Thingiverse

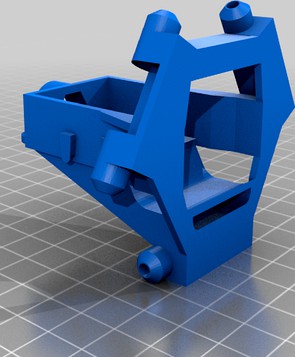

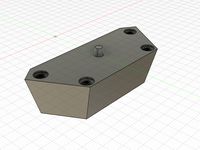

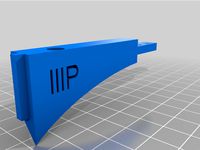

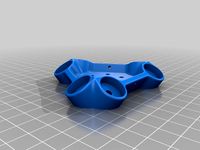

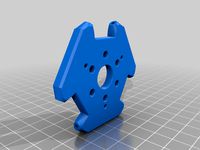

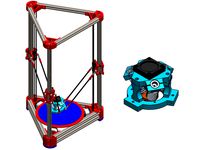

MPMD Effector replacement with secondary fan

by Thingiverse

Last crawled date: 4 years, 1 month ago

Just wanted to see if this was possible. Note: I have a new, different version that uses a side fan as the secondary instead of the straight through fan.https://www.thingiverse.com/thing:3945643

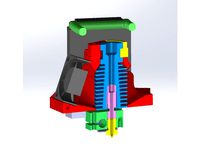

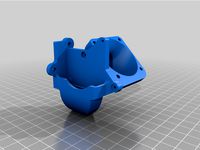

I designed a complete replacement for the metal effector and heatsink casing that includes a space for an additional 10mm cooling fan (same size as is already on the hotend.) The fan can be wired with a Y connector to the heatsink fan connector. The rods connect to the plastic effector using 6 M3 20mm screw. In order to ensure clearance for the fans the connectors on the effector are slightly larger than those on the carriages making the rods NOT parallel. So far I have not noticed any problem with prints.

I have a silicone sock on my heater block and so far I have not noticed any heat issues with the PLA I used to print the design. It would probably be better printed in a higher temp plastic though.

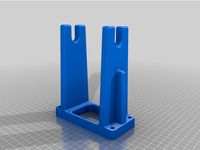

This part requires the printer to be calibrated to ensure proper sizing.

I actually printed the current version using an older version of the design.

To assemble the part you need to disassemble the existing effector but you do not need to remove the throat or nozzle from the block.

The heater has to be removed from the block by loosening the small grub screw in the block and sliding the heater out (unless you have disconnected the wiring at the printer and have the wires loose.)

In order to do this you will probably need to loosen the throat from the heat sink so you can get enough clearance or you may be able to just slide the heat sink down through the effector to get the required clearance.

Be very careful when handling the heatsink, heater and thermistor as these wires are very delicate.

Pre-fit all parts before putting the part in place. Fit all screws to ensure that they will fit before assembling and adjust if necessary.

The heater has to be fed in from the side (through the side opening) and the heatsink is fed up through the bottom. This is why the heater has to be removed from the block in order to fit it. At this point you will have the heater wire feeding through the hole in the side of the effector.

If you have unwrapped the heater, fan and thermistor from the bowden connector and have them unplugged from the printer you can just feed the heater wire out through this side effector hole without removing the heater from the block.

Once the heater has been put in place and tightened, position the silicone sock and slide the heat sink back into place, positioning it so that it can be tightened onto the casing using the original screws. Be very careful with this step as you are pushing the heat sink up and at the same time you need to be watching the heater wires so they do not get snagged on the side of the effector.

Set the throat position so the nozzle will protrude slightly below the effector and tighten it into place. Ensure the spacing at the top where the bowden connector sits is filled with the PTFE tubing. If it is too short cut a small piece of smaller PTFE that will fit inside the larger tubing and fill in any gap. Tighten the bowden connector in place using the grub screw.

The rods are held in place on the effector using M3 20mm screws. Use one of the small lock washers on the outside but not on the inside of the rod end. Tighten the bolt using an appropriately sized nut on the inside.

Install the 2nd fan and wire the heater, thermistor and fans back up.

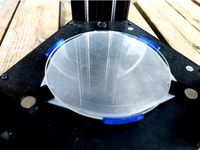

Once everything is reinstalled re-calibrate your bed levelling before printing.

I have included some pictures showing the new effector printing a Benchy (thing:2795629.) The Benchy was sliced using the stock Cura 4.2.1 'Draft 0.2 mm' profile adjusted to print .21 mm layer height and 0.7 wall thickness. Also adjusted the brim width to 4mm. everything else was left the same.

White PLA @200 and bed @60 with print speed at 60

The print completed successfully without any major defects. It completed the stack without an issue ( previously the stack always caused a failed print or a shifted print) but the arches above the doors did continue to warp up although they did not cause any issue as they have for me previously.

I have also included a small print (dragon thing:2830051) sliced in Cura 4.3 @50% using the default settings adjusted to 0.21 layer height. I had no printing issues with this one either.

These are my calibration numbers. You need to set ones for your own machine but I thought these might be helpful in case you are not sure.

Note: M4MPMD, Silicone sock, magnetic bed clips, glass bed, Litho-frame column shields.

M666 X0.00 Y-0.22 Z-0.26

M665 L133.69 H125.94 R71.19 S120.00 A0.60 B0.50 C-0.25

M851 Z-0.26

Things still to do:

redesign the rod holders to provide enough clearance and to ensure rods remain parallel.

Design a base part to direct air directly on parts where the nozzle is rather than just through the effector base.

I designed a complete replacement for the metal effector and heatsink casing that includes a space for an additional 10mm cooling fan (same size as is already on the hotend.) The fan can be wired with a Y connector to the heatsink fan connector. The rods connect to the plastic effector using 6 M3 20mm screw. In order to ensure clearance for the fans the connectors on the effector are slightly larger than those on the carriages making the rods NOT parallel. So far I have not noticed any problem with prints.

I have a silicone sock on my heater block and so far I have not noticed any heat issues with the PLA I used to print the design. It would probably be better printed in a higher temp plastic though.

This part requires the printer to be calibrated to ensure proper sizing.

I actually printed the current version using an older version of the design.

To assemble the part you need to disassemble the existing effector but you do not need to remove the throat or nozzle from the block.

The heater has to be removed from the block by loosening the small grub screw in the block and sliding the heater out (unless you have disconnected the wiring at the printer and have the wires loose.)

In order to do this you will probably need to loosen the throat from the heat sink so you can get enough clearance or you may be able to just slide the heat sink down through the effector to get the required clearance.

Be very careful when handling the heatsink, heater and thermistor as these wires are very delicate.

Pre-fit all parts before putting the part in place. Fit all screws to ensure that they will fit before assembling and adjust if necessary.

The heater has to be fed in from the side (through the side opening) and the heatsink is fed up through the bottom. This is why the heater has to be removed from the block in order to fit it. At this point you will have the heater wire feeding through the hole in the side of the effector.

If you have unwrapped the heater, fan and thermistor from the bowden connector and have them unplugged from the printer you can just feed the heater wire out through this side effector hole without removing the heater from the block.

Once the heater has been put in place and tightened, position the silicone sock and slide the heat sink back into place, positioning it so that it can be tightened onto the casing using the original screws. Be very careful with this step as you are pushing the heat sink up and at the same time you need to be watching the heater wires so they do not get snagged on the side of the effector.

Set the throat position so the nozzle will protrude slightly below the effector and tighten it into place. Ensure the spacing at the top where the bowden connector sits is filled with the PTFE tubing. If it is too short cut a small piece of smaller PTFE that will fit inside the larger tubing and fill in any gap. Tighten the bowden connector in place using the grub screw.

The rods are held in place on the effector using M3 20mm screws. Use one of the small lock washers on the outside but not on the inside of the rod end. Tighten the bolt using an appropriately sized nut on the inside.

Install the 2nd fan and wire the heater, thermistor and fans back up.

Once everything is reinstalled re-calibrate your bed levelling before printing.

I have included some pictures showing the new effector printing a Benchy (thing:2795629.) The Benchy was sliced using the stock Cura 4.2.1 'Draft 0.2 mm' profile adjusted to print .21 mm layer height and 0.7 wall thickness. Also adjusted the brim width to 4mm. everything else was left the same.

White PLA @200 and bed @60 with print speed at 60

The print completed successfully without any major defects. It completed the stack without an issue ( previously the stack always caused a failed print or a shifted print) but the arches above the doors did continue to warp up although they did not cause any issue as they have for me previously.

I have also included a small print (dragon thing:2830051) sliced in Cura 4.3 @50% using the default settings adjusted to 0.21 layer height. I had no printing issues with this one either.

These are my calibration numbers. You need to set ones for your own machine but I thought these might be helpful in case you are not sure.

Note: M4MPMD, Silicone sock, magnetic bed clips, glass bed, Litho-frame column shields.

M666 X0.00 Y-0.22 Z-0.26

M665 L133.69 H125.94 R71.19 S120.00 A0.60 B0.50 C-0.25

M851 Z-0.26

Things still to do:

redesign the rod holders to provide enough clearance and to ensure rods remain parallel.

Design a base part to direct air directly on parts where the nozzle is rather than just through the effector base.

Similar models

thingiverse

free

Effector Fan Shroud by SummersideGuy

... out the tips for the filament fans and spaced them further apart, this gives room for the wiring from the heater and thermistor.

thingiverse

free

Chimera mount fan duct 5mm extended

...5mm to make silicon sock fit better, so i needed more clearance for the fan to blow below the nozzle and not on the heater block.

thingiverse

free

MPMD Dual Fan Custom Effector

...ace. i included some photos to demonstrate this as well as how to insert a small ptfe at the top of the heatsink to fill any gap.

thingiverse

free

Anycubic Chiron direct drive modification (almost all factory parts: extruder, v5 hotend, 4010 fan, 5015 radial fan)) by ggrzyk

...ble heat block in heatsink

mount pcb board

mount 4010 fan

connect all wires to pcb board

mount 5015 radial fan with two m4 screws

thingiverse

free

Rostock Max effector cable hook(3) by Duplicat

...rostock max effector cable hook(3) by duplicat

thingiverse

heater cable 2. thermistor wire 3. fan wire

thingiverse

free

Anycubic Kossel Linear Plus upgrade hotend E3D V6 effector by rosch8

...screws or better din7981 2,2x 4,5 mm screws or similar on the top of exxector there are 2 holes....

thingiverse

free

KP3 Custom fan hood with single 4010 blower by mentalgrinds

... the hood as a loop on the heatsink side. this intended to be a zip tie down point for the heater wires to isolate wire movement.

thingiverse

free

MPMD Double Fan Part Cooler by ksihota

...r fan can be used for this purpose.

to control the fans using your slicer and gcode, you need to upgrade your firmware to marlin.

thingiverse

free

MPMD E3D V6 Effector by ksihota

...base

rod connectors:

3 60mm m3 threaded rods (nuts and washers)

or

6 30mm m3 nuts bolts and washers

assorted wires and connectors

thingiverse

free

Heater for dry box by denyok

... fan cover was used to protect ventilator and ptc heater.

this heater block allow to increase temperature inside dry box to 51 c.

Mpmd

thingiverse

free

MPMD Spool Forks - single piece

...mpmd spool forks - single piece

thingiverse

mpmd filament spool

thingiverse

free

MPMD Replacement Spool Holder by dscpt

...mpmd replacement spool holder by dscpt

thingiverse

basic replacement mpmd rear mounted spool holder.

thingiverse

free

MPMD feet

...e vibration absorption.

i used some double sided tape to assemble them to the printer in case i ever need to unscrew the endcaps.

thingiverse

free

MPMD Leg

...iverse

this is yet another leg model for monoprice mini delta, because i did not like other models of it. stock screws are okay.

thingiverse

free

MPMD fan mount for radiator

...mpmd fan mount for radiator

thingiverse

for standard cooler 30mm

thingiverse

free

mpmd 40mm fan shroud by lsirhc

...

thingiverse

mpmd 40mm fan shroud remix of ericrobodox stock shroud.

i haven't tried it yet, it may interfere with the arms.

thingiverse

free

MPMD (Mini Delta) bowden slider - endstop shield

....

this slider solved it.

printable on mpmd. the one piece is not possible to print on mpmd and it is not easy to get it in place.

thingiverse

free

MPMD top spool holder

...mpmd top spool holder

thingiverse

slip this on top of the monoprice mini delta printer and put a spool on top.

thingiverse

free

MPMD Frame Column Shield Remix

...m tall, 1.6mm thick in most places, 0.8mm on the ends.

mpmd shield. check out my enclosure as well, they work together perfectly.

thingiverse

free

Glass Bed Retainer - Monoprice Mini Delta (MPMD) by bLITzJoN

...op. this requires a larger printer, so if the mpmd is all you have then look at the glass bed clip - monoprice mini delta (mpmd).

Effector

3d_ocean

$5

Radial Sound Effector

...e spheres will expand with your song. fully customisable, change the color, the size of the spheres or even put in different s...

3d_ocean

$12

3D Customizable Puzzle Set (16x10)

...mograph compatible (you can effect the pieces with mograph effector) - included also a non-mograph version with...

thingiverse

free

Effector by olo2000pm

...effector by olo2000pm

thingiverse

effector

thingiverse

free

CERAMBOT-Effector

...cerambot-effector

thingiverse

cerambot-effector

thingiverse

free

modulize effector by candyasdf

...ulize effector by candyasdf

thingiverse

mount things on effector with m3 screws

effector radius : 25.4mm

rod arm distance : 40mm

thingiverse

free

Delta Effector by zavier

...delta effector by zavier

thingiverse

delta effector with radial fan 50 and bltouch

thingiverse

free

D810 Effector by WhiteTiger13

...d810 effector by whitetiger13

thingiverse

this is d810 effector for d810 without autocalibration, and also cap for it.

thingiverse

free

Effector for Delta Printer

...effector for delta printer

thingiverse

effector for delta printer (3 color)

using diamond hotend

thingiverse

free

Delta effector magnetic by fpassos

...delta effector magnetic by fpassos

thingiverse

effector for e3dv6 hotend. i needed put the spheres (10mm) on the effector.

thingiverse

free

End Effector Gripper

...end effector gripper

thingiverse

end effector gripper

for a robotic arm

uses mg995 servo motor

Secondary

turbosquid

$149

Track Secondary Pulverizer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Chilled Water Secondary Pumps

...ee 3d model chilled water secondary pumps for download as max on turbosquid: 3d models for games, architecture, videos. (1270113)

turbosquid

$60

Secondary Atitude Indicator (AI, Artifical Horizon)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Modern style primary and secondary school architectural design SU model

... secondary school architectural design su model

3dexport

modern style primary and secondary school architectural design su model

3d_export

$8

transat bamboo

...3dexport diffuse and normal on primary uvmap ao on secondary :...

3d_export

$6

transat deauville

...3dexport diffuse and normal on primary uvmap ao on secondary :...

3d_export

$15

Maverick REV-6

...range, it is recommended to use it as a secondary additional...

3d_export

$10

maison du monde pinup stool

...diffuse texture on primary map : uvmap ao on secondary map : uvmap...

3d_export

$5

Scrap metal 3D Model

...spare object subject scrap metal iron breakage stuff waste secondary raw materials scrap metal 3d model talgat 39978...

3d_export

$15

insectoid monster

...insectoid mutant low poly<br>can be used in games as secondary character or enemy<br>created in blender 2.91<br>archive includes next...

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Replacement

3d_export

$12

replaceable bristle

...replaceable bristle

3dexport

this is 3d printable replaceable bristle toothbrush.

3d_export

$34

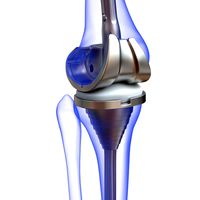

Knee Replacement

...h meets the lower leg. ... during a total knee replacement, the end of the femur bone is removed and replaced with a metal shell.

3d_export

$44

Hip Replacement

...omponents. the damaged femoral head is removed and replaced with a metal stem that is placed into the hollow center of the femur.

turbosquid

$59

Hip replacement

...el hip replacement for download as ma, c4d, lwo, lxo, and obj on turbosquid: 3d models for games, architecture, videos. (1520195)

turbosquid

$10

Module replacment station

...alty free 3d model module replacment station for download as on turbosquid: 3d models for games, architecture, videos. (1271271)

3d_export

$8

tool replacement gearbox

...tool replacement gearbox

3dexport

eccentric lifting mechanism, you can process according to available drawings.

turbosquid

$7

Globe Oil Atomizer Replacement Housing

... oil atomizer replacement housing for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1253839)

turbosquid

free

SLICE Ceramic Scapel (Replaceable Blade)

... (replaceable blade) for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1363525)

3d_export

$19

Knee Replacement Implant

...ntimeter<br>__________________________<br>poly count :<br>polygon count - 217440<br>vertex count - 108776

turbosquid

$19

(Project) Bad odor filtering sytem with support rail and pulley that assure a comfortable gel filter element replacement.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.