Thingiverse

OMC outdrive electric shift wire grommet by motojeff

by Thingiverse

Last crawled date: 3 years ago

This is a grommet i made for an OMC outdrive electric shift wire cable harness. GLM Part Number: 27931; Sierra Part Number: 18-2192; OMC Part Number: 379628

this was used on most OMC 120, 140, 165, 170, 190, 225 & 245 Hp Stern Drives between early 1970 to late 1980's

seen here: https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

Its common for people to break these trying to remove the out drive, or for them to just short out from wear.

This wire goes through the transom and needs to be sealed. We had a short in ours that was in the molded grommet part of the wire, and because a replacement harness is so expensive i decided id make my own out of things i already had so i could go fishing.

I used an old 2 wire US 110 plug off a broken ryobi charger, its a common wire like this one https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

I cut it to length, used some yamabond https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db in the area that the grommet will be located then took about around 8 inches of heat shrink tube https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db and went up and over the yamabond and heated it to shrink down over yamabond.

Next i printed my grommet out of ninjaflex SEMI-FLEX filament. https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

i then covered that now shrunken heatshrink tube with yamabond and run the printed grommet up over the tube it should be a snug fit i had to warm the grommet some before going over the heat shrink, the yamabond should act like lube. But test fit it first if its too loose add another layer of heat shrink and yamabond like the first and try again.

Install some new plug ends! the ends of the wire are just common bullet connectors like these: https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

Cover the grommet with yamabond and lace it through the transom and press the grommet into place so its flush like the original.

now check for leaks, mine seems to still float, so now lets get back to fishing already....

this was used on most OMC 120, 140, 165, 170, 190, 225 & 245 Hp Stern Drives between early 1970 to late 1980's

seen here: https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

Its common for people to break these trying to remove the out drive, or for them to just short out from wear.

This wire goes through the transom and needs to be sealed. We had a short in ours that was in the molded grommet part of the wire, and because a replacement harness is so expensive i decided id make my own out of things i already had so i could go fishing.

I used an old 2 wire US 110 plug off a broken ryobi charger, its a common wire like this one https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

I cut it to length, used some yamabond https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db in the area that the grommet will be located then took about around 8 inches of heat shrink tube https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db and went up and over the yamabond and heated it to shrink down over yamabond.

Next i printed my grommet out of ninjaflex SEMI-FLEX filament. https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

i then covered that now shrunken heatshrink tube with yamabond and run the printed grommet up over the tube it should be a snug fit i had to warm the grommet some before going over the heat shrink, the yamabond should act like lube. But test fit it first if its too loose add another layer of heat shrink and yamabond like the first and try again.

Install some new plug ends! the ends of the wire are just common bullet connectors like these: https://www.amazon.com/ELECTRIC-SHIFT-ASSEMBLY-GLM-Number/dp/B004AQU8X4/ref=as_li_ss_tl?ie=UTF8&qid=1482181490&sr=8-1&keywords=379628&linkCode=sl1&tag=wremot-20&linkId=2d8b4ef82d31687c4e435fcc86eba6db

Cover the grommet with yamabond and lace it through the transom and press the grommet into place so its flush like the original.

now check for leaks, mine seems to still float, so now lets get back to fishing already....

Similar models

thingiverse

free

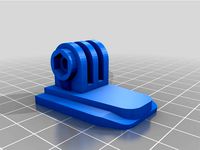

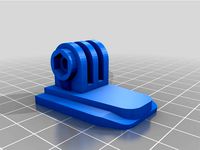

Bubble Tripod Action Camera Adapter by motojeff

...1fe3757bee01c054 (this set includes acorn nuts)

works with most gopro style action cameras that use this mounting style platform.

thingiverse

free

Depth Finder Transducer Trolling Motor Mount Bracket by motojeff

...depth finder transducers on to a minn kota or similar trolling motor with a 3.5-4in motor diameter. use 3m...

thingiverse

free

Assassin Ballistic Dart "Chinese Sleeve Arrow" - Trigger and Mount by GreekGadgetGuru

...results of this project. have fun, but take proper safety precautions and remember that every project you try is at your own risk

thingiverse

free

Pentomino (Tetris) Puzzle by Henry Dudeney by danellinwood

...7&keywords=aio+robotics+pla+filament+1.75mm&linkcode=sl1&tag=dellinwo-20&linkid=7c380586a7127d39933722cad3817193)

thingiverse

free

Vape Dual 18650 Unregulated Box Mod by dopesoner930

...mp;tag=wwwdopesonerc-20&linkid=b027d25b43b93913eee2366e71186ca4

printed in pla at 20 percent infill.

be careful when wiring!

thingiverse

free

Tabiger Soldering Iron Holder by betalab

...522957504&sr=8-3&keywords=creality+cr-10&linkcode=sl1&tag=betashop-21&linkid=9bbbf1eac6699ee5247480b2902f4fd1

thingiverse

free

Folding Video Transmitter Mount by m_beeson

....

i have really enjoyed this vtx folding mount. it has made live a bit simpler for transport.

video:https://youtu.be/lr0gb2tzde8

thingiverse

free

Easy to print grocery bag carrier/holder by motojeff

...amp;qid=1482087998&sr=1-9&keywords=lanyard&linkcode=sl1&tag=wremot-20&linkid=73d537c93b24a1b7a6a2e412e93aff54

thingiverse

free

MOSFET Mounting Systems by jbanion

...mp;qid=1512531094&sr=1-21&keywords=mosfet&linkcode=sl1&tag=jbanion-20&linkid=5380f6f658acfde91d2e3404a634d55a

thingiverse

free

Hex Driver Handle with Grip by Qrome

...2722&sr=8-3&keywords=bamtack+1.75mm+pla&linkcode=sl1&tag=blueskyrc-20&linkid=f273b7717c6bb5ec1f529d45859c153f

Motojeff

thingiverse

free

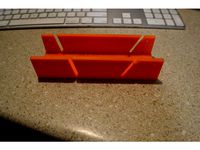

Cut Plug Herring Miter for Salmon Fishing by motojeff

...609&sr=8-15&keywords=slip+tie+mooching+rig&linkcode=sl1&tag=wremot-20&linkid=9c423394936c90c04df5c4362a818d6f

thingiverse

free

Easy to print grocery bag carrier/holder by motojeff

...amp;qid=1482087998&sr=1-9&keywords=lanyard&linkcode=sl1&tag=wremot-20&linkid=73d537c93b24a1b7a6a2e412e93aff54

thingiverse

free

Bubble Tripod Action Camera Adapter by motojeff

...1fe3757bee01c054 (this set includes acorn nuts)

works with most gopro style action cameras that use this mounting style platform.

thingiverse

free

Toy Hauler RV Patio Stabilizer to Ramp Bumper Adapter by motojeff

...mp;tag=wremot-20&linkid=a3e2a31a1d2f640de1ee640da9b1760b

ill try to add more details and pictures soon. print with supports.

thingiverse

free

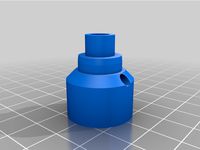

Action Camera Flex Bubble Tripod by motojeff

...ny 2 fork end mount as if mounting the camera (so you don't break the ears), and use the screw to pull the nut into the bore.

thingiverse

free

Action Camera Ball Joint / Flex Mount by motojeff

...ny 2 fork end mount as if mounting the camera (so you don't break the ears), and use the screw to pull the nut into the bore.

thingiverse

free

Depth Finder Transducer Trolling Motor Mount Bracket by motojeff

...=1521730899&sr=8-2&keywords=hose+clamp+5in&linkcode=sl1&tag=wremot-20&linkid=1dac75c649f5ab971160de95bc930d8f

thingiverse

free

Sticky Mounted Dog Poo Waste Bag Dispenser by motojeff

...key you can get it with out breaking a sweat i promise.

you can print the lid in another color and add some contrast if you like.

thingiverse

free

Fish-On Compatible Fishing Rod Holder Mount for 1.5in x .25in Gunnel Rails on Aluminum Drift Boats by motojeff

...sl1&tag=wremot-20&linkid=ccb94944b3e7e8aca01c508694e9d1fc

you can also use a 1/4in-20x1.25 bolt and matching nut or knob.

Outdrive

thingiverse

free

Maverick Ion Diff Outdrives for Dogbones by Myles97

...iff outdrives for dogbones by myles97

thingiverse

created in fusion360

maverick ion composite diff. outdrives (part no. mv28018)

thingiverse

free

RC18 outdrive (diff to dogbone connector) by AustinDavid

...er pla; i have some cf petg or cf nylon if that doesn't survive.

it should print fine without support in the stl orientation.

thingiverse

free

Reely Core/HBX 12891 differential outdrive cup - rear by szafir51

...ed it with reely core truggy and works fine with 4000kv motor with 3s battery.

should be compatibile with hbx 12891 desert truck.

thingiverse

free

Diff Outdrive Tunigy 118B Stadium Truck by Drese

...will make them even stronger

this version works fine, if i makle it on my 3d printer - needs maybe some customizations on yours?!

thingiverse

free

Tarmo open diff by Dex001

...screw to hold side gears m2x12-16mm screw to hold outdrive ...

thingiverse

free

Ball Differential setup cup by akau

...you can find right setup for balldiff with free outdrive this is printed with pla if you get elephant's...

thingiverse

free

RC Differential Tray by Xray965

...to alter this to match your bearing dimensions and outdrive etc. i will be making a second design shortly...

thingiverse

free

Schumacher Storm 2000 Knuckle Extension (Output Extender) by rcnand

...storm 2000 knuckle extension (output extender) by rcnand thingiverse outdrive adapter/output extender for the schumacher storm 2000 (knuckle extension...

thingiverse

free

Rc boat hull designs by Ttipton

...will be powerd by a traxxas velineon system and outdrive 1.21.18 i apologize for it being so long. i...

Omc

3ddd

$1

Marcel Bookcase with Decorative Set

...3ddd marcel , orla kiely , kelly hoppen , omc , enitial lab , стеллаж modern bookcase designed by...

thingiverse

free

OMC Carb Mixture Link by ecto1

...e the mixture screw linkages that links the outside lean rich knobs

to the carbs on older omc outboards as they get old and crack

thingiverse

free

OMC outboard cooling flush plate by mitchellbrink81

...re types will probably fit.

it'll probably fit many more models every omc between 5 and 25 hp up to 1970 will probably work.

unity_asset_store

$10

Python Mini Map

...your workflow with the python mini map asset from omc games. find this & other gui options on the...

thingiverse

free

Evinrude / OMC / Johnson COIL LOCATING RING PART NO. 317001 replaced by PART NO. 5534994 by aroundonme

...re touching the ring. if you push the coils out too far you may warp the ring and be putting the coils in the incorrect location.

thingiverse

free

Nema 17 with Planetary Gear Reduction by NeverDun

...17. i bought it from stepperonline motors and electronics (omcstepperonline.com). the part number is:...

thingiverse

free

OMC Johnson/Evinrude Pull Start Pinion Gear by Squirtica05

...pped (although it was still functioning). i think it is possible that this was a fluke, so i'll have to do some more testing.

thingiverse

free

Power Supply Line-in Cover by djdelorie

...switching power supply. specifically sized for the s-350-60 from omcstepperonline.com. drill and tap for 6-32...

thingiverse

free

Power Supply mounting clip by djdelorie

...screws on 25mm centers; sized specifically for s-350-60 from omcstepperonline.com ...

Grommet

design_connected

$16

Velvet Grommet Curtains

...velvet grommet curtains

designconnected

velvet grommet curtains computer generated 3d model.

thingiverse

free

grommet

...grommet

thingiverse

grommets for moss extractor, inflow hose 12/14, outflow 16/22. scale in slicer if necessary.

3d_sky

free

Curtains on the grommet

...curtains on the grommet

3dsky

curtains on the grommet.

thingiverse

free

Grommet by Mjminino

...grommet by mjminino

thingiverse

needed a grommet for my car firewall

3d_sky

free

Grommet curtains

...grommet curtains

3dsky

tulle blinds curtains

combined grommet curtains.

thingiverse

free

Grommet by jkavalik

...grommet by jkavalik

thingiverse

some kind of hole cover or cable grommet, made on request.

thingiverse

free

Cable grommet

...cable grommet

thingiverse

a simple cable grommet in 2 part : one in pla, the second in flex

thingiverse

free

Grommet (15mm) by walshy002000

...met designed for the ikea lack corner tv table. grommet suitable for other purposes and can easily be scaled for different sizes.

thingiverse

free

Boss Pedal Grommet

...boss pedal grommet

thingiverse

a simple replacement grommet for boss pedals. print in tpu

thingiverse

free

Grommet by CCinCapital

...his grommet to cover the hole i drilled on the kitchen island when i was installing devices under the sink, as seen in the photo.

Shift

3ddd

free

Shift Lamp

...amp

3ddd

artisan , shift

http://www.artisan.ba/en/products#collection/shift/69

turbosquid

$29

Shift Tuner

...osquid

royalty free 3d model shift tuner for download as fbx on turbosquid: 3d models for games, architecture, videos. (1236363)

turbosquid

$39

Shift cop car

...quid

royalty free 3d model shift cop car for download as fbx on turbosquid: 3d models for games, architecture, videos. (1236361)

turbosquid

$29

Shift Tuner red

...id

royalty free 3d model shift tuner red for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486834)

turbosquid

$20

Gear shift stick

...d

royalty free 3d model gear shift stick for download as dae on turbosquid: 3d models for games, architecture, videos. (1156597)

turbosquid

$9

Shift black coin

...d

royalty free 3d model shift black coin for download as max on turbosquid: 3d models for games, architecture, videos. (1626766)

turbosquid

$9

Shift gold coin

...id

royalty free 3d model shift gold coin for download as max on turbosquid: 3d models for games, architecture, videos. (1626763)

3ddd

$1

Pastoe \ Shift

...pastoe \ shift

3ddd

pastoe , тумба

современная тумба от фабрики "pastoe"

turbosquid

$2

gear shift knob

...y free 3d model gear shift knob for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1625614)

turbosquid

$5

car gear shift

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Wire

design_connected

$11

Wired

...wired

designconnected

wired computer generated 3d model.

design_connected

$11

Wires

...wires

designconnected

wires computer generated 3d model.

design_connected

$11

Wire

...wire

designconnected

ronda design wire computer generated 3d model. designed by roccadadria, luca.

3d_export

$5

wire

...wire

3dexport

wire 180x180 cm arhive rar 3dmax2019. obj. fbx. mat corona

turbosquid

$2

HDMI wire

... 3d model hdmi wire for download as wire, wire, fbx, and wire on turbosquid: 3d models for games, architecture, videos. (1644937)

turbosquid

free

wires

...bosquid

free 3d model wires for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1214233)

3ddd

$1

Wire chair

...wire chair

3ddd

wire chair

turbosquid

$10

wires

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

wire stripper

...wire stripper

3dexport

wire stripper 5 in 1

Electric

3d_export

$5

Electric pole

...electric pole

3dexport

electric pole for street, electricity line

3ddd

$1

electric mixer

...electric mixer

3ddd

electric mixer , миксер

electric mixer

3ddd

$1

electrical installation

...electrical installation

3ddd

electrical installation , розетка

electrical installation

turbosquid

$19

The electric water heater electric

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Electrical Outlet electric splitter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$20

Electric Guitar

...electric guitar

3docean

electric electric guitar guitar music music instrument

model of a electric guitar created in maya.

3d_ocean

$12

Electric Shaver

...electric shaver

3docean

electric electric shaver hair removal personal care shaver shaving

electric shaver created in 3ds max.

3ddd

$1

electrical switch

...h

3ddd

electrical , розетка

electrical switch from bticino company

series livinglight

3d_export

$7

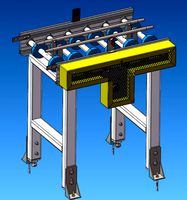

Electric Conveyor

...electric conveyor

3dexport

electric conveyor

3d_export

$5

electric drums

...electric drums

3dexport

electric drums