Thingiverse

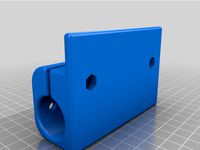

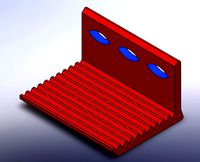

MPCNC Cable Chain Snap Fit Supports for Aluminum "L" angle bar (U.S. version) by 3dEz

by Thingiverse

Last crawled date: 3 years ago

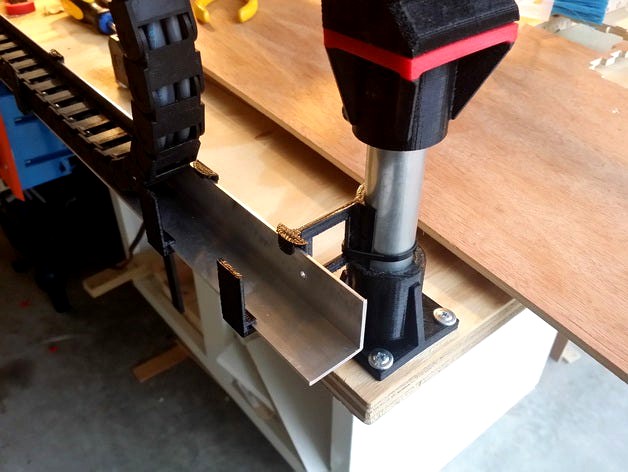

This set allows installation of an "L" Aluminum Angle Bar for the X and Y Axis cable chain.

I have made it snap-fit on the U.S. EMT tube (US Version), but I recommend wrapping with one zip tie after you position everything.

I was able to route the wires through the cable chain with connectors installed by wrapping the bundles with PFTE tape (plumbing teflon tape) and pulling them gently with a tweezer when there was a bit of snag.

Parts you will need:

1) Cable chain, such as this one: ($6 each)http://www.amazon.com/gp/product/B00880AVL2?psc=1&redirect=true&ref_=oh_aui_search_detailpage

2) Aluminum angle bar such as this one:http://www.homedepot.com/p/Everbilt-1-in-x-96-in-Aluminum-Angle-Bar-with-1-20-in-Thick-802587/204273981?MERCH=REC-_-PIPHorizontal1_rr-_-204273951-_-204273981-_-N

3) 2 X 5/16", 3" long screws for each axis, total of 4 screws if you are doing for X and Y. These will replace the 2.5" screw on the motor block to allow mounting the chain support bracket.

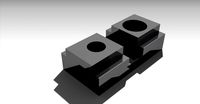

The STL's are as follows:

1) The biggest part is the mount to the motor block. Print one unit for each axis

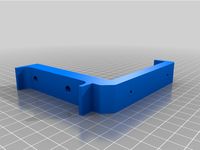

2) The end clip attaches to the EMT tube leg of the corner block - If you will need to print two of those, regardless of installing for 1 axis or 2 axis.

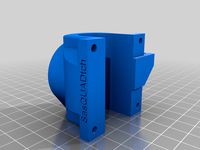

3) The XY clip combines 2 clips into one assembly if you are installing both X and Y cable chains.

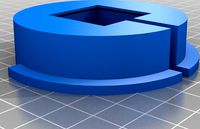

4) The small sliding clips holds and directs the cable chain into the rail when the axis is moving. I have printed 3 clips for each axis. Slide the clips in the aluminum bar.

Some general print advice: I initially planned to have these brackets designed to be printed laying down 90 degrees to avoid supports but after a few tests I realized the need for a curved "bump" to avoid snagging with the chain. So print the parts with supports keeping the orientation in the attached STL. Since the walls are thin, ensure your extrusion width is not creating hollow walls (check the sliced view). Finally, Reserve some time to gently remove all support material from the tiny slots (have a glass of wine while you do that :).

I have made it snap-fit on the U.S. EMT tube (US Version), but I recommend wrapping with one zip tie after you position everything.

I was able to route the wires through the cable chain with connectors installed by wrapping the bundles with PFTE tape (plumbing teflon tape) and pulling them gently with a tweezer when there was a bit of snag.

Parts you will need:

1) Cable chain, such as this one: ($6 each)http://www.amazon.com/gp/product/B00880AVL2?psc=1&redirect=true&ref_=oh_aui_search_detailpage

2) Aluminum angle bar such as this one:http://www.homedepot.com/p/Everbilt-1-in-x-96-in-Aluminum-Angle-Bar-with-1-20-in-Thick-802587/204273981?MERCH=REC-_-PIPHorizontal1_rr-_-204273951-_-204273981-_-N

3) 2 X 5/16", 3" long screws for each axis, total of 4 screws if you are doing for X and Y. These will replace the 2.5" screw on the motor block to allow mounting the chain support bracket.

The STL's are as follows:

1) The biggest part is the mount to the motor block. Print one unit for each axis

2) The end clip attaches to the EMT tube leg of the corner block - If you will need to print two of those, regardless of installing for 1 axis or 2 axis.

3) The XY clip combines 2 clips into one assembly if you are installing both X and Y cable chains.

4) The small sliding clips holds and directs the cable chain into the rail when the axis is moving. I have printed 3 clips for each axis. Slide the clips in the aluminum bar.

Some general print advice: I initially planned to have these brackets designed to be printed laying down 90 degrees to avoid supports but after a few tests I realized the need for a curved "bump" to avoid snagging with the chain. So print the parts with supports keeping the orientation in the attached STL. Since the walls are thin, ensure your extrusion width is not creating hollow walls (check the sliced view). Finally, Reserve some time to gently remove all support material from the tiny slots (have a glass of wine while you do that :).

Similar models

thingiverse

free

PrintNC - Cable Chain supports by evil_k

...5 machine screws.

printed everything in petg, 60% infill, 0.6mm nozzle.

solidworks files included if you need to change anything.

thingiverse

free

MPCNC Cable Chain Snap Fit Supports for Aluminum "L" angle bar (Beefy U.S. version) by anthonyalburton

...so i made them thicker and used an arc. recently changed to allow the cables to slide under bottom before installing the l-rail.

thingiverse

free

MPCNC Z Axis Cable Raceway

...r y axis

8 m3 x 10mm bolts (these replace the stock stepper motor bolts which are too short to clear the brackets and stock parts

thingiverse

free

ACRO Laser Cable Chains by 3boysdad

... the y-axis as well as the x-axis. then print another set using the mirror tool in your slicer for the right side of the y-axis.

thingiverse

free

MPCNC Primo Z Cable Chain Mount by truglodite

...z cable chain along the x or y axis. similar mpcnc primo z-cable mounts were too low to where...

thingiverse

free

Ender 3 Cable Chain Direct Drive Bullseye by Klingman

...axis and about 20 for the y axis.

you should experiment with the full range of movement of all the axis before starting printing.

thingiverse

free

Formbot T-Rex 2+ Y-Axis Cable Chain by afeathers1

... aluminum extrusion underneath the cable chain, so you can move around your printer without catching or damaging the cable chain.

thingiverse

free

Y axis cable chain for GEEETech I3 ProB(easy to assemble) by ybjack

...lock.stl

same part of source.

8/9 sorry, "y_cable_chain_print at_once.stl" has no cable lock. if you need, add above 5)

thingiverse

free

Ender 3 V2 LED Bar and V-Slot Clips for 2020 Extrusion by imaginepsn

...t the x-axis, you can print the led clips 45 version which can snap into the back of the x-axis.

remarks: no support is required.

thingiverse

free

Drag Chain Cable Raceway for Onefinity CNC by muddyfeet

...) m4 x 10mm flat head screws to secure drag chains

(1) m4 tap for threading holes

assemble per video:https://youtu.be/x7eg7uzhg84

3Dez

thingiverse

free

3DEZ Line Follower Snap by 3_DEZ

...system for the use with 3dez robotics systems. compatible with the vex edr robotics systems. works with most of the 3dez chassis.

thingiverse

free

3DEZ VEX Robot Chassis by 3_DEZ

...3dez vex robot chassis by 3_dez

thingiverse

a 3dez chasssis for use with the vex edr robotics systems.

thingiverse

free

3DEZ VEX cortex mount. by 3_DEZ

...r systems and they are made for the 3dez chassis. work with all vex edr products as holes lone up with the cortex mounting holes.

thingiverse

free

Solidoodle Dual Y Motor Drive by 3dEz

...tor drive by 3dez

thingiverse

this is described here:

http://www.soliforum.com/post/128328/#p128328

https://youtu.be/ja8bjmly2qw

thingiverse

free

3DEZ VEX Line Follower Chassis Robot by 3_DEZ

...se don't hesitate to contact us.https://www.youtube.com/channel/uc2a-uf0fhhlh5b7gtdulxbahttps://www.facebook.com/3dezchassis/

thingiverse

free

C-Wallet Remix by 3dEz

...need for the bearing, but here it is for now.

remix 2 - non-glued

= to remix 1 + screws (untested)

printed with bronze color pla

thingiverse

free

Mirroed extruder with adapted auto bed leveling mount by 3dEz

...create a small chamfer close to the left servo mount mounting screw. this is really the only difference from the original design.

thingiverse

free

MPCNC with Makerbase MKS TFT28 by 3dEz

...p you posted on that. you can easily adjust the display height thanks to the threaded rod

m5 nuts, and washers

m3 screws and nuts

unity_asset_store

$8

viking weapons

...elevate your workflow with the viking weapons asset from 3dez find this & other guns options on the unity...

unity_asset_store

free

Simple Cafe

...elevate your workflow with the simple cafe asset from 3dez find this & other urban options on the unity...

Mpcnc

thingiverse

free

MPCNC Laser Mount

...mpcnc laser mount

thingiverse

custom laser mount for mpcnc.

thingiverse

free

MPCNC Remix

...mpcnc remix

thingiverse

test

thingiverse

free

MPCNC Belt Mod

...mpcnc belt mod

thingiverse

belt mod for mpcnc. alternative to zip tie.

thingiverse

free

MPCNC Y PLATE

...mpcnc y plate

thingiverse

ender 3 printable y plate for mpcnc lowrider 2

thingiverse

free

MPCNC adapter for pen holder

...mpcnc adapter for pen holder

thingiverse

adapter to mpcnc

thingiverse

free

MPCNC Higher Feet

...mpcnc higher feet

thingiverse

extra height and width feet to minimize wobbling on higher mpcnc 2.5mm configurations.

thingiverse

free

MPCNC 30x30 Laser by DariusO

...mpcnc 30x30 laser by dariuso

thingiverse

mpcnc lasermodul in 30x30

thingiverse

free

mpcnc penholder

...mpcnc penholder

thingiverse

a quick remix of two different ideas

thingiverse

free

MPCNC Drillign Guide by isiks_tech

...mpcnc drillign guide by isiks_tech

thingiverse

mpcnc drilling guide for gantry rails.

thingiverse

free

MPCNC Proxxon Mount by CNC_Fan

...mpcnc proxxon mount by cnc_fan

thingiverse

this is my proxxon mount for use mpcnc

Snap

turbosquid

$10

SNAP ACTION SWITCH

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Trigger Snap Hook 3D Model

...ty climbing snap-hook snap-link link shackle holder latch swivel ring equipment

trigger snap hook 3d model firdz3d 88191 3dexport

3d_export

$15

Battery Snap 3D Model

...ial tool part electricity wire

battery snap 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl firdz3d 106985 3dexport

turbosquid

$8

Pro Snap Weight Clip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Стул Snap chair by Karim Rashid

... snap chair

дизайнер карим рашид. пластик, металл. моделилось по фото с сайта дизайнера, материалы vray

turbosquid

$10

Stainless Steel Snap E Ring

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Пуфы Porada Contract, пуф Porada Snap

...уф фабрика porada артикул snap

коллекция newwork the greatness

материал - кожа, отделка - капитоне.

высота -46, диаметр -52 .

3d_export

$25

press fit of automobile hub bearing and snap ring

...splacement curve is monitored during the pressing process. welcome to download and learn if you like. there are step files in it.

3d_export

free

Download free Clock Diamantini Domeniconi Snap 3D Model

...ccessory design home style modern living room decor free

clock diamantini domeniconi snap 3d model modelplusmodel 29252 3dexport

3d_export

$16

womennp2maxfbxobjmb

...womennp2maxfbxobjmb 3dexport polygonal model of a girl.<br>you can easily snap a skeleton for...

Aluminum

3d_export

$5

aluminum crutch

...aluminum crutch

3dexport

aluminum crutch

3d_export

free

aluminum cane

...aluminum cane

3dexport

aluminum cane

3d_export

$5

the aluminum canister

...

3dexport

the aluminum canister is designed for storing and transporting liquids( water), fuels and lubricants (gasoline, oils).

turbosquid

$2

Aluminum Wheel

...uid

royalty free 3d model aluminum wheel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371918)

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$40

Aluminum Can

... free 3d model aluminum can for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301606)

turbosquid

$15

Curved aluminum

...ee 3d model curved aluminum for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1260293)

turbosquid

$12

Aluminum pot

... free 3d model aluminum pot for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1653492)

3d_export

$5

Aluminum Bottle

... for shampoo, conditioner or any liquids (500ml 17floz) separated all parts, able to customize any color, material and finishing.

turbosquid

$19

Aluminum windows

...model aluminum windows for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1646740)

U

3ddd

$1

wii u

...wii u

3ddd

wii , игровая приставка

wii u

turbosquid

$10

U Couch

...turbosquid

royalty free 3d model u couch for download as c4d on turbosquid: 3d models for games, architecture, videos. (1388804)

turbosquid

$7

U for Umbrella

...uid

royalty free 3d model u for umbrella for download as max on turbosquid: 3d models for games, architecture, videos. (1695419)

turbosquid

$5

Letter U

...urbosquid

royalty free 3d model letter u for download as max on turbosquid: 3d models for games, architecture, videos. (1408533)

turbosquid

$5

Letter u

...urbosquid

royalty free 3d model letter u for download as max on turbosquid: 3d models for games, architecture, videos. (1408532)

3d_ocean

$4

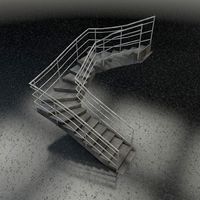

U-shape stairs

...u-shape stairs

3docean

concrete stairs u-shape

concrete u-shape stairs. ceiling height 300cm. stairs width 100cm.

turbosquid

$15

BonePile U

...oyalty free 3d model bonepile u for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546306)

turbosquid

$4

FONT U

...quid

royalty free 3d model font u for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549191)

3ddd

$1

U-Light by Henge

...u-light by henge

3ddd

u-light , henge

designer: massimo castagna

3d_export

$25

gy t hy iy u j u k c b hy u 3D Model

...gy t hy iy u j u k c b hy u 3d model

3dexport

matani

gy t hy iy u j u k c b hy u 3d model tigo 37441 3dexport

Chain

archibase_planet

free

Chain

...chain

archibase planet

chain chain link chain loop

chain n020708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

chain

...chain

3dexport

3d model chain

3d_export

$5

chain

...chain

3dexport

chain. obj,fbx,blend

archibase_planet

free

Chain

...se planet

chain circuit catena

chain - archicad parametrical gdl 3d model (*.gsm). regulation of the length, curvature and angle.

archibase_planet

free

Chain

...n

archibase planet

chain circuit catena

chain - archicad parametrical gdl 3d model(*.gsm). regulation of the length and angle xyz

3d_ocean

$5

Chain

...chain

3docean

3d models chain design elements

3d models, design elements

3d_ocean

$5

Chain

...chain

3docean

3d models chain design elements

3d models, design elements

turbosquid

$10

Chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1329200)

turbosquid

$9

chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1549461)

turbosquid

$2

Chain

...hain

turbosquid

royalty free 3d model chain for download as on turbosquid: 3d models for games, architecture, videos. (1148668)

Angle

design_connected

$25

Angle

...angle

designconnected

flou angle sleep furniture computer generated 3d model. designed by rodolfo dordoni.

3ddd

$1

FLOU / Angle

...flou / angle

3ddd

flou

кровать flou angle. все карты процедурные.

3ddd

free

Кровать ANGLE flou

...le , flou , постельное белье

кровать angle flou

design_connected

$16

Calin Angle

...calin angle

designconnected

ligne roset calin angle computer generated 3d model. designed by mourgue, pascal.

3d_export

$5

angle grease nipple

...angle grease nipple

3dexport

angle grease nipple

3ddd

$1

Двуспальная кровать Angle

...ngle. двуспальную кровать с подъемным механизмом angle оценят и те, кто любит практичность: кровать имеет объемый ящик для белья.

turbosquid

$10

Angle Wardrobe

...e 3d model angle wardrobe for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1301544)

turbosquid

$9

Angle Stool

...y free 3d model angle stool for download as max, skp, and skp on turbosquid: 3d models for games, architecture, videos. (1694318)

3d_export

free

angle bracket

...t 3d model part. it is the combination of a bra and ket (bra+ket = bracket) which represents the inner product of two functions.

turbosquid

$6

Angles Pouf

...e 3d model angles pouf for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1577097)

Cable

3d_export

free

Cables

...cables

3dexport

cables for your purposes

3d_export

free

cable belt for cable organization

...ze your cables in 3d printers. it will bend only to one direction. the area to put the cables per piece is aprox. 1,6cmx2,6cmx1cm

3d_ocean

$16

Ethernet Cable

...ethernet cable

3docean

cable computer electronics ethernet internet network connected

ethernet cable 3d model

3d_export

$65

cable

...cable

3dexport

simple rendering of the scene file

turbosquid

$14

Cable

...l cable for download as ma, max, fbx, 3ds, gltf, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1631358)

3ddd

$1

Cable Cover

...cable cover

3ddd

кабель

vertebra passacavo - cable cover

max + vray 2.20.03

3d_export

$15

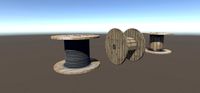

Cable reel

...without cable. textures 4k 4096x4096 targa, png, jpeg.<br>number of polygons without cable: 2896<br>with cable: 35328

3d_export

$7

short cable

...short cable

3dexport

rubber cord. very detailed. cable thickness: 2.55 mm total length: 55mm

3d_export

$5

USB CABLE

...usb cable

3dexport

turbosquid

$30

Cable Reels

...osquid

royalty free 3d model cable reels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1439507)

Bar

archibase_planet

free

Bar

...bar

archibase planet

bar bar rack

bar 2 - 3d model for interior 3d visualization.

archibase_planet

free

Bars

...bars

archibase planet

horizontal bar parallel bars

parallel bars - 3d model for interior 3d visualization.

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

3d_export

$10

bar

...bar

3dexport

modern bar

Supports

turbosquid

$5

Support

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Support 3D Model

...support 3d model

3dexport

support cantilever console

support 3d model tasal 73900 3dexport

3d_export

$5

phone support

...phone support

3dexport

phone

turbosquid

$12

Support bars

...squid

royalty free 3d model support bars for download as max on turbosquid: 3d models for games, architecture, videos. (1411542)

turbosquid

$8

support weights

...id

royalty free 3d model support weights for download as max on turbosquid: 3d models for games, architecture, videos. (1411538)

turbosquid

$2

headphone support

...royalty free 3d model headphone support for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357583)

turbosquid

$2

Support for flowers

...royalty free 3d model support for flowers for download as max on turbosquid: 3d models for games, architecture, videos. (1463543)

turbosquid

$14

Flower Support

...alty free 3d model flower support for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1497066)

turbosquid

$5

serum support

...yalty free 3d model serum support for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1551267)

3d_export

$10

spyro joystick support

...spyro joystick support

3dexport

joystick support of spyro dragon

Fit

turbosquid

$21

Fitting

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fitness

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

fittings

...fittings

3dexport

low poly 3d model for games

3d_export

$5

fittings

...fittings

3dexport

low poly 3d model for game

3d_export

$30

pipe fit

...pipe fit

3dexport

this models basically used for pipe fitting

3d_ocean

$19

Fitting room

...m fitting fitting room furniture interior materials photorealistic restaurant table textured wardrobe

fitting room with textures.

turbosquid

free

Fitness equipment, technogym tools, fitness ball

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

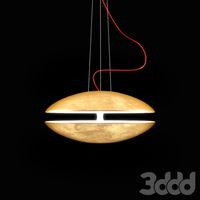

ITRE FIT

...itre fit

3ddd

itre

itre fit, моделировалась по фото. высота 800 мм, диаметр одного - 130 мм.

Version

3ddd

$1

Diamond version

...nd , version , ванна

visionnaire - diamond bath

turbosquid

$50

LibraryMini Version

...free 3d model librarymini version for download as max and jpg on turbosquid: 3d models for games, architecture, videos. (1617724)

design_connected

$34

Barocco Version 01

...barocco version 01

designconnected

zanotta barocco version 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Barocco Version 02

...barocco version 02

designconnected

zanotta barocco version 02 computer generated 3d model. designed by progetti, emaf.

turbosquid

free

![Door [2 versions]](/t/13243146.jpg)

Door [2 versions]

...rbosquid

free 3d model door [2 versions] for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223985)

turbosquid

$2

seat version 0.1

...

royalty free 3d model seat version 0.1 for download as blend on turbosquid: 3d models for games, architecture, videos. (1432653)

turbosquid

$12

Chip Version 03

...lty free 3d model chip version 03 for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1241145)

3d_export

$10

magnolia grandiflora mature version

...magnolia grandiflora mature version

3dexport

magnolia grandiflora mature version

3d_export

$8

room assets and voxel version

...room assets and voxel version

3dexport

room assets and voxel version

turbosquid

$35

Zil Civilian version

... model zil civilian version for download as cgf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639420)