Thingiverse

Paracord Weaver Arms by largo8

by Thingiverse

Last crawled date: 3 years, 1 month ago

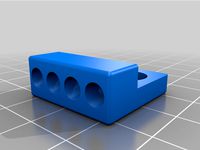

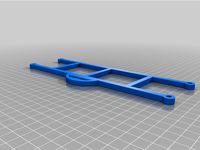

My son got into making paracord bracelets so we bought a wooden jig but it wouldn't make anything over approximately 14 inches. So I thought surely someone out there has created one to put in Thingiverse but I couldn't find a paracord weaver thing that I liked. So I designed one. The thing attached is the final result of several design iterations.

The intent of this design is to be used in sets of two. This weaver is designed so a yardstick can be inserted through the slot in the base so you can make a rough measurement for the desired bracelet size. The feet include flat little wings so you can clamp it to your work surface.

To complete the build you need the following items (I got them from Lowes Hardware):

1 yardstick (typically in paint department)

4 8x32 1" sheet metal screws (2 per each arm/leg)

2 8x32 nuts (2 per each arm)

2 additional 8x32 nuts or 8x32 wing nuts (1 per each arm)

2 1/4 inch plastic cable clamps (in electrical department - Gardner Bender is brand they carry)

1 set of paracord bracelet buckle (sized based on what you're making)

The yardstick goes in the long rectangular slot, place a screw through the hole perpendicular to the slot, place a (wing) nut on the opposite side. Tightening the screw squeezes the yardstick allowing the arm to stay in place. On mine I put super glue around the surface the of the hole the screw goes in to fix the screw in place - you could optionally glue the nut to the opposite side. Place an 8-32 nut in the small slot near the top of the arm. Slide the end of one plastic wire clamps through one of the ends of the desired paracord buckle. Put another 8-32 screw through the plastic wire clamp and insert the screw through the top of the arm and thread it through the nut you inserted previously into the arm.

When I printed one of the early designs, Cura defaulted to putting in supports which filled the the holes for the 8-32 screws. I highly recommend not including supports in your print settings - I think I broke the print trying to clean out the holes.

The SolidWorks model is provided as well as a single arm and double arm STL files.

Enjoy and support local scouting!

The intent of this design is to be used in sets of two. This weaver is designed so a yardstick can be inserted through the slot in the base so you can make a rough measurement for the desired bracelet size. The feet include flat little wings so you can clamp it to your work surface.

To complete the build you need the following items (I got them from Lowes Hardware):

1 yardstick (typically in paint department)

4 8x32 1" sheet metal screws (2 per each arm/leg)

2 8x32 nuts (2 per each arm)

2 additional 8x32 nuts or 8x32 wing nuts (1 per each arm)

2 1/4 inch plastic cable clamps (in electrical department - Gardner Bender is brand they carry)

1 set of paracord bracelet buckle (sized based on what you're making)

The yardstick goes in the long rectangular slot, place a screw through the hole perpendicular to the slot, place a (wing) nut on the opposite side. Tightening the screw squeezes the yardstick allowing the arm to stay in place. On mine I put super glue around the surface the of the hole the screw goes in to fix the screw in place - you could optionally glue the nut to the opposite side. Place an 8-32 nut in the small slot near the top of the arm. Slide the end of one plastic wire clamps through one of the ends of the desired paracord buckle. Put another 8-32 screw through the plastic wire clamp and insert the screw through the top of the arm and thread it through the nut you inserted previously into the arm.

When I printed one of the early designs, Cura defaulted to putting in supports which filled the the holes for the 8-32 screws. I highly recommend not including supports in your print settings - I think I broke the print trying to clean out the holes.

The SolidWorks model is provided as well as a single arm and double arm STL files.

Enjoy and support local scouting!

Similar models

thingiverse

free

Clamping system for MPCNC or similar by pavel569

...n reaching 7mm i pause and insert steel nut and continue printing.

nut 2 has hole through for inserting steel nut after printing.

thingiverse

free

Virtual Boy - TriPod Adapter and Quick Release Adapter by the16bitgamer

... screws into the bottom of the adapter, and screw in the mount of your choice. hammer in 10-32 nuts before for a more secure fit.

thingiverse

free

CNC Basic Table Clamps, Fix for Objects by MicMak

...dapter to connect arm with ramp.

additional i used a washer and 2 nuts per clamp.

this works fine for me also for bumpy surfaces.

thingiverse

free

Magnetic Paracord Buckle

...ml

i used hot glue to hold the magnets in the holes.

openscad files included, logo included may be removed in openscad if needed.

thingiverse

free

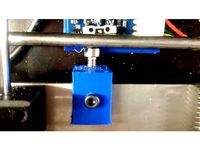

CTC adjustable Z-Endstop by Nanafalke

...crew and a nut. place the nut into the slot and drill a hole through your plattform wall. then clamp the thing in with the screw.

thingiverse

free

1/2 - 13 Nut Inserts Thread with slot for screwdriver by paultyrer

...crewdriver by paultyrer

thingiverse

these inserts screw into a 1/2-13 nut using the screw driver slot.

great for fidget spinners

thingiverse

free

Dremel Tool Holder for model 380 by MontanaMonk

...e added screw holes in the base so you can screw it to a larger block or screw on a small keel block to allow clamping in a vise.

grabcad

free

Clamp assembly

... m3x16 bolts through the flat side of side plate a. place the mounting plate over the four bolts and put a hex nut in the t-slot.

thingiverse

free

Euro Cylinder Cutaway Holder by zbzzn

...ll the places are cut.

you can clamp the holder in a vice where the thin area is. it will hold it in place while you are cutting.

grabcad

free

Small Fixture Clamp

...1/4" screw clearance slot. put a screw through the tapped hole and use it as a jack to get your clamp to the desired height.

Largo8

thingiverse

free

Dial Indicator Mount for Monoprice 13860 / Wanahao i3 by largo8

...y! please let me know if you would like to have the file in a different format and i will do my best to post the desired format.

thingiverse

free

LED String Mount for Monoprice 13860 / Wanahao i3 by largo8

...zon-lighting-theater-backlighting-increase/dp/b01gjfdn30/ref=sr_1_1?ie=utf8&qid=1494102115&sr=8-1&keywords=b01gjfdn30

thingiverse

free

Modular Bar and Snap Covid Mask Ear Saver by largo8

...ions - flowers, devil horns, lights... who knows.

if you're getting out there, be safe!

and support your local... whatever.

Weaver

3ddd

$1

Oriental Weavers rugs1

...ва ( 1200х1700px, 700х1000px)

collection rugs oriental weavers. the archive 100 texture of good quality (1200х1700px, 700х1000px)

3ddd

$1

Oriental Weavers rugs2

...тва ( 1200х1700px, 700х1000px) collection rugs oriental weavers. the archive 90 texture of good quality (1200х1700px, 700х1000px)

3ddd

$1

Oriental Weavers rugs3

...ва ( 1200х1700px, 700х1000px) collection rugs oriental weavers. the archive 130 texture of good quality (1200х1700px, 700х1000px)

3d_export

$39

Dota 2-Weaver 3D Model

... 2-weaver 3d model

3dexport

dota dota2 monster character insect unusual cockroach

dota 2-weaver 3d model worldit69 97792 3dexport

turbosquid

$9

Oriental Weavers Sphinx Montego Rug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Hakko BED-5 MR-02 Weaver

... free 3d model hakko bed-5 mr-02 weaver for download as blend on turbosquid: 3d models for games, architecture, videos. (1565400)

3d_export

$40

orb weaver spider

... on a 1024 single atlas.<br>preview images rendered in real-time renderer.<br>collada, fbx, and obj formats included.

3d_export

$52

sigourney weaver ellen ripley

... obj head photorealistic head textured huwoman people character face realistic woman head anatomy eye ear photorealistic textured

3ddd

$1

карниз с декором

...карниз с декором 3ddd jp weaver , карниз карниз. производитель jp weavere модель plas 1015....

3ddd

free

декоративная решетка

...weavere , решетка декоративная решетка на потолок. производитель jp weaver модель rmf. 3dsmax 2009+v-ray 1.5...

Paracord

3d_export

$5

knife paracord

...knife paracord

3dexport

ninjas knife paracord

turbosquid

$12

paracord mandala

...racord mandala for download as obj, stl, x, 3ds, dae, and fbx on turbosquid: 3d models for games, architecture, videos. (1667042)

thingiverse

free

Paracord holder by bbrown1951

...paracord holder by bbrown1951

thingiverse

this is a paracord holder. this holder should hold at least 25' of paracord.

thingiverse

free

paracord stone by Spawnabe

...paracord stone by spawnabe

thingiverse

for make paracord

thingiverse

free

Paracord Jig by Philhawtin

...paracord jig by philhawtin

thingiverse

paracord jig

monkey fist

thingiverse

free

Paracord Beads by sLpFhaWK

...paracord beads by slpfhawk

thingiverse

couple easy to print paracord beads

thingiverse

free

Paracord Fid by jolly_wrencher

..._wrencher

thingiverse

i created this for paracord weavers that don't have the time to go out and buy an actual paracord fid.

thingiverse

free

Paracord Spool Ladder by raar

...paracord spool ladder by raar

thingiverse

a simple ladder spool for paracord. use it for paracord 550 up to 100ft

thingiverse

free

Paracord Spool by drewdavid

...sten the ends i did an overhand knot through one of the holes and wrapped. designed for paracord 550, but works for similar rope.

thingiverse

free

Paracord Spool by gx206

...paracord spool by gx206

thingiverse

paracord spool size 84x100x4 mm

workshop-3d.rubuy me a coffee

Arms

archibase_planet

free

Arm

...ase planet

arm hand right hand skeleton

arm human skeleton right arm n030515 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3ddd

$1

arm chair

...arm chair

3ddd

arm chair , пуф

arm chair

turbosquid

$5

arm

...arm

turbosquid

royalty free 3d model arm for download as obj on turbosquid: 3d models for games, architecture, videos. (1306158)

turbosquid

free

Arm

...arm

turbosquid

free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1346955)

turbosquid

$29

Arm

...osquid

royalty free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1382436)

3d_export

$5

coat of arms

...coat of arms

3dexport

coat of arms

3ddd

$1

ARM SOFA

...arm sofa

3ddd

arm sofa

3ddd

$1

Arm chair

...arm chair

3ddd

arm chair

3ddd

$1

Arm chair

...arm chair

3ddd

угловое

arm chair

3ddd

$1

ARM CHAIR

...arm chair

3ddd

arm chair clothes