Thingiverse

NEMA17 Bowden Extruder M6 1.75mm by fASE-2

by Thingiverse

Last crawled date: 3 years ago

UPDATE JUL.22.2018:

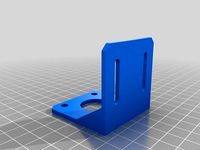

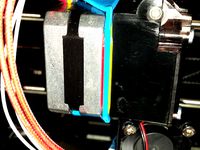

i made a DIRECT variant of the original beltless design for 1.75mm filament. the heatsink mount is a bit tight so i'll forego the clamp for now, but i'll fix this in the final revision. requires 4 x 25mm M3 screws, L-bracket, 4mm OD bowden tube running down the length of the heatsink.. i guess the clamps will need 2 x 10mm M3's. the original (light blue) design is still running problem free but i'm going to try some direct extrusion since i'm using a moving XY plane/bed and a stationary hot end.

UPDATE JUL.19.2018:

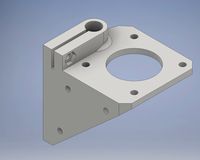

i'm just finishing designing the belted variant of the sliding tension block extruder. the picture does not show the 60T pulley or the 5mm drive shaft. this is one of my last projects for countersynchronized FDM as i transition to SLA/DLP resin which will use my existing table frame and a very similar Z-axis.

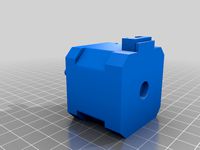

the belted 20T ---> 60T extruder was mainly designed for extra torque so i can finally use 2 spools of 3mm filament i bought 3 years ago... but once i perfect it, i'll include both a 3mm and 1.75 (maybe both in one) design. i have 2 sliding tension blocks in this extruder (48mm NEMA 17) but it can go up to 3 depending on how flat the M4/M5 tension block bearing screw is.

this will mount using a standard, metal, NEMA17 L-bracket and should work w/ both direct and bowden. i just have to figure out a standardized drive gear that does it all (which is unlikely).

in case you're wondering... the stepper is screwed in at the TOP and BOTTOM.

EDIT5: DO NOT print the NEMA14 extruder. besides being cute, this thing is totally useless and underpowered. the only way a NEMA14 will extrude reliably is w/ GEARS or if you can find one w/ holding torque around 30 oz-in or greater... mine at 14 oz-in is definitely not up to the task.

EDIT4: i had some parts left over and a NEMA14 that was begging for something to do, so i redesigned the extruder and posted WIP STLs. everything on it feels right so it should be OK. i'll test/reprint NEMA17 shortly thereafter. corrections to Tension Block: i think its an M4 x 12 holding the U-Groove bearing in place, but my M4 x 10 works just fine. also, NO washers above/below U-Groove bearing (if i used bridges then NO and if i printed supports then MAYBE).... i'll clean this page up soon and move on to something else. NEMA14 variant was printed too short/tall so i'll fix that later. NEMA14 height adjusted for M3 x 25mm, i just used the hex nuts as offsets in the picture, posted STL should be 1 "nut" taller (~2.4mm).

EDIT3: Tension Block rail gap is too tight. i'll adjust the gap so it slides properly.

EDIT2:

i still have to adjust 45 degree diagonals on both extruder and tension block since most people (including me) print infill at 45. this should optimize print time by minimizing unnecessary movement.

END EDIT2

**EDIT:

i posted the right STLs after comparing the files i was uncertain about. the extruder now has the right hole size for tapping M6 thread. the one i originally posted was exactly 6mm which wouldn't allow the right thread for the bowden tube fitting. the test block remains the same... i just renamed the file. the confusion stemmed from not being able to fit the M4 hex bolt into the tension block, but i'm pretty sure i cleared that up. it should be fine, but let me reprint, reassemble and test it before i give you the green light--i wouldn't want you wasting filament on a zonk.

if people are finding it difficult to print M3 holes on the first layer, i might modify the extruder STL by filling in the holes on that layer.

also, if people want to modify this thing for 3mm filament or make other changes, i can post the pre-booleans BLEND file for them.

END EDIT:**

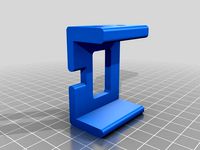

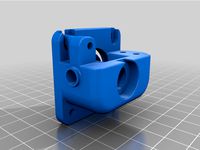

i made this thing a year ago, but only started using it recently. its heavily inspired by the Bulldog XL so i have to give credit where credit is due. i'll try to post the last STLs i exported from blender and hope that they're the right ones.

this page will be edited and revised once i figure things out. don't make this thing just yet.

here's what you'll need:

1) NEMA 17 Stepper Motor

2) 11mm MK7 Drive Gear

3) U604ZZ (604UU) Grooved Bearing (13mm OD, 4mm Height, 4mm ID)

4) M4 x 10mm Screw to secure the Grooved Bearing

5) 4 x M3 x 20mm Screw to attach Extruder to Stepper Motor

6) M4 x 25mm HEX Bolt to attach the Tension Block to the Extruder

7) M4 Flat Washer (between spring/extruder, and above/below U-Groove Bearing)

8) Spring (mine is about 8.2mm OD and 10mm Length)

9) M4 Wingnut to adjust Tension Block

Printed Parts:

Extruder and Tension Block

Tools:

Screwdriver, Drill, M4 and M6 Tap, File/Sandpaper (optional--to clean up the printed parts)

M4 tap requires 3.3mm drill hole, and M6 requires 5mm.

Known Problems:

--threading the 1.75mm filament is a challenge if its tightly wound (end of the spool)

--no practical application since i just use it the way it is, but really it should have some mounting holes to attach to a frame.

if anyone requests a different Bowden fitting, i'll post more STLs to correspond w/ your thread size.

INSTRUCTIONS:

-- print both parts (extruder and tension block)

-- clean up both parts: drill through 4 x M3 holes w/ 3mm or 1/8 bit, drill through M4 Hex Bolt w/ 4mm or slightly larger non-metric bit. drill down through tension block using 3.3mm bit or 1/8" (~3.10mm) also drill through any other holes to make em nice and round

-- tap M4 on tension block and M6 on extruder after drilling through w/ the right bit

-- assemble everything as shown BEFORE mounting it onto the stepper motor

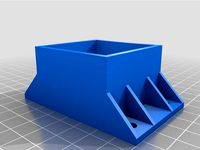

i printed w/o supports. your printer should be able to print ~1.8cm bridges on the tension block.

i made a DIRECT variant of the original beltless design for 1.75mm filament. the heatsink mount is a bit tight so i'll forego the clamp for now, but i'll fix this in the final revision. requires 4 x 25mm M3 screws, L-bracket, 4mm OD bowden tube running down the length of the heatsink.. i guess the clamps will need 2 x 10mm M3's. the original (light blue) design is still running problem free but i'm going to try some direct extrusion since i'm using a moving XY plane/bed and a stationary hot end.

UPDATE JUL.19.2018:

i'm just finishing designing the belted variant of the sliding tension block extruder. the picture does not show the 60T pulley or the 5mm drive shaft. this is one of my last projects for countersynchronized FDM as i transition to SLA/DLP resin which will use my existing table frame and a very similar Z-axis.

the belted 20T ---> 60T extruder was mainly designed for extra torque so i can finally use 2 spools of 3mm filament i bought 3 years ago... but once i perfect it, i'll include both a 3mm and 1.75 (maybe both in one) design. i have 2 sliding tension blocks in this extruder (48mm NEMA 17) but it can go up to 3 depending on how flat the M4/M5 tension block bearing screw is.

this will mount using a standard, metal, NEMA17 L-bracket and should work w/ both direct and bowden. i just have to figure out a standardized drive gear that does it all (which is unlikely).

in case you're wondering... the stepper is screwed in at the TOP and BOTTOM.

EDIT5: DO NOT print the NEMA14 extruder. besides being cute, this thing is totally useless and underpowered. the only way a NEMA14 will extrude reliably is w/ GEARS or if you can find one w/ holding torque around 30 oz-in or greater... mine at 14 oz-in is definitely not up to the task.

EDIT4: i had some parts left over and a NEMA14 that was begging for something to do, so i redesigned the extruder and posted WIP STLs. everything on it feels right so it should be OK. i'll test/reprint NEMA17 shortly thereafter. corrections to Tension Block: i think its an M4 x 12 holding the U-Groove bearing in place, but my M4 x 10 works just fine. also, NO washers above/below U-Groove bearing (if i used bridges then NO and if i printed supports then MAYBE).... i'll clean this page up soon and move on to something else. NEMA14 variant was printed too short/tall so i'll fix that later. NEMA14 height adjusted for M3 x 25mm, i just used the hex nuts as offsets in the picture, posted STL should be 1 "nut" taller (~2.4mm).

EDIT3: Tension Block rail gap is too tight. i'll adjust the gap so it slides properly.

EDIT2:

i still have to adjust 45 degree diagonals on both extruder and tension block since most people (including me) print infill at 45. this should optimize print time by minimizing unnecessary movement.

END EDIT2

**EDIT:

i posted the right STLs after comparing the files i was uncertain about. the extruder now has the right hole size for tapping M6 thread. the one i originally posted was exactly 6mm which wouldn't allow the right thread for the bowden tube fitting. the test block remains the same... i just renamed the file. the confusion stemmed from not being able to fit the M4 hex bolt into the tension block, but i'm pretty sure i cleared that up. it should be fine, but let me reprint, reassemble and test it before i give you the green light--i wouldn't want you wasting filament on a zonk.

if people are finding it difficult to print M3 holes on the first layer, i might modify the extruder STL by filling in the holes on that layer.

also, if people want to modify this thing for 3mm filament or make other changes, i can post the pre-booleans BLEND file for them.

END EDIT:**

i made this thing a year ago, but only started using it recently. its heavily inspired by the Bulldog XL so i have to give credit where credit is due. i'll try to post the last STLs i exported from blender and hope that they're the right ones.

this page will be edited and revised once i figure things out. don't make this thing just yet.

here's what you'll need:

1) NEMA 17 Stepper Motor

2) 11mm MK7 Drive Gear

3) U604ZZ (604UU) Grooved Bearing (13mm OD, 4mm Height, 4mm ID)

4) M4 x 10mm Screw to secure the Grooved Bearing

5) 4 x M3 x 20mm Screw to attach Extruder to Stepper Motor

6) M4 x 25mm HEX Bolt to attach the Tension Block to the Extruder

7) M4 Flat Washer (between spring/extruder, and above/below U-Groove Bearing)

8) Spring (mine is about 8.2mm OD and 10mm Length)

9) M4 Wingnut to adjust Tension Block

Printed Parts:

Extruder and Tension Block

Tools:

Screwdriver, Drill, M4 and M6 Tap, File/Sandpaper (optional--to clean up the printed parts)

M4 tap requires 3.3mm drill hole, and M6 requires 5mm.

Known Problems:

--threading the 1.75mm filament is a challenge if its tightly wound (end of the spool)

--no practical application since i just use it the way it is, but really it should have some mounting holes to attach to a frame.

if anyone requests a different Bowden fitting, i'll post more STLs to correspond w/ your thread size.

INSTRUCTIONS:

-- print both parts (extruder and tension block)

-- clean up both parts: drill through 4 x M3 holes w/ 3mm or 1/8 bit, drill through M4 Hex Bolt w/ 4mm or slightly larger non-metric bit. drill down through tension block using 3.3mm bit or 1/8" (~3.10mm) also drill through any other holes to make em nice and round

-- tap M4 on tension block and M6 on extruder after drilling through w/ the right bit

-- assemble everything as shown BEFORE mounting it onto the stepper motor

i printed w/o supports. your printer should be able to print ~1.8cm bridges on the tension block.

Similar models

thingiverse

free

Anycubic acryclic i3 dual (up to 4) bowden extruder stepper mount by hanshogeland

...nt blocks and spacers

2 x 1/2 inch aluminium pipe 285mm

6-8 m4x15-20

4 m4x30

10-12 m4 bolts

4mm drill (hss metal drill will work)

thingiverse

free

Compact Bowden Extruder by CaseyJohnson

...der arm

2 m3 x 25mm machine screw if you do not use springs on the extruder arm

1 m6 hex nut

1 bowden push fitting with m6 thread

thingiverse

free

Filament Filter for Bowden Extruder by TheWatson

... thread for pc4-m6 quick fitting. base should thread into most mk8 bowden extruder frame blocks except where m10 fitting is used.

thingiverse

free

Simple Extruder Drive Block only 3 parts!! by Zzyzxx71

...extruders are included. the tensioner arm and the axle will work with both.

fitment is good - test extrusion working as intended.

thingiverse

free

Filament Guide Direct Drive by DanChr89

...h 5,5mm drill bit, but i maybe think that its easier making m6 thread in them.

edit: 15-09-20

i uploaded a single push-in version

thingiverse

free

Simple Bowden Extruder by FerociousDesigns

...n your printers tolerances.

the m3 hole in the 'right' piece may need to be made slightly larger to ensure free movement.

thingiverse

free

Bowden Extruder Flex-Filament Adapter by titoBLN

...e.

assembling:

after i have assembled both adapter parts with two m3 screws i have drilled the "filament" hole on 2mm.

thingiverse

free

Simple bowden extruder for geared Nema 17 by Stargrove1

...lso included, a fixture to mount it at the smooth rods of a rostock mini if used in this combination, further m3 screws required.

thingiverse

free

Titan extruder bowden mount on 8mm (threaded) rod by Richard90

...oles in m3

and then screw it.

you'll need: 4 x m4 screw with nuts to fix it, and 2 x small m3 screw to block it in rotation.

thingiverse

free

Airtripper extruder Spring Bar by crooksUSA

...ith a 3mm drill bit.

since some may not have the right bit, i add an stl file with the holes for the m3 x 50mm enlarged slightly.

Fase

archibase_planet

free

Cleaner

...cleaner archibase planet crane lift fase cleaner - 3d model for interior 3d...

archive3d

free

Cleaner 3D Model

...cleaner 3d model archive3d crane lift fase cleaner - 3d model for interior 3d...

turbosquid

$5

Flower Vase Butterfly

...flower vase butterfly turbosquid royalty free 3d model flower fase butterfly for download as ma, max, obj, and fbx...

3d_export

$5

Old Gray Car Coupe From ChemodenStudio Low-poly

...texture size 128x128 (psd,png,jpeg) fbx, stl, blend: verts: 352 fase: 239 tris: 598 ready for...

3d_export

$5

Old Gray Car Minibus From ChemodenStudio Low-poly 3D

...3dexport texture size 128x128 (psd,png,jpeg).fbx, stl, blend: verts: 388 fase: 282 tris: 692 ready for...

3d_export

$5

Valve

...quick import. available formats fbx, obj. vertices - 3,741 fase - 3,697 textures 2048x2048 created in blender...

3d_export

$5

Valve

...quick import. available formats fbx, obj. vertices - 3,841 fase - 3,787 textures 2048x2048 created in blender...

3d_export

$5

Steel valve

...quick import. available formats fbx, obj. vertices - 5,122 fase - 5,186 textures 2048x2048 created in blender...

3d_export

free

Bronze valve

...quick import. available formats fbx, obj. vertices - 1,905 fase - 1,981 textures 2048x2048 created in blender...

3d_export

$5

Valve

...import. available formats fbx, obj, mtl vertices - 3,945 fase - 4,050 textures 2048x2048 texture maps - basecolor, roughness,...

Nema17

turbosquid

$1

Nema17 holder

...quid

royalty free 3d model nema17 holder for download as ipt on turbosquid: 3d models for games, architecture, videos. (1165167)

3d_export

$5

Stepper motor Nema17 17HS4401

...stepper motor nema17 17hs4401

3dexport

thingiverse

free

nema17

...nema17

thingiverse

moteur nema 17

thingiverse

free

Bracket for Nema17

...bracket for nema17

thingiverse

bracket for nema17 ( axis y, z)

thingiverse

free

nema17 mount by JonBAL

...nema17 mount by jonbal

thingiverse

nema17 mount

thingiverse

free

Support Nema17 by perryluca

...support nema17 by perryluca

thingiverse

motor support for nema17

thingiverse

free

Nema17 Mount by sitt

...nema17 mount by sitt

thingiverse

nema17 mount, abs, 30%infill

thingiverse

free

NEMA17 pg5 to Nema17 Adapter by kraegar

... (planetary geared nema 17) on a normal nema 17 motor project mounting plate.

i printed in atomic carbon fiber petg for strength.

thingiverse

free

Mount for NEMA17 by ImHuman

...mount for nema17 by imhuman

thingiverse

copy parts. mount for stepper motor nema17.

thingiverse

free

Seal nema17 by lisent

...seal nema17 by lisent

thingiverse

this is a seal for create separation between the nema17 and the support mount.

75Mm

cg_studio

$79

75mm Pak 97/383d model

...rld ww2 wwii

.obj .jpg .max .fbx .3ds - 75mm pak 97/38 3d model, royalty free license available, instant download after purchase.

3d_export

$79

75mm Pak 97-38 3D Model

... pak tank war weapon world

75mm pak 97-38 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl graverino 108478 3dexport

3d_ocean

$79

75mm Pak 97/38

...el originally created with 3ds max and rendered with vray the model is easy to modify, the main parts can be easily moved as i...

cg_studio

$149

M4A3 Sherman - 75mm - Mid production3d model

... .c4d .lwo .obj - m4a3 sherman - 75mm - mid production 3d model, royalty free license available, instant download after purchase.

cg_studio

$139

M4A2 Sherman - Colorado3d model

...m4a2 sherman colorado tank us marine corps pacific theatre 75mm m3 l/40 gun .c4d .obj .lwo .fbx .3ds -...

cg_studio

$139

M4A2 Sherman - Destroyer3d model

...m4a2 sherman destroyer tank us marine corps pacific theatre 75mm m3 l/40 gun .c4d .obj .lwo .fbx .3ds -...

cg_studio

$65

Pak 403d model

...pak 403d model cgstudio gun ww2 75mm artillery world war wwii 1943 army 1945 anti tank...

cg_studio

$125

Anti tank guns ww23d model

...anti tank guns ww23d model cgstudio gun ww2 75mm artillery wwii army 1945 antitank projectile weapon shell case...

3ddd

free

Indian vase

...311742 размеры: длинна маленькой вазы - 460mm, ширина - 75mm высота - 130mm длинна большой вазы - 600mm, ширина...

3d_export

$7

facemaskearloopweldingmachine

...the welding of one-time plane mask ear belt with 75mm standard ear band spacing. if you want to weld...

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

M6

design_connected

free

M6 Bed

...m6 bed

designconnected

ka design m6 bed sleep furniture computer generated 3d model. designed by joachim kleine allekotte.

3d_export

$49

BMW M6 3D Model

...bmw m6 3d model

3dexport

bmw m6 serie series sport car german luxury

here a bmw m6

3d_export

$35

BMW M6 3D Model

...bmw m6 3d model

3dexport

bmw m6 model car transportation gts gtr gt dtm

bmw m6 3d model shadowkeeper 2226 3dexport

3d_export

$20

BMW M6 3D Model

...bmw m6 3d model

3dexport

bmw m6 3d model sigma31 774 3dexport

3d_export

$20

BMW M6 E24 3D Model

...bmw m6 e24 3d model

3dexport

m6

bmw m6 e24 3d model racer_x 55190 3dexport

3d_export

$5

M6 Screw Visual 3D Model

...m6 screw visual 3d model

3dexport

m6 screw

m6 screw visual 3d model andrsketch 58904 3dexport

3d_export

$70

Bmw m6 3D Model

...bmw m6 3d model

3dexport

bmw

bmw m6 3d model afshin 37844 3dexport

3d_export

$50

Bmw M6 3D Model

...bmw m6 3d model

3dexport

bmw m5

bmw m6 3d model basit321 17592 3dexport

turbosquid

$15

Tactical Light-M6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

M6 Hex Bolt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

3d_export

$13

extruded table

...ed to give you the highest possible quality for up to 4k renders. there is no post-production used on any of the renders you see.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.