Thingiverse

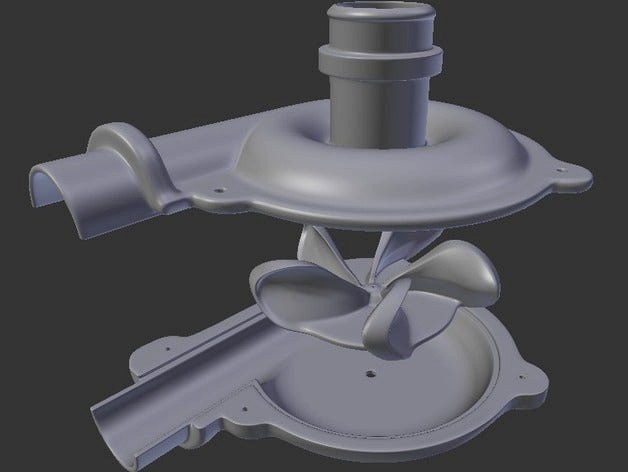

PJS Centrifugal Pump by pauljs75

by Thingiverse

Last crawled date: 3 years ago

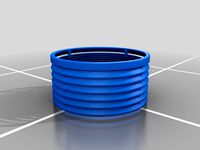

Centrifugal pump based on a design starting out with a torus. Can't say there's much science to this other than looking at how similar pumps were designed.

How well it works? Who knows?

--- Edit (9/7/2016) ---

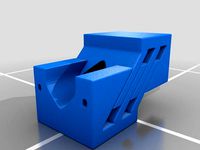

Added a new version to the files, mostly the same but some differences. Changed scaling a bit, but now it has a motor mount. I hope I have it sized correctly for brushless motors common to R/C applications. (At least if the measurements are what I think they are, should be scaled within a factor of 10. That'll depend on what your printer software does with the files.) In the middle of the motor mount, there's also a flared area that meets with the volute. That is intended for a simple gland seal which is made with waxed or grease-impregnated string. The wrap and clamping should only be tight enough to stop leaking but not bind the motor shaft from turning. (Stuff like that is a bit of trial and error.) As usual pre-check everything first before printing.

--- Edit (11/17/16) ---

Exported .stl files from Blender, as I'd guess some people still can't figure out how to open something in Blender, enable the export plugin, and use the drop-down menu to export in the desired format. Regardless of that, any problems with the .stl and I can't help much. Source reference files are the .blends, so if it exported bad from Blender there's not much else I can do for you. (Maybe change the scaling factor, that's about it.)

Some other suggestions for assembly would be to use self-tapping plastic screws, RTV or silicone sealer on the seating area of the volute perimeter. Hopefully something like that would be obvious enough. Also if anyone makes this, give feedback. I could still make some changes that may save drilling or making attaching the motor easier.

How well it works? Who knows?

--- Edit (9/7/2016) ---

Added a new version to the files, mostly the same but some differences. Changed scaling a bit, but now it has a motor mount. I hope I have it sized correctly for brushless motors common to R/C applications. (At least if the measurements are what I think they are, should be scaled within a factor of 10. That'll depend on what your printer software does with the files.) In the middle of the motor mount, there's also a flared area that meets with the volute. That is intended for a simple gland seal which is made with waxed or grease-impregnated string. The wrap and clamping should only be tight enough to stop leaking but not bind the motor shaft from turning. (Stuff like that is a bit of trial and error.) As usual pre-check everything first before printing.

--- Edit (11/17/16) ---

Exported .stl files from Blender, as I'd guess some people still can't figure out how to open something in Blender, enable the export plugin, and use the drop-down menu to export in the desired format. Regardless of that, any problems with the .stl and I can't help much. Source reference files are the .blends, so if it exported bad from Blender there's not much else I can do for you. (Maybe change the scaling factor, that's about it.)

Some other suggestions for assembly would be to use self-tapping plastic screws, RTV or silicone sealer on the seating area of the volute perimeter. Hopefully something like that would be obvious enough. Also if anyone makes this, give feedback. I could still make some changes that may save drilling or making attaching the motor easier.

Similar models

grabcad

free

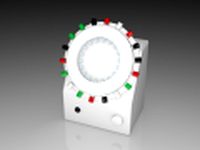

Casing for Pump

...casing for pump

grabcad

this is a volute casing with continuous reducing flow area for a centrifugal pump.

grabcad

free

Volute Casing - Centrifugal pump

...volute casing - centrifugal pump

grabcad

single volute casing of centrifugal pump

grabcad

free

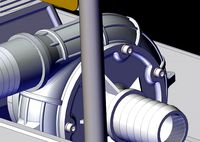

Motor and Centrifugal Pump

...motor and centrifugal pump

grabcad

make changes to the solidworks file to fit your pump needs.

grabcad

free

centrifugal pump

...centrifugal pump

grabcad

centrifugal pump volute

grabcad

free

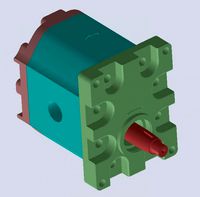

centrifugal pump

...centrifugal pump

grabcad

centrifugal pump with in volute casing

grabcad

free

Centrifugal Pump

...centrifugal pump

grabcad

centrifugal water pump, volute and impeller

grabcad

free

Centrifugal Pump

...centrifugal pump

grabcad

single stage centrifugal pump with volute casing

grabcad

free

pump casing

...pump casing

grabcad

centrifugal pump casing volute

grabcad

free

Request: A 2_d centrifugal pump(impeller and volute)

...p(impeller and volute)

grabcad

has 2d autocad drawing...

http://grabcad.com/requests/a-2_d-centrifugal-pump-impeller-and-volute

thingiverse

free

Small Water Pump by vonTugboat

...er it leaves my keyboard :) so be careful!! :) *note, the impeller changed since that picture was taken. it flows more now :)

Pauljs75

thingiverse

free

Pontiac Keychain by pauljs75

...pontiac keychain by pauljs75

thingiverse

keychain with pontiac emblem and text on it.

thingiverse

free

A Mystery Doodad by pauljs75

...a mystery doodad by pauljs75

thingiverse

an odd doodad thingamabober with no known purpose.

thingiverse

free

Trispoke Tessellation by pauljs75

...ljs75

thingiverse

based on the "trispokedovetile" discussed here:http://www.abovetopsecret.com/forum/thread1148223/pg1

thingiverse

free

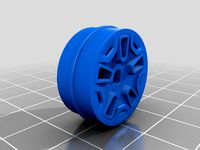

Wheel Jeeper XMOD by pauljs75

...this kind of stuff and would like to see more, don't forget to help out with a few bucks at: www.patreon.com/pauljs75

thanks!

thingiverse

free

Dual Stage Centrifugal Pump by pauljs75

...dual stage centrifugal pump by pauljs75

thingiverse

centrifugal pump with dual stages.

thingiverse

free

Cylindrical Diffuser by pauljs75

...erse

another seemingly random flow diffuser part thingamabober. or perhaps it's that one bit from an angry and ornery dalek?

thingiverse

free

Hex Measure Thingy by pauljs75

...hex measure thingy by pauljs75

thingiverse

thing made to measure hex nut diameters with both metric and imperial sizes.

thingiverse

free

Another Oddball Thingamabober by pauljs75

...ll thingamabober by pauljs75

thingiverse

just another oddball shaped object. might have some use or might not, but there you go.

thingiverse

free

Star Spray Attachment by pauljs75

...nt by pauljs75

thingiverse

star shaped hose end attachment. probably more entertaining if put on a lightweight collapsible hose.

thingiverse

free

A Wedge Clamper by pauljs75

..., and the wedging action should tighten it down. i may make another variant later on for anchoring to a surface with some screws.

Pjs

turbosquid

$12

PJ-Pendant

... free 3d model pj-pendant for download as , fbx, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1662577)

3ddd

$1

Потолочный светильник Örsjö Belysning

...jo belysning

pj52

потолочный светильник

производитель örsjö belysning дизайн ann morsing , beban nord коллекция pj

örsjö / швеция

3d_export

$45

DRDO BrahMos LLCM Missile 3D Model

...ry ss-n-26 oniks cruise weapon brahmos supersonic pj-10 3m55 onkis

drdo brahmos llcm missile 3d model visualmotion 47029 3dexport

3ddd

$1

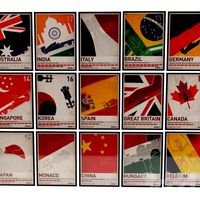

Графические постеры Formula-1 2011

...тему мира автогонок и визуальных кодов формулы-1, которые воплощены в цветах флагов различных стран, участвующих в соревнованиях.

3d_export

$15

brahmos cruise missile

...eight, rough, and metal.<br>please note; this may, or may not 3d print. not tested.<br>https://stgbooks.blogspot.com/

thingiverse

free

Accessori PJ masks by samuele79j

...accessori pj masks by samuele79j

thingiverse

accessori per pj masks

thingiverse

free

PJ Masks Stencils by IrisCalculator

...pj masks stencils by iriscalculator

thingiverse

pj masks character stencils: catboy, ghekko, and owelette.

3d_sky

free

pj wall lamp - orsjo

...iginally from the 1930s when it was used as industrial work lamp. pj had a bold and lively makeover and became an office classic.

3dfindit

free

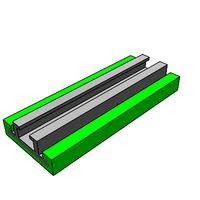

RXL-PJ-HL

...rxl-pj-hl

3dfind.it

catalog: wuxing

thingiverse

free

PJ Masks HQ

...e on our way!into the night to save the day!

far from perfect, this (little) hq is good enough for my boy, so good enough for me.

Centrifugal

turbosquid

$209

Carpet centrifuge

...royalty free 3d model carpet centrifuge for download as sldas on turbosquid: 3d models for games, architecture, videos. (1445260)

turbosquid

$32

Centrifugal Pump

... free 3d model centrifugal pump for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1643069)

3d_export

$12

Centrifugal Pump 3D Model

...centrifugal pump 3d model

3dexport

centrifugal pump

centrifugal pump 3d model fau 71172 3dexport

3d_export

$7

zy series centrifugal blower

...zy series centrifugal blower

3dexport

zy series centrifugal blower

3d_export

$20

Centrifugal pump 3D Model

... 3d model

3dexport

pump centrifugal turbomachinery turbo water machines industry

centrifugal pump 3d model qepasol 93421 3dexport

archive3d

free

Centrifuge 3D Model

...d

centrifuge spin dryer

dlc-213 n281107 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

Centrifuge Laboratory 3D Model

...oratory centrifuge

centrifuge laboratory 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl 3d1startup 105313 3dexport

3d_export

$7

centrifugal compressor

...ded, and also, step file and .stl files are also given so that anyone can operate this 3d model in any other designing softwares.

turbosquid

$120

Centrifugal Space Station

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

centrifugal fan 4-72-12 b4-72-12 no6 d c centrifugal fan

...centrifugal fan 4-72-12 b4-72-12 no6 d c centrifugal fan

3dexport

[centrifugal fan] 4-72-12, b4-72-12, no6 d, c centrifugal fan

Pump

3d_export

$5

pump

...pump

3dexport

pump

archibase_planet

free

Pump

...pump

archibase planet

petrol pump petrol station gas station

pump - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$8

Pumps

...ps

3docean

girls heels high kicks pumps shoes stilettos womens

womens high heels, pumps or stilettos. polygon model – no textures

3ddd

free

Pump

...ump

3ddd

pump , versus

производитель: versus

модель: pumphttp://www.versus.as/

turbosquid

$3

Pumps

...s

turbosquid

royalty free 3d model pumps for download as skp on turbosquid: 3d models for games, architecture, videos. (1275250)

3d_export

$5

pump

...pump

3dexport

turbosquid

$39

Realistic Water pump SYLLENT PUMP

...realistic water pump syllent pump for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1312864)

turbosquid

$150

Pumpe

...yalty free 3d model pumpe for download as ige, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1284318)

3d_export

$10

gear pump

...gear pump

3dexport

it is a gear pump in iges format

turbosquid

$19

Old Water Pumps Gas Pumps

...pumps gas pumps for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1207997)