Thingiverse

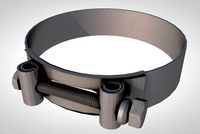

pneumatic extruder clamp, carriage adapter, and solenoid bracket by nicksears

by Thingiverse

Last crawled date: 3 years, 1 month ago

Pneumatic extrusion printing is actually very simple on almost any open source 3D printer. All you have to do is make this pneumatic extruder and set up post-processing scripts to turn on an output - this output opens a valve and applies pressurized air to dispense material.

Pressure

The hardest part may be a consistent source of high pressure air. If you have an air compressor/tank or house air at a lab/shop this will work best. I'm also working on an adaptation of a 2L soda bottle, these can hold up to 100 psi! (50psi safely) even still, use at your own risk). You should not need much more than 30 psi, and we will use a 30psi max regulator to the pressure we need (only ~10-15psi). Again the flow is: pressure source/regulator, solenoid to control flow, dispensing syringe.

Electronics

You do not use the existing extruder motor, but you do need an extra output like a controllable fan that can handle ~500mA (some fans are only 20-50mA). Alternatively, you can use the extruder heater output, but you will not be able to heat and control a nozzle tip and you may have to make firmware modifications to make it work. You will have to make sure a safety feature is disabled that kills the printer if the heater is on but an increase in temperature is not detected. This can be dangerous for (hot) plastic printing though, so use at your own risk! Some printers don't have this enabled by default, so for example the Monoprice Mini does not have an extra fan or open source firmware, but can use the extruder with this setup.

Toolpath

To automate the use of these outputs, you will have to install python and point your slicer to scripts that add lines of code (only a semicolon between scripts with the full path). One script turns the solenoid ON AFTER an UNretraction (make sure retraction is >0 in your slic3r) and unretraction should only and always happens when you want to start dispensing. Another script turns the solenoid OFF BEFORE a retraction to stop dispensing (if it stops AFTER the retraction it will leave a blob at the end of a line). A final script may be helpful to give a small pause (100ms) to let the material start extruding or there may be a delay and gap in the line. These scripts will run after slicing a file and insert the respective lines, and the order is critical (pause, on, off).

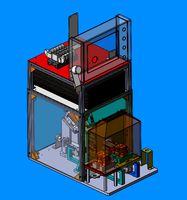

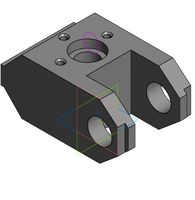

Extruder

For the physical setup, you will need the printed parts, solenoid valve, and some cheap dispensing syringes/tubing/connectors. The design includes a carriage mount for an anet a8-style printer, but I included the *.step file so you could more easily modify it. I also made a bracket to hold the solenoid so both it and the regulator could be on the top of the frame (pictures to come!) You need to use a 3-way solenoid - if you use a 2-way, the pressure will be trapped in the syringe and ooze, rather than venting.

Calibration

I've included custom calibration scripts that are in coarse, medium, and fine increments. You may need to change some of the coordinates if you printer size is different. First run the coarse calibration - it will begin with a loop tat the average speed that will allow you get a ballpark pressure with the regulator. It will then extrude 5 lines at the lowest speed through the highest. Whichever line is closest to the appropriate width is the correct speed to use with the medium and/or fine calibrations. It's really helpful to have a camera mounted directly to the extruder - the absolute cheapest "6 LED webcam" (~$4!) on ebay or amazon work great for this because they can be manually focused close like we need. You might get 2-3 because they are pretty cheap and you might get one DOA. Additionally, for the exact type linked, you remove the base, tap the stem with m3 thread, and screw into it with the bolt that retains the dispensing syringe. I've included "@pause" commands for use with Repetier Host to simplify taking pictures after printing calibration lines.

Bed Leveling

I highly recommend using auto-bed leveling with a conductive nozzle and metal bed to eliminate variability measuring line width. I may post this as a separate thing with details about how to enable it in the firmware. The physical setup is easy - fix a 3/16" thick 8x8" aluminum sheet from mcmaster-carr to the bed with binder clips. A precision ground surface or extreme flatness is not necessary (you will end up scratching it a bunch anyways). Then connect one alligator clip to the bed and one to the needle, and use those two wires in place of a typical mechanical endstop switch.

The links aren't working, you'll have to copy and paste the text into your browser, sorry!

https://www.amazon.com/dp/B000KKQIZG/ 3/8-18 NPT to 1/8-27 NPT adapterhttps://www.amazon.com/dp/B017VNO33S/ 1/8-27 NPT to 1/8 barbhttps://www.amazon.com/dp/B017VNOMZM/ 1/8 barb to 1/4-18 NPThttps://www.amazon.com/dp/B01BPQDG62/ Precision regulator (3-30 PSI)https://www.amazon.com/dp/B00VU14L4Y/ 3 way solenoid valvehttps://www.amazon.com/dp/B017UXCAQ6/ 1/8-27 NPT thread plughttps://www.amazon.com/dp/B01LH81EC6/ dispensing syringe (set of 5, 10, 30cc)https://www.amazon.com/dp/B003VY4M42/ Generic U19-A Night Vision Webcamhttps://www.mcmaster.com/#89015k239/ 6061 Aluminum Sheet 1/8" Thick, 8x8"https://www.mcmaster.com/#5108k43/ 1/8x1/4 PU tubing (25ft)

Pressure

The hardest part may be a consistent source of high pressure air. If you have an air compressor/tank or house air at a lab/shop this will work best. I'm also working on an adaptation of a 2L soda bottle, these can hold up to 100 psi! (50psi safely) even still, use at your own risk). You should not need much more than 30 psi, and we will use a 30psi max regulator to the pressure we need (only ~10-15psi). Again the flow is: pressure source/regulator, solenoid to control flow, dispensing syringe.

Electronics

You do not use the existing extruder motor, but you do need an extra output like a controllable fan that can handle ~500mA (some fans are only 20-50mA). Alternatively, you can use the extruder heater output, but you will not be able to heat and control a nozzle tip and you may have to make firmware modifications to make it work. You will have to make sure a safety feature is disabled that kills the printer if the heater is on but an increase in temperature is not detected. This can be dangerous for (hot) plastic printing though, so use at your own risk! Some printers don't have this enabled by default, so for example the Monoprice Mini does not have an extra fan or open source firmware, but can use the extruder with this setup.

Toolpath

To automate the use of these outputs, you will have to install python and point your slicer to scripts that add lines of code (only a semicolon between scripts with the full path). One script turns the solenoid ON AFTER an UNretraction (make sure retraction is >0 in your slic3r) and unretraction should only and always happens when you want to start dispensing. Another script turns the solenoid OFF BEFORE a retraction to stop dispensing (if it stops AFTER the retraction it will leave a blob at the end of a line). A final script may be helpful to give a small pause (100ms) to let the material start extruding or there may be a delay and gap in the line. These scripts will run after slicing a file and insert the respective lines, and the order is critical (pause, on, off).

Extruder

For the physical setup, you will need the printed parts, solenoid valve, and some cheap dispensing syringes/tubing/connectors. The design includes a carriage mount for an anet a8-style printer, but I included the *.step file so you could more easily modify it. I also made a bracket to hold the solenoid so both it and the regulator could be on the top of the frame (pictures to come!) You need to use a 3-way solenoid - if you use a 2-way, the pressure will be trapped in the syringe and ooze, rather than venting.

Calibration

I've included custom calibration scripts that are in coarse, medium, and fine increments. You may need to change some of the coordinates if you printer size is different. First run the coarse calibration - it will begin with a loop tat the average speed that will allow you get a ballpark pressure with the regulator. It will then extrude 5 lines at the lowest speed through the highest. Whichever line is closest to the appropriate width is the correct speed to use with the medium and/or fine calibrations. It's really helpful to have a camera mounted directly to the extruder - the absolute cheapest "6 LED webcam" (~$4!) on ebay or amazon work great for this because they can be manually focused close like we need. You might get 2-3 because they are pretty cheap and you might get one DOA. Additionally, for the exact type linked, you remove the base, tap the stem with m3 thread, and screw into it with the bolt that retains the dispensing syringe. I've included "@pause" commands for use with Repetier Host to simplify taking pictures after printing calibration lines.

Bed Leveling

I highly recommend using auto-bed leveling with a conductive nozzle and metal bed to eliminate variability measuring line width. I may post this as a separate thing with details about how to enable it in the firmware. The physical setup is easy - fix a 3/16" thick 8x8" aluminum sheet from mcmaster-carr to the bed with binder clips. A precision ground surface or extreme flatness is not necessary (you will end up scratching it a bunch anyways). Then connect one alligator clip to the bed and one to the needle, and use those two wires in place of a typical mechanical endstop switch.

The links aren't working, you'll have to copy and paste the text into your browser, sorry!

https://www.amazon.com/dp/B000KKQIZG/ 3/8-18 NPT to 1/8-27 NPT adapterhttps://www.amazon.com/dp/B017VNO33S/ 1/8-27 NPT to 1/8 barbhttps://www.amazon.com/dp/B017VNOMZM/ 1/8 barb to 1/4-18 NPThttps://www.amazon.com/dp/B01BPQDG62/ Precision regulator (3-30 PSI)https://www.amazon.com/dp/B00VU14L4Y/ 3 way solenoid valvehttps://www.amazon.com/dp/B017UXCAQ6/ 1/8-27 NPT thread plughttps://www.amazon.com/dp/B01LH81EC6/ dispensing syringe (set of 5, 10, 30cc)https://www.amazon.com/dp/B003VY4M42/ Generic U19-A Night Vision Webcamhttps://www.mcmaster.com/#89015k239/ 6061 Aluminum Sheet 1/8" Thick, 8x8"https://www.mcmaster.com/#5108k43/ 1/8x1/4 PU tubing (25ft)

Similar models

grabcad

free

propane regulator

...model 597fa pressure regulator for liquid or vapor propane service. it is adjustable from 1 - 15 psi and has 1/4" npt ports.

grabcad

free

3/8 NPT Pressure Regulator

...3/8 npt pressure regulator

grabcad

3/8 npt pressure regulator

grabcad

free

Pressure gauge

...pressure gauge

grabcad

1/4" npt psi gauge

thingiverse

free

Loc Line 1/4id, 1/8 NPT by jvanick

...oc line 1/4id, 1/8 npt by jvanick

thingiverse

1/4" loc line fitting by oscarino93, remixed to have a 1/8" npt fitting.

3dwarehouse

free

Pressure switch XMLF with adjustable...psi). Fluid connection 1/4 NPT female

...h adjustable differential. relay output. fluid connection 1/4 npt female #data_detection #telemecanique #traceparts #xmlfm01e2046

grabcad

free

Ashcroft Gauge 0.250 NPT 0-30 PSI

...ashcroft gauge 0.250 npt 0-30 psi

grabcad

pressure gauge

1/4" npt

0-30 pisg

3dwarehouse

free

Universal pressure sensor XMLF. 1 analogue...psi). Fluid connection 1/4 NPT female

...0 ma. pressure range -008 bar à 600 bar. fluid connection 1/4 npt female #data_detection #telemecanique #traceparts #xmlfm01d2026

grabcad

free

1/4"NPT Air Filter Regulator MAFRL1N14

...uot;npt air filter regulator mafrl1n14

grabcad

air filter/regulator, for 1/4"npt air line. max-air technology pn: mafrl1n14

3dwarehouse

free

7305 - PRESSURE REGULATOR MALE BSPT AND NPT DIAM D 1/4 INC C NPT1/8

...nd npt #7305_56_11 #legris__low_pressure #pneumatic_function_fittings #pressure_reducer_fittings #pressure_regulators #traceparts

3dwarehouse

free

Pressure transmitter XMLF. Analogue output...psi). Fluid connection 1/4 NPT female

....10 v pressure range -008 bar à 600 bar. fluid connection 1/4 npt female #data_detection #telemecanique #traceparts #xmlfm01d2016

Nicksears

thingiverse

free

smiley cube man body no support by nicksears

...pport by nicksears

thingiverse

i made a version of the smiley cube man's body that doesn't need support material.

enjoy!

thingiverse

free

individual buttons for Mmintbox by nicksears

... separate them, so modified the design to cut away the solid flat portion so it's usable as-printed. probably needs supports.

thingiverse

free

nicks peripump peristaltic pump by nicksears

... peripump itself definitely works (with a hand drill) but i'm currently assembling the gear reducer and will test it shortly.

thingiverse

free

McCormick salt or pepper grinder adapter (for drill, etc) by nicksears

...it with most printers for the actual diameter of ~42.75mm. adapted to 1/4" hexagonal bit to work with just about any drill.

thingiverse

free

plantronic voyager edge case by nicksears

...nt, but it allows you to remove easily. will add pictures when i can.

i've provided step and sldprt in case you want to edit.

thingiverse

free

nicks hysteresis calibrator by nicksears

...he file name (ie 0.5, 0.25mm). going in the opposite direction reverses this.

i tested this with a rather thick nozzle, so ymmv.

thingiverse

free

E3D clone M6 thread bowden to direct adapter by nicksears

...quests and i can make one that fits more recessed into the heatsink itself (but this will get complicated to screw it into place.

thingiverse

free

Magic chef replacement ice bucket by nicksears

...ing or rubber washer. if you are going to use the single piece version, i would verify the angle and let me know if it's off.

thingiverse

free

cubex e3d adapter for stock extruder by nicksears

... drawing of the e3d-v6 since it requires a model to post. let me know if you want one, i can ship you one for shipping cost ($7).

thingiverse

free

Nicks linear actuator paste extruder by nicksears

..., and holes for access to tighten the flag bolt - all so you can print two of them and mount them, side by side. (pictures soon).

Solenoid

turbosquid

$10

Solenoid table lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$14

automatic switch detection equipment

...plate yadeke cylinder photoelectric induction switch silver guide rail solenoid valve equal height bolt instrument hexagon pillar drag chain...

3d_export

$20

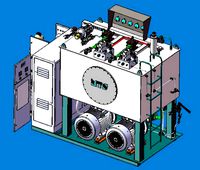

large hydraulic workstation

...station need: hydraulic pump, motor, cartridge valve, cartridge valve, solenoid valve, safety valve, etc. the motor drives the oil...

3d_export

$10

qvv5zl5 series manifold air distribution area valve plate valve seat air circuit board 14 spec

...air outlet is connected to the components (such as solenoid valve) that need air in the complete set of...

3d_export

$16

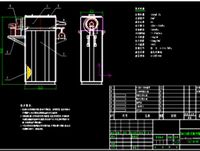

DMC24 pulse dust collector with CADbom caxa

...strip 18x15x3500 rubber 1<br>9 m12x219 u-clamp steel 2<br>10 pulse solenoid valve (1") 4<br>11 gb/t 3287-2000 flat seat union dn25...

3dfindit

free

Solenoid

...solenoid

3dfind.it

catalog: wandfluh

thingiverse

free

Solenoid by AaronAaronAaron

...perfectly, i forgot the size but will post it soon, it should cut a lot of time out of trying to set up a nice powerful solenoid.

thingiverse

free

Solenoid Case (sparkfun Solenoid - 5v small) by Revody_inc

...ase (sparkfun solenoid - 5v small) by revody_inc

thingiverse

for a solenoid - 5v (small) https://www.sparkfun.com/products/11015

3dfindit

free

Solenoids tubular

...solenoids tubular

3dfind.it

catalog: transmotec

thingiverse

free

Key to Rainbird solenoid

...key to rainbird solenoid

thingiverse

i needed a key -tool - for easier rotating a rainbird solenoid.

Pneumatic

3d_export

$7

pneumatic charging car

...pneumatic charging car

3dexport

pneumatic charging car

turbosquid

$20

pneumatic flap

...model pneumatic flap for download as dxf, ige, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1410890)

turbosquid

$2

pneumatic actuator

...l pneumatic actuator for download as 3ds, obj, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1333375)

turbosquid

$30

Cylinder pneumatic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

booster pneumatic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Pneumatic Fitting

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

pneumatic wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Pneumatic Unit 3D Model

...pneumatic unit 3d model

3dexport

pneumatic unit pressure velocity

pneumatic unit 3d model fau 71223 3dexport

turbosquid

$3

Pneumatic grinder

...r download as 3ds, dxf, obj, xsi, wrl, fbx, dwg, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1389593)

3d_export

free

pneumatic manifold block

...atic manifold block

3dexport

modified pneumatic manifold block for shooting particles, using festo valves installed on its face.

Carriage

archibase_planet

free

Carriage

...arriage

archibase planet

perambulator baby carriage pram

carriage n250908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

carriage

...carriage

3dexport

old fashion carriage model, more files here:

turbosquid

$140

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1482052)

turbosquid

$25

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1285944)

3d_export

free

carriage

...carriage

3dexport

game cart

3d_ocean

$15

Barrel Carriage

...ieval oak old transport wheels wine wood

this model contains a barrel and a carriage. it is a medieval type of wood oak carriage.

turbosquid

$40

Carriage

...ty free 3d model carriage for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290094)

turbosquid

free

Carriage

...yalty free 3d model carriage for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1239157)

3d_export

$5

Medieval carriage

...medieval carriage

3dexport

medieval carriage in fairy style

turbosquid

$58

Carriage

...d model carriage with scene for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1276262)

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Bracket

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket n280911 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder corbel bracket

bracket 9 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 10 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel console bracket

bracket 11 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder console bracket

bracket 12 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 13 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Adapter

3d_export

$10

Adapter 3D Model

...adapter 3d model

3dexport

adapter

adapter 3d model mur 20260 3dexport

archive3d

free

Adapter socket 3D Model

...dapter socket adapter

adapter socket n090211 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$400

cell adaptation

...

royalty free 3d model cell adaptation for download as blend on turbosquid: 3d models for games, architecture, videos. (1701655)

archive3d

free

Adapter 3D Model

...ups pc equipment

adapter extron n180813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

usb adapter

...royalty free 3d model usb adapter for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1582234)

turbosquid

$15

Power adapter

...free 3d model power adapter for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1510024)

turbosquid

$8

USB adapter

...e 3d model usb adapter for download as max, fbx, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1713542)

turbosquid

$30

adapter.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Nokia Adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Universal adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.