Thingiverse

printed mold for silicone hot liquid pump (artificial heart) and pinch valve by alisonleanne

by Thingiverse

Last crawled date: 2 years, 11 months ago

the tpe mold does not work. it seems the silicone will not cure when in contact with tpe. so printed the mold with abs and hips. need to break the inner part of the mold. the outer part is re-usable. the heart chambers can be driven with a servo or SMA. servo use far less power hungry and offers more control. the servo is placed in between 2 of the pumps (with a one way valve on each end), this will make a 2-chamber 4-valve heart. i made a vacuum chamber out of a 12v dc car air pump and a glass jar for the silicone. better than none.

update 16th Oct 2014: the duck bill valve works but not fell short of expectation. made valve1016, a design copied from the pulmonary semilunar valve of a human heart. can drill a few hole through the inner part or the mold to form silicone chordae tendineae if very soft molding silicone is used or larger servo is used. i use 4kg/cm servo.

update 18thOct2014:

heartvalve1016 works, performance not ideal. wall too thin. valve edge design fault (inside out). updated with heartvalve1018

end connector section for SMA arteryend1017 uploaded

update 18 Nov 2014

on the request from breye, uplaoded more pic. new heart valve. put the valve on each end, facing the same direction, clue with silicon. unless you what to try to grown tissues as lining or use the thing as support for growing tissues, or use part of organs like intestine or make one cavity with types of tissues, and drive with servo or low temp SMA, a rotary type of pump might be a better option. but i believe low temp (around 40 degree c) SMA with none contact (inductive) activation is a viable idea and worth trying for artificial hearts. comparing with motors, SMA is a lot lot lighter and smaller, maintenance free and last for ever (used within temperature and stress range) while a motor will eventually worn out . the down side is sma will drain a battery faster than motors for the same work. since i do not have a vacuum or compress chamber, i have difficulty pouring bubble-free silicone parts. I printed one with tpe, great, but can not match the heat resistance property of silicone. and worse, i have found out the silicone will not cure when in contact with tpe. i still think the silicone heart pump would be a better choice for implants. i do not want to invest in vacuum or compress chamber for silicone, so i am milling my high temp pump with aluminium or delrin. unlike the heart pump, these rotary pumps are not in one piece, requiring seals, not fully sealed like a heart pump, will not be as durable, however will serve my project well for now. hope this will help, Breye.

update 16th Oct 2014: the duck bill valve works but not fell short of expectation. made valve1016, a design copied from the pulmonary semilunar valve of a human heart. can drill a few hole through the inner part or the mold to form silicone chordae tendineae if very soft molding silicone is used or larger servo is used. i use 4kg/cm servo.

update 18thOct2014:

heartvalve1016 works, performance not ideal. wall too thin. valve edge design fault (inside out). updated with heartvalve1018

end connector section for SMA arteryend1017 uploaded

update 18 Nov 2014

on the request from breye, uplaoded more pic. new heart valve. put the valve on each end, facing the same direction, clue with silicon. unless you what to try to grown tissues as lining or use the thing as support for growing tissues, or use part of organs like intestine or make one cavity with types of tissues, and drive with servo or low temp SMA, a rotary type of pump might be a better option. but i believe low temp (around 40 degree c) SMA with none contact (inductive) activation is a viable idea and worth trying for artificial hearts. comparing with motors, SMA is a lot lot lighter and smaller, maintenance free and last for ever (used within temperature and stress range) while a motor will eventually worn out . the down side is sma will drain a battery faster than motors for the same work. since i do not have a vacuum or compress chamber, i have difficulty pouring bubble-free silicone parts. I printed one with tpe, great, but can not match the heat resistance property of silicone. and worse, i have found out the silicone will not cure when in contact with tpe. i still think the silicone heart pump would be a better choice for implants. i do not want to invest in vacuum or compress chamber for silicone, so i am milling my high temp pump with aluminium or delrin. unlike the heart pump, these rotary pumps are not in one piece, requiring seals, not fully sealed like a heart pump, will not be as durable, however will serve my project well for now. hope this will help, Breye.

Similar models

thingiverse

free

silicone mold for one way valve and pinch valve by alisonleanne

...rt. the heart valve is a duck bill valve. the other valve is for the 3 way pinch valve. next will be a servo driven heart (pump).

thingiverse

free

servo powered pinch valve by alisonleanne

... soft molding silicone, made the mold in wood (2 halves), then pour molding silicone into them, cure, glue together with silicon.

thingiverse

free

One Part Pecker Mold by mother-of-crafts-3d

..._search_asin_title?ie=utf8&psc=1

guild to helphttps://tabooless.net/guides/how-to-make-your-own-silicone-diy-dildo-creations/

cg_trader

$3

3D print data for small liquid pump with MG90S servo 2mm tube | 3D

...small tiny silicon tube liquid water pump servo motor mg90s flow hobby diy hobby diy mechanical parts mechanical parts water pump

cg_trader

$3

3D print data for small liquid pump with MG90S servo 3mm tube | 3D

...small tiny silicon tube liquid water pump servo motor mg90s flow hobby diy hobby diy mechanical parts mechanical parts water pump

cg_trader

$5

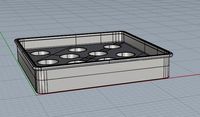

Lost wax casting liquid rubber RTV silicone mold pattern frame | 3D

...n frame box resin liquid rubber mold wax casting lost ring tools vulcanized sla dlp rtv silicone vacuum hobby diy hobby diy other

thingiverse

free

Silicon hot-end sleeve mold for Dremel Idea Builder by Codyacehardware

...very clean though you will probably want to let it cure for another 12 hours before you get it up to temp.

designed in tinkercad.

thingiverse

free

E3D V6 Silicone Booth Mold by neo777

... with alcohol 1:2). housing with no holes produces nicer boot. just need longer curing time about 4-6 days depending on humidity!

thingiverse

free

Silicone Sock mold for new e3dv6 Volcano by kazolar

...ther side. it's very hard to fill the mold entirely with a syringe, i found it to be impossible for the silicone i was using.

thingiverse

free

FLSun QQ-S Pro Heater Sock Mold by ArketypeDesign

... you find this a challenging and fun project, like i did.

ps- don't forget to do a pid tune on the hotend after installation.

Alisonleanne

thingiverse

free

knee/elbow wheel support by alisonleanne

...knee/elbow wheel support by alisonleanne

thingiverse

please see the pic.

thingiverse

free

tooth brushes and dental floss holder by alisonleanne

...tooth brushes and dental floss holder by alisonleanne

thingiverse

for electrical tooth brushes and dental floss

thingiverse

free

peristaltic pump by alisonleanne

...d 9mm od 1mm wall silicone tube used. the geared dc motor is taken from a toy robot i salvaged on council garbage collection day.

thingiverse

free

(ball bearing) roller hub by alisonleanne

... (with ball bearing) however they get crossed on top of each other. this hubs will hold the multiple of wires flat on the roller.

thingiverse

free

25 mm square aluminium tube sawing guide by alisonleanne

...for cutting 25 mm square aluminium tube. clamp may be used on each end to hold the guides in place. can be used on tube with lip.

thingiverse

free

magnetic drive centrifugal pump by alisonleanne

...ller is milled delrin.

will drive and control with outrunner+esc and arduino. still waiting for the 1000kv 2212 outrunner though.

thingiverse

free

gift box for Keyed Heart Gears Keychain by alisonleanne

...t on the box. i put my inside, both on the bottom and the lid, for my friend's wedding. i also add their initials on the key.

thingiverse

free

rotary hand tool (Demel type) attachment for cutting steel rod by alisonleanne

...to cut 4mm hss to 17mm length. skp file uploaded so u can adjust the to cut rods with different diameter and to different length.

thingiverse

free

cock roach locomotion studying model by alisonleanne

...pg as heat source, 8 arduino (linked) as control unit, 10 ultra sound range finders as sensors, with other things like gyro, etc.

thingiverse

free

long tpe tube by alisonleanne

...mentioned it. almost give up using the tpe. it is the best material for strength so far. elastic and much stronger than silicone.

Pinch

3ddd

$1

Pontus Desks Pinch

...pontus desks pinch

3ddd

pinch , письменный

pontus desks pinch

design_connected

$16

Pinch-Pleat Curtains

...pinch-pleat curtains

designconnected

pinch-pleat curtains computer generated 3d model.

3ddd

$1

Pinch two seat sofa

...pinch two seat sofa

3ddd

pinch

pendel two seat sofa.

pinch. london, england.

3d_export

$10

Clement coffee pinch 3D Model

...export

clement pinch table 3d textured furniture wood coffee russell pinch

clement coffee pinch 3d model goyamasta 37459 3dexport

turbosquid

$4

Tap handshower Pinch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Zuo Pinch Bar Stool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Chocolate Pinch Cake

...ad our <br>. you will received:<br>- 1 objects<br>- jpg (2000 x 2000px)<br>- obj file<br>- mtl file

3ddd

$1

contore bench

...bench 3ddd банкетка , contore product: contore bench brand: pinch design retailer: pinch design designer: russell pinch размеры height:...

3ddd

$1

Post office shelving

...post office shelving 3ddd стеллаж , pinch современный стеллаж от pinch design размеры: 1410w х 380d...

3ddd

$1

Clement coffee table

...table 3ddd журнальный , clement журнальный столик от студии pinch дизайн russell pinch размеры: 1300w x 500d x...

Artificial

3d_export

$12

artificial pond

...tificial pond

3dexport

artificial pond with reeds and water lilies, dimensions 3700x3800. 3ds max 2015 version, vray visualizer.

3d_export

$5

3d artificial respirator

...3d artificial respirator

3dexport

artificial ventilator, simple version without back connections

turbosquid

$3

Artificial Pillar Model

...lty free 3d model artificial pillar model for download as fbx on turbosquid: 3d models for games, architecture, videos. (1479028)

3d_export

$5

artificial indoor plant

...artificial indoor plant

3dexport

turbosquid

$30

Printable Artificial Ring

...l printable artificial ring for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1198888)

3d_ocean

$2

Artificial Grass Texture

...ature outdoor park pattern plant plastic play recreation surface synthetic texture textured turf

artificial turf or grass texture

cg_studio

$20

Artificial sheepskin red3d model

...sheepskin red fur pile

.max - artificial sheepskin red 3d model, royalty free license available, instant download after purchase.

turbosquid

free

Lighthouse on the artificial rock.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$59

Artificial cyber heart3d model

...i-fi

.obj .max .lwo .fbx .c4d - artificial cyber heart 3d model, royalty free license available, instant download after purchase.

cg_studio

$20

Artificial Sheepskin brown3d model

... floor room vray fur

.max - artificial sheepskin brown 3d model, royalty free license available, instant download after purchase.

Silicone

3d_export

$5

cake molds silicone

...cake molds silicone

3dexport

silicone cake molds

turbosquid

$19

Bunny Silicone

...ree 3d model bunny silicone for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1672014)

turbosquid

$5

Container Silicon

...for download as ma, max, obj, fbx, prj, unitypackage, and upk on turbosquid: 3d models for games, architecture, videos. (1415212)

turbosquid

$1

Silicone Oil Brush

...

royalty free 3d model silicone oil brush for download as max on turbosquid: 3d models for games, architecture, videos. (1700355)

cg_studio

$35

silicon gun3d model

...cgstudio

industrial slicon gun tool

.lwo - silicon gun 3d model, royalty free license available, instant download after purchase.

turbosquid

free

Acetic Silicon Sealant

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Silicone Cute Modern Lamp

...l silicone cute modern lamp for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1161149)

3ddd

$1

Silicon Power Ultima II I-Series

... usb , флешка

флеш накопитель silicon power ultima ii i-series.

turbosquid

$7

Ceramic with Silicon Mortar and Pestle 7

...licon mortar and pestle 7 for download as obj, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1482471)

3d_export

$5

12 pro silicone case - dio 3d print model

...ase for iphone 12 custom, flower model. you will have to configure the measures in your slicing program formats: .blend .obj .stl

Liquid

turbosquid

$29

Liquid Liquid Extractor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Liquid Logo

...liquid logo

3docean

liquid logo

liquid logo,you can change your logo

3d_export

$8

liquid soap

...liquid soap

3dexport

a bottle of liquid soap for any use.

3d_ocean

$5

liquid badge

...liquid badge

3docean

liquid badge you can replace your logo

liquid badge,you can replace your logo

3d_ocean

$4

Abstract Liquid

...ment liquid motion design splash water

high definition of abstract liquid mesh. great for motion graphic and product presentation

3d_export

$5

vape liquid bottle

...vape liquid bottle

3dexport

vape liquid bottle (~100ml)

turbosquid

$45

glass with liquid

...

royalty free 3d model glass with liquid for download as max on turbosquid: 3d models for games, architecture, videos. (1433929)

turbosquid

$39

liquid amber

...squid

royalty free 3d model liquid amber for download as max on turbosquid: 3d models for games, architecture, videos. (1345717)

turbosquid

$39

liquid amber

...squid

royalty free 3d model liquid amber for download as max on turbosquid: 3d models for games, architecture, videos. (1345458)

turbosquid

$20

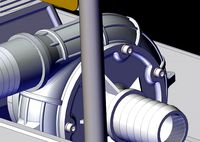

pump liquid

...osquid

royalty free 3d model pump liquid for download as max on turbosquid: 3d models for games, architecture, videos. (1163602)

Pump

3d_export

$5

pump

...pump

3dexport

pump

archibase_planet

free

Pump

...pump

archibase planet

petrol pump petrol station gas station

pump - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$8

Pumps

...ps

3docean

girls heels high kicks pumps shoes stilettos womens

womens high heels, pumps or stilettos. polygon model – no textures

3ddd

free

Pump

...ump

3ddd

pump , versus

производитель: versus

модель: pumphttp://www.versus.as/

turbosquid

$3

Pumps

...s

turbosquid

royalty free 3d model pumps for download as skp on turbosquid: 3d models for games, architecture, videos. (1275250)

3d_export

$5

pump

...pump

3dexport

turbosquid

$39

Realistic Water pump SYLLENT PUMP

...realistic water pump syllent pump for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1312864)

turbosquid

$150

Pumpe

...yalty free 3d model pumpe for download as ige, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1284318)

3d_export

$10

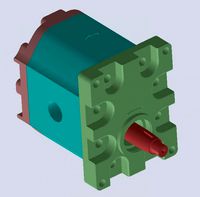

gear pump

...gear pump

3dexport

it is a gear pump in iges format

turbosquid

$19

Old Water Pumps Gas Pumps

...pumps gas pumps for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1207997)

Valve

3d_export

$5

Valve

...valve

3dexport

diverter valve

3d_export

$5

valve

...valve

3dexport

this is a 3d model of a valve available in all formats.

3d_export

free

valve

...valve

3dexport

simple valve 3d model, more free models here:

3d_export

$20

gate valve

...gate valve

3dexport

gate valve

3d_export

$10

stop valve

...stop valve

3dexport

stop valve

3d_export

$5

ball valve

...ball valve

3dexport

ball valve

3ddd

$1

valve 02

...valve 02

3ddd

клапан

water valve

3ddd

$1

Valve 01

...valve 01

3ddd

клапан

water valve

turbosquid

$19

Valve

...royalty free 3d model valve for download as ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1425806)

3d_export

$5

Valve

...exture for quick import. available formats fbx, obj. vertices - 3,741 fases - 3,697 textures 2048x2048 created in blender 3.1.2

Mold

3ddd

$1

molding

...molding

3ddd

молдинг

molding

3ddd

$1

molding

...molding

3ddd

молдинг , резьба

molding

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

design_connected

$16

Mold

...mold

designconnected

eternit mold computer generated 3d model. designed by charlot, michel.

Hot

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

3d_ocean

$6

Hot-air Balloon

...alloon model created with 3ds max 2010 3 types of file format for you choose(.max .fbx .obj ) high detailed model without texture

3ddd

$1

Hot Rod by Baghera

...hot rod by baghera

3ddd

baghera , машинка

hot rod by baghera.

Heart

3d_ocean

$6

Heart of hearts

...tive heart love original stylish

this is a model of a heart made out of hearts. its pretty easy to handle even though its hi-rez.

3d_ocean

$2

Heart

...heart

3docean

heart human heart red heart

human heart

3d_export

free

heart

...heart

3dexport

heart

3d_export

$20

Heart

...heart

3dexport

human heart

3d_ocean

$1

Heart

...heart

3docean

christmas couple heart love red valentine wedding

a red heart

3ddd

$1

Heart

...heart

3ddd

сердце , статуэтка

heart

3d_export

$5

heart

...heart

3dexport

the heart is created in voxel style.

3d_export

$6

Heart

...heart

3dexport

didactic 3d model of a human heart

3d_export

$7

heart

...heart

3dexport

lego heart.<br>9382 polygons.

3d_ocean

$2

Hearts

... shiny soppy valentine valentine's day valentines

hearts with textures. happy valentine’s day and thank you for looking.

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints