Thingiverse

Parametric Jaw Coupling with optional spider by dgm3333

by Thingiverse

Last crawled date: 4 years, 4 months ago

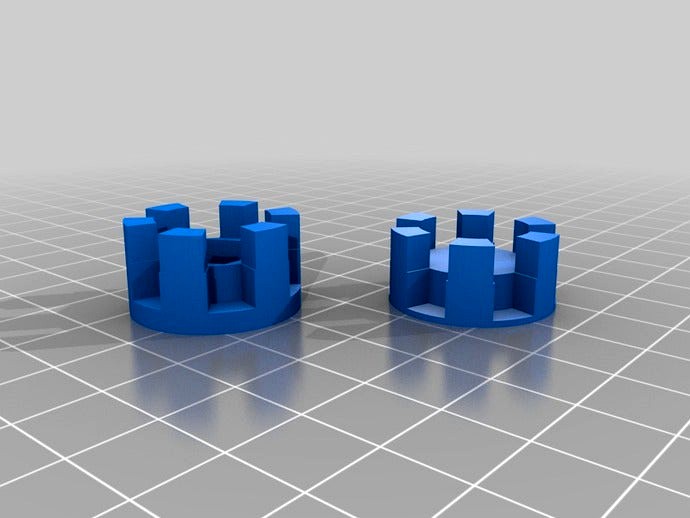

This is a remix of modilion and zignig's jaw coupling as I wanted one without a spider and a hub for attaching to shafts with variable attachment options on either hub.

Any number of struts (=legs=teeth) can be selected rather than the 2 per hub of the parent designs.

If the coupling is created without a spider then the each hub is cut out so they mesh tightly.

The current four options for attaching the couplings are:-

1) A captured nut and bolt perpendicular to the attachment shaft (eg for a motor shaft)

2) An inline captured nut into which can be screwed the main shaft (eg a threaded rod). (I'll probably drill and pin them together, but you could also use a self-locking nut, or possibly glue them.

3) A perpendicular hole through the entire hub to allow a bolt to be passed through (good for tubes which would be crushed by 1.

4) A slit though the base to allow it to clamp directly onto the shaft.

You can print the spider, but I'd probably make one out of Sugru/oogoo(http://www.instructables.com/id/How-To-Make-Your-Own-Sugru-Substitute/) as a rubbery compound will have better shock absorption properties. Hot glue has also been suggested which might be OK for use at room temperature. If you print the mold you can easily use it to make multiple spiders of any compound you like.

Any number of struts (=legs=teeth) can be selected rather than the 2 per hub of the parent designs.

If the coupling is created without a spider then the each hub is cut out so they mesh tightly.

The current four options for attaching the couplings are:-

1) A captured nut and bolt perpendicular to the attachment shaft (eg for a motor shaft)

2) An inline captured nut into which can be screwed the main shaft (eg a threaded rod). (I'll probably drill and pin them together, but you could also use a self-locking nut, or possibly glue them.

3) A perpendicular hole through the entire hub to allow a bolt to be passed through (good for tubes which would be crushed by 1.

4) A slit though the base to allow it to clamp directly onto the shaft.

You can print the spider, but I'd probably make one out of Sugru/oogoo(http://www.instructables.com/id/How-To-Make-Your-Own-Sugru-Substitute/) as a rubbery compound will have better shock absorption properties. Hot glue has also been suggested which might be OK for use at room temperature. If you print the mold you can easily use it to make multiple spiders of any compound you like.