Thingiverse

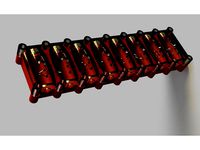

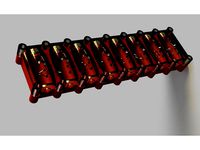

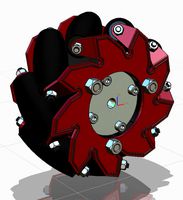

Projunk's Omniwheel Barrel Casting Form by MirecXP

by Thingiverse

Last crawled date: 3 years, 1 month ago

I have tried projunk's parametric omniwheels, it is great part for a robot. We have printed its barrels using FlexFill and it worked well on the carpet, but we had some issues using it on the smooth surface.

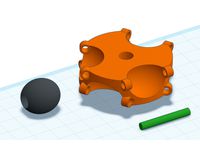

Now I've tried to cast the barrels from very soft polyurethane (Shore A20) using this mold. I think it will make the wheels more usable even with some other kind of material.

I have no prior experiences to casting, so I'll be glad if you have some proposals for enhancing the mold or the process.

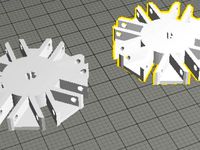

You have to use some 3mm screws to tight the mold parts together. Correct orientation of the assembly has the same text on both sides on the same place. Do not forget to insert the axles in the mold before casting and use some clay to protect the axle bottom holes, otherwise the material may leak. Use the clay also around the edges where the two parts connect.

It is necessary to make all 8 barrels at once using this form, because some liquid material may leak to the empty neighbour barrel cavity. The exact amount of a material to make the 8 barrels is about 17ml, it is enough to prepare 20ml of material. I have used 20ml plastic syringe to fill it. I had to use a small piece of shrinkable tubing at the syringe needle hub to fill the cavities easier. Fill each barrel slowly until some liquid will leak from the small air holes around.

I have not used any removal agent, so it was very hard to open the mold and get the barrels out of it without braking the mold. Good luck. :)

After removal of the barrels it is necessary to cut some excess material with a sharp knife, do not try to rip it off.

Print also the 1-layer washers and put them on the axle on each side of the barrel to prevent unwanted friction between the barrel's sides and the wheel body.

Now I've tried to cast the barrels from very soft polyurethane (Shore A20) using this mold. I think it will make the wheels more usable even with some other kind of material.

I have no prior experiences to casting, so I'll be glad if you have some proposals for enhancing the mold or the process.

You have to use some 3mm screws to tight the mold parts together. Correct orientation of the assembly has the same text on both sides on the same place. Do not forget to insert the axles in the mold before casting and use some clay to protect the axle bottom holes, otherwise the material may leak. Use the clay also around the edges where the two parts connect.

It is necessary to make all 8 barrels at once using this form, because some liquid material may leak to the empty neighbour barrel cavity. The exact amount of a material to make the 8 barrels is about 17ml, it is enough to prepare 20ml of material. I have used 20ml plastic syringe to fill it. I had to use a small piece of shrinkable tubing at the syringe needle hub to fill the cavities easier. Fill each barrel slowly until some liquid will leak from the small air holes around.

I have not used any removal agent, so it was very hard to open the mold and get the barrels out of it without braking the mold. Good luck. :)

After removal of the barrels it is necessary to cut some excess material with a sharp knife, do not try to rip it off.

Print also the 1-layer washers and put them on the axle on each side of the barrel to prevent unwanted friction between the barrel's sides and the wheel body.

Similar models

thingiverse

free

Barrel casting form for Projunk's Mecanum Wheel 82 mm by MirecXP

...d put them on the axle on each side of the barrel to prevent unwanted friction between the barrel's sides and the wheel body.

grabcad

free

Parametric 20ml single-use syringe

...bcad

free for commercial use (cc0 1.0 universal)

parametric 20ml syringe modeled after one i have lying around. with luer taper.

thingiverse

free

parametric universal heavy duty 20ml syringe extruder by BonsaiBrain

... print one can produce printed multimaterial candy.

if you want to read more about this, visit: www.ifeelbeta.de

best

bonsaibrain

grabcad

free

chocolate mold for praline apples

...at (surface against surface rubbing fast).

at half-make-up leave something free and pour liquid chocolate.

step, igs, solidworks

thingiverse

free

Dva Shaker Charm/ Keychain

... a silicone mold of it and do many cast in resin. the open area will be filled with glitter and liquid and covered in clear film.

thingiverse

free

Mold for chocolate shot by nazzaf

... make the shot but i didn't succed because the chocolate remained attached to the mold, maybe i had to use some baking spray.

thingiverse

free

Pumpkin stem mold by thebossness

...ncrete, rubber, candy, and ice/water. the holes on the sides are for a screw and nut to keep it secure, and not leak any liquids.

thingiverse

free

Mold for a 16mm Dice Mold

...inspired by wuerfel's fantastic moldmold system to produce something similar that would produce a free standing mold. i have...

thingiverse

free

Units currency by 24mhaggag

...ans. i plan on melting this using a barbecue that will have a air supply using a leaf blower. please spread and trade with units!

thingiverse

free

Chalktrail Mold by jetpuf

...iquid

260 grams by weight of plaster of paris

i have been using old acrylic craft paints we have had around the house for colors.

Mirecxp

thingiverse

free

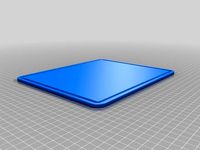

Cutting board by MirecXP

...rse

very simple cutting board to your kitchen.

the size is 250 x 210mm - the maximum prusa mk2 can print, so disable the skirt.

thingiverse

free

CitruSquee by MirecXP

...e hole diameter is 3mm).

i intend to make also a third part later, which will come in between these two and will catch the seeds.

thingiverse

free

Wire Drawer Divider by MirecXP

...our drawer has 6mm wires which are 90mm apart.

edit: added requested version for the bars which are 242mm apart + fusion360 file.

thingiverse

free

3/4" Hose adapter for 55mm outlet by MirecXP

...d to provide a connection for garden hose from 55mm outlet from my water container.

the hose fits very tight.

printed using petg.

thingiverse

free

![Wave lamp Yeah! [open top remix] by MirecXP](/t/8032375.jpg)

Wave lamp Yeah! [open top remix] by MirecXP

...co3d

i have just adapted its size and made the top open.

to print it, rotate it to start the print with the wider side on bottom.

thingiverse

free

Banana Pair Clip by MirecXP

... larger plugs (ø 9mm) i usually buy from ebay.

the tiny clip (ø 4.5mm) is for pure banana connectors soldered directly to a wire.

thingiverse

free

Small Cube Planters 7cm by MirecXP

...inside the walls might come in handy to hang the printed planter on some wire.

icon made from icon fonts is licensed by cc by 3.0

thingiverse

free

YunZhong Mini S2 Screwdriver Frogbox by MirecXP

...0

i have purchased the screwdriver here: https://www.aliexpress.com/item/4000278487411.html?spm=a2g0s.12269583.0.0.79f37017kfwfny

thingiverse

free

Lumix LX-100 scope 2" adapter by MirecXP

...ope.

no supports needed, just rotate the thing with bayonet side on the bottom.

thanks to fakcior for his base design of bayonet.

thingiverse

free

Small compasses case by MirecXP

...d project. i'm sure it is not optimally designed, so i will appreciate your comments to using the fusion 360 in a better way.

Projunk

thingiverse

free

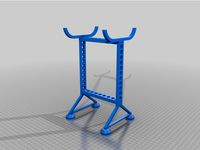

Parametric Stand for SpotMicroESP32 by projunk

...f.stl and stand_bottomhalf.stl which should be glued together. these parts can be used if the stand.stl does not fit the printbed

thingiverse

free

Parametric Shoulder Joint for SpotMicroESP32 by projunk

... part limbtopshell.stl is the same as the original part "limb_top_shell.stl" except for the screw hole for the bearing.

thingiverse

free

Parametric LCD Display Box for Reprap Smart Controller by projunk

...m.stl (1x)

screw m3x12 (4x)

optional parts:

bracket.stl (1x)

bracketmirrored.stl (1x)

screw m3x10 (4x)

nut m3 (4x)

washer m3 (4x)

thingiverse

free

Parametric Prusa i3 Frame Stabilizer kit by projunk

...(2x) (back)

m10 threaded rod 394 mm (2x) (y-axis)

m10 threaded rod 385 mm (2x) (sloping)

m10 nuts (46x)

m10 washers (46x)

thingiverse

free

SpotMicroESP32 (using 623ZZ bearings) by projunk

...oint between bottom shells to avoid collision with 20a buckconverters (bottom_cover_split_front.stl, bottom_cover_split_rear.stl)

thingiverse

free

Parametric Herringbone Differential for OpenRC F1 car by projunk

...arflataxle.stl (better fits the axle of the motor)

piniongearnuthole.stl (this requires a m3 nut and a small m3 screw, see photo)

thingiverse

free

Parametric Prusa i3 Stabilizer kit (Part 2) by projunk

... parts have been printed in abs (95% infill) except for the gasket and fanseal, which have been printed in ninjaflex (50% infill)

thingiverse

free

Barrel casting form for Projunk's Mecanum Wheel 82 mm by MirecXP

...d put them on the axle on each side of the barrel to prevent unwanted friction between the barrel's sides and the wheel body.

thingiverse

free

Parametric Hieroglyphic Alphabet (high resolution bitmaps) by projunk

... // determines the overall size of the character

pixelthickness = 2.0; // determines the thickness (z-direction) of the character

Omniwheel

3d_export

$5

omniwheels

...omniwheels

3dexport

omniwheels

thingiverse

free

omniwheel

...omniwheel

thingiverse

a 6 wheel omniwheel designed to work with hk0408 bearings

thingiverse

free

Omniwheel V1 by IGrebot

...omniwheel v1 by igrebot

thingiverse

first prototype of our omniwheel

thingiverse

free

Omniwheels by sfxrfc

...omniwheels by sfxrfc

thingiverse

this is designed to be used for the robocupjunior competition

thingiverse

free

omniwheel (Single file) by mario_chirinos

...omniwheel (single file) by mario_chirinos

thingiverse

single piece omniwheel with moving parts

thingiverse

free

MakeWiths - Sizeable Omniwheel by MongoToys

...makewiths - sizeable omniwheel by mongotoys

thingiverse

cool omniwheel design. can change the size, type and number of rollers.

unity_asset_store

$15

Megapoly.Art - AGV Omniwheel

... the megapoly.art - agv omniwheel asset from megapoly art. find this & other industrial options on the unity asset store.

thingiverse

free

OmniWheel MK1 by Scorch1262

...omniwheel mk1 by scorch1262

thingiverse

passend für 3 und 6mm achsen

thingiverse

free

OmniWheel MK2 by Scorch1262

...omniwheel mk2 by scorch1262

thingiverse

passend für 3 und 6mm achsen

thingiverse

free

25mm OmniWheel by SolidWorksMagi

...kezine.com/archive/2010/04/makerbot_giveaway.html

i really need a job ... but i can design a custom part if you like on contract.

Casting

3ddd

free

Sebastian Cast

...sebastian cast

3ddd

sebastian cast

карикатуры от себастьяна каста

3ddd

$1

Cast mini

...cast mini

3ddd

present time

подвесной светильник cast mini

материал: керамика

размер: 20x166

производитель: present time

turbosquid

$19

Cast Iron

...rbosquid

royalty free 3d model cast iron for download as max on turbosquid: 3d models for games, architecture, videos. (1609108)

3d_export

$6

Design of die casting machine

...design of die casting machine

3dexport

design of die casting machine

3ddd

$1

Wood Casting by Hilla Shamia

...wood casting by hilla shamia

3ddd

wood casting by hilla shamia

turbosquid

$30

Cast iron fenceClassic

...alty free 3d model cast iron fenceclassic for download as max on turbosquid: 3d models for games, architecture, videos. (1630755)

turbosquid

$15

Cast-iron bench

...id

royalty free 3d model cast-iron bench for download as max on turbosquid: 3d models for games, architecture, videos. (1239993)

turbosquid

$15

Cast-iron bench

...id

royalty free 3d model cast-iron bench for download as max on turbosquid: 3d models for games, architecture, videos. (1239991)

turbosquid

$13

Ring with 2 casts

...

royalty free 3d model ring with 2 casts for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1375610)

turbosquid

free

Caste Room with pillars

... 3d model caste room with pillars for download as xsi and fbx on turbosquid: 3d models for games, architecture, videos. (1305991)

Barrel

3d_ocean

$4

Barrel

...barrel

3docean

low poly medi evil barrel wood barrel

barrel, wood barrel, low poly,

3d_ocean

$12

Barrel

...barrel

3docean

barrel barrique drink oak barrel vine wood

a new barrel

3d_ocean

$3

Barrel

...barrel

3docean

barrel furniture

a high quality barrel .

3d_ocean

$4

Barrel

...barrel

3docean

barrel

a lowpoly barrel which is ready to use .

3d_export

$10

barrel

...barrel

3dexport

barrel

3d_export

$5

barrel

...barrel

3dexport

barrel

3d_export

$8

barrel

...barrel

3dexport

lolipop barrel

3d_export

$5

barrel

...barrel

3dexport

!!!radioactive barrel!!!

3d_export

free

barrel

...barrel

3dexport

old barrel

3d_export

$5

Barrel

...barrel

3dexport

high wooden barrel. reconstruction of medieval scandinavian barrel (viking age).

Form

3d_export

$5

Forms

...forms

3dexport

very gooooooooood forms)

design_connected

$13

Form

...form

designconnected

kartell form computer generated 3d model. designed by lissoni, piero.

3d_ocean

$3

Form

...reen screenshot texture ui wallppaper

form poly count:168 texture :1024×768 tga + alpha hope someone will find it useful .enjoy !

design_connected

$16

Form Pendants

...form pendants

designconnected

design house stockholm form pendants computer generated 3d model. designed by form us with love.

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it

3ddd

$1

Eurolegno | Forme

...rolegno , forme , om

источник: www.eurolegno.it