3dExport

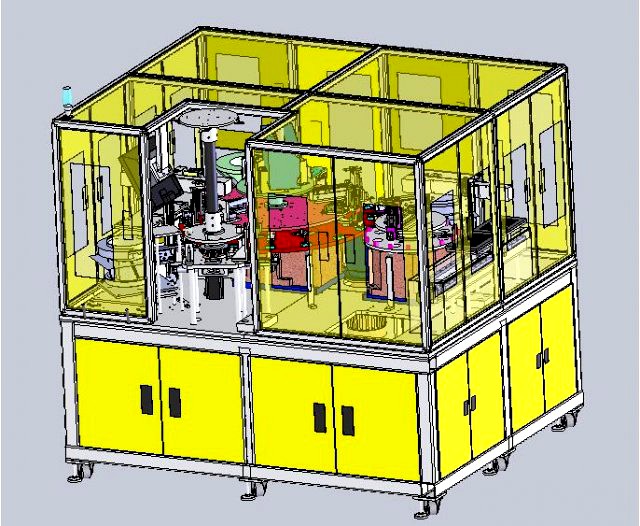

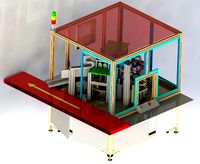

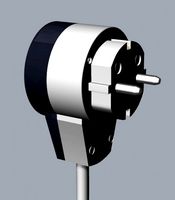

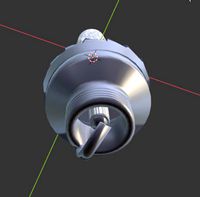

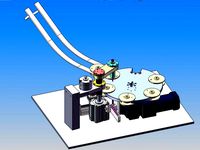

optical fiber head assembly machine network signal plug assembly equipment

by 3dExport

Last crawled date: 1 year, 10 months ago

optical fiber head assembly machine, network signal plug assembly equipment

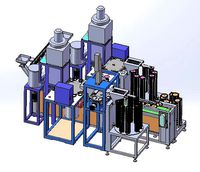

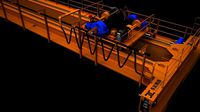

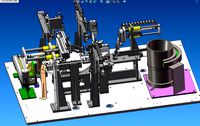

non standard assembly equipment for network signal plug of optical fiber head assembly machine 1. equipment description the products applicable to this equipment are: the assembly of optical fiber head, signal plug, communication connector and all kinds of optical fiber connector. the equipment is a new automatic assembly machine for optical fiber head: it is mainly used for the assembly of optical fiber network port communication and signal to interface products. the equipment is rotary operation. the feeding position is divided into three vibration discs and a material tray for feeding, that is, four optical fiber head parts are assembled together. the assembled product is the common optical fiber head, and the assembly parts are: optical fiber shell, the optical fiber plastic parts, optical fiber metal parts and optical fiber core are also the most central needle fiber head. the equipment uses a large turntable and two small turntables to complete the assembly and feeding. the largest rotary table in the middle is designed as a 16 position divider. the small turntable also has 16 working positions. the manipulator takes the optical fiber core from the feeding plate and places it in the center of the turntable for assembly in the optical fiber rubber parts, the overall operation principle of the equipment is: the feeding manipulator fetches the material into the small turntable, when the turntable rotates to the docking station with the large turntable, the cylinder in the large turntable clamps the product into the optical fiber head of the large turntable, and when the large turntable rotates to the next station, the stepper motor drives the small turntable to load the plastic parts, and the other vibration disk is the fiber shell feeding vibration disk when the optical fiber head of the finished product is rotated to the unloading position, the manipulator will pick up the finished products and put them into the receiving tray one by one. when the receiving tray is full, the equipment will give an alarm and prompt for manual material collection. the above fully automatic working principle of the equipment is as follows. 2、 the main assembly parts of the equipment are as follows: 1. fiber core feeding: the product is placed in the plastic box, and the feeding manipulator takes the product from the plastic box and puts it into the rotating disc, which can minimize the refueling time, and has the function of material shortage alarm. 2. fiber optic plastic parts feeding: the plastic parts are automatically fed by vibrating disc and direct vibrating feeder, and have the function of shortage alarm. 3. optical fiber metal parts feeding: the metal parts are automatically fed by the vibration disk and the direct vibration feeder, and have the function of shortage alarm. 4. feeding of optical fiber shell: the optical fiber shell is also provided with vibration disk and direct vibrator to realize automatic feeding, and has the function of shortage alarm. 5. splitter turntable: 16 station rotating disc. the large turntable is divided into three layers. the bottom layer is used for rotating disc and fixed fixture. the middle layer is fixed by the clamping mechanism of each cylinder, and the top layer is used to install junction box, gas pipe, etc 6. loading and discharging manipulator: draw products from the index plate, and automatically switch materials according to the attributes indicated by the software, and set the functions of the loading and unloading manipulator. the above is the function and principle of this device, and there are many more details. here we will not introduce more details. we can download and study other smart design structures directly. after downloading, we can have time to slowly study and study. this is a very good set of drawings for automatic assembly equipment of optical fiber head. we are welcome to study and study. thank you. three main technical parameters: category specification parameter overall dimension: 2100 * 1700 * 2000mm (l * w * h) input voltage: ac-220v50 hz or ac-380v, 50 hz optional maximum power of the whole machine: 2.2k w (when 220 v) input gas pressure: 0.4-0.6 mpa gas consumption: 1.5 l / min production efficiency (c / t): ≤ 4.0 s / one equipment utilization rate: ≥ 95% processing method: automatic picking, feeding, automatic assembly, automatic receiving manipulator motion resolution: 0.005 mm manipulator repetitive positioning accuracy: ≤± 0.02 mm control communication mode: manual disc programming mode: touch screen parameter modification

non standard assembly equipment for network signal plug of optical fiber head assembly machine 1. equipment description the products applicable to this equipment are: the assembly of optical fiber head, signal plug, communication connector and all kinds of optical fiber connector. the equipment is a new automatic assembly machine for optical fiber head: it is mainly used for the assembly of optical fiber network port communication and signal to interface products. the equipment is rotary operation. the feeding position is divided into three vibration discs and a material tray for feeding, that is, four optical fiber head parts are assembled together. the assembled product is the common optical fiber head, and the assembly parts are: optical fiber shell, the optical fiber plastic parts, optical fiber metal parts and optical fiber core are also the most central needle fiber head. the equipment uses a large turntable and two small turntables to complete the assembly and feeding. the largest rotary table in the middle is designed as a 16 position divider. the small turntable also has 16 working positions. the manipulator takes the optical fiber core from the feeding plate and places it in the center of the turntable for assembly in the optical fiber rubber parts, the overall operation principle of the equipment is: the feeding manipulator fetches the material into the small turntable, when the turntable rotates to the docking station with the large turntable, the cylinder in the large turntable clamps the product into the optical fiber head of the large turntable, and when the large turntable rotates to the next station, the stepper motor drives the small turntable to load the plastic parts, and the other vibration disk is the fiber shell feeding vibration disk when the optical fiber head of the finished product is rotated to the unloading position, the manipulator will pick up the finished products and put them into the receiving tray one by one. when the receiving tray is full, the equipment will give an alarm and prompt for manual material collection. the above fully automatic working principle of the equipment is as follows. 2、 the main assembly parts of the equipment are as follows: 1. fiber core feeding: the product is placed in the plastic box, and the feeding manipulator takes the product from the plastic box and puts it into the rotating disc, which can minimize the refueling time, and has the function of material shortage alarm. 2. fiber optic plastic parts feeding: the plastic parts are automatically fed by vibrating disc and direct vibrating feeder, and have the function of shortage alarm. 3. optical fiber metal parts feeding: the metal parts are automatically fed by the vibration disk and the direct vibration feeder, and have the function of shortage alarm. 4. feeding of optical fiber shell: the optical fiber shell is also provided with vibration disk and direct vibrator to realize automatic feeding, and has the function of shortage alarm. 5. splitter turntable: 16 station rotating disc. the large turntable is divided into three layers. the bottom layer is used for rotating disc and fixed fixture. the middle layer is fixed by the clamping mechanism of each cylinder, and the top layer is used to install junction box, gas pipe, etc 6. loading and discharging manipulator: draw products from the index plate, and automatically switch materials according to the attributes indicated by the software, and set the functions of the loading and unloading manipulator. the above is the function and principle of this device, and there are many more details. here we will not introduce more details. we can download and study other smart design structures directly. after downloading, we can have time to slowly study and study. this is a very good set of drawings for automatic assembly equipment of optical fiber head. we are welcome to study and study. thank you. three main technical parameters: category specification parameter overall dimension: 2100 * 1700 * 2000mm (l * w * h) input voltage: ac-220v50 hz or ac-380v, 50 hz optional maximum power of the whole machine: 2.2k w (when 220 v) input gas pressure: 0.4-0.6 mpa gas consumption: 1.5 l / min production efficiency (c / t): ≤ 4.0 s / one equipment utilization rate: ≥ 95% processing method: automatic picking, feeding, automatic assembly, automatic receiving manipulator motion resolution: 0.005 mm manipulator repetitive positioning accuracy: ≤± 0.02 mm control communication mode: manual disc programming mode: touch screen parameter modification

Similar models

cg_trader

$19

Electric toothbrush automatic assembly machine

...rial manufacture assembly mechanic components electrical plc toothbrush electric feeding industrial machine electrical components

cg_trader

$29

Fully automatic bulb assembly production line

...ture assembly mechanic components electrical bulb test feed dispensing load unload rivet industrial machine electrical components

3d_export

$25

automobile valve assembly machine

...of course, it can also be used to make similar products. it can be transformed into another different device...

cg_trader

$9

A vibrating disc feeding mechanism

...eding mechanism position machine industry manufacture production assembly factory automatic industrial machine industrial factory

cg_trader

$6

Rotating vibration loading mechanism

...ustrial machine industry equipment manufacture production assembly factory automatic engine industrial machine industrial factory

cg_trader

$5

Printer accessories bearing automatic assembly machine

... industry industrial manufacture assembly mechanic components electrical printer bearing industrial machine electrical components

3d_export

$27

automatic assembly equipment for motor parts

...f this set of drawings is very complex and has great learning value. i hope you will download it. don't miss the opportunity.

cg_trader

$180

Optical fiber laser marking machines Assembly

...e tool part device laser masking fiber optical galvanometer polarizer label industrial machine industrial part industrial factory

cg_trader

$29

Motor automatic assembly production line

...eyor belt, and the clamping manipulator will perform the clamping and assembly. after completion, the fixture will work in a loop

3d_export

$5

automatic brazing process assembly equipment for heating disk

...ne body contains detailed information the drawings of the parts and components can be edited, and the general format is included.

Network

3ddd

$1

Network table by Henge

...network table by henge

3ddd

henge

network table by henge

3d_export

$35

network office design

...network office design

3dexport

network office 3d model design

turbosquid

$120

Global Network

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Road Network

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

social Network

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Network 149 chair

...network 149 chair

designconnected

roda network 149 chair computer generated 3d model. designed by dordoni, rodolfo.

design_connected

$16

Network 159 armchair

...twork 159 armchair

designconnected

roda network 159 armchair armchairs computer generated 3d model. designed by rodolfo dordoni.

3d_ocean

$15

Wireless Broadband Network Router

... computer networking. similar to popular styles of wireless routers. this model was created in 3d studio max 2008 and has a ma...

3d_export

$30

Road Network 3D Model

...

3dexport

roads network highway

road network 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl msaeed 103734 3dexport

turbosquid

$3

DOUBLE NETWORK PLUG

...d model double network plug for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370379)

Fiber

turbosquid

$29

fiber-cement

...squid

royalty free 3d model fiber-cement for download as obj on turbosquid: 3d models for games, architecture, videos. (1391259)

turbosquid

$59

Muscle Fiber

...royalty free 3d model muscle fiber for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1261019)

turbosquid

free

Fiber optics

...d model fiber optics for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1211912)

turbosquid

$10

fiber Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$2

Fiber Textures

...extures. tileable and editable. 512×512 pixel sized. jpg , tga image format given. unlimited color possibilities. stay connected

design_connected

$13

Fiber Wood Rug

...fiber wood rug

designconnected

ligne roset fiber wood rug computer generated 3d model. designed by ligne roset.

turbosquid

$7

Fiber Lounge Chair

...

royalty free 3d model fiber lounge chair for download as max on turbosquid: 3d models for games, architecture, videos. (1658264)

3d_export

$20

fiber optics 3D Model

...l

3dexport

light object lamp home decorative bright table element fiber optics furniture

fiber optics 3d model braz 5913 3dexport

turbosquid

$15

Solar Fibers Solarway

...l solar fibers solarway for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559873)

3d_export

$5

Carbon fiber seamless 3D Model

...carbon fiber seamless 3d model

3dexport

carbon fiber seamless texture

carbon fiber seamless 3d model gryxitl 79178 3dexport

Optical

design_connected

$9

Optic

...optic

designconnected

alessi optic computer generated 3d model. designed by colombo, joe.

3ddd

$1

обои OPTIC

...обои optic

3ddd

в архиве текстуры и фото обоев из коллекции optic.

archive3d

free

Optics 3D Model

...optics 3d model

archive3d

optics

optics - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$49

optical eyewear

...id

royalty free 3d model optical eyewear for download as max on turbosquid: 3d models for games, architecture, videos. (1592243)

3d_ocean

$5

optical mouses

...al mouses

3docean

3d models computer electronics mouse

optical mouses 3d models. realistic mouse model. custom and unique design.

turbosquid

$10

Optic cross

...yalty free 3d model optic cross for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1683403)

turbosquid

$7

OPTIC Mirror

... free 3d model optic mirror for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1223927)

turbosquid

free

Fiber optics

...d model fiber optics for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1211912)

turbosquid

$8

Mouse optical

...3d model mouse optical for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1504476)

turbosquid

free

Optical puzzle

... optical puzzle for download as max, ige, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1405925)

Signal

archibase_planet

free

Signals

...signals

archibase planet

lift equipment elevator signals

elevator signals - 3d model for interior 3d visualization.

archibase_planet

free

Signal

...e planet

fire-extinguishing equipment fire-alarm fire signal

fire signal - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$3

Signal

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Signal H-134

...signal h-134

3ddd

signal

стул signal h-134

3ddd

free

SIGNAL обеденная группа

...signal обеденная группа

3ddd

signal

обеденная группа signal loreto

3ddd

free

Signal q-088

...signal q-088

3ddd

signal , стул

кресло signal q-088

3ddd

$1

LN-SC Signal

...ln-sc signal

3ddd

стул , signal

стул ln-sc signal, польша

archive3d

free

Signals 3D Model

...ve3d

lift equipment elevator signals

elevator signals - 3d model for interior 3d visualization.

3d_export

$15

Signal Tower

...signal tower

3dexport

3ddd

$1

Berlin Signal

...al (польша)

высота: 105 см

размеры матраса: 200х160 см

материал: дерево (гевея), металл

цвет: дерево - белый, металл – чёрный

Plug

3d_export

$5

plug

...plug

3dexport

3d_export

$5

plug cover

...plug cover

3dexport

plug cover

3d_export

$5

spark plug

...spark plug

3dexport

spark plug

3d_export

free

spark plug

...spark plug

3dexport

spark plug

turbosquid

$30

plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Equipment

archibase_planet

free

Equipment

...quipment

archibase planet

technics equipment technique

equipment n110708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

MEDICAL EQUIPMENT, Equipement Medical

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

exercise equipment

...exercise equipment

3dexport

exercise equipment

3d_export

$10

Pool equipment

...pool equipment

3dexport

pool equipment landshaft

3d_export

$65

equipment

...equipment

3dexport

simple rendering of the scene file

3d_export

$30

equipment

...equipment

3dexport

simple rendering of the scene file

3ddd

$1

Refrigeration Equipment

...refrigeration equipment

3ddd

холодильное оборудование.

refrigeration equipment

3ddd

free

Office equipment

...office equipment

3ddd

проектор , принтер

a set of office equipment.

3ddd

$1

плитка Equipe

... плитка , керамогранит

equipe серия curvytile 26,5 x 26,5 см

(есть версия 2011 max)

3d_export

$19

shop equipment

...shop equipment

3dexport

shop equipment 3d model. include obj, max, fbx files.

Assembly

3d_export

$7

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

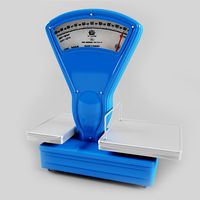

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Head

3d_export

$5

head

...head

3dexport

simulated female head.

3d_ocean

$5

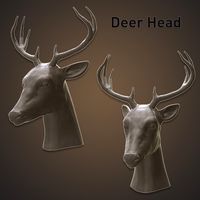

Deer Head

...deer head

3docean

deer head

simple model of deer head with neck.

cg_studio

$25

Marble Head - Head A3d model

... - head a3d model

cgstudio

.ma - marble head - head a 3d model, royalty free license available, instant download after purchase.

turbosquid

$5

Head

...ad

turbosquid

royalty free 3d model head for download as max on turbosquid: 3d models for games, architecture, videos. (1230068)

turbosquid

free

The Head

...urbosquid

royalty free 3d model the head for download as max on turbosquid: 3d models for games, architecture, videos. (1386205)

turbosquid

free

Head

...

turbosquid

royalty free 3d model head for download as blend on turbosquid: 3d models for games, architecture, videos. (1276899)

3d_export

$10

bull head

...bull head

3dexport

bull head

3d_export

$5

girl head

...girl head

3dexport

head girl

3d_export

$5

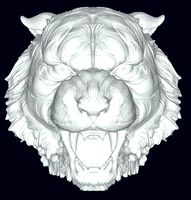

Tigger-head

...tigger-head

3dexport

tigger-head

3d_export

$5

head on a spear

...head on a spear

3dexport

head on a spear