Thingiverse

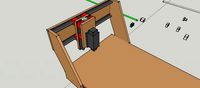

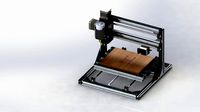

MultiBot CNC by reality_boy

by Thingiverse

Last crawled date: 3 years, 3 months ago

**** Note, there is a new version of this project.

https://www.thingiverse.com/thing:4645791

This is a mostly 3D printed CNC Router that was heavily inspired by Nikodem Bartnik's DIY Dremel CNC, however all parts are original designs by me.

https://www.instructables.com/id/DIY-3D-Printed-Dremel-CNC/

The goal was to make a low cost CNC machine that used only easily obtainable parts. I tried to make it modular as well so there is plenty of flexibility in the design.

There are many options for assembly:

The base can be made out of wood or you can use 8020 aluminum profiles. A wooden base would save a bit on the cost, if you have the tools to make it strong.

The Y axis can use single or dual smooth rods, dual rods will help reduce deflection and rotation in the X direction but it adds a bit of height and some more expense.

There are optional standoffs for the stepper motors that when combined with a longer lead screw and a pair of bearings can be used to tension the lead screw to add support and reduce whip along with helping reduce the load on the stepper motor bearings.

The size can easily be adjusted up or down by increasing or shrinking the length of the rods and lead screws. A larger build volume is always nice but there is a linear relationship between build volume and flex (smaller build volume is more solid).

You can use any controller and stepper drivers however I am using a low cost CNC shield on an Arduino UNO with GRBL v1.1j and TMC2208 drivers to reduce the noise. Going with DRV8825 or A4988 would probably better if your focus is on machining wood. I highly recommend fitting a cooling fan to the drivers, they can handle a lot more current with active cooling than without.

Materials:

2 600 mm x 12 mm smooth rods for y axis

2 400 mm x 12 mm smooth rods for the x axis

2 200 mm)x 12 mm smooth rods for the z axis

2 600 mm x 8 mm 8 mm lead (2 mm pitch, 4 starts) lead screw for the y axis

1 450 mm x 8 mm, 8 mm lead (2 mm pitch, 4 starts) lead screw for the x axis

1 200 mm x 8 mm, 8 mm lead (2 mm pitch, 4 starts) lead screw for the z axis

6 LM12LUU linear bearings

4 48 mm Nema 17 stepper motors, 2 A, 1.8 degree step

8 608ZZ skateboard bearings to help support the lead screws

1 UNO + CNC Shield + 4 TMC2208 drivers to control the stepper motors

1 24v 3A power supply for the CNC shield

1 500 W spindle, if you want to machine wood

26 M5 x 12 mm hex cap screws

100 M3 x 12 mm hex cap screws

Optional 8020 base frame:

2 600 mm 8020 aluminum extrusions

5 400 mm 8020 aluminum extrusions

56 M5 x 12 mm hex cap screws

56 M5 T-nuts

Misc optional:

4 8 mm to 5 mm aluminum couplers to attach the steppers to the lead screws. A model for a 3D printed clamp is provided as an alternative

4 8 mm anti backlash nuts to reduce play on the lead screws. The nuts that come with the lead screws work just fine, but this can tighten things up and reduce a small bit of backlash

2 600 mm x 12 mm smooth rods for y axis, this doubles the number of smooth rods on the y axis

2 LM12LUU linear bearings for the y axis to go with the smooth rods

Fusion 360 Files:

clamp 8MM https://a360.co/3j9rC2Q

control box https://a360.co/3j6oa92

corner bracket 25 mm https://a360.co/3laRGME

corner bracket 40 mm https://a360.co/32izrwj

coupler 5 mm to 8 mm https://a360.co/2YuzyUd

rail clamp https://a360.co/3hpC3if

spindle controller left https://a360.co/3hpgtKI

spindle controler right https://a360.co/2YrdMRt

x carriage https://a360.co/2EcwAgt

y carriage https://a360.co/3grzB9s

y clamp https://a360.co/3l5Tvue

servo standoff https://a360.co/3gjJbuZ

Y Dual Rod:

y carriage dual axis https://a360.co/2YveNHY

y clamp dual axis https://a360.co/3gw9kHn

Z Carriage Version 1:

drag knife holder https://a360.co/3hpgGO0

pen holder https://a360.co/31oy8fK

z carriage https://a360.co/2Qj6aMf

z carriage motor https://a360.co/3j9EaHq

Z Carriage Version 2:

pen holder v2 https://a360.co/34ssBGY

z carriage v2 https://a360.co/2YoQRpK

z carriage v2 motor clamp https://a360.co/2CSk2Ki

Printer settings

Print with PLA at 20% infill 0.4 mm line width, 0.2 mm layer height, 1.2 mm wall thickness and 1.0 mm top/bottom thickness. All parts are oriented for optimal printing already. And all are designed to print without a brim, raft, or support.

Change List

2020/08/24, re-exported the files to correct some issues.

2020/08/25, finalized v2 clamp system

https://www.thingiverse.com/thing:4645791

This is a mostly 3D printed CNC Router that was heavily inspired by Nikodem Bartnik's DIY Dremel CNC, however all parts are original designs by me.

https://www.instructables.com/id/DIY-3D-Printed-Dremel-CNC/

The goal was to make a low cost CNC machine that used only easily obtainable parts. I tried to make it modular as well so there is plenty of flexibility in the design.

There are many options for assembly:

The base can be made out of wood or you can use 8020 aluminum profiles. A wooden base would save a bit on the cost, if you have the tools to make it strong.

The Y axis can use single or dual smooth rods, dual rods will help reduce deflection and rotation in the X direction but it adds a bit of height and some more expense.

There are optional standoffs for the stepper motors that when combined with a longer lead screw and a pair of bearings can be used to tension the lead screw to add support and reduce whip along with helping reduce the load on the stepper motor bearings.

The size can easily be adjusted up or down by increasing or shrinking the length of the rods and lead screws. A larger build volume is always nice but there is a linear relationship between build volume and flex (smaller build volume is more solid).

You can use any controller and stepper drivers however I am using a low cost CNC shield on an Arduino UNO with GRBL v1.1j and TMC2208 drivers to reduce the noise. Going with DRV8825 or A4988 would probably better if your focus is on machining wood. I highly recommend fitting a cooling fan to the drivers, they can handle a lot more current with active cooling than without.

Materials:

2 600 mm x 12 mm smooth rods for y axis

2 400 mm x 12 mm smooth rods for the x axis

2 200 mm)x 12 mm smooth rods for the z axis

2 600 mm x 8 mm 8 mm lead (2 mm pitch, 4 starts) lead screw for the y axis

1 450 mm x 8 mm, 8 mm lead (2 mm pitch, 4 starts) lead screw for the x axis

1 200 mm x 8 mm, 8 mm lead (2 mm pitch, 4 starts) lead screw for the z axis

6 LM12LUU linear bearings

4 48 mm Nema 17 stepper motors, 2 A, 1.8 degree step

8 608ZZ skateboard bearings to help support the lead screws

1 UNO + CNC Shield + 4 TMC2208 drivers to control the stepper motors

1 24v 3A power supply for the CNC shield

1 500 W spindle, if you want to machine wood

26 M5 x 12 mm hex cap screws

100 M3 x 12 mm hex cap screws

Optional 8020 base frame:

2 600 mm 8020 aluminum extrusions

5 400 mm 8020 aluminum extrusions

56 M5 x 12 mm hex cap screws

56 M5 T-nuts

Misc optional:

4 8 mm to 5 mm aluminum couplers to attach the steppers to the lead screws. A model for a 3D printed clamp is provided as an alternative

4 8 mm anti backlash nuts to reduce play on the lead screws. The nuts that come with the lead screws work just fine, but this can tighten things up and reduce a small bit of backlash

2 600 mm x 12 mm smooth rods for y axis, this doubles the number of smooth rods on the y axis

2 LM12LUU linear bearings for the y axis to go with the smooth rods

Fusion 360 Files:

clamp 8MM https://a360.co/3j9rC2Q

control box https://a360.co/3j6oa92

corner bracket 25 mm https://a360.co/3laRGME

corner bracket 40 mm https://a360.co/32izrwj

coupler 5 mm to 8 mm https://a360.co/2YuzyUd

rail clamp https://a360.co/3hpC3if

spindle controller left https://a360.co/3hpgtKI

spindle controler right https://a360.co/2YrdMRt

x carriage https://a360.co/2EcwAgt

y carriage https://a360.co/3grzB9s

y clamp https://a360.co/3l5Tvue

servo standoff https://a360.co/3gjJbuZ

Y Dual Rod:

y carriage dual axis https://a360.co/2YveNHY

y clamp dual axis https://a360.co/3gw9kHn

Z Carriage Version 1:

drag knife holder https://a360.co/3hpgGO0

pen holder https://a360.co/31oy8fK

z carriage https://a360.co/2Qj6aMf

z carriage motor https://a360.co/3j9EaHq

Z Carriage Version 2:

pen holder v2 https://a360.co/34ssBGY

z carriage v2 https://a360.co/2YoQRpK

z carriage v2 motor clamp https://a360.co/2CSk2Ki

Printer settings

Print with PLA at 20% infill 0.4 mm line width, 0.2 mm layer height, 1.2 mm wall thickness and 1.0 mm top/bottom thickness. All parts are oriented for optimal printing already. And all are designed to print without a brim, raft, or support.

Change List

2020/08/24, re-exported the files to correct some issues.

2020/08/25, finalized v2 clamp system

Similar models

thingiverse

free

CNC 1610, 2418, 3018 AXIS X-Z

...ssages or in comments

if you have any questions

write private messages or in comments

if you want to thank me

4276 4000 8861 6777

thingiverse

free

Anet A8 Upgrade motor and top plate on Z axis ... by Robchiks

...t - http://s.click.aliexpress.com/e/hasldbs

x shaft carriage for "titan aero" - http://s.click.aliexpress.com/e/rukpv48

thingiverse

free

MendelMax Z axis mounts and clamp for a 10mm smooth rod, 1/4 lead screw by LT1Pat

...z axis mount to accomodate a 10mm smooth rod and a 1/4" lead screw

the bearing bore has been modified to fit a r4zz bearing.

thingiverse

free

CNC Machine Parts by jszewczyk

...earings mount for axis x and y

6800 zz bearings 10x19x5mm mount for axis z and 10mm rods

608 2rs bearings 8x22x7 dumper for a bed

thingiverse

free

CNC Z-Axis

...4 x nylon or brass spacer 20 mm

it is really easy to assemble this item!

this is for: https://www.thingiverse.com/thing:3904668

grabcad

free

CNC Router for PCB

...me 12 mm with scs12uu bearing in x,y axis and hard chorme 12 mm with scs12uu bearing in z axis as linear guide

i use acrylic 8 mm

3dwarehouse

free

3D Printer Detailed Design

...gn

3dwarehouse

a design for a 3d printer. uses belt-and-pinion for x and y axes, dual lead screws and stepper motors for z axis.

3dwarehouse

free

3D Printer Detailed Design

...gn

3dwarehouse

a design for a 3d printer. uses belt-and-pinion for x and y axes, dual lead screws and stepper motors for z axis.

thingiverse

free

Prusa i3 Mk3 Bearing Z Axis Top Mount by jlnevill

...he lead screws then check that the z axis stepper motor mounts are square to the frame.

this design requires two 608 bearings.

thingiverse

free

Z Axis Lead screw (trapezoidal thread) parts for Prusa Steel by oloand

... files where the holes for the smooth rods is 12.1 mm. normally, you shouldn't use these. the new files has the suffix _12mm.

Multibot

thingiverse

free

MultiBot CNC v2 by reality_boy

... machine definition

multibot.tools, fusion 360 tool library, contains my own tools, use as a starting point for your own library.

thingiverse

free

Dusty the dust separator by reality_boy

...can read more on this on my hackaday project page:https://hackaday.io/project/176110-multibotcnc-v2/log/187263-rise-of-dusty-20 improvements chris notap has an idea for cutting the...

Reality

turbosquid

$1

Sword of reality

...d

royalty free 3d model sword of reality for download as c4d on turbosquid: 3d models for games, architecture, videos. (1306992)

turbosquid

$35

REALITY SHOW STUDIO

...royalty free 3d model reality show studio for download as obj on turbosquid: 3d models for games, architecture, videos. (1157398)

turbosquid

$10

Decorative Elements - Reality

... decorative elements - reality for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1666803)

turbosquid

$10

Virtual Reality Booth

... virtual reality booth for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1408776)

turbosquid

$50

Virtual Reality Matrix Plug

...ee 3d model virtual reality matrix plug for download as blend on turbosquid: 3d models for games, architecture, videos. (1467014)

turbosquid

$2

Cardboard Virtual Reality Glases

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Virtual Reality Headset

...bosquid

royalty free 3d model vr for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1207905)

3d_export

$30

9d virtual reality chair-vr

...9d virtual reality chair-vr

3dexport

9d game

3d_export

$20

Reality Dream Home 3D Model

...p 3d architecture design exterior lumion masion dream home cheap different

reality dream home 3d model firstliight 87425 3dexport

turbosquid

$30

Toilet - Bahtroom Design - Reality -3Ds Max - Wet

...m design - reality -3ds max - wet for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1666820)

Boy

archibase_planet

free

Boy

...boy

archibase planet

nan boy people

boy - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy people

boy 1 n230614 - 3d model (*.gsm+*.3ds) for 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

man boy guy

boy n080409 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy man people

boy stand n240414 - 3d model (*.gsm+*.3ds) for 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy man people

boy 2 n230614 - 3d model (*.gsm+*.3ds) for 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy man people

boy sitting n260814 - 3d model (*.gsm+*.3ds) for 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy man teenager person youth

boy n110512 - 3d model (*.gsm+*.3ds) for 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy man-child people

boy n311013 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy man people

boy sit n240414 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Boy

...boy

archibase planet

boy baby child people

boy sitting n211214 - 3d model (*.gsm+*.3ds) for 3d visualization.

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)