Thingiverse

Prankapult by HardlyForeal

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is a modified version of thing:1381027.

I try to take a purist route and don't think a 3d printed object should need glue or welding if at all possible. I've modified it to snap the supports onto the base, and to use c-clips to hold the supports together. I tried to use split snap posts for the connection between support A and support B, but the layer adhesion isn't good enough at this size, and the tabs just break. So I added the C-Clips, and they hold with plenty of strength.

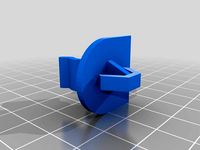

Note the orientation of the throwing arm to Support A during assembly, shown in the first image. The throwing arm is installed in that position and then wound before installing the base. Assembly is the same as the video at the original thing except for snapping and using the c-clips instead of welding with a soldering iron or gluing.

I also modified the size of the hole in the spring to provide less clearance, and therefore less chance of it spinning passed the corners.

Because the ammo basket requires bridging in the through-hole, the insertion of the throwing arm may be rough, but should fit. But if it doesn't fit for some reason, wedging the basket on works just as well (which is what I did before I expanded the clearance).

When printing, I printed Support A, the spring/throwing arm, and the c-clips solid. I set the infill pattern and top and bottom layer patterns to "concentric" to add as much spring and as little chance of fracturing as possible. Everything else I printed at a 10% infill.

I try to take a purist route and don't think a 3d printed object should need glue or welding if at all possible. I've modified it to snap the supports onto the base, and to use c-clips to hold the supports together. I tried to use split snap posts for the connection between support A and support B, but the layer adhesion isn't good enough at this size, and the tabs just break. So I added the C-Clips, and they hold with plenty of strength.

Note the orientation of the throwing arm to Support A during assembly, shown in the first image. The throwing arm is installed in that position and then wound before installing the base. Assembly is the same as the video at the original thing except for snapping and using the c-clips instead of welding with a soldering iron or gluing.

I also modified the size of the hole in the spring to provide less clearance, and therefore less chance of it spinning passed the corners.

Because the ammo basket requires bridging in the through-hole, the insertion of the throwing arm may be rough, but should fit. But if it doesn't fit for some reason, wedging the basket on works just as well (which is what I did before I expanded the clearance).

When printing, I printed Support A, the spring/throwing arm, and the c-clips solid. I set the infill pattern and top and bottom layer patterns to "concentric" to add as much spring and as little chance of fracturing as possible. Everything else I printed at a 10% infill.

Similar models

thingiverse

free

Wall snap grib - spring loaded by SWM

...t 2 and 3 should be printed in two copies with 100 % infill and part 1 in one copy.

the assembly is a tight fit, but works great!

thingiverse

free

Elliptical Gear alternate arms by zc41485

... assembly. this remix replaces the clips on the arms with a hole and a pin. needs glue for assembly, but far less likely to snap.

thingiverse

free

Honda Odyssey Hood Latch Clip by dhackle10

... the hood latch bar no problem. i printed it in abs, but petg should work fine too. i also printed with supports and 100% infill.

thingiverse

free

Switch Blade Wallet by Cisco_

...th external money clip or no money clip. swap between them no problem

prints wit no support and no glue required when assembling.

thingiverse

free

Printed Spring Clip by catzcradle

...layers at 245 temp. supports on. files are in inches. the parts should just snap together and lock once the hub is snapped in.

thingiverse

free

Dial gauge clip by mread

...t may be that less dense infills will give less spring tension.

i would recommend using this with the power off, to avoid damage.

grabcad

free

Trebuchet Catapult - Snap Together

...together after printing with a bit of force.

i used pennies for the weights, designed to throw a marsh mellow or ping pong ball.

thingiverse

free

Cable Clip

...clip

thingiverse

clip to hold cell phone or other cables. use supports if printing flat and high infill so it doesn't break.

thingiverse

free

Prusa i3 MK3S Gantry Frame Clip by grahammoucka

...side using prusa slicer to select the face to print on. it doesn't need any supports and should be stronger printed that way.

thingiverse

free

9mm Speedloader by Sdhilks

...hen the bending parts. if printed vertically, there is a high chance of breakage at a layer line. print this part at 100% infill.

Hardlyforeal

thingiverse

free

Customizable C-Clip Peg by HardlyForeal

...p (or whatever) and merged with your existing geometry to create an attachment.

full description and usage is at the c-clip page.

thingiverse

free

Customizable C-Clip - Updated by HardlyForeal

...om. this should allow the most stability during flexing, as very little force will be in a direction trying to separate strands.

thingiverse

free

Envisalink 3 Vista 20p mounting adapter by HardlyForeal

...ine. otherwise, i am working on finding a new mounting location and designing a new adapter, and will update this when i am done

thingiverse

free

Thumbwheel Keeper for Maker Select and possibly other Prusa I3 clones by HardlyForeal

...f the thumbwheels for the clones are the same size, so they obviously may need scaling a bit to get the right fit on your wheels.