Thingiverse

OpenLock 2.0 Spiral Stair Infinite Tread by Start2

by Thingiverse

Last crawled date: 3 years ago

A spiral stair tread, 30deg/8.4mm tall and 38.1R (3in dia/1.75R)

Wanted to set up a spiral stair that could hold figures. Use as many as you need to get as high as required.

Kudos to Printablesceneryhttp://www.printablescenery.com/product-category/rampage-system/

Rampagehttp://www.thingiverse.com/thing:1821631

OpenLock 4.0http://www.thingiverse.com/thing:1833963

DevonJoneshttp://www.thingiverse.com/thing:2034428

Cobble Pattern by Siennahttp://www.thingiverse.com/thing:1921325

Using Devon Jones Curved wall "cut_stone.wall.TA.1.5rx0.5.curved.openlock" which is a wall made to fit the H floor tile (a 2" inside radius) and the .5inch wall has a 2" outside radius. Created the stair to fit within this open 3in diameter (1.5 in radius).

You would need to use OL2 HE to finish a 8"dia tower floor or 9"dia. with walls.

Here: http://www.thingiverse.com/thing:2055430

Design: Started with 38.1 dia tread and peg was to be made to fit the "hole". As I made the initial set of treads, I had to print upside down as to not use supports. After printing, realized I could use filament as the peg through the treads. They individually would spin around and I had to glue together to make the picture.

2nd Gen tread had pattern, and I still printed upside down, but used 3.3 hole. Was tight for a 3mm filament as the filament expanded when I used a heat gun with the filament in the "V" of a metal shelving unit leg. Still had to glue. I have changed the tread to have a "key" to set the 60 degree tread to have a 30 degree overlap. Also set the attachment to the round middle support to the outside dia.for greater strength as I broke a few on the bed at that point. (Use the tread end to remove from the bed, not the peg end) Still had to print upside down.

3rd Gen tread had pattern, and supports to allow printing right side up. Still using 3.3 dia hole as the dia is a snug fit for the filament. If you use 1.75dia filament, you can print a 3mm peg, or resize the hole. Also a nail, wood dowel, or other metal support will suffice.

This method used filament for no real good reason.

4th gen had tread pegs and side risers separate and to glue together. Added tabs to locate side risers and treads properly to each other as you build up the stair. Very fiddly, thus rejected.

5th gen. Finally a good all round solution. Set tread to print peg and side risers UP. This allowed one piece treads again, with good fidelity on the stair pattern. No side riser and a spacer peg needed on first tread may not have the best stability for many very heavy figures, but works quite nicely. Top tread needed to have no peg or riser to fit under second floor. Detail obtained was worth it. Tabs in treads space the 60deg treads to 30deg each step which allows a 1" base to fit well on each tread. If you make a very high staircase, the original tread may provide the most stability, (or scale a plain tread with peg and side riser to 5.4mm in z and use that as the base peg and side riser support you may need to stabilize the staircase.)

Spiral Stair Base

Provided all bases plain for your own pattern.Spiral Stair F is round 4" dia (=4x OpenLock "F" tiles clipped together) and Spiral Stair "round" is 3in dia to fit within the Devon Jones walls. As the treads are spaced at 8.4 high, they should (at 5 treads) fit just under the 2nd floor if the floor is set at 50.8mm resting upon the walls. To go higher, just add additional treads. I believe you will have to glue the treads to make it work, although you could always use painters tape on the outside edge to keep the treads together.

"Base" is just a bottom of the stair with a hole for the treads support peg.

"Down" has a clip to allow a fill piece to be added to make it a ground floor "Base", or left out to allow you to go "down".

01/23/17 Updated bases to correct clip size. Added BASE FROUND and DOWN FROUND which is a 3" halfround married to 4" halfround (2xF Tiles)

01/23/17 Added 4x4 U tiles, both BASE and DOWN styles. Took out concept model as it was large and not needed with as built pictures available.

01/25/17 Corrected "math" and clarified notes.

01/27/17 Corrected Treads to match original design size. New treads have supports to print right side up, and tabs for spacing.

2/2/17 Re-thought, why have supports/tabs etc. Why print upside down? Now treads print right side up. Only issue...need to have a different top tread, and a spacer at the bottom. Spacer, 10 cobble treads, 3 tops + plain/top set (for both plain printing or to add your own pattern) and the same plain/top set with a tab with the correct spacing for 30deg treads as shown in the picture. Bottom of tread Tab hole may need cleaning. Spacer can be resized to the height you need to make up any difference you may have in your floor design. Plain top treads or add your own floor design, are now the same tread.

This should complete this design, but still may tweak for ease of use. Typical wall height is 50.8 and you will need spacer first, then 4 treads + 1 top tread to utilize. Tread heights are 8.4. If you use floor supports, add an additional tread in the 180deg stair, by cutting off the tabs and rotate counter clockwise equally to add in the extra tread.

2/16/17 https://www.flickr.com/photos/nigel_brown/9708771924 Added photo example (by Nigel Brown) similar to the memory that was lingering in my head on the spiral stair design.

Wanted to set up a spiral stair that could hold figures. Use as many as you need to get as high as required.

Kudos to Printablesceneryhttp://www.printablescenery.com/product-category/rampage-system/

Rampagehttp://www.thingiverse.com/thing:1821631

OpenLock 4.0http://www.thingiverse.com/thing:1833963

DevonJoneshttp://www.thingiverse.com/thing:2034428

Cobble Pattern by Siennahttp://www.thingiverse.com/thing:1921325

Using Devon Jones Curved wall "cut_stone.wall.TA.1.5rx0.5.curved.openlock" which is a wall made to fit the H floor tile (a 2" inside radius) and the .5inch wall has a 2" outside radius. Created the stair to fit within this open 3in diameter (1.5 in radius).

You would need to use OL2 HE to finish a 8"dia tower floor or 9"dia. with walls.

Here: http://www.thingiverse.com/thing:2055430

Design: Started with 38.1 dia tread and peg was to be made to fit the "hole". As I made the initial set of treads, I had to print upside down as to not use supports. After printing, realized I could use filament as the peg through the treads. They individually would spin around and I had to glue together to make the picture.

2nd Gen tread had pattern, and I still printed upside down, but used 3.3 hole. Was tight for a 3mm filament as the filament expanded when I used a heat gun with the filament in the "V" of a metal shelving unit leg. Still had to glue. I have changed the tread to have a "key" to set the 60 degree tread to have a 30 degree overlap. Also set the attachment to the round middle support to the outside dia.for greater strength as I broke a few on the bed at that point. (Use the tread end to remove from the bed, not the peg end) Still had to print upside down.

3rd Gen tread had pattern, and supports to allow printing right side up. Still using 3.3 dia hole as the dia is a snug fit for the filament. If you use 1.75dia filament, you can print a 3mm peg, or resize the hole. Also a nail, wood dowel, or other metal support will suffice.

This method used filament for no real good reason.

4th gen had tread pegs and side risers separate and to glue together. Added tabs to locate side risers and treads properly to each other as you build up the stair. Very fiddly, thus rejected.

5th gen. Finally a good all round solution. Set tread to print peg and side risers UP. This allowed one piece treads again, with good fidelity on the stair pattern. No side riser and a spacer peg needed on first tread may not have the best stability for many very heavy figures, but works quite nicely. Top tread needed to have no peg or riser to fit under second floor. Detail obtained was worth it. Tabs in treads space the 60deg treads to 30deg each step which allows a 1" base to fit well on each tread. If you make a very high staircase, the original tread may provide the most stability, (or scale a plain tread with peg and side riser to 5.4mm in z and use that as the base peg and side riser support you may need to stabilize the staircase.)

Spiral Stair Base

Provided all bases plain for your own pattern.Spiral Stair F is round 4" dia (=4x OpenLock "F" tiles clipped together) and Spiral Stair "round" is 3in dia to fit within the Devon Jones walls. As the treads are spaced at 8.4 high, they should (at 5 treads) fit just under the 2nd floor if the floor is set at 50.8mm resting upon the walls. To go higher, just add additional treads. I believe you will have to glue the treads to make it work, although you could always use painters tape on the outside edge to keep the treads together.

"Base" is just a bottom of the stair with a hole for the treads support peg.

"Down" has a clip to allow a fill piece to be added to make it a ground floor "Base", or left out to allow you to go "down".

01/23/17 Updated bases to correct clip size. Added BASE FROUND and DOWN FROUND which is a 3" halfround married to 4" halfround (2xF Tiles)

01/23/17 Added 4x4 U tiles, both BASE and DOWN styles. Took out concept model as it was large and not needed with as built pictures available.

01/25/17 Corrected "math" and clarified notes.

01/27/17 Corrected Treads to match original design size. New treads have supports to print right side up, and tabs for spacing.

2/2/17 Re-thought, why have supports/tabs etc. Why print upside down? Now treads print right side up. Only issue...need to have a different top tread, and a spacer at the bottom. Spacer, 10 cobble treads, 3 tops + plain/top set (for both plain printing or to add your own pattern) and the same plain/top set with a tab with the correct spacing for 30deg treads as shown in the picture. Bottom of tread Tab hole may need cleaning. Spacer can be resized to the height you need to make up any difference you may have in your floor design. Plain top treads or add your own floor design, are now the same tread.

This should complete this design, but still may tweak for ease of use. Typical wall height is 50.8 and you will need spacer first, then 4 treads + 1 top tread to utilize. Tread heights are 8.4. If you use floor supports, add an additional tread in the 180deg stair, by cutting off the tabs and rotate counter clockwise equally to add in the extra tread.

2/16/17 https://www.flickr.com/photos/nigel_brown/9708771924 Added photo example (by Nigel Brown) similar to the memory that was lingering in my head on the spiral stair design.

Similar models

thingiverse

free

OpenForge 2.0 Wood Floor House Up & down Stone Stairwell by Start2

.../www.thingiverse.com/thing:1640999

special note of thanks to xloud - original spiral stairhttp://www.thingiverse.com/thing:995196

3dwarehouse

free

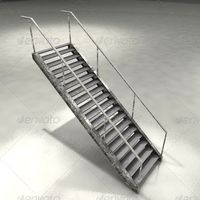

Staircase Treads

... your needs. this component has an oak tread, a concrete riser and steel side supports. #spteps #stair #staircase #stairs #treads

thingiverse

free

OpenForge 2.0 Mag Wood Floor House Stairwell Up Door Down by Start2

.../www.thingiverse.com/thing:1126259

special note of thanks to xloud - original spiral stairhttp://www.thingiverse.com/thing:995196

thingiverse

free

OpenForge 2.0 Mag Stone Floor House Stairwell Up Door Down by Start2

.../www.thingiverse.com/thing:1126259

special note of thanks to xloud - original spiral stairhttp://www.thingiverse.com/thing:995196

3dwarehouse

free

Jens3D Spiral Staircase

...rcase

3dwarehouse

simple spiral stair of metal components. modify one tread/riser and all will update! #spiral #stair #staircase

grabcad

free

Spiral Stair Case

...nnected to a center column. the treads rotate around this central point as you go up or down the stair, creating a spiral design.

3dwarehouse

free

Spiral stair

...ipe railings. begins with riser, does not end with riser. #einar #einsir #metal #pipe #risers #spiral_stairs #stair #stairs #wood

grabcad

free

Spiral Stairs

...spiral stairs

grabcad

use for going to up side or down side, from one floor to another level

grabcad

free

Spiral Staircase

...nnected to a center column. the treads rotate around this central point as you go up or down the stair, creating a spiral design.

grabcad

free

SHEETMETAL STAIR RISER, ANGLE BRACKET SUPPORT, CHEMGRATE TREAD

...this will be tied into my "shrimp line assy" latest rev...http://grabcad.com/library/2nd-floor-assy-shrimp-line-rev-02

Start2

thingiverse

free

OpenLock Adaptors-Wood Catwalk Set by Start2

...ng:1821631

openlock 4.0 http://www.thingiverse.com/thing:1833963

and devonjones openforgehttp://www.thingiverse.com/thing:1640999

thingiverse

free

OpenLock Adapter- Wood Corner by Start2

...ng:1821631

openlock 4.0 http://www.thingiverse.com/thing:1833963

and devonjones openforgehttp://www.thingiverse.com/thing:1640999

thingiverse

free

OpenLock Adapters Plain by Start2

...t-category/rampage-system/

rampage http://www.thingiverse.com/thing:1821631

openlock 4.0 http://www.thingiverse.com/thing:1833963

thingiverse

free

OpenLock Adapters-Wood Set by Start2

...3

and devonjones openforgehttp://www.thingiverse.com/thing:1640999

finishes the set with http://www.thingiverse.com/thing:2155569

thingiverse

free

OpenLock Derivitives by Start2

...rd tiles are based. this will open up for uses in curved roadways, mine track curves and tower options.

tiles are 6mm 25.4 based.

thingiverse

free

OpenLock Adapter-Stone Corner by Start2

...old-school-floor-adaptors/

spartan782 remixed these stone tiles with openlock slots here:http://www.thingiverse.com/thing:2064069

thingiverse

free

OpenForge 2.0 Spiral Stair Up (ORIG) OpenLock Base by Start2

...//www.thingiverse.com/thing:251178

special note of thanks to xloud - original spiral stairhttp://www.thingiverse.com/thing:995196

thingiverse

free

OpenForge 2.0 Spiral Stair Up OpenLock Base by Start2

...nd devonjones

openforge 2.0 http://www.thingiverse.com/thing:1910972

moved discussion to:http://www.thingiverse.com/thing:2055430

thingiverse

free

OpenForge 2.0 Mag + Door Full Spiral Stair by Start2

...//www.thingiverse.com/thing:171315

special note of thanks to xloud - original spiral stairhttp://www.thingiverse.com/thing:995196

thingiverse

free

OpenForge 2.0 Mag House Stone Stairwell by Start2

...//www.thingiverse.com/thing:171315

special note of thanks to xloud - original spiral stairhttp://www.thingiverse.com/thing:995196

Openlock

thingiverse

free

Rampage OpenLOCK Base Pack by Printablescenery

...ock herehttp://www.printablescenery.com/rampage-openlock

note: you need to remove the supports in front of the openlock supports.

thingiverse

free

OpenLock Tudor Door by LaCrosseInventersGuild

...r by lacrosseinventersguild

thingiverse

a quick remix of the door to be usable as an openlock wall ( not attached to the floor )

thingiverse

free

InfinityOpenlock - Openlock to Infinitylock clip by DungeonWorks

...infinityopenlock - openlock to infinitylock clip by dungeonworks

thingiverse

here is the clip for infinitylock to openlock.

thingiverse

free

Spiral Stairs OpenLOCK - N by oa10712

...spiral stairs openlock - n by oa10712

thingiverse

a modification of a spiral staircase changed to fit with the openlock system.

thingiverse

free

OpenLOCK Risers by misalo1

...sers for openlock tiles.

more to come...

i have tested e & s (pictures to follow)

i have not test printed r, sa, sb, u... yet

thingiverse

free

Miniature Sundial with Openlock by melabam

...hingiverse.com/thing:2534898

the bush tiles with and without openlock can be found here.https://www.thingiverse.com/thing:2637591

thingiverse

free

OpenLock Derivitives by Start2

...rd tiles are based. this will open up for uses in curved roadways, mine track curves and tower options.

tiles are 6mm 25.4 based.

thingiverse

free

OpenLock Wood Floor by PropheticFiver

...r

thingiverse

2x2 openlock wood floor using the openforge wood floor pattern.

prints beautifully on my ender 3 without supports

thingiverse

free

OpenLOCK to WarLOCK Adaptor Clip by Deac0n78

...rlock's own adapter clips i fumbled around until i had one that fit perfectly. this is my first but hopefully not last thing.

thingiverse

free

OpenLOCK Tessellation Templates by Printablescenery

...alls.

31 july 2020 (version 8.6) g-wall and oa-floor have had geometry fixes due to them having issues in some software programs.

Tread

3d_export

$5

tank treads

...tank treads

3dexport

turbosquid

$10

Tread-Stopper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tank Treads

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

vizpark

$10

Tread Floor

... the set includes fully tileable 8k, 4k and 2k textures with basecolor, height, ao, normal, roughness, and specular level layers.

turbosquid

$39

rubber tread wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

rim tread sedan

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$27

Tire Treads V6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$16

medieval tread wheel crane

...medieval tread wheel crane

3dexport

turbosquid

$39

rubber wheel tread tire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

sport rim tread wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Infinite

turbosquid

$15

Infinite Energy

...id

royalty free 3d model infinite energy for download as c4d on turbosquid: 3d models for games, architecture, videos. (1463932)

3d_ocean

$5

The Infinite Maze

... a maze as big as you want. the single maze section works out to be 30m x 30m x 3m. there are some separate wall sections that...

turbosquid

$4

infinite geometry

...e geometry for download as 3ds, obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1272938)

3d_ocean

$5

infinite studio for cinema 4d

.../seamless/changeable background studio setup for cinema 4d (physical and advanced render).check more images, 3d preview section….

turbosquid

$20

Infinite Splinter Teal Rug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Clean Infinite Studio + HDRI

...nfinite background that can be colorized easily to your liking . features: ready to render generated hdri using objects 5 lock...

3d_ocean

$8

Infinite Backdrop Studio + HDRI image

...up for product visualizations in cinema 4d. it mimics a reflective photographic studio. backdrop and floor is set-up to blend ...

3d_export

$15

xbox controller halo infinite limited edition

...max 2021, obj and fbx files does not include hdri. model, ideal for interior decoration, video game assets and whatever you need.

humster3d

$40

3D model of TAG Heuer Meridiist Infinite

...3d model of tag heuer meridiist infinite in various file formats. all our 3d models were created maximally close to the original.

3d_export

$19

infinite science fiction tunnel interior

...e fiction tunnel interior

3dexport

very long science fiction hallway or gangway tunnel interior. perfect for looping animations.

Spiral

3ddd

$1

italamp spirale

...italamp spirale

3ddd

italamp , spirale

italamp spirale

3ddd

free

Verpan / Spiral

...verpan / spiral

3ddd

spiral , verpan

verpan люстра spiral

3d_export

free

Spiral staircase

...spiral staircase

3dexport

spiral staircase

turbosquid

$5

Spiral

...quid

royalty free 3d model spiral for download as and sldpr on turbosquid: 3d models for games, architecture, videos. (1214311)

3d_export

$5

Spiral lamp

...spiral lamp

3dexport

spiral lamp in modern style.

turbosquid

$59

Spiralizer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$4

Spiral stairs

...spiral stairs

3docean

spiral stairs

spiral stairs 270 cm high inner radius 40 cm outer radius 120 cm

3d_export

$5

Spiral stairs

...spiral stairs

3dexport

spiral stairs<br>.blend

3d_export

$9

vdb spiral

...vdb spiral

3dexport

vdb spiral with different resolutions: low, middle and high

3d_ocean

$17

Spiral staircase

...uble handle handrail interior lux luxury metal modern open stairs realistic render spiral stair staircase stairs

spiral staircase

Stair

3d_ocean

$5

stairs

...stairs

3docean

metal stairs

metal stairs

archibase_planet

free

Stair

...stair

archibase planet

stair stairs staircase spiral stairs

stair n040914 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Stair

...stair

archibase planet

stair pool stairs stairs pool ladders

stair 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Stair

...stair

archibase planet

stair stairs playground

stair - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Stair

...stair

archibase planet

stair staircase stairs

stair metal - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Stair

...stair

archibase planet

stair staircase flight of stairs

stair n310514 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Stairs

...stairs

archibase planet

stairs staircase stair

stair step s - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Stair

...stair

archibase planet

stair stairs staircase

stair element n151014 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Stair

...air

archibase planet

stair stairs front staircase staircase

stair n111014 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Stair

...stair

archibase planet

stair staircase glass staircase stairs

stair glass - 3d model (*.gsm+*.3ds) for interior 3d visualization.

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур