Thingiverse

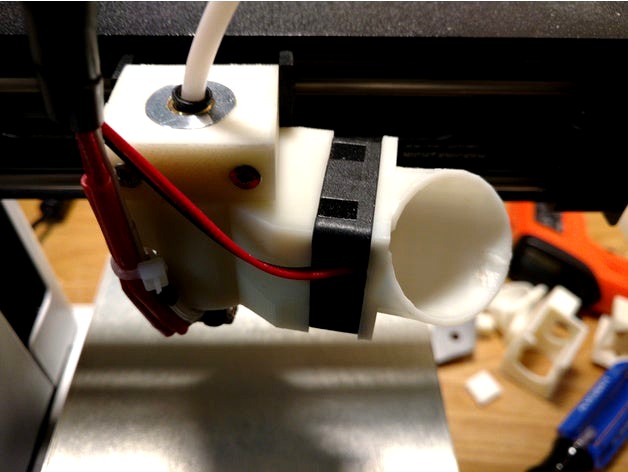

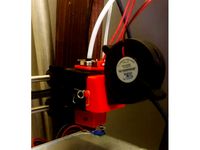

MPSM Side-Port V6 Hot-End Mount for ABS by DtEW

by Thingiverse

Last crawled date: 3 years ago

This is a special-application^ mount and fan duct set to adapt an E3D V6-style hot-end^^ for use on a Monoprice Select Mini/Malyan M200 printer.

^ See "THE PROBLEM" below.

^^ The design of this mount was based on a RepRap Champion V6 hot-end as the reference, which I understand to be a good functional clone of the E3D V6 hot-end. It is likely that it's also a dimensional clone, esp. for the parts that matter to a mount (i.e. heat-sink). If you have an genuine E3D V6 hot-end and a pair of quality calipers, message me and we can trade notes on dimensions.

THE PROBLEM

The MP Select Mini/Malyan M200 is a compact, unenclosed, single-gantry-style printer whose electronics is integrated into the main body under the build area. In the absence of an enclosure, it is particularly hard for it to print ABS without warping. At the same time, typical enclosures that people make for this printer puts the electronics in the warm air, which then creates potential issues with heat dissipation.

As easy as it is to focus on the lack-of/need-for an enclosure to maintain the sort of build area temperature associated with successful ABS prints, the real problem is that of heat loss by the printed part. Observation suggests that the stock fan/heat-sink for the hot-end contributes significantly to that heat loss. Even with a modified fan shroud that deletes (or nullifies) the print cooling duct on a bone-stock setup, the airflow that goes into the stock heat-sink can only exit above (harmlessly) and below (right into the print area after it goes around the heater core). It does both. The constant flow blowing out of the bottom of the stock heat-sink exacerbates the cooling rate of the topmost layers, which of course then results in lifting and warping.

There is little we can do about the air exit paths of the stock heat-sink (short of blocking-off one end, which would be inadvisable), as it is part of a proprietary hot-end. The only saving grace is that the stock 30mm fan does not generate a great deal of airflow, but is mostly sufficient at staving off the heat-creep of the stock hot-end.

But... what about a different hot-end/heat-sink? Can the heat-sink exhaust (and intake, for that matter) be managed better in order to reduce/eliminate constant airflow blowing at or in-the-vicinity of the print?

I think so. Enter the E3D V6 hot-end (and clones).

THE DESIGN GOALS

G1. Maximize the cooling efficiency of the heat-sink without resorting to a bigger fan.

G2. Reduction (or elimination) of constant airflow to/from the build area as a consequence of actively cooling the heat-sink.

G3. Minimize the offset from the stock nozzle position to maintain the maximum possible build area, without resorting to unusual mounting solutions/tricks.

THE DESIGN SOLUTIONS

S1. A straight-through airflow path through the heat-sink made possible by an innovative side-port design.

S2. Active cooling of the heat-sink is achieved by a pull-fan configuration, with a nozzle-directed exhaust.

S3. Y-axis offset (the only axis that must be shifted given the greater depth of the V6 hot-end) is minimized, with only +0.4mm (stock nozzle diameter) of wall thickness separating the heat-sink cavity from the X-axis carriage.

THE CAVEATS

C1. The mount isn't magic, and won't solve all your warping problems. But does work better. Hell, I like it because it's mine. :)

C2. The exhaust-end of a fan is noisier than the intake-end. That's the open end that more-or-less faces you. If you feel that the stock fan is noisy... then this isn't going to make it better. Just the opposite.

C3. I have made no provisions for attaching a print cooling fan and duct. Note that I do plan on designing an appropriate one in the near future. That said, I will make no promises, which is why I did not even include an attachment boss in the current design (and when I do, it will be on the bracket, so the extra print should be minimal). You should not utilize this mount unless your primary printing task is ABS or materials prone to warping.

PRINTING NOTES

Any hot-end mount needs to be printed in a higher-melting-temperature material, such as ABS or PETG. This one is no different.

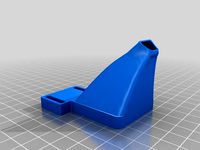

The parts were designed to be printed in the orientations provided. You will probably benefit from full supports, and brims might be necessary for ABS. In ABS, I have found that the mount body benefits from scaling-up the X-axis by 2% in the slicer, while leaving the other axes alone. Neither the bracket nor nozzle requires scaling in ABS, and hence can be printed together. Otherwise, the dimensions of the design are accurate so that it can be printed in other materials that might not require any scaling, or different scaling (PETG, nylon?).

You will need 2x counter-sunk 3mm x 25mm bolts, and 2x 3mm nuts. Metric, obviously. Hex or Phillips head, your choice.

You will need 2 of the square nuts that are part of the Monoprice Select Mini hot-end and heat-sink assembly (there will be 4 from the disassembly for you to utilize).

The counter-sunk holes on the bracket can benefit from a little reaming with a countersink bit. But if you don't, it'll still be okay.

^ See "THE PROBLEM" below.

^^ The design of this mount was based on a RepRap Champion V6 hot-end as the reference, which I understand to be a good functional clone of the E3D V6 hot-end. It is likely that it's also a dimensional clone, esp. for the parts that matter to a mount (i.e. heat-sink). If you have an genuine E3D V6 hot-end and a pair of quality calipers, message me and we can trade notes on dimensions.

THE PROBLEM

The MP Select Mini/Malyan M200 is a compact, unenclosed, single-gantry-style printer whose electronics is integrated into the main body under the build area. In the absence of an enclosure, it is particularly hard for it to print ABS without warping. At the same time, typical enclosures that people make for this printer puts the electronics in the warm air, which then creates potential issues with heat dissipation.

As easy as it is to focus on the lack-of/need-for an enclosure to maintain the sort of build area temperature associated with successful ABS prints, the real problem is that of heat loss by the printed part. Observation suggests that the stock fan/heat-sink for the hot-end contributes significantly to that heat loss. Even with a modified fan shroud that deletes (or nullifies) the print cooling duct on a bone-stock setup, the airflow that goes into the stock heat-sink can only exit above (harmlessly) and below (right into the print area after it goes around the heater core). It does both. The constant flow blowing out of the bottom of the stock heat-sink exacerbates the cooling rate of the topmost layers, which of course then results in lifting and warping.

There is little we can do about the air exit paths of the stock heat-sink (short of blocking-off one end, which would be inadvisable), as it is part of a proprietary hot-end. The only saving grace is that the stock 30mm fan does not generate a great deal of airflow, but is mostly sufficient at staving off the heat-creep of the stock hot-end.

But... what about a different hot-end/heat-sink? Can the heat-sink exhaust (and intake, for that matter) be managed better in order to reduce/eliminate constant airflow blowing at or in-the-vicinity of the print?

I think so. Enter the E3D V6 hot-end (and clones).

THE DESIGN GOALS

G1. Maximize the cooling efficiency of the heat-sink without resorting to a bigger fan.

G2. Reduction (or elimination) of constant airflow to/from the build area as a consequence of actively cooling the heat-sink.

G3. Minimize the offset from the stock nozzle position to maintain the maximum possible build area, without resorting to unusual mounting solutions/tricks.

THE DESIGN SOLUTIONS

S1. A straight-through airflow path through the heat-sink made possible by an innovative side-port design.

S2. Active cooling of the heat-sink is achieved by a pull-fan configuration, with a nozzle-directed exhaust.

S3. Y-axis offset (the only axis that must be shifted given the greater depth of the V6 hot-end) is minimized, with only +0.4mm (stock nozzle diameter) of wall thickness separating the heat-sink cavity from the X-axis carriage.

THE CAVEATS

C1. The mount isn't magic, and won't solve all your warping problems. But does work better. Hell, I like it because it's mine. :)

C2. The exhaust-end of a fan is noisier than the intake-end. That's the open end that more-or-less faces you. If you feel that the stock fan is noisy... then this isn't going to make it better. Just the opposite.

C3. I have made no provisions for attaching a print cooling fan and duct. Note that I do plan on designing an appropriate one in the near future. That said, I will make no promises, which is why I did not even include an attachment boss in the current design (and when I do, it will be on the bracket, so the extra print should be minimal). You should not utilize this mount unless your primary printing task is ABS or materials prone to warping.

PRINTING NOTES

Any hot-end mount needs to be printed in a higher-melting-temperature material, such as ABS or PETG. This one is no different.

The parts were designed to be printed in the orientations provided. You will probably benefit from full supports, and brims might be necessary for ABS. In ABS, I have found that the mount body benefits from scaling-up the X-axis by 2% in the slicer, while leaving the other axes alone. Neither the bracket nor nozzle requires scaling in ABS, and hence can be printed together. Otherwise, the dimensions of the design are accurate so that it can be printed in other materials that might not require any scaling, or different scaling (PETG, nylon?).

You will need 2x counter-sunk 3mm x 25mm bolts, and 2x 3mm nuts. Metric, obviously. Hex or Phillips head, your choice.

You will need 2 of the square nuts that are part of the Monoprice Select Mini hot-end and heat-sink assembly (there will be 4 from the disassembly for you to utilize).

The counter-sunk holes on the bracket can benefit from a little reaming with a countersink bit. But if you don't, it'll still be okay.

Similar models

grabcad

free

E3D V6 Hot End, Heat Sink Fan Mounting Clip

...e fdm 3d printer components can be downloaded here:

https://grabcad.com/library/fused-deposition-modeling-3d-printer-components-2

thingiverse

free

Monoprice Select Mini V2. Dual Fan Mount. by lowfat

...-cooling-5015-fan-50mm-dc12v-1 by aleksandr ivanov. the 30mm fan model is https://grabcad.com/library/30mm-fan-1 by mitch pricer.

thingiverse

free

All-in-one E3D v6 Fan & Part Cooling Shroud by Justpass

...from the base, the air will blow and cool your nozzle instead!

will work great using standard flathead e3d nozzle or mk8 nozzles.

thingiverse

free

All-in-one E3D v6 Fan & Part Cooling Shroud V2 by Justpass

...from the base, the air will blow and cool your nozzle instead!

will work great using standard flathead e3d nozzle or mk8 nozzles.

thingiverse

free

Lulzbot TAZ Extended / Adjustable Nozzle Fan Duct for e3D / hexagon hot ends by SuperSolid_3D

...re you can slide it up and down for adjustment, and doesn't require heat-set insert nuts for mounting the fan with m3 screws.

thingiverse

free

water cooled heat sink by chiranjeevi

...eat break and nozzle and heater block as per e3d dimensions. this was done because i use the e3d v6 and didnot want to change it.

thingiverse

free

Folger Tech Kossel with E3D V6 Hot End - Part Cooling Fan Duct by Scotty-G

...ted out of abs in vertical orientation (.2mm orientation & 1mm thick walls) so supports did not fill air pathway inside duct.

thingiverse

free

Cooling duct for Sunhokey Prusa i3 with E3D-V6 Hot End by twforeman

...unt to move the ring lower down.

modified from http://www.thingiverse.com/thing:714939 to mount to nozzle plate and fit e3d-v6.

thingiverse

free

e3d v6 lulzbot fans by D125

...ooling fans designed by me and the extruder fan was designed by loco. use the stock heat inserts and screws on the cooling ducts.

thingiverse

free

Huxley E3D V6 Hot End Mount with Airflow Fix by henriksod

...ems with airflow, making my hot-end cooling too inefficient for proper functionality.

made in inventor 2016, .ipt files attached.

Dtew

thingiverse

free

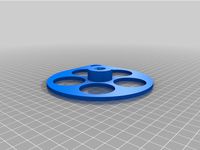

1" x 16' climbing webbing spool by DtEW

...erse

this is a spool for the storage/organization of 1" nylon climbing webbing. it will accommodate roughly 16 feet of it.

thingiverse

free

Conical burr interface for Nuvita manual coffee grinder by DtEW

...cement (left side of picture, printed in natural abs) was designed using all the available space within the ceramic conical burr.

thingiverse

free

PLA Cooling Duct for the Hot end Mount for ABS by DtEW by VA3TNE

...right shape.

and, now i can control the cooling fan separately from the e3d cooling fan using embedded g-code commands.

73

va3tne

thingiverse

free

Flexible filament guide for MP Select Mini w/Anycubic Mk8 extruder modified w/OEM gear & flat bearing by DtEW

...earing substituted with a plain, non-grooved 4x10x4mm miniature bearing.

requires slightly longer m3 bolts. 25mm does the trick.

thingiverse

free

Parametric Webbing Spool by Julowe

...some perhaps to your/the model's detriment. inspiration taken from dtew#39;s static webbing spool because it looked great, but the...

thingiverse

free

Flexible filament guide (w/ PTFE Bowden Tubing) for MP Select Mini w/Anycubic Mk8 extruder modified w/OEM gear & flat bearing by rumpstrudel

...coupler all the way to the idler/extruder gear. thanks dtew for the guide i used it to print the...

Mpsm

thingiverse

free

MPSM Mosquito 2GT

... mosquito 2gt

thingiverse

my adaptation of the mosquito to the mpsm.

printed in petg

1/12/20 added 4010 blower mounting and duct

thingiverse

free

MPSM E3D mount by tekhertz

...mpsm e3d mount by tekhertz

thingiverse

just another e3d mount, fits into original carriage on mpsm v1

thingiverse

free

Best MPSM Post Caitlin by Dr_Joel

...best mpsm post caitlin by dr_joel

thingiverse

for most charming post on the facebook mpsm group.

thingiverse

free

Santa and Sleigh Spinner for MPSM by itsonlym3

...santa and sleigh spinner for mpsm by itsonlym3

thingiverse

topper/spinner for the mpsm and just in time for christmas. ;-)

thingiverse

free

MPSM Vent and single fan by Quadfather818

...and single fan by quadfather818

thingiverse

moved fan from back of mpsm-v2 for heat bed rewire and added to passive cooling vent

thingiverse

free

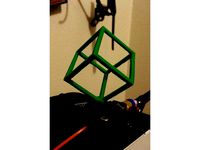

Cube Spinner MPSM by oxamo

...cube spinner mpsm by oxamo

thingiverse

a spinner for the extruder wheel.

thingiverse

free

MPSM Bowden Clip by Rico_3D

...mpsm bowden clip by rico_3d

thingiverse

for hot end and extruder

thingiverse

free

MPSM Bed Rewiring Parts

...mpsm bed rewiring parts

thingiverse

3d printer parts.

thingiverse

free

Gyro Spinner For MPSM by itsonlym3

...gyro spinner for mpsm by itsonlym3

thingiverse

topper/spinner for your extruder.https://youtu.be/swbjup3tcym

thingiverse

free

MPSM Blower - no part duct by jbkuma

...sm that fits stock carriage. no part cooler. i use a separate $9 clip fan for part cooling that is dead silent and works great.

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Hot

3d_export

$12

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

$9

Hot Tub

...hot tub

3dexport

hot tub - 4k png/tif textures

3d_export

free

hot chili

...hot chili

3dexport

hot chili<br>for fruits and getegables collection

3d_export

$5

hot air balloon

...hot air balloon

3dexport

hot air balloon

3d_export

free

Hot dog shop

...hot dog shop

3dexport

hot dog shop

turbosquid

$90

hot venue

...rbosquid

royalty free 3d model hot venue for download as fbx on turbosquid: 3d models for games, architecture, videos. (1336949)

turbosquid

$20

Hot Rod

...

turbosquid

royalty free 3d model hot rod for download as ma on turbosquid: 3d models for games, architecture, videos. (1351690)

turbosquid

$1

Hot dog

...turbosquid

royalty free 3d model hot dog for download as max on turbosquid: 3d models for games, architecture, videos. (1450961)

3d_ocean

$6

Hot-air Balloon

...alloon model created with 3ds max 2010 3 types of file format for you choose(.max .fbx .obj ) high detailed model without texture

3ddd

$1

Hot Rod by Baghera

...hot rod by baghera

3ddd

baghera , машинка

hot rod by baghera.

Port

3ddd

$1

lualdi porte

...lualdi porte

3ddd

lualdi porte , дверь

двери фабрики lualdi porte

turbosquid

free

port

...

turbosquid

royalty free 3d model port for download as blend on turbosquid: 3d models for games, architecture, videos. (1447959)

3d_export

$65

port

...port

3dexport

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

3d_export

$65

port

...port

3dexport

simple rendering of the scene file

Abs

3ddd

free

Preciosa AB

...preciosa ab

3ddd

preciosa

lustra preciosa ab s 12 svetilnikami

turbosquid

$8

abe oodworld

...squid

royalty free 3d model abe oodworld for download as obj on turbosquid: 3d models for games, architecture, videos. (1607965)

3ddd

$1

Ab King Pro

...ab king pro

3ddd

тренажер

тренажер ab king pro.

3d_export

$19

Upper ab machine

...upper ab machine

3dexport

3d_ocean

$16

AB King 3D Model

...ab king 3d model

3docean

3d ab king athletic model trainer

highly detailed ab king model file formats: .max, obj, fbx.

3ddd

$1

Ecosmart AB Series

...ab series

3ddd

камин

ecosmart ab series.

polys: 327 574

price: $565.00http://www.ecosmartfire.com/

био-спиртовые камины

turbosquid

$15

House ABS V106

...ree 3d model house abs v106 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1216161)

turbosquid

$11

Fabiela Pillow AB

...odel fabiela pillow ab for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1574015)

turbosquid

$70

AB Sun Parakeets

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$65

AB American Goldfinch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$5

End Table

...y free 3d model end table for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1445493)

turbosquid

$1

End Table

...free 3d model end table for download as sldpr, sldpr, and ige on turbosquid: 3d models for games, architecture, videos. (1535510)

Side

3ddd

free

Side-by-side холодильник

...side-by-side холодильник

3ddd

холодильник

side-by-side холодильник samsung

turbosquid

free

siding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кресло Side

...ресло side

3ddd

side , eero saarinen

eero saarinen кресло side.

материалы corona render.

3ddd

$1

Side-by-Side SHARP SJ-F78PEBE

... холодильник

холодильник side-by-side sharp sj-f78pebe, габариты (шxгxв) 89x77x183 см, с материалами

3ddd

$1

Liebherr Refrigerator Side By Side Sbes 7165

... side sbes 7165

3ddd

liebherr , холодильник

liebherr refrigerator side by side sbes 7165

3ddd

$1

Side table

...side table

3ddd

журнальный

classic side table

3ddd

$1

Зеркало Side

...зеркало side

3ddd

винтаж , зеркало

зеркало side

3ddd

$1

Side Table

...side table

3ddd

кофейный , круглый

side table

3ddd

$1

Side table

...side table

3ddd

приставной

bed side table, coffee table

3ddd

$1

Side table

...side table

3ddd

журнальный , круглый

стол журнальный side table

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)