Thingiverse

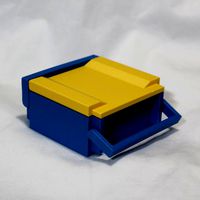

MPCNC - Belt Tensioner Parametric Remix for US or IE Version by GeoDave

by Thingiverse

Last crawled date: 3 years ago

Update 4/9/2016

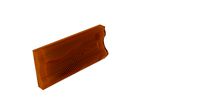

Rev10: Belt Tensioner Plate revised to have option to add reinforcement at the end. I had the previous version break when I pulled the bolt to much to clear the Conduit cap.

Update 3/12/2016

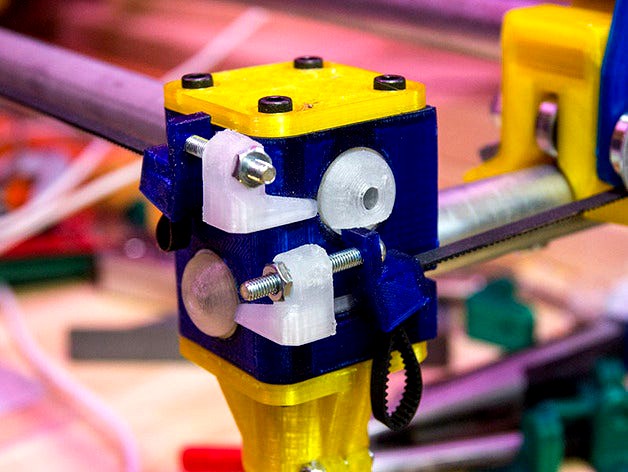

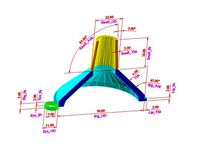

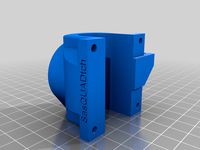

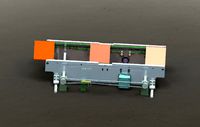

After playing with this design a couple of days, I came up with a change that seems to have solved all my problems I could see with it. I connected the bolt above the belt clamp so I could put a screwdriver on the bolt head while tightening the nut. I also put the open part of the belt clamp to the inside so it would be in line with the belt path. Since the bolt pulls the top part of the clamp more, I added a 15 degree angle to that so the bolt would be close to perpendicular with the clamp. The 1st photo shows it in place. I left the other designs here in case anyone would rather use them. The new files are:

BeltTensionerPlate_Rev8.scad

Bolt_DbleBeltClamp_15deg_Rev1.scad

BeltTensionerPlate_2x_2xBoltDleBeltClamps_Rev8.stl

(print 4 of these for the new design)

Bolt_DbleBeltClamp_2x_15deg_Rev1.stl

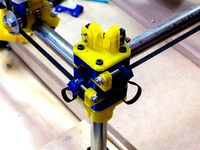

I liked this technique for tensioning the belt, but wanted to be able to adjust some dimensions, so I copied the geometry into openscad and made some of the dimensions variable.

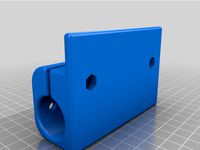

This works with: http://www.thingiverse.com/thing:1401177 & probably also the totem mpcnc corner design. I made 2 versions of the clamps. One uses the teeth of the belt to match teeth cut into the plastic & the other uses a double up to a single width for the belt to clamp it. I am leaning towards the double up design, since it is easier to insert the belt & also.

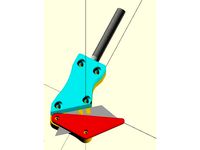

I would print BeltTensionerPlate2x_2xGrooveBeltClamps_2xDbleBeltClamps_Rev5.stl which has both style clamps with it & see which you like best. If you print the belt clamps seperately, I would print at least 2 at a time so each layer of plastic has longer time to cool before the next layer.

There are 3 openscad files included:

BeltTensionerPlate_Rev5.scad

DbleBeltClamp_Rev16.scad

GrooveBeltClamp_Rev16.scad

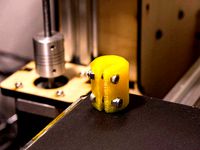

I am using #10 x 1.5" bolts, but you could also use M5x35 or 40mm bolts. The shorter the bolt the less tensioning you can adjust.

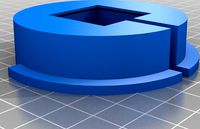

Each openscad file defaults to printing 2 parts. There are several variables in each file that you can adjust. You will need 2 plates & 2 belt clamps at each corner. The belt clamp openscad file have the variable Qty you can set to 1, 2, 4, or 8. I am printing these parts at 40% infill.

The DbleBeltClamp part I hard coded the belt way, so there is less variables you can adjust there.

I used the Groove part from:http://www.thingiverse.com/thing:925911

I used the Bolt Clamping part and tensioning holding plates from:http://www.thingiverse.com/thing:1191395

I used the smooth groove cut from:http://www.thingiverse.com/thing:824458

Rev10: Belt Tensioner Plate revised to have option to add reinforcement at the end. I had the previous version break when I pulled the bolt to much to clear the Conduit cap.

Update 3/12/2016

After playing with this design a couple of days, I came up with a change that seems to have solved all my problems I could see with it. I connected the bolt above the belt clamp so I could put a screwdriver on the bolt head while tightening the nut. I also put the open part of the belt clamp to the inside so it would be in line with the belt path. Since the bolt pulls the top part of the clamp more, I added a 15 degree angle to that so the bolt would be close to perpendicular with the clamp. The 1st photo shows it in place. I left the other designs here in case anyone would rather use them. The new files are:

BeltTensionerPlate_Rev8.scad

Bolt_DbleBeltClamp_15deg_Rev1.scad

BeltTensionerPlate_2x_2xBoltDleBeltClamps_Rev8.stl

(print 4 of these for the new design)

Bolt_DbleBeltClamp_2x_15deg_Rev1.stl

I liked this technique for tensioning the belt, but wanted to be able to adjust some dimensions, so I copied the geometry into openscad and made some of the dimensions variable.

This works with: http://www.thingiverse.com/thing:1401177 & probably also the totem mpcnc corner design. I made 2 versions of the clamps. One uses the teeth of the belt to match teeth cut into the plastic & the other uses a double up to a single width for the belt to clamp it. I am leaning towards the double up design, since it is easier to insert the belt & also.

I would print BeltTensionerPlate2x_2xGrooveBeltClamps_2xDbleBeltClamps_Rev5.stl which has both style clamps with it & see which you like best. If you print the belt clamps seperately, I would print at least 2 at a time so each layer of plastic has longer time to cool before the next layer.

There are 3 openscad files included:

BeltTensionerPlate_Rev5.scad

DbleBeltClamp_Rev16.scad

GrooveBeltClamp_Rev16.scad

I am using #10 x 1.5" bolts, but you could also use M5x35 or 40mm bolts. The shorter the bolt the less tensioning you can adjust.

Each openscad file defaults to printing 2 parts. There are several variables in each file that you can adjust. You will need 2 plates & 2 belt clamps at each corner. The belt clamp openscad file have the variable Qty you can set to 1, 2, 4, or 8. I am printing these parts at 40% infill.

The DbleBeltClamp part I hard coded the belt way, so there is less variables you can adjust there.

I used the Groove part from:http://www.thingiverse.com/thing:925911

I used the Bolt Clamping part and tensioning holding plates from:http://www.thingiverse.com/thing:1191395

I used the smooth groove cut from:http://www.thingiverse.com/thing:824458

Similar models

thingiverse

free

Makerfarm i3v 10" Y-axis belt clamp by GeoDave

...wire ties & replacing them.

i used the belt clamping idea from:http://www.thingiverse.com/thing:643799 to create this part.

thingiverse

free

MPCNC - Totem Corner Parts Remix to make it Parametric by GeoDave

...this design parametric since it has a lot of similarties. the downside of this design is you cannot print...

thingiverse

free

Prusa i3 Updated Y Carriage by Terrapinmfg

...dated bed plate as well.

there is a stp file of the assembly as well as the .stl files for the printed parts and the bed plate.

thingiverse

free

Pulley Customizer Bodged Together by jimtoolman

...ere are some glitches that you have to watch out for. there are many variables that affect the model that may or may not be used.

thingiverse

free

Prusa Y-axis belt tensioner by chrille

...th the build plate mounted on top.

sorry for the sketchup design. i haven't taken the plunge into parametric modelling yet...

thingiverse

free

Yet another belt tension for the MPCNC ( 10mm belt + 2 Bearing ) by 3jcube

...place i used 10mm m3 bolts.

its need support for printing so if you don't like work with supports this thing is not for you.

thingiverse

free

FT-5 Adjustable tension Y carriage replacements by osmoses

... longer.

part is using these inserts:https://www.amazon.com/gp/product/b01iz1rn0a/ref=oh_aui_detailpage_o03_s01?ie=utf8&psc=1

thingiverse

free

Belt Tensioner, adjustable by boksbox

...spring type belt tensioner into an adjustable and rigid form.

fits gt-2 belts. openscad files included for your customization.

thingiverse

free

Anet A8 X-Axis Tensioner Improvement by TheAussieGonz

...where it was needed.

the result needed some reaming to fit the original bolt, so you could experiment with scaling, perhaps 105%.

thingiverse

free

Remix of MPCNC Tangential Knife by GeoDave

...d to a value from 0 to 20.

see the original design: https://www.thingiverse.com/thing:2624654 for further details on this design.

Geodave

thingiverse

free

Shower Caddy accessory holder by GeoDave

... upside down on out shower caddy. i did this a few months back, but changed the design recently to make it stay in place better.

thingiverse

free

Wood Bracket with Wire Clip by GeoDave

...be either at 0 or 90 degrees to wood bracket. i included the openscad & dxf files if you want to adjust this to other sizes.

thingiverse

free

Gimbal Spinner by GeoDave

...elow 24mm for the inside width clearance distance or below 54mm for the gimbal distance. i will take a look at fixing that soon.

thingiverse

free

Spinning Top with Thumbwheel by GeoDave

... works.

https://youtu.be/fpaissfvmqm

here is the openscad source file for the thumbwheelhttps://www.thingiverse.com/thing:2407027

thingiverse

free

Parametric Shaft Coupler by GeoDave

... - m3x14mm bolts & locknuts for the 5mm to 5mm that is shown printed in yellow petg.

you can also open this in the customizer

thingiverse

free

Thumbwheel for a Jack Screw by GeoDave

...ese parts, i realized this might make a good spinning top. here is a link to that top. https://www.thingiverse.com/thing:2407034

thingiverse

free

Remix of Meade Autostar holder for LXD75/LX90 mount by GeoDave

... added 1mm extra around the holes.

i used 2 - m3x16mm screws with locknuts & printed at 40% infill with esun silver pla pro.

thingiverse

free

Parametric Tapered Spacer by GeoDave

... the larger diameter against the wheels & they did not roll at all. the 2nd & 3rd photo should show what i mean by this.

thingiverse

free

A Very Customizable Funnel by GeoDave

...gs in the openscad script.

i changed the hook_xx variable names to a more appropriate eye_xx names after a friend mentioned this.

thingiverse

free

Parametric Honeycomb containers by GeoDave

...file to varie the size of them based on 8 variables. since making this, i have made a number of containers for various purposes.

Mpcnc

thingiverse

free

MPCNC Laser Mount

...mpcnc laser mount

thingiverse

custom laser mount for mpcnc.

thingiverse

free

MPCNC Remix

...mpcnc remix

thingiverse

test

thingiverse

free

MPCNC Belt Mod

...mpcnc belt mod

thingiverse

belt mod for mpcnc. alternative to zip tie.

thingiverse

free

MPCNC Y PLATE

...mpcnc y plate

thingiverse

ender 3 printable y plate for mpcnc lowrider 2

thingiverse

free

MPCNC adapter for pen holder

...mpcnc adapter for pen holder

thingiverse

adapter to mpcnc

thingiverse

free

MPCNC Higher Feet

...mpcnc higher feet

thingiverse

extra height and width feet to minimize wobbling on higher mpcnc 2.5mm configurations.

thingiverse

free

MPCNC 30x30 Laser by DariusO

...mpcnc 30x30 laser by dariuso

thingiverse

mpcnc lasermodul in 30x30

thingiverse

free

mpcnc penholder

...mpcnc penholder

thingiverse

a quick remix of two different ideas

thingiverse

free

MPCNC Drillign Guide by isiks_tech

...mpcnc drillign guide by isiks_tech

thingiverse

mpcnc drilling guide for gantry rails.

thingiverse

free

MPCNC Proxxon Mount by CNC_Fan

...mpcnc proxxon mount by cnc_fan

thingiverse

this is my proxxon mount for use mpcnc

Ie

3d_export

$5

Coffee machine kahve makinesi ie

...coffee machine kahve makinesi ie

3dexport

turbosquid

$149

MZMA Moskvitch-403 IE 1963

...l mzma moskvitch-403ie 1963 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1585239)

3d_export

$99

izh moskvitch-412 ie 1967

...t interior (top). the right dashboard and steering wheel<br>original factory tire m-107 (100386 polygons on the tire 1 pcs)

3d_export

$99

azlk moskvitch-412 ie 1972

...(2-3 interation turbosmooth)<br>original factory tire m-145 (174528 polygons on the tire 1 pcs)<br>version 12.07.2020

3ddd

$1

ikea raskog

...ikea raskog 3ddd ikea http://www.ikea.com/ieen/products/chairs-stools-benches/stools-benches/r%c3%a5skog-stool-blue-art-00299321/ ...

3d_export

$65

Fiat Tempra SX AK

...ak 3dexport fiat tempra italy italian sx ak 1.6 ie uno regeta tofas detailed interior full<br>no texture full...

3ddd

$1

Tea set from the Big Bang Theory / Набор для чаепития

...взрыва" чайник:http://www.amazon.com/rachael-ray-teakettles-crescent-gradient/dp/b0099r6c5c/ref=sr_1_2?s=kitchen&ie;=utf8&qid;=1448531462&sr;=1-2&refinements;=p_n_feature_twenty_browse-bin%3a3254105011 мёд:http://www.amazon.com/gunters-clover-honey-bears-12/dp/b00394vll6/ref=sr_1_7?s=grocery&ie;=utf8&qid;=1449085284&sr;=1-7&keywords;=honey чашки: http://www.amazon.com/color-curve-assorted-gibson-overseas/dp/b00593ky0e/ref=sr_1_5?s=home-garden&ie;=utf8&qid;=1449138685&sr;=1-5&keywords;=mug+set ложки:http://www.amazon.com/artaste-59311-stainless-teaspoon-6-25-inch/dp/b0149lp3qg/ref=sr_1_3?s=home-garden&ie;=utf8&qid;=1449138465&sr;=1-3&keywords;=teaspoon поднос: http://www.amazon.com/vintage-wooden-serving-inches-carved/dp/b00urefuz4/ref=sr_1_291?s=home-garden&ie;=utf8&qid;=1449143138&sr;=1-291&keywords;=tray+wood сахарница: http://www.amazon.com/porcelain-teapot-creamer-sugar-bowl/dp/b0084ohfbq/ref=sr_1_66?s=home-garden&ie=utf8&qid;=1449144667&sr;=1-66&keywords;=creamer+and+sugar+service файл мах 2016!!! +файл мах 2013 vray +файл мах...

3d_export

$5

Samurai Helmet

...sub-division ready, if you choose. i have included textures, ie diffuse, roughness, metallic, normal and displacement...

3ddd

$1

Подушки

...подушки 3ddd подушка линк:http://www.amazon.com/gp/product/b005dem7iq/ref=as_li_ss_tl?ieutf8&tag;=hotocoaneyost-20&linkcode;=as2&camp;=1789&creative;=390957&creativeasin;=b005dem7iq ...

3ddd

free

Wooden Desktop Warfare kit

...desktop warfare kit 3ddd оружие набор моделей метательных орудий http://www.amazon.com/miniature-ballista-kit-desktop-warfare/dp/b005ws0sha/ref=sr_1_2?s=toys-and-games&ie=utf8&qid;=1409952796&sr;=1-2&keywords;=wooden+desktop+warfare ...

Tensioner

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$5

tension ring

...oyalty free 3d model tension ring for download as fbx and stl on turbosquid: 3d models for games, architecture, videos. (1553452)

turbosquid

$3

Tension Chair

...free 3d model tension chair for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1251503)

3d_export

$5

transformador de tension

...transformador de tension

3dexport

transformador de tension entrada 460vac salida 220vac marca audax

turbosquid

$20

Motorbike Chain Tensioner

...y free 3d model motorbike chain tensioner for download as stl on turbosquid: 3d models for games, architecture, videos. (1428322)

turbosquid

$25

TENSION-WOOD-CHAIR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

tension-bentwood-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Tension engagement ring

...n engagement ring for download as obj, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1491631)

3d_export

$10

Ruby Tension set Ring 3D Model

...ruby tension set ring 3d model

3dexport

tension set ruby ring in 18k

ruby tension set ring 3d model rehansheikh 25254 3dexport

turbosquid

$20

Superficial Tension Exp. Image.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Parametric

turbosquid

$25

Parametric

...oyalty free 3d model parametric for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1683196)

3ddd

$1

Parametric Wall

...parametric wall

3ddd

панель

parametric wall with shelf

3d_export

$5

parametric table

...parametric table

3dexport

parametric table model created on rhinoceros 6. this 3d model includes: .gh, .3dm files

turbosquid

$2

Parametric Seat

...id

royalty free 3d model parametric seat for download as max on turbosquid: 3d models for games, architecture, videos. (1691557)

turbosquid

$2

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1690373)

turbosquid

$2

parametrical chandelier

...lty free 3d model parametrical chandelier for download as dxf on turbosquid: 3d models for games, architecture, videos. (1257635)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691303)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691148)

turbosquid

$19

Parametric Bench

...ty free 3d model parametric bench for download as max and max on turbosquid: 3d models for games, architecture, videos. (1713396)

turbosquid

free

Parametric wall

...ee 3d model parametric wall for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1356869)

Belt

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

Remix

turbosquid

$5

MODA Collection Remix Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

remix yamaha rm1x

...remix yamaha rm1x

3dexport

geometry triangles 15.2k vertices 7.6k pbr no textures 1 materials 1 uv layers yes

3d_ocean

$5

Vray fabric Kvadrat remix green - tileable

...th vray and 3dsmax. high-resolution texture images (2000×2000 px) file included: shader vray 2.40 texture image 3ds max 2011 file

turbosquid

$20

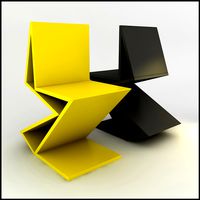

Gerrit Rietveld 1938 Zig Zag Chair Remix

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

multicolored remix parametric table furniture

... fbx, obj, mtl, archive with textures. the model has no glitches. render and materials - vray . without using plugins. good use!

3ddd

$1

Barovier&Toso / Manhattan Remix 7192

... 004293-142405

в коллекции есть люстры 7, 9, 12 рожковые. диаметр соответственный 1000, 1250, 1500 мм.

3ddd

$1

Muuto fiber chair

...grey/grey, dusty green/dusty green, nature/oak, natural white/oak upholstery options remix 183/black, remix 133/grey, remix 643/dusty red leather options black...

3ddd

$1

Barovier&Toso 7190-7195

...7190-7195 3ddd barovier&toso потолочнай люстра фабрики barovier&toso;, коллекция manhattan remix артикул 7190-7195. размеры в inches: 39"...

3d_export

$5

3D Locking Handle Weatherproof Storage Box Container

...handle weatherproof storage box container 3dexport new, improved and remixd! no screws required. print-in-place. weatherproof. parametric. 2 parts. easy...

cg_studio

$49

HTC One Mini 2 Amber Gold3d model

...cell phone mobile cellular super lcd touchscreen touch screen remix amber gold .max .obj .mb .lwo .fbx .c4d .3ds...

Version

3ddd

$1

Diamond version

...nd , version , ванна

visionnaire - diamond bath

turbosquid

$50

LibraryMini Version

...free 3d model librarymini version for download as max and jpg on turbosquid: 3d models for games, architecture, videos. (1617724)

design_connected

$34

Barocco Version 01

...barocco version 01

designconnected

zanotta barocco version 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Barocco Version 02

...barocco version 02

designconnected

zanotta barocco version 02 computer generated 3d model. designed by progetti, emaf.

turbosquid

free

![Door [2 versions]](/t/13243146.jpg)

Door [2 versions]

...rbosquid

free 3d model door [2 versions] for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223985)

turbosquid

$2

seat version 0.1

...

royalty free 3d model seat version 0.1 for download as blend on turbosquid: 3d models for games, architecture, videos. (1432653)

turbosquid

$12

Chip Version 03

...lty free 3d model chip version 03 for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1241145)

3d_export

$10

magnolia grandiflora mature version

...magnolia grandiflora mature version

3dexport

magnolia grandiflora mature version

3d_export

$8

room assets and voxel version

...room assets and voxel version

3dexport

room assets and voxel version

turbosquid

$35

Zil Civilian version

... model zil civilian version for download as cgf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639420)