Thingiverse

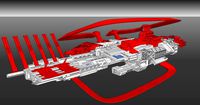

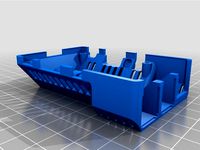

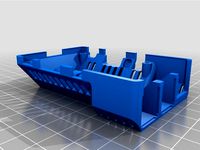

Power Supply, Raspberry Pi, Relay Module, Fan Case by anhtien

by Thingiverse

Last crawled date: 3 years ago

It's a long name but it has multiple uses: cooling down the AC/DC power supply, switching on/off the AC/DC power supply remotely. It is also a Raspberry Pi / Relay Module case.

You can refer to the included connection diagram to see how things are connected inside this case.

Hardware:

Raspberry Pi with Octoprint preloaded and ready to be accessed from a Web Browser. If not, search online to see how to set it up.

A relay module, one channel is good for this purpose but I have 2 channel module installed because I will want to remotely turning on/off other devices (light, music, or anything that will connect to my “future” power bar). With one channel relay module, everything could be turned on/off together with the 3D printer. However, controlling other devices separately might be more practical such as leaving music on and keep the 3D printer off to cool it down after so many hours of usage. The price is about the same for 2 or 1 channel relay module.

A terminal strip (optional but I recommend it for ease of connectivity and power distribution). Please use the electrical ring connectors at all connections if you can, don't be cheap on this because one loose wire can cause a very damaging spark.

Two 40mm fan, 12vdc type of course.

Also need 3 x M3 screws and 2 nuts on top right, 2 screws and 2 nuts on the bottom right (or #6 3/8” machine screws worked too)

Use wood screws (such as #6 3/8”) to fasten terminal strip to the frame. Remove existing M3 screw from the power supply (top left) and replace with longer M3 screw (spare from the Anet A8).

The design could fit different type of Raspberry Pi and/or Relay Module, if you can not snap the board(s) in you could use tie-wrap through the honeycomb holes, double-sided tape or crazy glue to secure the Raspberry and Relay Module to the frame.

Follow the attached wiring diagram to connect the components together, make sure you orient the Raspberry Pi to have the network cable toward the back or else the network cable might get caught with the X-axis / Z-axis bars & rod. Also connect the fans with label pointing outside to suck the hot air out of the power supply and not blowing dust into it.

Software:

Octopi comes with GPIO already pre-installed, use SSH to login using pi username. To check if it’s available enter command:

gpio readall

If it comes back with information then you are good to go. If not, check wiringpi.com to see how to install.

Wiring Diagram:

In order for the octopi to control the relay, the “live” wire from main power should go to the “live” port #1 on the AC/DC power supply. The neutral line from main power goes to COM port on the relay module. Connect a new neutral line from NO (Normally Open) port on the relay module to the power supply Neutral port #2. Connect the ground straight from main power to the AC/DC power supply ground port #3. A side note about my AC/DC 12vdc power supply, I think the Anet A8 comes with incorrect internal wiring and I “had” to use my neutral line as “COM” line, it should really be the “hot/live” wire to be used as COM line. Well, since I don’t have another 12vdc power supply I can’t verify if All Anet A8 are like that or not. Anyway, the point is to have the Hot wire from main power to the relay’s COM port, then Normally Open (NO) port goes to AC/DC Hot wire. I just show what works for me, you might have to switch live and neutral wires if it does not work for you.

The Raspberry Pi uses the WiringPi connection scheme so check it out and use the proper GPIO pin. To demonstrate the pinout scheme, if you have the same Raspberry Pi Rev B as mine, then the 5vdc is the first pin on the outer row, ground is the third pin, and GPIO 1 is on the 6th pin. Those are NOT the actual pin number, those are for locating where they are on the board. The actual pin for 5vdc is header pin #2, ground is header pin #6, and GPIO is header pin #12. In fact the “gpio readall” command shows the pinout for your board, dont' use the BCM pinout.

Once logged in, edit the file .bashrc and add the following two lines:

alias a8on='gpio mode 1 out;gpio write 1 0'

alias a8off='gpio write 1 1;gpio mode 1 in'

Save and exit, then enter command “source .bashrc” to activate it. If you do your wiring properly, you should be able to enter command “a8on” and see the unit goes up, “a8off” to see it turned off.

Print settings:

I used Repetier to print, needed to move object 7mm on X-axis to the right to center it. Maybe it’s my Repetier setup that was incorrect.

Slicer configuration:

Print settings:

Layer high 0.2mm, Infill 30%, Speed 37mms, Do generate Support Material.

Filament settings: PLA 1.75mm, depending on your filament I set mine to 215 deg for extruder, 65 deg for hot bed.

Update 1: Adding version 3 with stronger and thicker wall (4mm instead of 2mm) and the thin version with higher retaining tabs for the relay module (v2a)

You can refer to the included connection diagram to see how things are connected inside this case.

Hardware:

Raspberry Pi with Octoprint preloaded and ready to be accessed from a Web Browser. If not, search online to see how to set it up.

A relay module, one channel is good for this purpose but I have 2 channel module installed because I will want to remotely turning on/off other devices (light, music, or anything that will connect to my “future” power bar). With one channel relay module, everything could be turned on/off together with the 3D printer. However, controlling other devices separately might be more practical such as leaving music on and keep the 3D printer off to cool it down after so many hours of usage. The price is about the same for 2 or 1 channel relay module.

A terminal strip (optional but I recommend it for ease of connectivity and power distribution). Please use the electrical ring connectors at all connections if you can, don't be cheap on this because one loose wire can cause a very damaging spark.

Two 40mm fan, 12vdc type of course.

Also need 3 x M3 screws and 2 nuts on top right, 2 screws and 2 nuts on the bottom right (or #6 3/8” machine screws worked too)

Use wood screws (such as #6 3/8”) to fasten terminal strip to the frame. Remove existing M3 screw from the power supply (top left) and replace with longer M3 screw (spare from the Anet A8).

The design could fit different type of Raspberry Pi and/or Relay Module, if you can not snap the board(s) in you could use tie-wrap through the honeycomb holes, double-sided tape or crazy glue to secure the Raspberry and Relay Module to the frame.

Follow the attached wiring diagram to connect the components together, make sure you orient the Raspberry Pi to have the network cable toward the back or else the network cable might get caught with the X-axis / Z-axis bars & rod. Also connect the fans with label pointing outside to suck the hot air out of the power supply and not blowing dust into it.

Software:

Octopi comes with GPIO already pre-installed, use SSH to login using pi username. To check if it’s available enter command:

gpio readall

If it comes back with information then you are good to go. If not, check wiringpi.com to see how to install.

Wiring Diagram:

In order for the octopi to control the relay, the “live” wire from main power should go to the “live” port #1 on the AC/DC power supply. The neutral line from main power goes to COM port on the relay module. Connect a new neutral line from NO (Normally Open) port on the relay module to the power supply Neutral port #2. Connect the ground straight from main power to the AC/DC power supply ground port #3. A side note about my AC/DC 12vdc power supply, I think the Anet A8 comes with incorrect internal wiring and I “had” to use my neutral line as “COM” line, it should really be the “hot/live” wire to be used as COM line. Well, since I don’t have another 12vdc power supply I can’t verify if All Anet A8 are like that or not. Anyway, the point is to have the Hot wire from main power to the relay’s COM port, then Normally Open (NO) port goes to AC/DC Hot wire. I just show what works for me, you might have to switch live and neutral wires if it does not work for you.

The Raspberry Pi uses the WiringPi connection scheme so check it out and use the proper GPIO pin. To demonstrate the pinout scheme, if you have the same Raspberry Pi Rev B as mine, then the 5vdc is the first pin on the outer row, ground is the third pin, and GPIO 1 is on the 6th pin. Those are NOT the actual pin number, those are for locating where they are on the board. The actual pin for 5vdc is header pin #2, ground is header pin #6, and GPIO is header pin #12. In fact the “gpio readall” command shows the pinout for your board, dont' use the BCM pinout.

Once logged in, edit the file .bashrc and add the following two lines:

alias a8on='gpio mode 1 out;gpio write 1 0'

alias a8off='gpio write 1 1;gpio mode 1 in'

Save and exit, then enter command “source .bashrc” to activate it. If you do your wiring properly, you should be able to enter command “a8on” and see the unit goes up, “a8off” to see it turned off.

Print settings:

I used Repetier to print, needed to move object 7mm on X-axis to the right to center it. Maybe it’s my Repetier setup that was incorrect.

Slicer configuration:

Print settings:

Layer high 0.2mm, Infill 30%, Speed 37mms, Do generate Support Material.

Filament settings: PLA 1.75mm, depending on your filament I set mine to 215 deg for extruder, 65 deg for hot bed.

Update 1: Adding version 3 with stronger and thicker wall (4mm instead of 2mm) and the thin version with higher retaining tabs for the relay module (v2a)

Similar models

grabcad

free

Bracket for Raspberry Pi 3 with LM2596 DC-DC step down converter module

...lm2596 dc-dc step down converter module. the lm2596 module is used to supply power for raspberry from switching mode power supply

thingiverse

free

Anet A8 PSU cover with switch, relays, fan and OctoPrint

...additional details) one power switch (note: there are two similar versions of this switch, one with countersink screw heads...

thingiverse

free

OctoPrint Dual instances control box by Sp4wN

...fit in the box, or you can buy a similar one:https://www.aliexpress.com/item/ugreen-usb-2-0-type-a-male-to-b-male-printer-cable-sync-data-charger-cable/32416310263.html dupont wires:https://www.aliexpress.com/item/wavgat-dupont-line-120pcs-20cm-male-to-male-male-to-female-and-female-to-female-jumper/32501238474.html usb hub i have used is...

thingiverse

free

Raspberry Pi GPIO Power Blocker for Prusa by Shwalamazula

...spberry-pi-zero-w-preparation-and-installation_2180

power pins are blocked as well. this is for externally-powered raspberry pis.

thingiverse

free

Zixtec LM2596 DC to DC Converter, Power Supply Step Down Module

...px_yo_dt_b_asin_title_o01_s00?ie=utf8&psc=1

i will just use a dab of hot glue to secure the box to the bottom of the printer.

thingiverse

free

Versatile Power Supply Cover/Enclosure

... the power supply into the case (the wires will be squeezed into the remaining area).

secure with m3 screws on the back and side.

thingiverse

free

Anet A8 Power Supply Cover incl. fused C-14 power socket, 2 channel Relais and RS-15-5 5v Power supply by caesar_1111

...)

as always i included the freecad model.

caesar

ps: be careful when clipping in the rs-15-5 since the clips as somehow fragile.

thingiverse

free

Raspberry Power Supply by Joeend11

...is: 5v 3a dc/dc converter with usb port, 7-24 input voltage kis3r33s step-down module. sellers may be found by any search engine.

thingiverse

free

Relaybox for Raspberry Pi/Arduino by Dslp

...o 2.1 mm dc sockets are attached to the side and the required power supply units can be connected. i also used m3 thread inserts.

thingiverse

free

Relay Control OctoPrint Wanhao i3 by Jeffeb3

...print can keep on doing whatever it was doing before calling that script, wihtout waiting for the sleep or the command to finish.

Anhtien

thingiverse

free

Tabletop 40mm Fan by anhtien

...y anhtien

thingiverse

this simple 40mm fan frame design comes with 2 flavors, nothing fancy. just clip it to the 12vdc adapter.

thingiverse

free

Android / iPhone stand by anhtien

...t a generic smart phone stand, the slot's width is 19mm. print with 50mms speed and 30% infill, support generation required.

thingiverse

free

Calibration Dice by anhtien

...e roman numerals version.

i printed it using the repetier default setup (60mms speed, 20% infill), 200deg extruder 50deg hot bed.

thingiverse

free

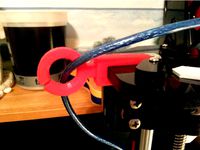

Spaceship Filament / Cable Guide by anhtien

...nt to be another filament guide but i made it large enough to be used as my usb cable guide. it kinda looks like a spaceship :-)

thingiverse

free

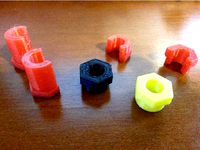

Screw Washers / Spacers by anhtien

...u just print the sizes you need.

add a brim of 5mm when printing if required

update1: added v1 with more clearance between copies

thingiverse

free

Big mouth Funnels by anhtien

...to the flask. one is 33mm wide, the other 43mm wide.

they were designed thin to save on filament.

update 1: added a 50mm funnel.

thingiverse

free

Teeny Tiny Boxes by anhtien

... for tight fit, once snapped in you might need a knife or flat screw driver to take those off. they certainly won't fly away.

thingiverse

free

Rod Support for the Spool Holder by anhtien

...erse.com/thing:2512609). this is probably more useful for the long rod holding many spools which might bend due to heavy weight.

thingiverse

free

360w 12vdc Power Supply Cover by anhtien

...upply. the screw holes are for m4 screws but i have #6-32 3/8 screws and nuts and they fit too (5 screws and 2 nuts are needed).

thingiverse

free

T8 threaded rod spacers by anhtien

...s good to snap in the middle of the rod, also comes with the extra long version. the full nut version is for the end of the rod.

Relay

turbosquid

$50

Relay Spaceship

... model relay spaceship for download as skp, 3ds, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1655800)

3ddd

$1

Scavolini / Grand Relais

...scavolini / grand relais

3ddd

scavolini

scavolini модель grand relais дизайн gianni pareschi

3ddd

$1

Сантехника Globo Relais

... унитаз , зеркало

сантехника globo relais

умывальник,зеркало,унитаз.

3d_export

$8

relay automatic assembly line

...relay automatic assembly line

3dexport

relay automatic assembly line

3ddd

free

Унитаз и биде Relais

... биде , унитаз

унитаз art.re001 bi и биде art.re009 bi

turbosquid

free

Relay 8 pin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$110

Power relay station3d model

...el

cgstudio

.3ds .fbx .max .obj - power relay station 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Стол обеденный -Scavolini- Grand Relais

...s

3ddd

обеденный , scavolini

обеденный стол scavolini - grand relais, в трёх расцветках.

3d_export

$10

relay jd1912 12v 40a with connector

...lowing bodies: 1. relay jd1912 12v 40a - 1 piece; 2. connector housing - 1 piece; 3. terminal with a part of the wire - 4 pieces.

3ddd

free

Globo Relais furnitures

... , раковина

раковина с консолью st070.ne

зеркалоsp070.bi

стакан re0381x

мыльница re0391x

Raspberry

3d_export

free

raspberry

...raspberry

3dexport

3d model of a raspberry. i tried to make it realistic.

turbosquid

$27

Raspberries

...y free 3d model raspberries for download as max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1354176)

turbosquid

$14

Raspberries

...y free 3d model raspberries for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1364663)

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$99

Raspberry

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

raspberries

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Raspberries 3D Model

...raspberries 3d model archive3d raspberries raspberry raspberries n300911 - 3d model (*.3ds) for interior 3d...

3d_export

$5

raspberry fruit

...raspberry fruit

3dexport

3d_export

$5

raspberry

...y different sizes. their color ranges from light burgundy to pink. there are formats: obj, 3ds, blend, dae, fbx, mtl.<br>:)

evermotion

$12

raspberries 23 am130

...evermotion raspberries 23 am130 evermotion key 23 food fruit raspberry fruits am130 raspberries highly detailed 3d model of raspberries...

Pi

design_connected

$11

Pi

...pi

designconnected

ligne roset pi chairs computer generated 3d model. designed by thibault desombre.

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$18

pied

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люста emme pi light

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

бра классическое emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

design_connected

$16

Pi-Air

...pi-air

designconnected

living divani pi-air lounge chairs computer generated 3d model. designed by harry & camila.

3d_ocean

$15

Manneken Pis

...picting a naked little boy urinating into a fountain’s basin. (wikipedia) the model was sculpted in blender 2.70a rendered wit...

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люстра классическая фирма: emme pi light

артикул: 3595/5/cot/12/wh

Supply

turbosquid

$1

supplies

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

black supply

...black supply

3dexport

black supply size: 57.9 x 29.2 x 34 sm

turbosquid

$20

Office Supplies

...lty free 3d model office supplies for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1273636)

3d_export

free

office supplies

...office supplies

3dexport

turbosquid

$8

Supply Drop

...e 3d model supply drop for download as fbx, obj, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1663721)

turbosquid

$75

Supply Helicopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$65

Supply Ship

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Village Supplies

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Power Supply

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

school supplies

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Module

turbosquid

$4

Module

...

turbosquid

royalty free 3d model module for download as max on turbosquid: 3d models for games, architecture, videos. (1259603)

3d_export

free

Martian module

...martian module

3dexport

martian module objects 18 textures are missing

design_connected

$39

Kennedee Moduls

...kennedee moduls

designconnected

kennedee moduls computer generated 3d model. designed by massaud, jean-marie.

design_connected

$39

Sayonara Moduls

...sayonara moduls

designconnected

bbb emmebonacina sayonara moduls computer generated 3d model. designed by decursu, giorgio.

design_connected

$27

Togo Moduls

...togo moduls

designconnected

ligne roset togo moduls computer generated 3d model. designed by ducaroy, michel.

design_connected

$34

Nuvola Moduls

...nuvola moduls

designconnected

bonaldo nuvola moduls 2-seater computer generated 3d model. designed by giuseppe viganò.

3d_export

free

Hibernation module

...hibernation module

3dexport

design_connected

$27

Sabi moduls

...sabi moduls

designconnected

paola lenti sabi moduls 2-seater computer generated 3d model. designed by francesco rota.

3d_export

$50

pls concrete module

...pls concrete module

3dexport

pls concrete module<br>pls with concrete mobile mixer module m5

turbosquid

free

Hibernation module

...squid

free 3d model hibernation module for download as blend on turbosquid: 3d models for games, architecture, videos. (1667696)

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Power

turbosquid

$100

power

...ower

turbosquid

royalty free 3d model power for download as on turbosquid: 3d models for games, architecture, videos. (1421990)

3d_export

$5

Power

...power

3dexport

3d_export

$5

power outlets

...power outlets

3dexport

power outlets

3ddd

$1

lion power

...lion power

3ddd

лев , статуя

lion power gold sculpture

3ddd

$1

Sea Power

...

компас , море , часы

часы с компасом sea power

3ddd

free

Meridiani / Power

...power

3ddd

meridiani , круглый

стол power производитель meridiani, диаметр 120,высота 67

3d_export

$5

Power Surge

...power surge

3dexport

the power surge is a all mesh carnival ride to lower in game part count and lag

turbosquid

$8

Airport Ground Power Unit (AXA Power )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Power Houser

...rbosquid

royalty free 3d model power houser for download as on turbosquid: 3d models for games, architecture, videos. (1333800)

3d_export

$5

power outlet

...power outlet

3dexport

power outlet<br>format file maya 2018, 3d max 2017, obj, fbx

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.