GrabCAD

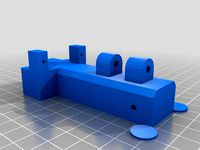

MuFly 6 Tricopter

by GrabCAD

Last crawled date: 1 year, 10 months ago

My Independent Study and capstone design project at UMass Dec, 2014.

This is the 3d model of the Tri-copter I build using a 3d printed mold to fabricate an organically optimized carbon fiber body.

This is the journey of evolution of design, using by rethinking the fundamental building blocks of thought, finding the geometric equilibrium of structures and building fundamental 3d curve structures inspired by biology, technology, advanced materials (carbon fiber) and advanced fabrication techniques like 3d printing, these are then optimized by iterative FEA (Finite Element Analysis) and the understanding of stress flow distribution optimization.

The body is composed of 4 pieces, the Endo-shell (Inner Shell) & the 3 Limbs, which are designed by taking inspiration from biological joints with ligament and cartilage. The 'Ball' in this case is the shell's limb stub as the pivot point, the cartilage is made of shock dampening foam (Poron) under the indented pad region and the ligament is made of quick tie shoe laces.

During impact the arms disengage, as the foam goes into compression absorbing the immediate shock. The rest of the kinetic energy goes in loosening the bungee friction nut (quick tie Lace) which converts the energy into heat. This way the limbs are isolated from the most massive part of the body, i.e. the Endo-shell containing the huge battery pack and 70% of the total weight and the kinetic energy of the individual limb is absorbed by the dampening system.

Along with impact the dampening system also isolates the body i.e. the flight control board and the camera) from motor vibration.

The props are 9443 carbon props from hobby power, they auto align from the centrifugal force and fold during impact.

Thus all one has to do is zip up the ties and your ready to fly!

This is the 3d model of the Tri-copter I build using a 3d printed mold to fabricate an organically optimized carbon fiber body.

This is the journey of evolution of design, using by rethinking the fundamental building blocks of thought, finding the geometric equilibrium of structures and building fundamental 3d curve structures inspired by biology, technology, advanced materials (carbon fiber) and advanced fabrication techniques like 3d printing, these are then optimized by iterative FEA (Finite Element Analysis) and the understanding of stress flow distribution optimization.

The body is composed of 4 pieces, the Endo-shell (Inner Shell) & the 3 Limbs, which are designed by taking inspiration from biological joints with ligament and cartilage. The 'Ball' in this case is the shell's limb stub as the pivot point, the cartilage is made of shock dampening foam (Poron) under the indented pad region and the ligament is made of quick tie shoe laces.

During impact the arms disengage, as the foam goes into compression absorbing the immediate shock. The rest of the kinetic energy goes in loosening the bungee friction nut (quick tie Lace) which converts the energy into heat. This way the limbs are isolated from the most massive part of the body, i.e. the Endo-shell containing the huge battery pack and 70% of the total weight and the kinetic energy of the individual limb is absorbed by the dampening system.

Along with impact the dampening system also isolates the body i.e. the flight control board and the camera) from motor vibration.

The props are 9443 carbon props from hobby power, they auto align from the centrifugal force and fold during impact.

Thus all one has to do is zip up the ties and your ready to fly!

Similar models

grabcad

free

Shock Absorber

...shock absorber

grabcad

a mechanical device designed to dampen shock caused by kinetic energy

grabcad

free

A Shock Absorber

...ubsequently dissipated. the majority of shock absorbers are a type of dashpot (a damper that resists motion by viscous friction).

grabcad

free

Shock Absorber Assembly

...signed to absorb and damp shock impulses. it does this by converting the kinetic energy of the shock into another form of energy.

grabcad

free

Shock Absorber

...gned to absorb and damp shock impulses. it does this by converting the kinetic energy of the shock into another form of energy...

grabcad

free

Shock Absorber (Fusion 360+Inventor files)

...nsion movement into heat by reducing and slowing down the magnitude of vibrations. it is then dissipated through hydraulic fluid.

grabcad

free

SHOCK ABSORBER

...the kinetic energy of the shock into another form of energy which is then dissipated. most shock absorbers are a form of dashpot.

grabcad

free

SHOCK ABSORBER

...it does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated.

grabcad

free

Shock Absorber

... the kinetic energy of the shock into another form of energy which is then dissipated. most shock absorbers are a form of dashpot

grabcad

free

Shock Absorber

...it does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated.

grabcad

free

Shock Absorber

...it does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated.

Mufly

grabcad

free

MuFly Tricopter

...s a cad model of a tricopter uav drone for personal use and gis map data retrieval. i designed it for a school sponsored project.

grabcad

free

MuFly 3d Print Optimization Project

...evolving project optimizing the concept of my previous mufly 6 uav body for 3d printing, that i am collaborating with e.t. on ...

Tricopter

3d_export

$5

Moon copter 3D Model

...model 3dexport spaceship mooncopter tricopter aircraft drone helicopter robot rctricopter moon copter 3d model manu.kvs16051 93671...

3dbaza

$7

Tricopter (346642)

...tricopter (346642)

3dbaza

tricopter 3d model

thingiverse

free

tricopter parts by miketulen123

...tricopter parts by miketulen123

thingiverse

tricopter parts

thingiverse

free

Tricopter by outcastrc

...tricopter by outcastrc

thingiverse

tricopter design

uses 1/2" wood spars, and assorted 3mm hardware.

thingiverse

free

Delta Tricopter by zdar

...delta tricopter by zdar

thingiverse

a delta style tricopter.

thingiverse

free

Tricopter Prototype by brentd

...tricopter prototype by brentd

thingiverse

mini tricopter prototype

thingiverse

free

Tricopter Yaw by 2Mars

...mm rods, suitable as a tail joint.

(based on tricopter rcexplorer.se http://rcexplorer.se/projects/2011/09/the-tricopter-v2-5/)

thingiverse

free

tricopter base by gpatel522

...tricopter base by gpatel522

thingiverse

tricopter base for anyone to use. no commercial use.

thingiverse

free

Tricopter V2.5 by Crazyinventor

...tricopter v2.5 by crazyinventor

thingiverse

these are the printed parts that go to my tricopter v2.5.

thingiverse

free

Tricopter Hook by Lowfiero

...tricopter hook by lowfiero

thingiverse

just a quick wall hook for my batbone tricopter.

6

3d_export

$18

tulip 6

...tulip 6

3dexport

tulip 6

3d_export

$5

hinge 6

...hinge 6

3dexport

hinge 6

3ddd

$1

MASIERO / FLASHWOOD STL 6 + 6

...6

3ddd

masiero

торшер flashwood stl 6 + 6 фабрики masiero

http://www.masierogroup.com/c87_697/it/flashwood%20stl%206%20+%206.ashx

turbosquid

$110

Atmos Cannon 2000 6*6

...yalty free 3d model atmos cannon 2000 6*6 for download as skp on turbosquid: 3d models for games, architecture, videos. (1528591)

turbosquid

$1

ae 6 6 electric locomotive

... free 3d model ae 6 6 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707537)

turbosquid

$39

A-6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

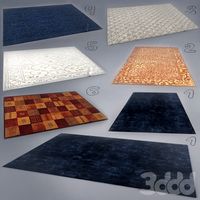

6 ковров

...6 ковров

3ddd

ковры , ковер

6 ковров

turbosquid

$12

Calligraphic Digit 6 Number 6

...hic digit 6 number 6 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389336)

turbosquid

$19

Case For Phone 6 Girl 6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Iphone 6 & 6 Plus All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.