Thingiverse

Neje Master (1or 2) Laser Improved Fanbox (or similar Laser) by Renba

by Thingiverse

Last crawled date: 3 years, 3 months ago

Protect your Laser ! Avoid over Heating!

A great improvement for your ears and the life span of your laser.

The excellent NEJE LASER come with an horribly noisy 30x30x10mm fan!

It produces a noise of 38Db ! Check the datasheet FXDS3010-1

Indeed as it is small, there is no secret, it must turn at 14000 RPM (revolutions per minute) to produce a flow of 4 Cubic Feet per Minute (CFM) .

At full power, the 20W Neje laser reaches 51°~52°C after 6 minutes and must remains at this temperature.

If the laser diode temperature continues to rise exceeding the maximum operating temperature, the diode can be catastrophically damaged or the long term performance may degrade significantly.

If the laser diode’s operating temperature is reduced by about 10 degrees, the lifetime will statistically double.

Laser module lifetimes can be extended significantly by maintaining the case temperature at the low end of the operating temperature range.

(source : http://www.worldstartech.com/what-determines-the-lifetime-of-a-laser-module/)

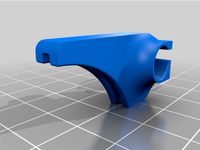

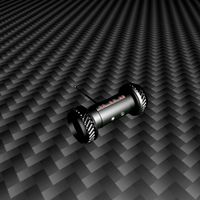

I created this part with an aerodynamic design to be able to fit a 40x40x10mm fan that will deliver twice the air volume (7.7 CFM) and much quieter since it only produces 21Db !

My choice is a Sunon Fan Maglev Series 40x40x10 which you can find here at a very low price :https://s.click.aliexpress.com/e/_984Gbh

For the X axis, the new assembly is 236gr on the scale.

The old assembly with the small fan was 210gr.

The Nema 17 42x42x30 motors have a torque of 16Ncm or 1.6kg/cm, so you need a weight of more than 1.6kg to start having 'step slip' problems, so there is a margin...

We are far away from the limits of the nema 17 stepper motors used.

Besides, it is this same type of motor that animates the Y axis.

And on the Y-axis this motor drives the weight of two motors, and the X-axis with the laser... That is a much bigger weight difference than the 26gr I added on the X-axis by making this modification

The 4 2.2mm holes are user to screw the 4 Allen srcrews with a 2mm Allen Tool by the top side

No external hardware needed, the original 4 Allen screws are long enought and fit perfectly the assembly.

The original FXDS 3010-1 Fan can be replaced by this Sunon https://s.click.aliexpress.com/e/_AV1D55, this Sunon has the same parameters as the original one.

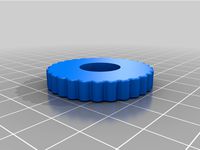

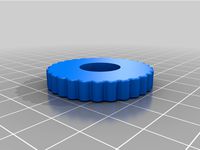

Check also my Neje Laser Unobstructed Focus Knobhttps://www.thingiverse.com/thing:4634582

Think to improve the cutting perforance using a LONG FOCUS LENS

like this https://s.click.aliexpress.com/e/_AYpshn

Have you ever noticed that when you cut a thick material, the sides of the workpiece are no longer perpendicular?

It is because of the focus, the beam is thin over a small distance, the more the laser goes down into the material the larger the diameter of the beam and therefore the laser power is no longer concentrated in a fine beam...

Thanks to the long focus, you can cut thicker materials because the laser beam remains concentrated into a fine beam over a longer length.

If you have problems using Lightburn instead of Neje software, simply follow this guide.https://www.northlakeswoodwork.com/blog/2020/7/5/affordable-laser-engraving-lightburn-setup-for-neje-master-2

Please like and post a pic of your print !

Happy Printing !

Renba

A great improvement for your ears and the life span of your laser.

The excellent NEJE LASER come with an horribly noisy 30x30x10mm fan!

It produces a noise of 38Db ! Check the datasheet FXDS3010-1

Indeed as it is small, there is no secret, it must turn at 14000 RPM (revolutions per minute) to produce a flow of 4 Cubic Feet per Minute (CFM) .

At full power, the 20W Neje laser reaches 51°~52°C after 6 minutes and must remains at this temperature.

If the laser diode temperature continues to rise exceeding the maximum operating temperature, the diode can be catastrophically damaged or the long term performance may degrade significantly.

If the laser diode’s operating temperature is reduced by about 10 degrees, the lifetime will statistically double.

Laser module lifetimes can be extended significantly by maintaining the case temperature at the low end of the operating temperature range.

(source : http://www.worldstartech.com/what-determines-the-lifetime-of-a-laser-module/)

I created this part with an aerodynamic design to be able to fit a 40x40x10mm fan that will deliver twice the air volume (7.7 CFM) and much quieter since it only produces 21Db !

My choice is a Sunon Fan Maglev Series 40x40x10 which you can find here at a very low price :https://s.click.aliexpress.com/e/_984Gbh

For the X axis, the new assembly is 236gr on the scale.

The old assembly with the small fan was 210gr.

The Nema 17 42x42x30 motors have a torque of 16Ncm or 1.6kg/cm, so you need a weight of more than 1.6kg to start having 'step slip' problems, so there is a margin...

We are far away from the limits of the nema 17 stepper motors used.

Besides, it is this same type of motor that animates the Y axis.

And on the Y-axis this motor drives the weight of two motors, and the X-axis with the laser... That is a much bigger weight difference than the 26gr I added on the X-axis by making this modification

The 4 2.2mm holes are user to screw the 4 Allen srcrews with a 2mm Allen Tool by the top side

No external hardware needed, the original 4 Allen screws are long enought and fit perfectly the assembly.

The original FXDS 3010-1 Fan can be replaced by this Sunon https://s.click.aliexpress.com/e/_AV1D55, this Sunon has the same parameters as the original one.

Check also my Neje Laser Unobstructed Focus Knobhttps://www.thingiverse.com/thing:4634582

Think to improve the cutting perforance using a LONG FOCUS LENS

like this https://s.click.aliexpress.com/e/_AYpshn

Have you ever noticed that when you cut a thick material, the sides of the workpiece are no longer perpendicular?

It is because of the focus, the beam is thin over a small distance, the more the laser goes down into the material the larger the diameter of the beam and therefore the laser power is no longer concentrated in a fine beam...

Thanks to the long focus, you can cut thicker materials because the laser beam remains concentrated into a fine beam over a longer length.

If you have problems using Lightburn instead of Neje software, simply follow this guide.https://www.northlakeswoodwork.com/blog/2020/7/5/affordable-laser-engraving-lightburn-setup-for-neje-master-2

Please like and post a pic of your print !

Happy Printing !

Renba

Similar models

thingiverse

free

Neje Laser Unobstructed Focus Knob by Renba

.../blog/2020/7/5/affordable-laser-engraving-lightburn-setup-for-neje-master-2

as a simple return, please like and post your print !

thingiverse

free

Neje laser engraver focus knob by WRonX

...er's focus.

designed and tested on neje engraver (this model exactly), but should fit most laser diodes with 12mm brass knob.

thingiverse

free

Motorized Z axis laser engraver by Ntn35

...motorized z axis laser engraver by ntn35

thingiverse

z axis with stepper motor for 3dpburner2, laser neje 20w

grabcad

free

Laser module NEJE 20W

...laser module neje 20w

grabcad

laser diode 20w module neje

thingiverse

free

NEJE Laser Engraver Focus Wheel by archie73

...need to adjust for your printers tolerances, but it has about +0.8mm on the diameter of the lense. (12mm)

fits neje laser diodes.

thingiverse

free

NEJE Laser Focus Knob by buckeyes1997

...ingiverse

this is a larger outter focus knob for the neje laser head. it fits snug over the existing laser knob for the optics.

grabcad

free

NEJE A40640 MPCNC Tool Mount

...neje a40640 mpcnc tool mount

grabcad

a mounting plate for attaching a neje a40640 diode laser to an mpcnc primo

thingiverse

free

Neje 40watt laser fixed focus block 22mm by mfann72

...ocus laser figured someone else might be able to use it

you might print this 1% bigger mine shrank to 21.78mm after printin

3dwarehouse

free

Laser-based Snow Depth Sensor - Lufft SHM31

...roughout the lifetime of the sensor. #weather_sensors #automatic_weather_station #weather_station #lufft #laser #snow #snow_depth

thingiverse

free

NEJE Laser modification by Ketttensaegentechnik

...ave a new axis concept. with the angle you can fixed the laser on the machine table. with this setup you have more opportunities.

1Or

thingiverse

free

Meade DSI PRO Spacer for Auto Guider by vlxjim

...can lightly sand them down or just scale it 1or 2% smaller. in my case it was a good...

thingiverse

free

9 Tooth Herringbone Gear with Large Base by dmserve

...on 4 printers. i think that passes as success. 1or 2 of them may have be user error. (forcing...

thingiverse

free

Power Supply by rmorrow50

...50v at 20a and, on the left is a 1or 2 cell lithium ion charger. i used the stock...

thingiverse

free

Bench Power Supply/Charger by rmorrow50

...at up to 20a, on the left is a 1or 2 cell lithium ion charger. i used the stock...

cg_trader

$229

Collection of Laboratory 1or 2

...tory 1or 2

cg trader

3d collection of laboratory 1or 2 laboratory lab, available formats max, bip, ready for 3d animation and ot

cg_trader

$179

Collection of Library 1or 2

...ibrary 1or 2

cg trader

librarian collection of library 1or 2 3d library, formats include max, bip, ready for 3d animation and ot

cg_trader

$177

Collection of Bar 1or 2

...of bar 1or 2

cg trader

collection of bar 1or 2 3d model restaurant lounge music, formats max, bip, ready for 3d animation and ot

3dwarehouse

free

TheeMan's Really long-Term big overlapping Tamper with decks base.

...to have many rooms. and hold up to any 1or more cars safely. my pick's are jeep / atv....

Renba

thingiverse

free

Ethernet Cable Organizer by Renba

...cable organizer by renba

thingiverse

a simple ethernet cable organizer 24 ports

i use it when i must replace a switch in a rack

thingiverse

free

Hotend Front for Anycubic Mega-S (Remix from Renba) by Uzhul

...bic mega s. there are the hotted cables in the way. so i made my own version. it fits in the other parts from the original design

thingiverse

free

3018 Rail Snap-on Durst Cover (also 1610, 2040, 2418,... series) by Renba

...o match your printer bed.

adjust with a cutter or dremel.

as a simple return, please like (if you like) and post a picture.

renba

thingiverse

free

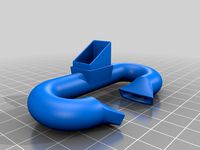

Suspended Vacuum Hose Holder for CNC / Wood Tools by Renba

...://www.thingiverse.com/thing:4652282

as a simple return, please like and post your print!

happy printing and wood milling !

renba

thingiverse

free

Steadycam Feiyu G3 Ultra Holder for Gopro Mounting Acc. by Renba

... compatible mounting accessories.

printed with support and pla carbon

of course you have to print both sides...

happy printing !!

thingiverse

free

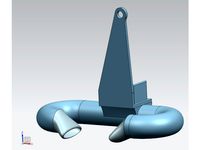

Mercury / Mariner Inflatable Pump Nozzle by Renba

... to have a correct fit with the valve.

you can put a small screw 16mm long and 1.5 to 2mm wide to push on the valve if necessary.

thingiverse

free

Dishwasher Soap Basket by Renba

...s best to melt them gently (see pics).

all request about improvement of this simple thing are welcome ;)

happy printing ;)

renaud

thingiverse

free

Neje Laser Unobstructed Focus Knob by Renba

.../blog/2020/7/5/affordable-laser-engraving-lightburn-setup-for-neje-master-2

as a simple return, please like and post your print !

thingiverse

free

Anycubic Photon Self VAT drainer (Dripping holder) by Renba

...n it. i highly recommend this very practical little accessory.

https://s.click.aliexpress.com/e/_d9clokq

please post your makes !

thingiverse

free

Crown Macro-Tech Main Cable Fix by Renba

...le securely in place.

i used neoprene glue to fix the piece and the cable inside the piece.

thank you for publishing your work.

Fanbox

thingiverse

free

anycubic mega s Hotend Fanbox by Hassprediger

...klebt und bei den oberen habe ich selbst schneidende schrauben verwendet

ich nutze dazu https://www.thingiverse.com/thing:2577163

thingiverse

free

Fanbox for Printrbot Air Nozzle System by moltenplastic

...ube attached that leads to a nozzle on the print head which you aim at the molten plastic from within the printer build platform.

thingiverse

free

40 mm Fanbox for RF2000 3D-Printer to replace the standard fans by a 40mm / 24 volt fan by AlbinBallad

... a 40mm / 24 volt fan by albinballad

thingiverse

fanbox replacement for the renkforce rf2000 to use one single 40mm / 24volt fan

thingiverse

free

Anycubic I3 Mega Remixed Fanbox for BLTouch by rronni

...hing:2824005

update 25.11.2018:

the fanduct bend after a while so i have moved the cut a little bit. this should solve the issue.

thingiverse

free

I3 Mega Ultrabase Hotend Fanbox by bamarayne

...e metal parts that are taken off. it definitely makes the printer run quieter. you can also use a 5015 fan for the parts cooling.

thingiverse

free

Anycubic I3 Mega-S Printhead Case Cover Honeycomb Hotend Fanbox Upgrade by hazweio

...the fan duct you see in the picture is this (anycubic i3 mega s - fan duct by matism09):https://www.thingiverse.com/thing:3564168

thingiverse

free

Anycubic I3 Mega Improved Hotend Fanbox 1 Piece Clean

...s and added corners to the bottom part for aesthetics.

to be printed with some supports (maybe tilt it to one of the fans sides).

thingiverse

free

Anycubic i3 Mega Mega-S Upgrade Printhead Cable Cover and Holder Case Honeycomb Hotend Fanbox by hazweio

...the fan duct you see in the picture is this (anycubic i3 mega s - fan duct by matism09):https://www.thingiverse.com/thing:3564168

thingiverse

free

Anycubic i3 Mega fan duct for 5015 radial fan by D1_

...plate nor they couldn´t get fixed on the hotend fanbox with a screw. so i designed my own one....

thingiverse

free

i3 mega fan duct for radial fan of type 5015

...thingiverse this fan duct can be used with renbas fanbox for me the original provided fan duct has an...

Neje

thingiverse

free

Neje Master Risers

...neje master risers

thingiverse

this is risers for the neje master. there is a left and right part.

the neje master lifted 5cm

thingiverse

free

Ortur NEJE Adapter by Zimmant

... carriage.

"neje back plate v1.stl" is a quick adapter plate that is untested.

both use a captive design for m3 nuts.

thingiverse

free

NEJE Laser Mount by buckeyes1997

...ap neje 7w laser. the mount has 4 holes for the m3 screws to the laser body and 3 holes for mounting on a frame or machine base.

thingiverse

free

Neje / KkMoon Holder for Laser

...

i destroyed my laser engraving holder of my neje master / kkmoon, so i designed a new one in fusion 360.

100% infill, enjoy it!

thingiverse

free

Neje master Adjustable Z axis by Zig1100

...neje master adjustable z axis by zig1100

thingiverse

neje master 1 or 2 adjustable x-z axis.

thingiverse

free

NEJE Laser modification by Ketttensaegentechnik

...ave a new axis concept. with the angle you can fixed the laser on the machine table. with this setup you have more opportunities.

thingiverse

free

neje qwik release for neje module slide by dav88

...r on back with holes facing horizontal and the pin flat side down for no supports.

ps. it is in inches. scale up 2540% to get mm.

thingiverse

free

NEJE Laser Wall Mount by bobenhimen

...t by bobenhimen

thingiverse

wanted to clear up some desk space, made a wall mount tab for the neje.

no supports or brim needed.

thingiverse

free

NEJE Laser Focus Knob by buckeyes1997

...ingiverse

this is a larger outter focus knob for the neje laser head. it fits snug over the existing laser knob for the optics.

thingiverse

free

Neje Leg Holder by xHubbyx

...neje leg holder by xhubbyx

thingiverse

simple leg holder to help keep it in place and square..

Master

3ddd

$1

Master

...master

3ddd

besana , master

фабрика: besana

master

размер: 80х60х80

design_connected

$20

Masters

...photo-realistic 3d models of the kartell masters chair by philippe starck for 3d architectural and interior design presentations.

3ddd

$1

Masters

...ка на производительяhttp://www.designboom.com/design/philippe-starck-masters-chair-for-kartell-at-milan-design-week-09/

3d_export

$5

master roshi

...master roshi

3dexport

master roshi 3d model good quality for animation

design_connected

$18

Masters Stool

...masters stool

designconnected

kartell masters stool computer generated 3d model. designed by starck, philippe.

3ddd

free

Key Master

...key master

3ddd

игровой автомат , key master

д 950 / ш 950 / в 1850

3ddd

$1

Стул: Masters Chair

... kartell

стул: masters chair

коллекция: masters

бренд: kartell

страна: италия

размеры, см: 83x54x54; высота сиденья – 47.

3d_export

$5

master bedroom

...master bedroom

3dexport

zhu design<br>a modern tropical inspired master bedroom for your model

3ddd

$1

kartel masters

...el masters

3ddd

kartel , masters

в архиве присутствует fbx и модель в 2011 версии макса.

turbosquid

$150

Master Bedroom

...osquid

royalty free 3d model master bedroom for download as on turbosquid: 3d models for games, architecture, videos. (1329485)

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

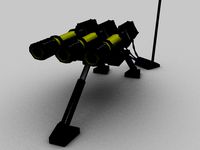

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Similar

3d_export

$20

sports car similar to a chevrolet

...sports car similar to a chevrolet

3dexport

a sports car similar to a chevrolet. high-poly and low-poly models

turbosquid

$10

2 Similar Cutlery Sets

...odel 2 similar cutlery sets for download as c4d, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1609168)

turbosquid

$49

Gun similar to Colt Peacemaker

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Gun similar to Jericho 941

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Gun similar to Colt 1911

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

The girl similar to Mandy 3D Model

...autiful sexy

the girl similar to mandy 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl iasha3d39286 103194 3dexport

3d_export

$10

coffee machine similar lavazza tiny

...commended for photorealistic rendering of domestic environments, the model is in real scale and has dimensions of 29.6x11xh 25 cm

turbosquid

$49

Gun similar to Desert Eagle .44 Magnum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

The girl similar to Mandy

...real-world scale and is centered at 0,0,0.

objects, materials, textures use meaningful names.

mapping is only overlapping in hair

turbosquid

$35

Ground Surveillance Drone (Similar to Tom Clancy's Rainbow Six: Siege drone)

...om clancy's rainbow six: siege drone) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1341540)

Improved

cg_studio

$49

Robot Z300 (improved version)3d model

...o

.3ds .fbx .max .obj - robot z300 (improved version) 3d model, royalty free license available, instant download after purchase.

3d_export

$39

Robot Z300 improved version 3D Model

...fantasy sci-fi robots bot humanoid droid sci fi materials character

robot z300 improved version 3d model alekrazum 55067 3dexport

3d_export

$75

CV-90 Improved

...nnon. export versions are fitted with hägglunds e-series turrets, armed with either a 30 mm mk44 or a 35 mm bushmaster autocannon

turbosquid

$55

(Important textures coming back soon after improvements)Cuboid gazebo bench area

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

COMPLETE AUDI 80-100 SHIFT LEVER REPAIR KIT WITH IMPROVED BUSHING

...dexport

• sleeve - 1 pc. • elastic band - 1 pc. • hinge - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$7

REPAIR KIT FOR GEARSHIFT LEVER AUDI 80-100 IMPROVED

...ar of the gum is excluded. - rusk - 1 pc. - elastic band - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$30

cup mask machine front section stereo mask manufacturing machine improved version

...ing rack cad outsourcing list. the drawings are mature drawings that have been produced.<br>drawing version solidworks 2018

3d_export

free

oven - forno

...oven - forno

3dexport

gradually i'm trying to improve my 3d.

3d_export

$75

T-55

...nally, but these improvements made the tank more efficient and lethal. the t-55 was officially adopted by the soviet army in 1958

3d_export

$5

civil registration authorities

...civil registration authorities

3dexport

city wedding square. the model can be used for projects, to improve the project, etc.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ALPEREN-2

...alperen-2

3ddd

комод , alperen-2

комод с зеркалом alperen-2

design_connected

$27

Confluences 2 2-Seater Sofa

... 2-seater sofa

designconnected

ligne roset confluences 2 2-seater sofa computer generated 3d model. designed by nigro, philippe.