GrabCAD

![[NASA Challenge] Transonic Wind Tunnel Test Section Design](/previews/12413003.jpg)

[NASA Challenge] Transonic Wind Tunnel Test Section Design

by GrabCAD

Last crawled date: 1 year, 10 months ago

For additional information, explanations, and renders, please see the PDF document labeled “Detailed Explanation”. This is my submission to the NASA Challenge: New Transonic Wind Tunnel Test Section, and serves as a design concept to develop more efficient wind tunnel test sections.

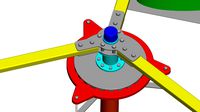

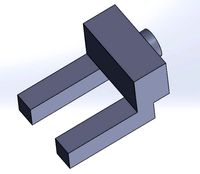

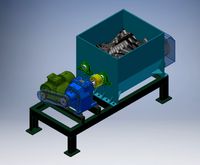

The design consists primarily of two features to greatly enhance the efficiency of current wind tunnels. Most prominently, the conveyor belt system allows for the movement of test sections in and out of the wind tunnel. For a singular wind tunnel, the maximum amount of required test sections is solely two. Given that testing lasts for multiple hours at a time, an inactive test section can be reconfigured for the following test, without the need for more sections — namely, additional test sections would add unnecessary costs. Consequently, the conveyor/turntable design featured in this submission ensures the ability to reconfigure entire test sections while simultaneously allowing for the testing of another section in the wind tunnel.

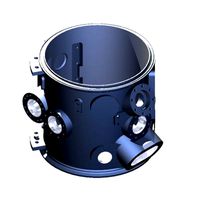

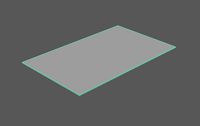

Secondly, each test section is covered in 264 polycarbonate panels, mounted to the walls. Each panel can be electrically connected to the remainder of the system via a pogo pin connection (again, please see the PDF for greater detail). The panels mount to the frame of the test section, which has been designed with nuts welded to its interior. The test section frame is hollow (with struts for support) to allow for wiring to connect all the panels together. This concept allows for the complete reconfiguration of entire test sections, without needing to construct new frames for the test section exterior. Furthermore, by institutionalizing the mounting of sensors and models in a test section, wind tunnels worldwide can utilize the same mechanism, making it simple to test a model in any tunnel. In essence, this technology potentially could set the stage for institutionalized wind tunnel testing system in the years to come. As a matter of additional redundancy in the system (thus ensuring that panels don't come loose during testing), to remove a panel, one would have to push inwards, pull out, and then in again, making it effectively impossible to dislodge a panel during testing. Sadly, due to time constraints, this wasn't modeled.

If there are questions about the design, I’d be glad to answer them in the comments section! I’d like to give a huge thank you to GrabCAD and NASA for hosting this competition. I wish my fellow competitors the best of luck!

The design consists primarily of two features to greatly enhance the efficiency of current wind tunnels. Most prominently, the conveyor belt system allows for the movement of test sections in and out of the wind tunnel. For a singular wind tunnel, the maximum amount of required test sections is solely two. Given that testing lasts for multiple hours at a time, an inactive test section can be reconfigured for the following test, without the need for more sections — namely, additional test sections would add unnecessary costs. Consequently, the conveyor/turntable design featured in this submission ensures the ability to reconfigure entire test sections while simultaneously allowing for the testing of another section in the wind tunnel.

Secondly, each test section is covered in 264 polycarbonate panels, mounted to the walls. Each panel can be electrically connected to the remainder of the system via a pogo pin connection (again, please see the PDF for greater detail). The panels mount to the frame of the test section, which has been designed with nuts welded to its interior. The test section frame is hollow (with struts for support) to allow for wiring to connect all the panels together. This concept allows for the complete reconfiguration of entire test sections, without needing to construct new frames for the test section exterior. Furthermore, by institutionalizing the mounting of sensors and models in a test section, wind tunnels worldwide can utilize the same mechanism, making it simple to test a model in any tunnel. In essence, this technology potentially could set the stage for institutionalized wind tunnel testing system in the years to come. As a matter of additional redundancy in the system (thus ensuring that panels don't come loose during testing), to remove a panel, one would have to push inwards, pull out, and then in again, making it effectively impossible to dislodge a panel during testing. Sadly, due to time constraints, this wasn't modeled.

If there are questions about the design, I’d be glad to answer them in the comments section! I’d like to give a huge thank you to GrabCAD and NASA for hosting this competition. I wish my fellow competitors the best of luck!

Similar models

grabcad

free

NASA Transonic Wind Tunnel Test Section Design

...in, making it effectively impossible to dislodge a panel during testing. sadly, due to time constraints, this wasn't modeled.

grabcad

free

NASA Challenge: New Transonic Wind Tunnel Test Section

...nasa challenge: new transonic wind tunnel test section

grabcad

nasa challenge: new transonic wind tunnel test section

grabcad

free

![[Design Concept] New Transonic Wind Tunnel Test Section | NASA 2022](/t/12053983.jpg)

[Design Concept] New Transonic Wind Tunnel Test Section | NASA 2022

...test section

additional files to follow :

- complete design

- installing mechanism and animation

- wind tunnel simulation result

grabcad

free

![[Mechanical Design] New Transonic Wind Tunnel Test Section | NASA 2022](/t/12050280.jpg)

[Mechanical Design] New Transonic Wind Tunnel Test Section | NASA 2022

...tion

additional files on progress :

- complete design soon

- installing mechanism and animation

- wind tunnel simulation result

grabcad

free

Interchangeable wind tunnel test section

...interchangeable wind tunnel test section

grabcad

nasa challenge of transonic wind tunnel test section

grabcad

free

Just some renderings of the NASA Challenge: New Transonic Wind Tunnel Test Section

...d tunnel test section

grabcad

https://grabcad.com/challenges/nasa-challenge-new-transonic-wind-tunnel-test-section

rendus plans

grabcad

free

Prototype Nasa

...prototype nasa

grabcad

nasa challenge: new transonic wind tunnel test section

grabcad

free

NASA Challenge: New Transonic Wind Tunnel Test Section

... the test section.

low cost, every elements already exists.

safety deflectors system to rapidly swap out models and test section.

grabcad

free

NASA Wind Tunnel Facility

...this design is the choice and improves operational and human factors in the wind tunnel facility and supports wind tunnel tests .

grabcad

free

NASA Challenge: New Transonic Wind Tunnel Test Section

...nasa challenge: new transonic wind tunnel test section

grabcad

https://www.linkedin.com/in/andrepereirabarros

Transonic

3d_export

$7

Transonic Wind Tunnel

...transonic wind tunnel

3dexport

transonic wind tunnel

3d_export

$60

dassault etendard iv p recon version

...recon version 3dexport the dassault étendard iv is a transonic carrier-borne strike fighter aircraft developed and manufactured by french...

3d_export

$60

hawker hunter

...hawker hunter 3dexport the hawker hunter is a transonic british jet-powered fighter aircraft that was developed by hawker...

3d_export

$60

saab 32 lansen

...lansen 3dexport the saab 32 lansen is a two-seat, transonic military aircraft designed and manufactured by saab from 1955...

3d_export

$60

north american f-86 sabre

...sabre 3dexport the north american f-86 sabre is a transonic jet fighter aircraft. produced by north american aviation, the...

3d_export

$60

dassault etendard iv m

...iv m 3dexport the dassault étendard iv is a transonic carrier-borne strike fighter aircraft developed and manufactured by french...

thingiverse

free

Transonic Blade

...arhammer 40k universe. used by sicarian ruststalkers of adeptus mechanicus.

lifesize model ~93 cm(36.6 in)

3 patterns available.

thingiverse

free

Sensor Holder for Transonic (dialysis) by pravdaz

...)

on the model in photo, the gap between the holes was not exact (corrected since). i screwed in a bit hard and a break occurred.

thingiverse

free

Warhammer40K Transonic Razor by ZaalriMakes

...he complete model so if you print it as one scaled down print they will be sliced and use a bit more filament than a solid model.

thingiverse

free

Startnummer Halterung Clamp for Start number Aero Seatstem by NoLuckN0Sk1ll

...your bike. i took the values by my fuji transonic from 2017. i printed a bit smaller with a...

Tunnel

turbosquid

$2

Tunnel

...

turbosquid

royalty free 3d model tunnel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1519777)

turbosquid

$30

Tunnel

...royalty free 3d model tunnel for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1376614)

turbosquid

free

Tunnel

...free 3d model tunnel for download as c4d, blend, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1678612)

turbosquid

$22

Tunnel

...y free 3d model tunnel for download as c4d, fbx, 3ds, and obj on turbosquid: 3d models for games, architecture, videos. (1558251)

turbosquid

$20

TUNNEL

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Tunnels

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

tunnel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

tunnel

...tunnel

3dexport

simple rendering of the scene file

3d_export

$65

tunnel

...tunnel

3dexport

simple rendering of the scene file

3d_export

$65

tunnel

...tunnel

3dexport

simple rendering of the scene file

Nasa

turbosquid

$49

Nasa Marscopter

...id

royalty free 3d model nasa marscopter for download as max on turbosquid: 3d models for games, architecture, videos. (1323349)

turbosquid

$500

NASA Crawler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Nasa Rocket

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

NASA Spool.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

US NASA 3D Model

...us nasa 3d model

3dexport

spaceship ship nasa battle blender

us nasa 3d model antonielfelain 96625 3dexport

turbosquid

$99

NASA MIT Wing

...oyalty free 3d model nasa mit wing for download as ma and max on turbosquid: 3d models for games, architecture, videos. (1510099)

turbosquid

$29

NASA Electronic Telescope

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Real flag NASA

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$41

NASA FAST Satellite 3D Model

...odel

3dexport

nasa space satellite earth aurora sensor panel solar orbit

nasa fast satellite 3d model visualmotion 20244 3dexport

3d_export

$20

22k photorealistic earth - nasa

...tures directly from nasa.<br>nasa solar system bundle coming soon!<br>contact info@teichmanmedia.eu for all iquiries.

Wind

design_connected

$4

Wind

...wind

designconnected

emmemobili wind dining tables computer generated 3d model. designed by chiara vaghi.

3d_ocean

$4

Wind Turbine

...n

and render setup turbine wind

wind turbine, modeled with cinema4d r13 , render setup and textured, custom logo for wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

3d_export

$40

wind turbine

...wind turbine

3dexport

wind turbine

Challenge

turbosquid

$120

Challenger 2 and challenger 2 TES

...e 3d model challenger 2 and challenger 2 tes for download as on turbosquid: 3d models for games, architecture, videos. (1430319)

3d_export

$59

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8

3d_export

$20

dodge challenger 1970

...dodge challenger 1970

3dexport

dodge challenger 1970

3d_export

$15

Dodge Challenger Hellcat

...dodge challenger hellcat

3dexport

dodge challenger hellcat

turbosquid

$80

challenger-2

...rbosquid

royalty free 3d model challenger-2 for download as on turbosquid: 3d models for games, architecture, videos. (1498848)

3d_export

$5

dodge challenger car

...dodge challenger car

3dexport

3d model dodge challenger!

turbosquid

$99

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1489358)

turbosquid

$49

Dodge Challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1698375)

turbosquid

$10

dodge challenger

...

royalty free 3d model dodge challenger for download as blend on turbosquid: 3d models for games, architecture, videos. (1405948)

3d_export

free

dodge challenger srt8

...dodge challenger srt8

3dexport

dodge challenger srt8 free model

Section

archibase_planet

free

Section

...section

archibase planet

storefront shelving rack

section 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Section

...section

archibase planet

post storefront stay

section 10 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Section

...section

archibase planet

sta post desk

section 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Section

...section

archibase planet

settee seat furniture

double section f1278 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Section

...section

archibase planet

settee seat furniture

double section f1277 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Section

...section

archibase planet

storefront glass case show-case

section 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Section

...section

archibase planet

showcase show-case glass case

section 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

sectional column

...sectional column

3dexport

sectional reinforced column 400x400 mm

turbosquid

free

Tree Section

...ction

turbosquid

free 3d model tree section for download as on turbosquid: 3d models for games, architecture, videos. (1263969)

turbosquid

$9

Sectional sofa

...uid

royalty free 3d model sectional sofa for download as max on turbosquid: 3d models for games, architecture, videos. (1638909)

Test

turbosquid

$99

test

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1251637)

turbosquid

$63

TEST

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1446233)

turbosquid

$1

test

...st

turbosquid

royalty free 3d model test for download as fbx on turbosquid: 3d models for games, architecture, videos. (1360941)

3d_export

free

johnny test

...johnny test

3dexport

johnny test 3d

turbosquid

$15

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

gripper test

...gripper test

3dexport

robot gripper test model

Design

3ddd

$1

LINE DESIGN (Doors Design)

...line design (doors design)

3ddd

дверь

modern doors design - line design concept

turbosquid

$5

designer

...alty free 3d model designer for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1422665)

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

$1

Bagno design

...bagno design

3ddd

bagno design , унитаз

санитария bagno design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3d_export

free

designer

..., trees and much more. the model has 3 types of parts: - 4 cells - 6 cells - 8 cells the *.max file contains 5 colored materials.

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

3d_export

$7

Crusher design

...crusher design

3dexport

crusher design