Thingiverse

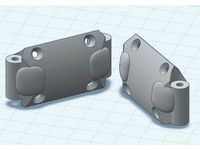

MyRCCar Dogbone Making Tool by dlb5

by Thingiverse

Last crawled date: 3 years, 1 month ago

MARK, CUT, DRILL, SAND and RUN with your 3d printed rc car!!!

Emmm... what?¿? with a piece of plastic?¿?

Ok, this is a tool to help you measure and mark, drill and hold your dogbones and pins while sanding them.

To use it, you should go as follows:

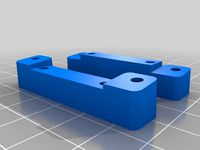

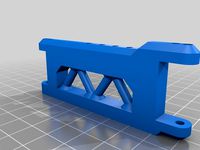

First of all would be to mark a 5mm piano wire to be cutted at the desired length. For this, use the convex surface to place the piano wire starting in the "0", then use the "ruler" to position your pen tip at the desired length or nearest one. You can do this always by hand with a ruler and a pen, but you should be able to rotate the piano wire over the convex surface while holding the pen in position to draw a circle around the wire. After that you can introduce it in the 5 mm hole to hold it with the 2 M3 screws in place to help you cut it. The selector button must be near the side to allow the 5mm wire to go through the tool.

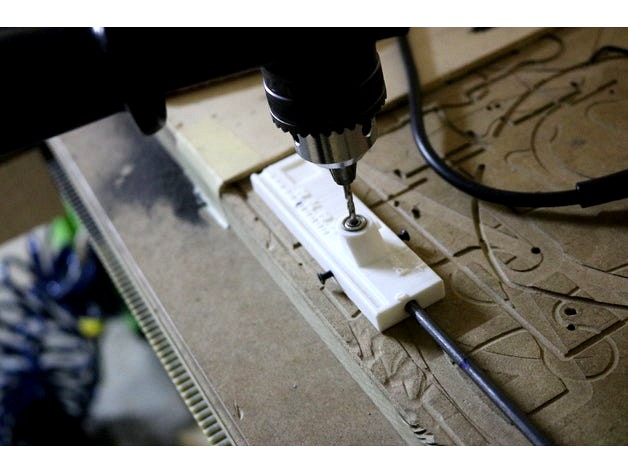

Second, after cutting the 5mm piano wire to the desired length (must be dogbone extreme to extreme distance) you must drill both sides to be able to introduce the pins. For this, you must put the selector button in the "drill position", introduce the cutted 5mm wire from the left side till touching the selector button and then fix its position with the 2 M3 screws.

Drilling with the 3mm bit over a 5mm piano wire wont be easy, and if you try it just holding a big drilling machine it will be really hard, also previously marking the place for the pin. So i think i have quite a nice solution: The tool and its two 3x10x4 bearings shoud help you perfectly align perpendicular and centered where the hole must be. The bearings can rotate with the drilling tool and maybe they shoud allow a little of perpendicular force deviation while drilling.

One time you have your dogbone with its holes, you must take the 3mm piano wire and mark and cut it twice for each dogbone with the provided 10mm and 12mm depth holes. Introduce the wire in the hole and mark arround it to cut it after that.

It's a good idea to sand the "heads" of th main piece trying to give it a half-spherical shape. For doing this you can put the select button in the sanding position and use the thumb button to avoid the dogbone to turn while you push it against a sanding cylinder. You can also introduce your cutted pins in the 3mm or 2mm holes to sand their "heads".

If you can't access 3x10x4 bearings maybe you can use 5x10x4 ones and the provided adaptor. The idea is that the walls of the adaptor or the bearing turns all together, so you shouldn't damage them much.

Needed Material:

2x 3x10x4 bearings or 2x 5x10x4 + adaptor

2x M3 Hex Socket Head 16mm or longer screws

Dremel like machine with cutting disk, sanding cylinder and if possible 3mm drill bit.

Protection Glasses

If you plan to use this in a MyRCCar config with printed FR diff vases, they should be compatible. A 1/8 center diff also uses 3mm pins but if you don't glue the pins and pray they could get shooted from the car. I made some covers for this 1/8 center diff vases so the pins shouldn't get shooted. If you are interested in this addons please tell me and i'll publish them.

As always, i encourage you to join the MyRCCar Group if you are really interested in the project.

Also, if you are using 02024+converter as center diff. You will need 2mm pins and holes for this side of the dogbone, so maybe you would use the 2mm adaptor for 5x10x4 bearings to use a 2mm drill bit. There is a special 2mm hole to hold the pin while sanding the extremes.

Do the drills over a "martir" table, so, one time you have drill the backpart of the thing you don't drill the floor or something undesired.

Emmm... what?¿? with a piece of plastic?¿?

Ok, this is a tool to help you measure and mark, drill and hold your dogbones and pins while sanding them.

To use it, you should go as follows:

First of all would be to mark a 5mm piano wire to be cutted at the desired length. For this, use the convex surface to place the piano wire starting in the "0", then use the "ruler" to position your pen tip at the desired length or nearest one. You can do this always by hand with a ruler and a pen, but you should be able to rotate the piano wire over the convex surface while holding the pen in position to draw a circle around the wire. After that you can introduce it in the 5 mm hole to hold it with the 2 M3 screws in place to help you cut it. The selector button must be near the side to allow the 5mm wire to go through the tool.

Second, after cutting the 5mm piano wire to the desired length (must be dogbone extreme to extreme distance) you must drill both sides to be able to introduce the pins. For this, you must put the selector button in the "drill position", introduce the cutted 5mm wire from the left side till touching the selector button and then fix its position with the 2 M3 screws.

Drilling with the 3mm bit over a 5mm piano wire wont be easy, and if you try it just holding a big drilling machine it will be really hard, also previously marking the place for the pin. So i think i have quite a nice solution: The tool and its two 3x10x4 bearings shoud help you perfectly align perpendicular and centered where the hole must be. The bearings can rotate with the drilling tool and maybe they shoud allow a little of perpendicular force deviation while drilling.

One time you have your dogbone with its holes, you must take the 3mm piano wire and mark and cut it twice for each dogbone with the provided 10mm and 12mm depth holes. Introduce the wire in the hole and mark arround it to cut it after that.

It's a good idea to sand the "heads" of th main piece trying to give it a half-spherical shape. For doing this you can put the select button in the sanding position and use the thumb button to avoid the dogbone to turn while you push it against a sanding cylinder. You can also introduce your cutted pins in the 3mm or 2mm holes to sand their "heads".

If you can't access 3x10x4 bearings maybe you can use 5x10x4 ones and the provided adaptor. The idea is that the walls of the adaptor or the bearing turns all together, so you shouldn't damage them much.

Needed Material:

2x 3x10x4 bearings or 2x 5x10x4 + adaptor

2x M3 Hex Socket Head 16mm or longer screws

Dremel like machine with cutting disk, sanding cylinder and if possible 3mm drill bit.

Protection Glasses

If you plan to use this in a MyRCCar config with printed FR diff vases, they should be compatible. A 1/8 center diff also uses 3mm pins but if you don't glue the pins and pray they could get shooted from the car. I made some covers for this 1/8 center diff vases so the pins shouldn't get shooted. If you are interested in this addons please tell me and i'll publish them.

As always, i encourage you to join the MyRCCar Group if you are really interested in the project.

Also, if you are using 02024+converter as center diff. You will need 2mm pins and holes for this side of the dogbone, so maybe you would use the 2mm adaptor for 5x10x4 bearings to use a 2mm drill bit. There is a special 2mm hole to hold the pin while sanding the extremes.

Do the drills over a "martir" table, so, one time you have drill the backpart of the thing you don't drill the floor or something undesired.

Similar models

thingiverse

free

Gameboy Zero XY Button Wells by Rittai3D

...the button wells to crack.

updated: rev 1: reduce height of wells 5mm->4mm and pin from 8mm->5.5mm.

pin interferes with pcb

thingiverse

free

EMAX 250 Nighthawk - Fatshark 600TVL plate - adjustable angle by Telnoi

...b the hole using a metal screw.

afterwards, use a nylon m3 screw to save weight and cut off or sand down the heads on both sides.

thingiverse

free

TPA3116 Bluetooth amplifier enclosure by isakh1

...de diameter to clean the upright pins of the bottom plate.

note 3: clean all the button pins for any irregularity on the outside

thingiverse

free

Self Centering Drill and Marking Guide by Bob68

... items up to 100mm or larger with two sets of spacers. the drill guide needs a washer of each size stuck in the hole for drilling

thingiverse

free

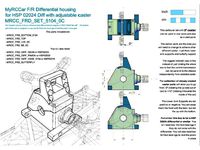

MyRCCar Central Differential Housing for HSP02024 Diff conversion, SST09304 and other 1/8 diffs. by dlb5

... it will fit in myrccar universal chassis. also please join the myrccar group to help improving myrccar, yourrccar i hope soon ;)

thingiverse

free

Laser Cut BB Bearing by stupidrob

...77 cal) for balls

red 'r's are just assembly markings

.100 holes can be used to pin pieces together with coat hanger wire

thingiverse

free

MyRCCar F/R Differential Housing for HSP 02024 Diff. with adjustable caster (OLD) by dlb5

...this housing for the hsp 02024 fr diff or similar becouse i think is one of the easiest to...

grabcad

free

Extruder Mk8 Nozzel

...e here.

you must print hollow with 1.5mm wall and drill the starting holes with a 2mm drill bit, the end holes are drilled at 3mm

thingiverse

free

Pizzaschieber | Laser Cut by grumpy_scrambler

...er

thingiverse

3mm plywood. front edge must be sanded. mesh holes are used to remove excess flour before placing it in the oven.

thingiverse

free

Glasses Case with Magnetic Closure by eclarkmeyer

... i used a #60 drill bit to ream the hinge pin bores. i customized mine by adding my initials to the lid at a depth of .001".

Dlb5

thingiverse

free

Adapter to fit NiKO2On's printed HSP 02024 gear into dlb5's MTC Diff by Saccco

...'s myrccar central differential housing for hsp02024 diff conversion, sst09304 and other 1/8 diffs. check remix links for it.

thingiverse

free

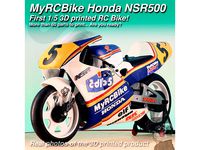

MyRCBike NSR500, First 1/5 3D Printed Hobby Level RC Bike: number 5 by dlb5

...st test ride of the v1 bike here:https://youtu.be/0ou5d9lsckc

if you want to find the full publication please come to see it here

thingiverse

free

MyRCCar 1/10 Buggy / Truggy LED Lights Holders (OLD) by dlb5

...ore space for shocks or due to caster.

i hope "you see the light" with this thing and start making your myrccar soon!!!

thingiverse

free

MyRCCar MTC Styled Lower Suspension Arm 769 (even easier to print) by Saccco

...769 (even easier to print) by saccco thingiverse thanks dlb5 made my own version of the lower arms. intended...

thingiverse

free

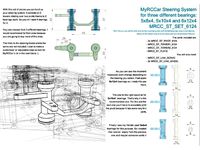

MyRCCar Steering System for three different bearings: 5x8x4, 5x10x4 and 6x12x4 by dlb5

... would be related more to the whole proyect please join the myrccar group. i hope i see you there soon building your own rc car:)

thingiverse

free

MyRCCar Center Diff. Remote Locking System by dlb5

... myrccar group and don't forget to introduce yourself! :)

note: the shared main body part is for a fixed blocked center diff.

thingiverse

free

Airbrush CNC Support and control with Marlin (OLD) by dlb5

...ease take a look at this video:video you can now also take a look to 5my first attemps airbrushing cmyk

will you give it a try?¿?

thingiverse

free

MyRCCar OBTS Chassis Building Instructions by dlb5

... shell, bumper, wing and lights

myrccar 1/10 buggy / truggy led lights holders. rc car light show!

myrccar 1/10 4th build testing

thingiverse

free

MyRCCar 1/10 Truggy rc car. With TITAN Shell, Bumper, Wing and Lights (OLD) by dlb5

...he car to put the shell lower or maybe accomodate some foam.

hope you like it and start soon making your own 3d printed rc car :)

Myrccar

thingiverse

free

Tarmo3 with myrccar truck body

...tarmo3 with myrccar truck body

thingiverse

i made a new front mount for the myrccar to connect to the tarm o3

thingiverse

free

Shock Spacer for MyRCCar by BotYoyo

...shock spacer for myrccar by botyoyo

thingiverse

you may need this shock spacer for some of the 1/10 shocks.

thingiverse

free

MyRCCar 1/10 12mm Wheel HEX (for HSP 188015 CVD) by BotYoyo

...12mm wheel hex (for hsp 188015 cvd) by botyoyo

thingiverse

this is a wheel hex remix for myrccar if you are using hsp 188015 cvd

thingiverse

free

MyRCCAR MTC Servo On Front RigAixs

...ing servo on the front bridge will keep the chasiss more stable when turning, so i give a try. and it works better as expected :)

thingiverse

free

MyRCCar LAS 0C and 6C for Ø3.0 x 56mm suspension rod by BotYoyo

...ension rod for myrccar. you may noticed the whole is not deep enough for the rod. this remix has deeper holes could fit 56mm rod.

thingiverse

free

MyRCCar MTC Improved Lower Suspension Arm 769 (easier to printer) by BotYoyo

...good. by not increase the weight, i just remix it to make it stronger and much easier to print. (maybe looks a little better? xd)

thingiverse

free

MyRCCar MTC Parts (Updated) by Saccco

...m.

for the complete chassis head on to dlb5's: myrccar 1/10 monster /crawler chassis with configurable 270 to 330mm wheelbase

thingiverse

free

MyRCCar OBTS Chassis Building Instructions by dlb5

... shell, bumper, wing and lights

myrccar 1/10 buggy / truggy led lights holders. rc car light show!

myrccar 1/10 4th build testing

thingiverse

free

Stronger Lower Arm Holder for MyRCCar MTC by BotYoyo

...ot which i broke it by a 0.3m height landing.

i just added some extra plastic to the weak spot. now the lower arm is rock solid!

thingiverse

free

MyRCCar MTC Styled Lower Suspension Arm 769 (even easier to print) by Saccco

...by saccco

thingiverse

thanks dlb5!

made my own version of the lower arms. intended to print without support.

hexa and m support.

Dogbone

thingiverse

free

Dogbone by Alvarocorgar

...dogbone by alvarocorgar

thingiverse

just a dogbone of 60mm and 40 centre to centre

thingiverse

free

USA1 Dogbone by pickled52

...usa1 dogbone by pickled52

thingiverse

usa1 dogbone

thingiverse

free

Type V Dogbone by Smatonis

...type v dogbone by smatonis

thingiverse

astm type v dogbone

thingiverse

free

Dogbone insulator

...dogbone insulator

thingiverse

have not tried it yet outside, suggest using a waterproof substrate

thingiverse

free

Instron dogbone mold by Mediated_Matter

... dogbone mold by mediated_matter

thingiverse

mold to make dogbone material samples for mechanical testing on the instron machine

thingiverse

free

Big dogbone and more parts by Alvarocorgar

...big dogbone and more parts by alvarocorgar

thingiverse

big dogbone 8mm diameter for 3mm axle

thingiverse

free

Earphone Dogbone by Vijay Menon by CopabX

...earphone dogbone by vijay menon by copabx

thingiverse

a dogbone to wrap extra earphone wire around.

thingiverse

free

ASTM D638-14 Type I Dogbone

...astm d638-14 type i dogbone

thingiverse

atsm d638-14 type i dogbone

thingiverse

free

Dogbone Cookie Cutter by pryan215

...dogbone cookie cutter by pryan215

thingiverse

for making homemade dog treats

thingiverse

free

Connector for wooden Traintracks / Dogbone by Orngrimm

...e

for a collegue, i quickly modeled and printed a bunch of "dogbone"-connectors for his childs playset from trainlabs.

Tool

turbosquid

$21

Tool box with tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archibase_planet

free

Tools

...tools

archibase planet

tools instruments implements

tools n070114 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_ocean

$12

Tools

...tools

3docean

hammer metal old screw tools wrench

maya

turbosquid

$6

Tool Cart / Tool Box

...

royalty free 3d model tool cart / tool box for download as on turbosquid: 3d models for games, architecture, videos. (1241859)

3d_ocean

$15

crimp tool

... tool copper cutter crimp crimp tool electrical electrical tools press tools pressing tool tools wire cutter

created in maya 2013

3d_ocean

$5

Tools

...tools

3docean

3d models paint tools work

3d,models,works,paint,art,create,working,

3d_export

free

tools

...tools

3dexport

coldsteel

turbosquid

$15

Tools

...turbosquid

royalty free 3d model tools for download as blend on turbosquid: 3d models for games, architecture, videos. (1331352)

3ddd

$1

bar tool

...bar tool

3ddd

барный

bar tool

turbosquid

$35

tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Making

3d_export

$5

make make planet

...make make planet

3dexport

turbosquid

$1

Make

...ke

turbosquid

royalty free 3d model make for download as obj on turbosquid: 3d models for games, architecture, videos. (1403181)

3ddd

free

make up

...make up

3ddd

косметика

makeup

turbosquid

$65

Make an interior

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Make Up Stand

...bosquid

royalty free 3d model make up stand for download as on turbosquid: 3d models for games, architecture, videos. (1542368)

turbosquid

$12

make up table

...quid

royalty free 3d model make up table for download as max on turbosquid: 3d models for games, architecture, videos. (1280789)

turbosquid

$1

Make up desk

...oyalty free 3d model make up desk for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1222023)

turbosquid

$1

Make up desk

...oyalty free 3d model make up desk for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1222007)

turbosquid

$29

Ammo making machine

...aking machine for download as max, unitypackage, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1572915)

turbosquid

$29

Making light Collection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.