Thingiverse

Monoprice X Extension 228mm Maker Select by chinaman4u

by Thingiverse

Last crawled date: 3 years ago

This is a low or zero cost modification. Need that extra few mm of space to print?

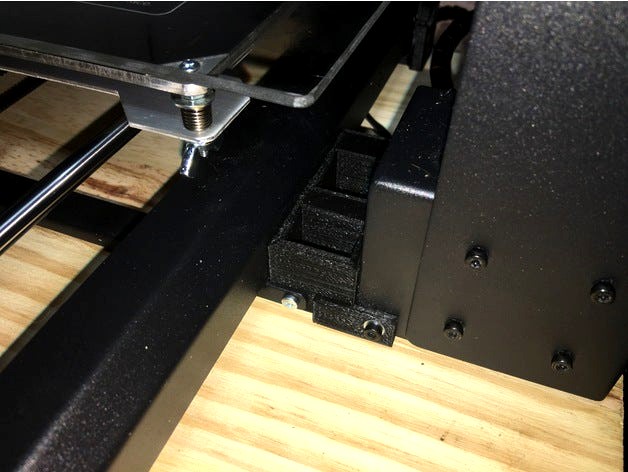

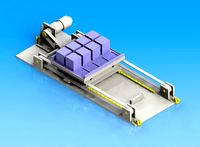

I made this spacer in Sketchup allowing me to increase my X axis from 200mm to 228. It does require a lot of work/disassembly to make this modification. I just needed a slightly larger print area and found this to be a great solution. I now run my Monoprice Maker Select V2.1 at 228mm(x) by 214mm(y), using a 250mmx400mm glass bed clipped to stock bed.

THE TOP FRAME WILL NEED TO BE BENT or CUT in order to make this modification work. It works with the Z-brace! (SEE PHOTOS)

THE PRINT BED NEEDS TO BE DRILLED to allow for flush mounted bolts. Do not run the drill fast, run it really slow, to prevent the drill from grabbing and cutting through. Or use a cone shaped sanding stone on a Dremel. Aluminum bed is very soft. The screws on the heated bed needs to be convert to flush bolts so it doesn't get in the way of the larger glass bed.

The x axis shafts are too short, so the x axis shaft mounts will be needed to be flipped to the outside to make this modification work. And it is the most difficult job since there is very little clearance to get an allen wrench to tighten the block from the backside, but it is doable, with a lot of patience.

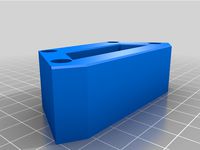

The belt will also be too short, so a different belt tensioner is used to make up the length. I used the WanHao Duplicator I3 2.1 and Plus Belt Tensioner by AlexWYYC and reused the stock belt.

You will need two M5 0.80 x 40 screws, and one M3 0.50 x 20 and an appropriate nut.

You will also need a larger glass print bed.

You need 4x flush bolts and nuts and adjusting thumbwheel for hot bed.

Glass bed is the major cost. No longer rods/belts needed. Just print the X extension spacer and the belt tensioner and a quick trip to Lowe's.

Note: This is my first attempt at making something on my own. I am unhappy with the finish of the part, but it is usable as is. I used 50% infill but I would recommend 100%. I will not be doing any more work and have included the Sketchup file for your use. You can also use anything for a spacer, a 30mm metal sleeve, for example.

I made this spacer in Sketchup allowing me to increase my X axis from 200mm to 228. It does require a lot of work/disassembly to make this modification. I just needed a slightly larger print area and found this to be a great solution. I now run my Monoprice Maker Select V2.1 at 228mm(x) by 214mm(y), using a 250mmx400mm glass bed clipped to stock bed.

THE TOP FRAME WILL NEED TO BE BENT or CUT in order to make this modification work. It works with the Z-brace! (SEE PHOTOS)

THE PRINT BED NEEDS TO BE DRILLED to allow for flush mounted bolts. Do not run the drill fast, run it really slow, to prevent the drill from grabbing and cutting through. Or use a cone shaped sanding stone on a Dremel. Aluminum bed is very soft. The screws on the heated bed needs to be convert to flush bolts so it doesn't get in the way of the larger glass bed.

The x axis shafts are too short, so the x axis shaft mounts will be needed to be flipped to the outside to make this modification work. And it is the most difficult job since there is very little clearance to get an allen wrench to tighten the block from the backside, but it is doable, with a lot of patience.

The belt will also be too short, so a different belt tensioner is used to make up the length. I used the WanHao Duplicator I3 2.1 and Plus Belt Tensioner by AlexWYYC and reused the stock belt.

You will need two M5 0.80 x 40 screws, and one M3 0.50 x 20 and an appropriate nut.

You will also need a larger glass print bed.

You need 4x flush bolts and nuts and adjusting thumbwheel for hot bed.

Glass bed is the major cost. No longer rods/belts needed. Just print the X extension spacer and the belt tensioner and a quick trip to Lowe's.

Note: This is my first attempt at making something on my own. I am unhappy with the finish of the part, but it is usable as is. I used 50% infill but I would recommend 100%. I will not be doing any more work and have included the Sketchup file for your use. You can also use anything for a spacer, a 30mm metal sleeve, for example.

Similar models

thingiverse

free

MP Select Mini GT2 Y & X Belt Clips / Tensioner Monoprice by A_Makers_Life

...more travel.

you will need to drill and tap 2 m3 screws to mount this to the bed. i used a 2.5mm / 2s drill bit & a 3mm tap.

thingiverse

free

CR-10S S5 Y-Axis Belt Tensioner Mount

...tps://www.amazon.com/3d-synchronous-straighten-tensioner-creality/dp/b07rfrrx7p

gear:https://www.amazon.com/gp/product/b072c9831q

thingiverse

free

Monoprice Select Mini. X Axis Belt Tensioner Mod. by lowfat

...sm w/o an x-axis shroud is normal. so i've added versions that you can use that don't require the shroud to be installed.

thingiverse

free

Improved Anet A8 RepRap X-Axis Belt Tensioner by WedgeSD

...want to wrap the belt around the bearing and insert into the housing then bolt the bearing in place, as shown in the photo's.

thingiverse

free

X-axis belt tensioner - Prusa I3 by scampagna

...ation needed. this part makes it possible to add the functionality of tensioning the belt of the axis x on the side of the motor.

thingiverse

free

CR-10S Y-Axis Belt Tensioner by eliaolgiati

...eed:

m4 hex head bolt

m4 hex head nut

the other standard parts are provided by the stock belt tensioner installed on the printer.

thingiverse

free

CR-10 X-axis tensioner shim spacer by Goblins

...im for the x-axis right mount bearing.

it will center the belt at the center of the rail and not on the side as in stock machine.

thingiverse

free

i3 Duplicator Y belt pulley tensioner by Xierion

... locknuts

(optional) 1 x m5 washer (for adjustment bolt)

see also the x belt tensioner: https://www.thingiverse.com/thing:2655574

thingiverse

free

X-Axis belt tensioner for geared GT2 pulley by ibschreiber

...want to wrap the belt around the bearing and insert into the housing then bolt the bearing in place, as shown in the photo's.

thingiverse

free

Elk's X-Axis T5 Belt Tensioner for Mendel by elk

...k

thingiverse

my version of a belt tensioning system for mendel x axis and t5 belt.

i use it since some time and it works great.

Chinaman4U

thingiverse

free

2" telescope dust cap by chinaman4u

...2" holes for telescope dust cap. fits perfectly, printed in pla. feel free to make any modifications for your own remakes.

thingiverse

free

quick release FX12 Davis Sanford Magnum XG by chinaman4u

...reccommended, i think is better to prevent separation of layers when attached to tripod. includes sketchup file, stl, and gcode.

228Mm

3d_export

$5

traverse mechanism of heavy workpiece

...(dp) × π× (ia) × (ib) × 1 / 60<br>=600×80×π×(1/9)×(40/49)×1/60=228mmsec<br>(according to the operating speed (ns): 600rpm)<br>key points of structure...

3d_sky

free

Kludi ZENTA - 3897391757-8884

...according to the manufacturer's scheme: diameter - 45mm, height -228mm ...

thingiverse

free

Kenner Tie Fighter Wing by apcoyne

...your printer has a build plate of at least 228mm in one horizontal axis print the complete wing files,...

thingiverse

free

Simple Deadpool Bust - work in progress by JBarrera30

...of champions game. approx. dimensions: ****108mm by 104mm by 228mm haven't printed it yet, but i'm working on getting...

thingiverse

free

GWR Steam Locomotive Builders Plate by atgordon

...too small to print this full size (556mm x 228mm, so i jigsawed the plate into two pieces and...

thingiverse

free

IMA-GO mini 3D Printer by gunawansy

...firmware: https://github.com/gunawansy/ima-go rods: 6mm smooth rods: 1 6mm x 228mm x 2 y axis 2 6mm x 220mm x...

thingiverse

free

Star Wars Outer Rim Game Insert by irmcdermott

...and one. unfortunately since the player boards are around 228mm the main trays are slightly longer than that, so...

thingiverse

free

CTC Adjustable Glass Bed Corner Clamp by m4t42

...sliders are the right shape for my 151mm x 228mm glass plate from wanhao.co.uk i'm also about to design...

thingiverse

free

Pen Holder for office (Customizable) (Small Version) by STEV-o

...extra pockets at the left side. new dimensions: length: 228mm width: 120mm height:...

Monoprice

thingiverse

free

Display frame for Monoprice MP10

...display frame for monoprice mp10

thingiverse

display frame for monoprice mp10

thingiverse

free

Bridge covers Monoprice MP10

...bridge covers monoprice mp10

thingiverse

bridge covers monoprice mp10

thingiverse

free

Monoprice Coin by Peyton_Guyot

...monoprice coin by peyton_guyot

thingiverse

print this!

thingiverse

free

Voxel Monoprice spool holder by avalero

...voxel monoprice spool holder by avalero

thingiverse

voxel monoprice spool holder

thingiverse

free

Monoprice select mini knob by BramRausch

...monoprice select mini knob by bramrausch

thingiverse

this is a replacement knob for the monoprice select mini.

thingiverse

free

Monoprice 3d printer hook by dmitriyf

...monoprice 3d printer hook by dmitriyf

thingiverse

this is an attachment to monoprice select 3d printer v2

thingiverse

free

monoprice ultimate spool mount by death4u

...older by danmannert to monoprice ultimate 3d printer. it clips into the slot on the top of the printer for the optional enclosue.

thingiverse

free

Monoprice Mini Delta Foot

...a foot for a monoprice mini delta. it helps to increase airflow under the printer. it also helps to reduce the volume of the fan.

thingiverse

free

Monoprice Select Mini Fan Guard

...y fan protection. this is an essential upgrade.

used it on the monoprice select mini pro (from www.3dprinthings.be).

perfect fit!

thingiverse

free

Monoprice Cable Tie Mount

... but had to cut down the straps a bit to make them work. designed a quick mount that fits the full strap, item 6457 on monoprice.

Extension

3d_export

$5

extension plug - extension socket

...model. low poly and game ready. with blender files and texture (.png).<br>verts: 424<br>faces: 364<br>tris: 808

3ddd

$1

Moooi, Extension Chair

... стул , вешалка

стулья фирмы moooi, коллекция extension

turbosquid

$300

Bedroom Extension

...

royalty free 3d model bedroom extension for download as skp on turbosquid: 3d models for games, architecture, videos. (1682078)

3d_export

$5

palo extensible

...palo extensible

3dexport

turbosquid

$39

Leg Extension

...ee 3d model leg extension for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1276776)

3d_export

$5

lampe extensible architecte

...lampe extensible architecte

3dexport

lampe extensible architecte maisons du monde

turbosquid

$20

Leg Extension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Garage Extension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Extension cable

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Moooi Extension Chair

...moooi extension chair

3ddd

moooi

http://www.moooi.com/products/extension-chair

Select

3ddd

$1

TUBADZIN SELECT

...max 2014, 2011.

fbx 2014, 2013, 2011,

obj

_____________________________________http://www.tubadzin.pl/en/collection/324

3ddd

$1

Плитка Selection

... supergres , плитка

плитка selection - supergres ceramiche

turbosquid

$15

Christmas Selection

...royalty free 3d model christmas selection for download as fbx on turbosquid: 3d models for games, architecture, videos. (1696333)

turbosquid

$39

Vases selection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SELECTIVE RACKING SYSTEM

...yalty free 3d model selective racking system for download as on turbosquid: 3d models for games, architecture, videos. (1282512)

turbosquid

$10

Hansgrohe ShowerTablet Select

...ee 3d model hansgrohe showertablet select for download as max on turbosquid: 3d models for games, architecture, videos. (1336955)

turbosquid

$29

Chill selectional sofa

...odel chill selectional sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1465691)

3ddd

free

Lunaria - Nova, ASA Selection

... asa selection , dried flowers

ветка лунарии в вазе nova, asa selection

3ddd

$1

inno SELECT SLIM chair

...inno select slim chair

3ddd

inno

high detailed inno select slim chair

turbosquid

$29

Select Chaise Lounge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Maker

3d_ocean

$17

Coffee Maker

...coffee maker

3docean

breakfast coffee drip electric maker morning

detailed coffee maker and a plug.

3ddd

$1

coffee maker

...coffee maker

3ddd

кофемашина

coffee maker

3d_export

$10

chapati maker

...chapati maker

3dexport

it is a indian traditional chapati maker

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Сoffee maker

...er

archibase planet

coffee maker percolator coffee-machine

сoffee maker n020112 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

coffee maker percolator coffee-machine

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Juice Maker

...juice maker

3ddd

соковыжималка

fully detailed kenwood juice maker

archibase_planet

free

Coffee maker

...hibase planet

coffee maker percolator coffee-machine

coffee maker n140611 - 3d model (*.gsm+*.3ds) for interior 3d visualization.