Thingiverse

MPCNC Primo J Bosch Colt 1HP Mount by truglodite

by Thingiverse

Last crawled date: 3 years, 4 months ago

[

Updated version... tested and MPCNC Primo approved (unofficially;) )! I removed the old STL and replaced it with new versions. Both newer versions have a shortened clamp nose to eliminate interference with the home corner parts on a Primo.

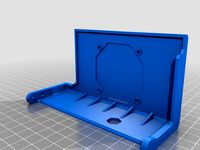

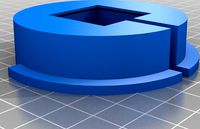

I uploaded a second stl with a vacuum flange and matching modified brush holder, intended to be used with chschmit's CNC vacuum assembly. You can find the rest of the required parts for the vacuum attachment here:https://www.thingiverse.com/thing:3131476

Note that I made a small update to the vac flange router mount to beef up the plastic around where the flange bolts go. So if you happened to print the earlier version without the beefed up bolt holes and it has cracked, you may want to reprint an updated version (it will not crack even if you bump it fairly hard). I uploaded a photo showing the difference between the old and new bolt hole areas, which can be used for reference.

I remixed the original "Clamp_Lower_Brush.stl" part to accept M3 nuts for non-glued assembly. This also allows removal for easier access to the spindle nut. Simply push 2 nuts in from the sides, and bolt it to the router flange with some M3 bolts (preferably with washers).

I also recently added a 1pc print for the vacuum clamp and plenum. I found glue inadequate to hold the original design together. So I made the whole deal 1pc without really messing with any of the dimensions. This is a stop gap until I can redesign a lower profile plenum (for lower reduction of workspace).

]

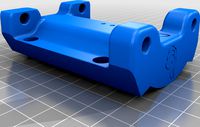

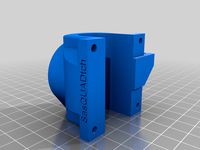

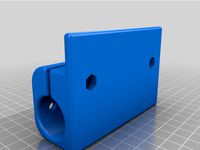

There are some 2 piece designs to mount the 1hp Bosch Colt router on the MPCNC Primo/Burly, but I wanted a stiffer 1pc design. So I drew this this tool mount for my MPCNC Primo J (25.4mm). It is intended to mount to the MPCNC like the original Burly/525 tool mount, but no is drilling required:

https://www.thingiverse.com/thing:1671517

I resized the pipe bolt holes to M5 clearance, and increased the counterbores to 9mm diameter to fit the M5x30 allen bolts I use with my Primo nut traps. The router clamp uses 2@ M5x30 allen bolts and M5 nylock nuts. The clamp nuts are captured for convenience.

I didn't use a sloping top like many Colt mounts out there. The flat top allows the router to be rotated as needed, which can help with some scenarios where router power cable clearance or location may be an issue. The flat top also adds convenience when it comes to designing adapters to quickly swap in other common MPCNC tools like drag knifes, lasers, etc. The spindle lock access hole lines up with the button only if the router is rotated to the correct orientation.

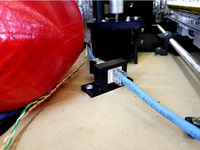

Note the power cord on the Colt exits to the side, which is generally problematic for the MPCNC design. It is usually aligned with either the X or Y axis to clear the trucks when homing, and even then if you have a sufficiently tall build, the cord may still crash into the side rails when homing (depending on the z height when homing). So unless you modify the cord strain relief, you must always pay attention to z height before homing on a Colt equipped MPCNC!

I printed in PETG for heat resistance and stiffness. PLA is not wise for a cnc motor holder. I setup my slicer to use 4 walls, 8 tops/bottoms, and 45% infill on all my printed tools... but up it to 70% infill in for this part as you will want the extra stiffness. Build plate only supports are needed. The part is already oriented ready to print. Flipping it over will increase support material and print time, and make the more visible top surface look nasty.

Updated version... tested and MPCNC Primo approved (unofficially;) )! I removed the old STL and replaced it with new versions. Both newer versions have a shortened clamp nose to eliminate interference with the home corner parts on a Primo.

I uploaded a second stl with a vacuum flange and matching modified brush holder, intended to be used with chschmit's CNC vacuum assembly. You can find the rest of the required parts for the vacuum attachment here:https://www.thingiverse.com/thing:3131476

Note that I made a small update to the vac flange router mount to beef up the plastic around where the flange bolts go. So if you happened to print the earlier version without the beefed up bolt holes and it has cracked, you may want to reprint an updated version (it will not crack even if you bump it fairly hard). I uploaded a photo showing the difference between the old and new bolt hole areas, which can be used for reference.

I remixed the original "Clamp_Lower_Brush.stl" part to accept M3 nuts for non-glued assembly. This also allows removal for easier access to the spindle nut. Simply push 2 nuts in from the sides, and bolt it to the router flange with some M3 bolts (preferably with washers).

I also recently added a 1pc print for the vacuum clamp and plenum. I found glue inadequate to hold the original design together. So I made the whole deal 1pc without really messing with any of the dimensions. This is a stop gap until I can redesign a lower profile plenum (for lower reduction of workspace).

]

There are some 2 piece designs to mount the 1hp Bosch Colt router on the MPCNC Primo/Burly, but I wanted a stiffer 1pc design. So I drew this this tool mount for my MPCNC Primo J (25.4mm). It is intended to mount to the MPCNC like the original Burly/525 tool mount, but no is drilling required:

https://www.thingiverse.com/thing:1671517

I resized the pipe bolt holes to M5 clearance, and increased the counterbores to 9mm diameter to fit the M5x30 allen bolts I use with my Primo nut traps. The router clamp uses 2@ M5x30 allen bolts and M5 nylock nuts. The clamp nuts are captured for convenience.

I didn't use a sloping top like many Colt mounts out there. The flat top allows the router to be rotated as needed, which can help with some scenarios where router power cable clearance or location may be an issue. The flat top also adds convenience when it comes to designing adapters to quickly swap in other common MPCNC tools like drag knifes, lasers, etc. The spindle lock access hole lines up with the button only if the router is rotated to the correct orientation.

Note the power cord on the Colt exits to the side, which is generally problematic for the MPCNC design. It is usually aligned with either the X or Y axis to clear the trucks when homing, and even then if you have a sufficiently tall build, the cord may still crash into the side rails when homing (depending on the z height when homing). So unless you modify the cord strain relief, you must always pay attention to z height before homing on a Colt equipped MPCNC!

I printed in PETG for heat resistance and stiffness. PLA is not wise for a cnc motor holder. I setup my slicer to use 4 walls, 8 tops/bottoms, and 45% infill on all my printed tools... but up it to 70% infill in for this part as you will want the extra stiffness. Build plate only supports are needed. The part is already oriented ready to print. Flipping it over will increase support material and print time, and make the more visible top surface look nasty.

Similar models

thingiverse

free

Bosch PR20EVSK Colt Mount for MPCNC by purefield

...nt for your mpcnc tool mount.

one version with a flange for dust collection one without.

rotated to keep the cord from the rails.

thingiverse

free

MPCNC Primo Tool Mount (Burly remix) by truglodite

...lts i use. ironically, despite a 'keep sharp edges' remesh operation and mesh boolean, the stl file size actually shrunk!

thingiverse

free

MPCNC primo tool mount for Dewalt D26200 by toastfr35

...o hold vacuum hose) will fit in a 21mm (or larger) internal diameter tube.

remixed from https://www.thingiverse.com/thing:1772756

thingiverse

free

MPCNC Primo Pen Mount on Spindle Mount by MattMed4

...olidworks part file to be used for customization for your pen/plotter.

the clamping bolt hole is for m3 bolts, nuts, and washers.

thingiverse

free

Bosch Colt CNC Vacuum - Brush Remix by truglodite

... to reduce file size to the final 35mb (still portly). the added strength and reliability are well worth the bandwidth though. ;)

thingiverse

free

Floating Z mpcnc primo and Burly by 81LS1Camaro

...d yet, i am using a previous one that i had to grind and drill to make work. it should be good to use, let me know if you use it.

thingiverse

free

MPCNC Primo Laser Mount 40mm by TheDima

...mpcnc primo laser mount 40mm by thedima

thingiverse

mpcnc primo laser mount for a 40mm laser modul

used m5 bolts and nuts

thingiverse

free

MPCNC clamp by AdamDam

...ge was clamp for an m4 bolt added a clamp for an m6... i suggest big flange washer. for the adjust bolt you need an m8 nut + bolt

thingiverse

free

MPCNC Primo Vacuum Tubing Z Mount by truglodite

...robust regardless of print settings, but the dovetail on the vacuum clamp part relies on wall thickness to get it's strength.

thingiverse

free

MPCNC Primo DWP611 Tool Mount by sf_designs

...dwp611 tool mount by sf_designs

thingiverse

dwp611 tool mount for mpcnc primo.

the tool mounts fit ryan's primo tool plates.

Truglodite

thingiverse

free

RCWL-0516 Cover by truglodite

... made it thin but with some clearance, to save filament and minimize interference. it fits nicely for me printed in abs on my a8.

thingiverse

free

SSR Cover (Remix) by truglodite

.... a pair of zipties may be used to secure the wires in their tubes. sized to work with larger wires and crimp on spade terminals.

thingiverse

free

8mm LED Strip Clip by truglodite

... have to remove the adhesive backing, but loose enough to where you can still slide the strip in even if the adhesive is exposed.

thingiverse

free

Ramps Enclosure Remix (lid pin added) by truglodite

.... so i did this remix to add a flange and holes to accept a pin/bolt that locks the lid shut (so it won't fall from gravity).

thingiverse

free

Keystone Surface Mount (single) by truglodite

...small gap on 2 sides of the keystone's face once installed, but it's barely noticeable and they still hold very securely.

thingiverse

free

Anet A8 20mm Printed Rubber Foot by truglodite

... flat headed screws. i just used some small self tapping flat heads, but a set of machine screws and nuts could also get it done.

thingiverse

free

Micro SD Card Extension, Cards, & Stick Mount by truglodite

... room is for my larger usb3 readers to fit, but the standard usb hole inside secures smaller sticks too. prints without supports.

thingiverse

free

4ch Mosfet Enclosure by truglodite

...assive cooling. the slots alone are adequate for my application, but comment if you need me to add a lid with a fan port instead.

thingiverse

free

Double Mosfet Box by truglodite

...n to save filament. the dimensions are designed for a 0.45mm printer line width (0.4mm nozzle), but other settings may work fine.

thingiverse

free

IEE VFD Enclosure Control Box by truglodite

...cts where you want a honkin' big vfd with "3 button menus". i made the rear compartment over sized for this reason.

1Hp

thingiverse

free

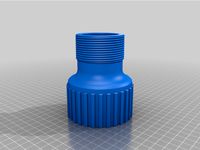

Adapter for 1HP QP bomb to intex hose by Teleldo

...adapter for 1hp qp bomb to intex hose by teleldo

thingiverse

adapter for 1hp qp bomb to intex hose

thingiverse

free

Improved Eurorack Parametric Panel by mdroberts1243

...this remix i changed the openscad code to handle 1hp and 2hp panel widths. i fixed the vertical hole...

thingiverse

free

1.25 inch Pool Nozzle by rlegault

...much less power than the main filter pump of 1hp filter pump is on when we swim and also...

thingiverse

free

Plastic Extruder by laughingman

...spec'ed at 1/2hp 1640rpm 4.5amps the gearbox is 11:1 1hp ...

thingiverse

free

100mm vacuum hose gate by ois_face

...i use these to ensure maximum vacuum from my 1hp shop vac that has two vacuum hoses coming from...

thingiverse

free

Eurorack M3 Rail System

...parameters can be adjusted within fcstd files. to achieve 1hp - 30hp (x+) rail lengths. body 30 hp rails...

thingiverse

free

Bosch PR20EVS Router Base by twuelfing

...the tool's axle. i made this for my little 1hp bosch router. i can use laser cut templates out...

grabcad

free

Air compressor 1HP

...air compressor 1hp

grabcad

air compressor 1hp

grabcad

free

motor eléctrico 1hp

...motor eléctrico 1hp

grabcad

motor eléctrico 1hp

Primo

3ddd

$1

Eichholtz / Primo Large

...oltz , primo

http://www.eichholtz.com/wall-lamp-primo-large-0087001631114.aspx

3ddd

$1

Skandiform Primo

...iform primo

3ddd

skandiform

кресло фирмы skandiform, модель primo, 2015. кожа, хром.

габаритные размеры (шхвхг): 530х850х590 мм

3ddd

$1

BNOS / Primo Space

...dd

om , тумба

комплект шкафов серии primo space фирмы bnos. подробнее на www.bnos.com.ua

3ddd

$1

BNOS / Primo Space

... , стол

стол для руководителя серии primo space фирмы bnos. подробнее на www.bnos.com.ua

3d_export

$65

Fiat Primo 3D Model

...fiat primo 3d model

3dexport

fiat primo concept car 500 128 roadster coupe prototype

fiat primo 3d model cardess 30926 3dexport

3d_export

$5

El Primo Matreshka

...el primo matreshka

3dexport

3d model el primo from brawl stars. style - toy matreshka. vertices: 4584 faces: 4762

turbosquid

$10

Primo wall sconce

...

royalty free 3d model primo wall sconce for download as max on turbosquid: 3d models for games, architecture, videos. (1263862)

3ddd

free

Baby Expert / Primo Amore

...baby expert / primo amore

3ddd

baby expert

детская кроватка baby expert primo amore

3ddd

free

Baby Expert / Primo Amore

...aby expert / primo amore

3ddd

комод , baby expert

комод детский baby expert primo amore

turbosquid

$79

Water Cooler Primo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mpcnc

thingiverse

free

MPCNC Laser Mount

...mpcnc laser mount

thingiverse

custom laser mount for mpcnc.

thingiverse

free

MPCNC Remix

...mpcnc remix

thingiverse

test

thingiverse

free

MPCNC Belt Mod

...mpcnc belt mod

thingiverse

belt mod for mpcnc. alternative to zip tie.

thingiverse

free

MPCNC Y PLATE

...mpcnc y plate

thingiverse

ender 3 printable y plate for mpcnc lowrider 2

thingiverse

free

MPCNC adapter for pen holder

...mpcnc adapter for pen holder

thingiverse

adapter to mpcnc

thingiverse

free

MPCNC Higher Feet

...mpcnc higher feet

thingiverse

extra height and width feet to minimize wobbling on higher mpcnc 2.5mm configurations.

thingiverse

free

MPCNC 30x30 Laser by DariusO

...mpcnc 30x30 laser by dariuso

thingiverse

mpcnc lasermodul in 30x30

thingiverse

free

mpcnc penholder

...mpcnc penholder

thingiverse

a quick remix of two different ideas

thingiverse

free

MPCNC Drillign Guide by isiks_tech

...mpcnc drillign guide by isiks_tech

thingiverse

mpcnc drilling guide for gantry rails.

thingiverse

free

MPCNC Proxxon Mount by CNC_Fan

...mpcnc proxxon mount by cnc_fan

thingiverse

this is my proxxon mount for use mpcnc

Colt

turbosquid

$3

Colt

...colt

turbosquid

royalty free 3d model colt for download as on turbosquid: 3d models for games, architecture, videos. (1243730)

3ddd

$1

Colt

...colt

3ddd

легковой автомобиль

3ddd

$1

Colt 1911

...colt 1911

3ddd

пистолет , кольт

colt 1911

turbosquid

$25

colt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Colt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

COLT

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Colt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Colt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

Colt M1911

...3docean

browning colt gun m1911 pistol war weapon

high detailed model of colt m1911. textures and materials in vray are included.

turbosquid

$32

Colt M 1911 .4 Automatic Colt

... 3d model colt m 1911 .4 automatic colt for download as sldas on turbosquid: 3d models for games, architecture, videos. (1611710)

Bosch

3ddd

$1

BOSCH

...bosch

3ddd

bosch , чайник

чайник bosch

3ddd

$1

Bosch

...dd

bosch , wlx20462by , стиральная машина

bosch

3ddd

$1

Bosch

...bosch

3ddd

bosch , печь

bosch hba 63 a 263 f

3ddd

$1

BOSCH

...bosch

3ddd

bosch , свч

встраиваемая микроволновая печь bosch hmt 85 mr 63

3ddd

$1

Bosch

... газовая плита , плита

варочная поверхность bosch ppq 726m90e.

3ddd

$1

bosch

...bosch

3ddd

стиралка , стиральная машина

стиральная машина bosch

3ddd

$1

Blender bosch

...blender bosch

3ddd

bosch , блендер

blender bosch

3ddd

$1

Миксер Bosch

...миксер bosch

3ddd

bosch , миксер

миксер bosch.

3ddd

$1

Bosch HBA23B250E

...bosch hba23b250e

3ddd

bosch , духовка

oven bosch-hba23b250e

3ddd

free

Комбайн BOSCH

...омбайн , bosch , кухонный комбайн

комбайн bosch

J

3d_export

$17

J-7mg

...j-7mg

3dexport

j-7mg

3d_export

$5

j hook

...j hook

3dexport

j hook

3d_export

$17

J-21 jastreb

...j-21 jastreb

3dexport

j-21 jastreb

3d_export

$17

Chengdu J-10

...chengdu j-10

3dexport

chengdu j-10

turbosquid

$96

J-20

...20

turbosquid

royalty free 3d model j-20 for download as max on turbosquid: 3d models for games, architecture, videos. (1658873)

turbosquid

$68

J-10A

...a

turbosquid

royalty free 3d model j-10a for download as max on turbosquid: 3d models for games, architecture, videos. (1658854)

turbosquid

$30

J-7

...j-7

turbosquid

royalty free 3d model j-7 for download as max on turbosquid: 3d models for games, architecture, videos. (1538420)

turbosquid

$14

Fence J

...turbosquid

royalty free 3d model fence j for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313345)

turbosquid

$7

J for Jug

...rbosquid

royalty free 3d model j for jug for download as max on turbosquid: 3d models for games, architecture, videos. (1688347)

turbosquid

$5

Letter J

...urbosquid

royalty free 3d model letter j for download as max on turbosquid: 3d models for games, architecture, videos. (1408483)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)