Thingiverse

![MP Select Mini Rodus Maximus Bed Extension for MK2 MK3 heatbeds [V 1.5] by simkhovich](/previews/8286122.jpg)

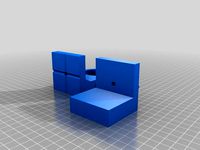

MP Select Mini Rodus Maximus Bed Extension for MK2 MK3 heatbeds [V 1.5] by simkhovich

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is not a fully developed unit, only endeavor if you want to remix/build upon, there is a reason why rods are not popular

Hardware Prerequisites:

1x 10Pcs 250 x 3mm DIY Toy Model Drive Stainless Steel Connecting Rods $8.75- prime

Or any other 10 count 250mm+ 3mm rods

any 2 8mm 300mm rods

A longer G2 Belt of your Choice.

Essentially a must https://www.amazon.com/gp/product/B01MRCZKIX/ref=oh_aui_detailpage_o05_s00?ie=UTF8&psc=1

8x M3 square nuts

8x M3x14mm Socket Head Cap Screw (need right angle allen wrench)

2x M3 x 30 mm

2x M3 Nuts (ideally locking nuts)

Total: around $29.99

NOTE: Whatever heatbed you use it has to have holes that are spaced 209 mm apart, so any heatbed that claims to be 214mm should work

NOTE2: Make sure your power supply can support the new heatbed, i'm not sure if the new 7 Amp power adapter can

[Highly recommend]

Vice

Small Hammer

[Optional]

Metal idlers and teeth upgrade.

Taping oil.

3D printable Prerequisites:

[Highly recommend]

Variable z stop mod

MPSM Y Limit Switch Bracket

[based on need]

glass clamps for bed

Instrictions:

1) insert the M3 square nuts in to the clamps

2) make sure the tensioner and the belt clip fit in to one another as the tolerance is tight

3b) Now the holes as expected don't fit the tolerance and are too small, this is a good thing here as it's all held by friction, unfortunately 2.85mm drill bits are not that common so take the file that looks like an ice pic and heat it up with a lighter or stove and using a pair of pliers separate it from the fandle once hot, don't burn yourself, let cool and now you can toss this bad boy in a drill chuk and work all the holes where the rods go in a vice with the prices mounted in the position that will resist compression. DO NOT DRILL THE M3 screw holes. WARNING IT WILL GET HOT ENOUGH TO BURN YOU AND THE PLASTIC, use taping oil or wd40 or something like a glass of water to keep the file cool or it will help warp the parts in the vice.

4) start hammering the rods one at a time in to the pieces like a kebab (small hammer might be needed) starting with the X axis (the sides that have a 2 on top and 3 on bottom hole pattern) refer to image for how it should look and estimate the position of the 8mm rods for the clamps go slow and fix position constantly if you need to move something or remove a rod toss it in the drill Chuck and spin it out. There will be bending flexing and misalignment, hammer it all.

5) you should now have a set of 2 contraptions each held with 5 rods. space them so they fit the heatbed and measure the belt length needed with clips make sure to leave a bit of slack and cut the belt to length.

6) mount the other 10 rods to make the platform square (more or less refer to picture for overhang and orientation)

7) time to take out the old plate, unscrew carefully one by one the screws that hold down the heatbed careful not to lose the little spring tensioners, you will reuse them for the new bed,

8) wiring, i'm going to leave this up to you

Changelog

8/2/2018 - Major change to clamp and heatbed hole location, increase print area and screws are more accessible

8/1/2018 - Slight change rotated model to use less supports

Hardware Prerequisites:

1x 10Pcs 250 x 3mm DIY Toy Model Drive Stainless Steel Connecting Rods $8.75- prime

Or any other 10 count 250mm+ 3mm rods

any 2 8mm 300mm rods

A longer G2 Belt of your Choice.

Essentially a must https://www.amazon.com/gp/product/B01MRCZKIX/ref=oh_aui_detailpage_o05_s00?ie=UTF8&psc=1

8x M3 square nuts

8x M3x14mm Socket Head Cap Screw (need right angle allen wrench)

2x M3 x 30 mm

2x M3 Nuts (ideally locking nuts)

Total: around $29.99

NOTE: Whatever heatbed you use it has to have holes that are spaced 209 mm apart, so any heatbed that claims to be 214mm should work

NOTE2: Make sure your power supply can support the new heatbed, i'm not sure if the new 7 Amp power adapter can

[Highly recommend]

Vice

Small Hammer

[Optional]

Metal idlers and teeth upgrade.

Taping oil.

3D printable Prerequisites:

[Highly recommend]

Variable z stop mod

MPSM Y Limit Switch Bracket

[based on need]

glass clamps for bed

Instrictions:

1) insert the M3 square nuts in to the clamps

2) make sure the tensioner and the belt clip fit in to one another as the tolerance is tight

3b) Now the holes as expected don't fit the tolerance and are too small, this is a good thing here as it's all held by friction, unfortunately 2.85mm drill bits are not that common so take the file that looks like an ice pic and heat it up with a lighter or stove and using a pair of pliers separate it from the fandle once hot, don't burn yourself, let cool and now you can toss this bad boy in a drill chuk and work all the holes where the rods go in a vice with the prices mounted in the position that will resist compression. DO NOT DRILL THE M3 screw holes. WARNING IT WILL GET HOT ENOUGH TO BURN YOU AND THE PLASTIC, use taping oil or wd40 or something like a glass of water to keep the file cool or it will help warp the parts in the vice.

4) start hammering the rods one at a time in to the pieces like a kebab (small hammer might be needed) starting with the X axis (the sides that have a 2 on top and 3 on bottom hole pattern) refer to image for how it should look and estimate the position of the 8mm rods for the clamps go slow and fix position constantly if you need to move something or remove a rod toss it in the drill Chuck and spin it out. There will be bending flexing and misalignment, hammer it all.

5) you should now have a set of 2 contraptions each held with 5 rods. space them so they fit the heatbed and measure the belt length needed with clips make sure to leave a bit of slack and cut the belt to length.

6) mount the other 10 rods to make the platform square (more or less refer to picture for overhang and orientation)

7) time to take out the old plate, unscrew carefully one by one the screws that hold down the heatbed careful not to lose the little spring tensioners, you will reuse them for the new bed,

8) wiring, i'm going to leave this up to you

Changelog

8/2/2018 - Major change to clamp and heatbed hole location, increase print area and screws are more accessible

8/1/2018 - Slight change rotated model to use less supports

Similar models

thingiverse

free

Towel Hanger by FunFunBoy

...20 mm m3 screw and an m3 nut to assemble it and you may need to drill the hole with 3mm drill bit to make hole fit your m3 screw.

thingiverse

free

Creality Ender-2 X Belt Cover and adjustable Endstop by PedaBot

...gh. for endstop mount need: 2 m3 nut 2 m3 spezial-nut (i used nut from my adjustable anet heatbed) you can use also other m3 nuts

thingiverse

free

Drill Machine Jig by PCatt

... a drill machine.

f.e. to clamp it into a vice and mount a polishing wheel.

the hole is 43mm,

you just need 2 nuts and bolds....

thingiverse

free

Parametric drill stop by ksuszka

... it till the nut is in the position

gently unscrew the long screw leaving the nut in the place

put the washer and the final screw

thingiverse

free

Drill attachment for the Vice mechanical v2.0 by Shlagork

...ink the hole for the screw is not centered, but it works.

you need a screw, like m3 with hexagonal head, not sure about the size.

thingiverse

free

FormBot T-Rex 2 / Heatbed holder by Felix22

...rom formbot

print glas 3mm

total 8 mm

you need:

1x screw m6 x 50mm

1x nut m6 (outside diameter 10mm)

8x screw m3 x 12mm

8x nut m3

thingiverse

free

Universal SmartPhone Clamp for Tripod by Scorpion722

...for the tripod screw is empty (use a 5 mm drill bit if needed)

screw the clamp to the tripod

insert your phone and you are done !

thingiverse

free

Anet A8 3-point heatbed leveling addon by Kotvic

...and watch first layer to be just right. if it is too close or too far, adjust origin position in your firmware or adjust endstop.

thingiverse

free

VIKI 2 LCD Prusa i3 mount by jkoljo

...ackets to printer frame have captive nuts.

the design requires printed files + 8x 20mm m3 bolts and 4x m3 nuts. washers optional.

thingiverse

free

Headphone Stand On Lamp

...es for bolts.

for lamp holes you need drill 4 holes to 4mm and for 2 small holes for m3 drill holes to 3mm.

sorry for my english.

Rodus

3dwarehouse

free

rodu

...rodu

3dwarehouse

ilma laudadeta

3dwarehouse

free

Novogotická hrobka rodu Staňků

.... #gotická #gotické #gotický #hrob #hrobka #hřbitov #novogotická #novogotické #novogotický #novogotika #rod #rodu #staňků #staňěk

3dwarehouse

free

Novorenesanční hrobka rodu Fornerů

...u starého kostela, karviná-doly #doly #forner #fornerové #fornerů #hrobka #karviná #novorenesanční #renesanční #u_starého_kostela

3dwarehouse

free

Historický statek č.p. 13 v Hejné

...tatek č.p. 13 v hejné

3dwarehouse

historický statek rodu kohoutů v hejné #hejná #klatovy #lidová_architektura #památky #plzeňsko

3dwarehouse

free

Helina chalupa - cottage

...ttage

3dwarehouse

helina chalupa z rodu čapov na slávikovom laze. helin's cottage form čapo line on settlement slávikov laz.

3dwarehouse

free

Moszna

...w będącego wlaścicielemm.in.zamku w mosznej w latach 1866-az do śmierci 1893 pomnik został zniszczony w 1950roku #moszna #pomniki

3dwarehouse

free

Stremehl Schloss in Polen

... nazywana była 'wilczym gniazdem' #castle #donżon #labes #poland #radowo_małe #schloss #strzmiele #szczecin #zamek #łobez

3dwarehouse

free

Chapel StJ.Nepomucky

...835. v kapli je umístěno lapidárium soch s expozicí o historii kaple. #chapel #kapelle #kaple #neoghotic #neugotisch #novogotický

3dwarehouse

free

Kościół fil. pw. Trójcy Św. w Proboszoczowie

...owa kaplica rodu von redernów z około 1750r. #architektura_sakralna #barok #dolny_śląsk #kościół #kościół_ucieczkowy #proboszczów

Maximus

turbosquid

$16

Maximus

...y free 3d model maximus for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1674857)

3d_ocean

$5

Maximus Gladiator Helmet

...s helmet from the gladiator movie poly count: 5308, with turbo smooth 22721 file formats: 3ds max 2013 default, 3ds, fbx and obj

3d_ocean

$15

Maximus GT

...an sports transport vehicle

generic and low polygon sports car. for the latest model, visit my website: http://syndicate3d.at.ua/

cg_studio

$15

Maximus GT3d model

... gt3d model

cgstudio

.3ds .max .dxf .obj - maximus gt 3d model, royalty free license available, instant download after purchase.

3d_export

$15

Maximus GT 3D Model

...t

maximus gt generic sports car vehicle transport sedan coupe game ready classic

maximus gt 3d model clutchtrigger 44995 3dexport

3d_export

$80

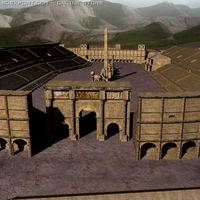

Circus Maximus 3D Model

... rome race chariot horse ben hur benhur arena stadium racetrack ancient gladiator

circus maximus 3d model bustermk2 5588 3dexport

turbosquid

$44

Maximus sofa corner

...el maximus sofa corner for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1451291)

turbosquid

$99

Antonov AN124 Maximus

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

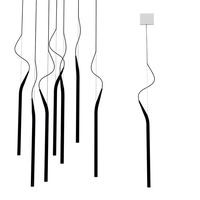

MAXIMUS RECTANGULAR CHANDELIER

...s masterfully crafted linear wrought iron frame, finished in a rich pyrite bronze, instills in this piece a cool industrial feel.

3d_export

$49

Asian Elephant Elephas Maximus 3D Model

...imals low poly lowpoly photoreal realistic textures nature fauna

asian elephant elephas maximus 3d model humster3d 57754 3dexport

Heatbeds

thingiverse

free

HeatBed by moreken

...heatbed by moreken

thingiverse

heatbed for my printer3d "moredelta"

thingiverse

free

heatbed (double heatbed) holder by Vo_Van_163

... bigger size than work desk. this holder - is good solution for me/ and also this is a good solution for double hotbed regulation

thingiverse

free

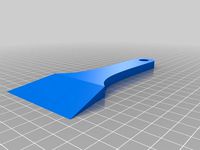

Heatbed Spatula by Brabus453

... spatula by brabus453

thingiverse

heatbed spatula

this is a simple spatula to scrape the heatbed from the first layer residues.

thingiverse

free

Heatbed Mount for round Heatbeds by OliverReinecke

...y bottom board to fix the heatbed-mount. but of coursse there are lots of alternatives to do this... its up to you. hope it helps

thingiverse

free

Heatbed plane test

...the accuracy of printings over the size of my heatbeds ... this simple object allows to see where the...

thingiverse

free

Heatbed Knob by Sp0nge

...heatbed knob by sp0nge

thingiverse

craftbot plus heatbed knob

print it in abs and put a nut inside.

thingiverse

free

Heatbed cable cover

... the heatbed when i placing the pei sheet.

so i designed this small cover, it clips right down over the +/- screws on the heatbed

thingiverse

free

Heatbed Mosfet controller by oscar_diciomma

...heatbed mosfet controller by oscar_diciomma

thingiverse

heatbed mosfet controller

thingiverse

free

Parametric Heatbed Clamp by verglor

...y verglor

thingiverse

minimalistic heatbed clamps that do not get in way of nozzle.

can be customized for any heatbed thickness.

thingiverse

free

Heatbed support

...ail

heatbed size 328mm

use m5x10 with washers or m5x8 for the 20x20 profile

m4 for heatbed

can be use with wells of 45mm of diam.

Mp

turbosquid

$19

MP-5

...-5

turbosquid

royalty free 3d model mp-5 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1537795)

turbosquid

$3

MP-18

...turbosquid

royalty free 3d model mp-18 for download as blend on turbosquid: 3d models for games, architecture, videos. (1506436)

turbosquid

$5

Mp-28

...quid

royalty free 3d model mp-28 for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1613220)

turbosquid

$5

Nightstand MP

...yalty free 3d model nightstand mp for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1655571)

turbosquid

$25

MP 3008

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

MP 28

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

MP-44

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

MP-153

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Mp 41

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

MP-44.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mk2

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

Mk3

turbosquid

$50

cention mk3

...ty free 3d model cention mk3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454148)

turbosquid

$129

MK3 Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Toyota Supra MK3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$44

cention mk3 low poly

...d model cention mk3 low poly for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454666)

turbosquid

$30

Challenger I Mk3 Falcon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

American Frag hand grenade MK3

...free 3d model american frag hand grenade mk3 for download as on turbosquid: 3d models for games, architecture, videos. (1393624)

turbosquid

$20

Mk3 US Navy Combat Knife

...ty free 3d model mk3 us navy combat knife for download as fbx on turbosquid: 3d models for games, architecture, videos. (1172791)

3d_export

$29

Ford Fiesta MK3 Modified 3D Model

...7 tumerfx mtumer mehmet t?mer 1993 1995 1996 wrc special modifed modifiye

ford fiesta mk3 modified 3d model mtumer 30698 3dexport

3d_export

$99

Toyota Supra Mk3 19861993 3D Model

...ort fast coupe japan 1986 1987 1988 1989 1990 1991 1992 1993 tuning turbo

toyota supra mk3 19861993 3d model squir 62530 3dexport

turbosquid

$5

Timothy Oulton Mars Chair MK3

...on mars chair mk3 for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1209782)

Extension

3d_export

$5

extension plug - extension socket

...model. low poly and game ready. with blender files and texture (.png).<br>verts: 424<br>faces: 364<br>tris: 808

3ddd

$1

Moooi, Extension Chair

... стул , вешалка

стулья фирмы moooi, коллекция extension

turbosquid

$300

Bedroom Extension

...

royalty free 3d model bedroom extension for download as skp on turbosquid: 3d models for games, architecture, videos. (1682078)

3d_export

$5

palo extensible

...palo extensible

3dexport

turbosquid

$39

Leg Extension

...ee 3d model leg extension for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1276776)

3d_export

$5

lampe extensible architecte

...lampe extensible architecte

3dexport

lampe extensible architecte maisons du monde

turbosquid

$20

Leg Extension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Garage Extension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Extension cable

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Moooi Extension Chair

...moooi extension chair

3ddd

moooi

http://www.moooi.com/products/extension-chair

Select

3ddd

$1

TUBADZIN SELECT

...max 2014, 2011.

fbx 2014, 2013, 2011,

obj

_____________________________________http://www.tubadzin.pl/en/collection/324

3ddd

$1

Плитка Selection

... supergres , плитка

плитка selection - supergres ceramiche

turbosquid

$15

Christmas Selection

...royalty free 3d model christmas selection for download as fbx on turbosquid: 3d models for games, architecture, videos. (1696333)

turbosquid

$39

Vases selection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SELECTIVE RACKING SYSTEM

...yalty free 3d model selective racking system for download as on turbosquid: 3d models for games, architecture, videos. (1282512)

turbosquid

$10

Hansgrohe ShowerTablet Select

...ee 3d model hansgrohe showertablet select for download as max on turbosquid: 3d models for games, architecture, videos. (1336955)

turbosquid

$29

Chill selectional sofa

...odel chill selectional sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1465691)

3ddd

free

Lunaria - Nova, ASA Selection

... asa selection , dried flowers

ветка лунарии в вазе nova, asa selection

3ddd

$1

inno SELECT SLIM chair

...inno select slim chair

3ddd

inno

high detailed inno select slim chair

turbosquid

$29

Select Chaise Lounge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

Bed

...bed

3ddd

bed , постельное белье , постель

bed

3d_export

$7

bed adairs bed

...rs bed

3dexport

bed adairs bed in modern style. if you want a smoother surface, please turn on turbosmooth in the modifier list.

V

design_connected

$16

V Chair

...v chair

designconnected

v chair computer generated 3d model.

design_connected

$11

V Hanglamp

...v hanglamp

designconnected

arturo alvarez v hanglamp computer generated 3d model. designed by alvarez, arturo .

turbosquid

$25

Borbet V

...v

turbosquid

royalty free 3d model borbet v for download as on turbosquid: 3d models for games, architecture, videos. (1381618)

turbosquid

free

Saturn V

...rn v

turbosquid

free 3d model saturn v for download as blend on turbosquid: 3d models for games, architecture, videos. (1651098)

turbosquid

$40

V motor

...turbosquid

royalty free 3d model v motor for download as max on turbosquid: 3d models for games, architecture, videos. (1379483)

turbosquid

$7

V for Van

...rbosquid

royalty free 3d model v for van for download as max on turbosquid: 3d models for games, architecture, videos. (1695889)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408535)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408534)

turbosquid

$15

BonePile V

...oyalty free 3d model bonepile v for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546310)

turbosquid

$2

FONT V

...quid

royalty free 3d model font v for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549450)

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)