Thingiverse

MPMD Double Fan Part Cooler by ksihota

by Thingiverse

Last crawled date: 3 years, 8 months ago

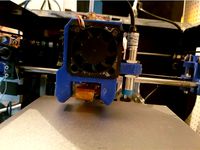

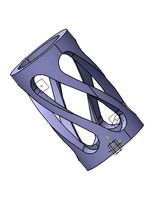

This is a rebuild of my original Part Cooling fan setup for the MPMD.

UPDATE21/12/2020

I have added a few extra pictures to show how close some of the parts are and to show how to adjust the nozzle position in order to allow the vents to clear the block/sock.

I loosened the nozzle (while hot) so it extended about 8.5mm and then hand tightened the throat to the nozzle. Then with the block heated I tightened the nozzle with a wrench. This should allow the nozzle to clear the base of the vent and allow the air flow to clear the block.

You can also see the small piece of capricorn at the top of the throat which is inserted to close off any extra space in that area.

SUMMARY

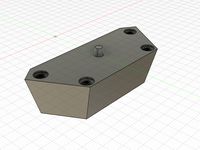

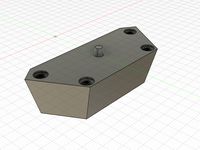

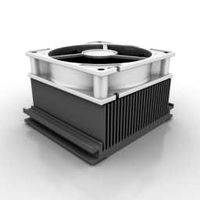

The main component is a replacement part for the heat sink casing. It has no closed backing so the heatsink can be removed with the heater and thermistor still attached to the hot end. It also has a hexagonal opening at the top that holds the bowden connector firmly in place. I made the casing slightly larger than the heat sink in order to provide a better cooling flow around the heatsink.

The front fan shroud has to be replaced as I did not include the ears on the casing to hold the fan spring clip (which I did not like.) Instead, the new shroud is attached to the casing using 2 short M3 machine screws.

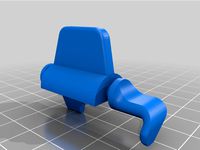

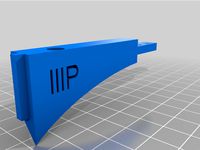

The front fan no longer provides part cooling unless you add the triple lower vent manifold. The lower vent redirects the air from the shroud to the nozzle. The front shroud includes a slider that allows the air flow to be redirected away from the printed part if required.

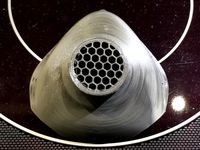

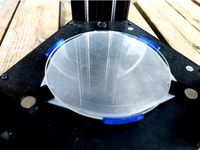

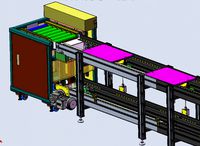

The Triple Lower Vent attaches from the bottom using 3-M3 countersunk machine screws. Because the vent adds some height, the nozzle on the printer may need to be lowered in order to clear the bottom. I use a small piece of capricorn inside the larger PTFE to extend the distance.

The triple vent allows part cooling around the whole nozzle. In order to take full advantage you need to add the Side Fans Manifold.

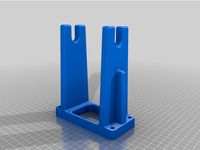

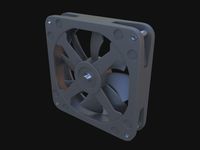

The Side Fans Manifold holds 2-4010 duct fans. These are attached to the manifold and then the manifold is placed around the casing and fastened using the back screw hole in the effector plate and lower vent manifold.

In order to work properly these two fans need to be joined with a Y connector and attached to the upper cooling fan wire. The front fan needs to be rewired to its own 12v line. The 12v line that feeds the lower fan can be used for this purpose.

To control the fans using your slicer and GCode, you need to upgrade your firmware to Marlin.

UPDATE21/12/2020

I have added a few extra pictures to show how close some of the parts are and to show how to adjust the nozzle position in order to allow the vents to clear the block/sock.

I loosened the nozzle (while hot) so it extended about 8.5mm and then hand tightened the throat to the nozzle. Then with the block heated I tightened the nozzle with a wrench. This should allow the nozzle to clear the base of the vent and allow the air flow to clear the block.

You can also see the small piece of capricorn at the top of the throat which is inserted to close off any extra space in that area.

SUMMARY

The main component is a replacement part for the heat sink casing. It has no closed backing so the heatsink can be removed with the heater and thermistor still attached to the hot end. It also has a hexagonal opening at the top that holds the bowden connector firmly in place. I made the casing slightly larger than the heat sink in order to provide a better cooling flow around the heatsink.

The front fan shroud has to be replaced as I did not include the ears on the casing to hold the fan spring clip (which I did not like.) Instead, the new shroud is attached to the casing using 2 short M3 machine screws.

The front fan no longer provides part cooling unless you add the triple lower vent manifold. The lower vent redirects the air from the shroud to the nozzle. The front shroud includes a slider that allows the air flow to be redirected away from the printed part if required.

The Triple Lower Vent attaches from the bottom using 3-M3 countersunk machine screws. Because the vent adds some height, the nozzle on the printer may need to be lowered in order to clear the bottom. I use a small piece of capricorn inside the larger PTFE to extend the distance.

The triple vent allows part cooling around the whole nozzle. In order to take full advantage you need to add the Side Fans Manifold.

The Side Fans Manifold holds 2-4010 duct fans. These are attached to the manifold and then the manifold is placed around the casing and fastened using the back screw hole in the effector plate and lower vent manifold.

In order to work properly these two fans need to be joined with a Y connector and attached to the upper cooling fan wire. The front fan needs to be rewired to its own 12v line. The 12v line that feeds the lower fan can be used for this purpose.

To control the fans using your slicer and GCode, you need to upgrade your firmware to Marlin.

Similar models

thingiverse

free

MPMD Effector Part Cooling Vents and Casing

...re assembling on the effector. i also place all bolts and fit nuts prior to assembly as well to ensure that everything fits well.

thingiverse

free

Geeetech MeCreator´s mk8 extruder fan shroud by Lugge

...ng right out of the nozzle

i also included a version of the fan shroud without the sensor mount for those who doesn't use one

thingiverse

free

Da Vinci 2.0 Rear mount cooling fan shroud by mordiev

... you attach this to. see the instructions for more information.

i lowered the aim of the left nozzle.10/6/2014 it was too high.

thingiverse

free

Tronxy P802/Anet A8 Mk10 Extruder Fan Shroud

...with an instant improvement in control allowing for less retraction and higher print speeds with no degradation in print quality.

thingiverse

free

MPMD feet

...e vibration absorption.

i used some double sided tape to assemble them to the printer in case i ever need to unscrew the endcaps.

thingiverse

free

E3D fan fastener with Prusa fan shroud by ssombra

...t (there is not much room for a nut) and a m3x6mm screw.

additional hardware: m3x12mm screw (2), m3x30mm screw (1), m3 nuts (3).

thingiverse

free

Cooling nozzle for Jubilee printer by edsped

...oud but can use super glue as called out in the instructions for the original nozzle.

print as it is on the bed without supports.

thingiverse

free

Titan Aero mount for Kodama Trinus by TheGreatMrBill

...d is also a remix with a new lip to seal up the 40mm fan where it connects and a modified exit vent giving better flow direction.

thingiverse

free

Fan Shroud - Monoprice Maker Select (Duplicator 9) mk2

...ower ring to keep the air flow clear.

this has bee working tremendously well and seems to provide even cooling around the print.

thingiverse

free

Artist-D Circular Shroud for stock 4010 Blower Fan by ericlam_UCSF

...oud rather than leaking at fan/shroud interface.

may need to widen screw holes to prevent breaking if using screw to tap threads.

Ksihota

thingiverse

free

Predator Extruder Feed Sleeve by ksihota

... need to be sanded slightly to fit properly

if you use it, leave me a comment to indicate if it works or if it needs adjustments.

thingiverse

free

Operation Game Pieces by ksihota

...y as well as a single stl with all the parts.

i am not sure what the names are really supposed to be so i just named them myself.

thingiverse

free

1995 Volvo 850 seatbelt release button by ksihota

...riginal by filling in the centre underside. this makes for a stronger part and makes the print cleaner when printing on its edge.

thingiverse

free

Ryobi One+ Hybrid Leaf blower switch by ksihota

... canada. it is a one+ model. i have included a full picture of it for reference. the switch is a side toggle, not a slide switch.

thingiverse

free

Simple Face Shield by ksihota

... for intended use.

if you do try and like the design but find the size is not right let me know and i can resize it if necessary.

thingiverse

free

Filastruder Electronics Case by ksihota

...f the filastruder case where the switches and temp controller used to reside.

let me know if you find any issues with the design.

thingiverse

free

Unusual filter masks by ksihota

...thing down the nose. maybe an old sock?

obviously the filter aspect would require some redesigning, but it can be done if needed.

thingiverse

free

Hard Shell Filter Mask by ksihota

...hile printing you may have better success. of course by printing in tpu the print would also take quite a bit longer than in pla.

thingiverse

free

Ryobi Backpack Leaf Blower Nozzles by ksihota

...as a little wider and not quite as high.

i have not yet tested either nozzle ends yet. i will add comments about their use later.

thingiverse

free

MPMD E3D V6 Effector by ksihota

...base

rod connectors:

3 60mm m3 threaded rods (nuts and washers)

or

6 30mm m3 nuts bolts and washers

assorted wires and connectors

Mpmd

thingiverse

free

MPMD Spool Forks - single piece

...mpmd spool forks - single piece

thingiverse

mpmd filament spool

thingiverse

free

MPMD Replacement Spool Holder by dscpt

...mpmd replacement spool holder by dscpt

thingiverse

basic replacement mpmd rear mounted spool holder.

thingiverse

free

MPMD feet

...e vibration absorption.

i used some double sided tape to assemble them to the printer in case i ever need to unscrew the endcaps.

thingiverse

free

MPMD Leg

...iverse

this is yet another leg model for monoprice mini delta, because i did not like other models of it. stock screws are okay.

thingiverse

free

MPMD fan mount for radiator

...mpmd fan mount for radiator

thingiverse

for standard cooler 30mm

thingiverse

free

mpmd 40mm fan shroud by lsirhc

...

thingiverse

mpmd 40mm fan shroud remix of ericrobodox stock shroud.

i haven't tried it yet, it may interfere with the arms.

thingiverse

free

MPMD (Mini Delta) bowden slider - endstop shield

....

this slider solved it.

printable on mpmd. the one piece is not possible to print on mpmd and it is not easy to get it in place.

thingiverse

free

MPMD top spool holder

...mpmd top spool holder

thingiverse

slip this on top of the monoprice mini delta printer and put a spool on top.

thingiverse

free

MPMD Frame Column Shield Remix

...m tall, 1.6mm thick in most places, 0.8mm on the ends.

mpmd shield. check out my enclosure as well, they work together perfectly.

thingiverse

free

Glass Bed Retainer - Monoprice Mini Delta (MPMD) by bLITzJoN

...op. this requires a larger printer, so if the mpmd is all you have then look at the glass bed clip - monoprice mini delta (mpmd).

Cooler

archibase_planet

free

Cooler

...hibase planet

wine-cooler wine cooler kitchen equipment

rk wine cooler uc - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

cooler

cooler seyedmms n271212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

refrigerator cooler kitchen's technics

cooler - 3d model for interior 3d visualization.

archibase_planet

free

Cooler

...er

archibase planet

pc equipment cooler computer equipment

cooler n040908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

cooler cpu fan pc equipment

cooler asus n080211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Cooler

...cooler

3dexport

water cooler. program maya 2018. materials v-ray 3.6.

3d_export

$5

Juice cooler

...juice cooler

3dexport

juice cooler

turbosquid

$10

Cooler

...uid

royalty free 3d model cooler for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1478561)

turbosquid

$20

cooler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

cooler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Double

3ddd

free

Double

...double

3ddd

double , sicis

диван double от итальянской фабрики sicis next art

3d_ocean

$5

double stairs

...double stairs

3docean

double stairs

double stairs

3d_export

$5

double handle

...double handle

3dexport

double handle

3d_export

$5

double fastener

...double fastener

3dexport

double fastener

3ddd

$1

double bed

...double bed

3ddd

двуспальная

double bed

design_connected

free

Chair Double

...chair double

designconnected

free 3d model of chair double

3ddd

$1

Double Leaves

...double leaves

3ddd

double leaves

кресло китайской фабрики double leaves. vray, 3dmax 2013, гамма 2.2, текстуры в комплекте.

3ddd

free

Люстра Double

...люстра double

3ddd

double , david chipperfield

2004

размеры в архиве

3d_export

free

couch - double

...couch - double

3dexport

couch double with texture and .psd files for personal customization

3d_export

$10

double layer double speed chain

...d chain

3dexport

double layer speed chain (design very detailed) 3d model drawing model file reference using solidworks software

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Part

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$59

Mechanical Part

...id

royalty free 3d model mechanical part for download as c4d on turbosquid: 3d models for games, architecture, videos. (1410833)

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)