanashii

... atx format adapter so i made my own adapter. better use hard plastic to stick psu to pc's case without breaking the adapter.

Mk2

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

Mk2S

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

Spacer

turbosquid

$55

Spacer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

grendizer & double spacer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Hex Spacers M3 Male-Female

... spacers m3 male-female

3dexport

hex spacers m3 male-female with length from 5mm to 60mm for printed circuit boards. step files.

3d_export

$5

industrial lift - spacer crane

...crane<br>- 500 kg<br>- render 3ds max 2020 and corona renderer.<br>- formats: max 2020, max 2017, obj, fbx, stp

3d_export

$5

spacer hanging light

...lampshades: any total number of lamps: 6 polys: 18 546 verts: 19 045 https://imperiumloft.ru/lyustry-175/ev_a048924-eurosvet.html

turbosquid

$5

Industrial lift Spacer crane Renaissance construction

...naissance construction for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1571898)

3d_export

$7

industrial lift - spacer crane renaissance construction

...ction<br>- 750 kg<br>- render 3ds max 2020 and corona renderer.<br>- formats: max 2020, max 2017, obj, fbx, stp

3d_export

$10

Spacer Sliding Wardrobe 1200 Hanger

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$5

Hockey puck 3D Model

...hockey puck 3d model 3dexport hockey puck spacer washer disk shim hockey puck 3d model gizmo_fbi 28754...

3d_export

$5

Front 30mm Lift Kit for 1996-2004 Nissan Pathfinder and 1997-2003 Infiniti QX4

...terrano r50, regulus 1997-2003 infiniti qx4 - front strut spacer ...

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.