Thingiverse

Monoprice Select Mini Thumbwheel Leveling System by ahutton1972

by Thingiverse

Last crawled date: 3 years ago

Update December 22, 2018

A new Version 2 Thumbwheel Leveling System is available here:

https://www.thingiverse.com/thing:3280396

It's much better than this one!

Please consider trying the newer version above as it works much better and is more reliable.

Update February 14, 2018

I've changed this from a work in progress to final. I do not plan on making any other changes to this system unless someone indicates a problem. Several have been successful with this system so I am making the move. Thanks to those that gave it a try in the beta stage!

Update: February 11, 2018

It was brought to my attention that the regular back bracket was missing the countersunk holes for the springs. I've updated the files and recommend everyone update that bracket with the newer file. The bracket without the countersunk is still usable if you use one of the the spring cup washers on the bottom.

Update: February 11, 2018

I've added a version of the front bracket with the magic number layer heights embossed in it. You can choose the original version or the magic number version as you please. No need to print both.

Update: February 10, 2018

I've added a back bracket with an integrated wire harness for those that choose to do the heat bed wire modification. You can use the same wheels with this bracket. It has a slot to hold a zip tie if you wish to secure your wires for strain relief. You choose which bracket you want to use. No need to print both.

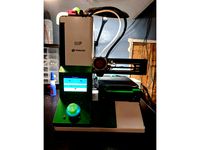

Monoprice Select Mini Thumbwheel Leveling System

This is a thumb wheel leveling system I designed for the Monoprice Select Mini 3D Printer. This system is designed to be completely printable on the MP Select Mini and installed without any drilling or modification to the existing hardware. In doing this, the mod takes up some Z-height that you will lose for taller prints. The advantage of this system is that it is easily installed and removed if a larger Z-height is required.

Note: This is a prototype (Beta) leveling system that I may still tinker with based on recommendations and required improvements

Please follow the installation instructions below in order to be successful with this mod. DO NOT attempt to print until you have installed the correctly sized provided spacer

Also, I HAVE NOT tested the z-spacers with a glass bed. Do so at your own risk

Parts List:

4 M2 X 25mm screws to secure to the heat bed. I am currently using M2 X20mm screws and it does work, but you have more flexibility with the longer screws. DO NOT use M3 screws and DO NOT use the current screws used to hold the heat bed. They will not work. Must be M2. I used hex head M2 screws because that's what I had on hand, but you can use whichever head style you like. Countersunk style heads would probably be the best.

4 M2 nylon lock nuts or lock washers. I prefer the lock nuts as they are more secure

4 M2 nuts. 8 if you choose to go the lock washer route.

8 M2 washers to prevent the M2 screws from falling through the heat bed screw holes.

Existing printer springs, cup washers and screws that secure the bed to the y-axis rods

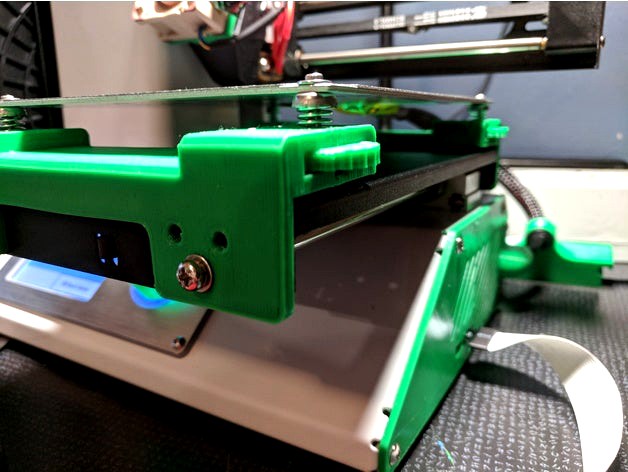

InstallationPlease reference the photos provided when putting together your system.

1.) Print all parts before assembly. DO NOT INSTALL ANY PARTS until you have printed out both the front and back brackets, the thumb wheels, and the necessary spacer.

2.) In order to print the brackets on the MP Select Mini, you will have to adjust your printer settings in Cura (or your particular slicer) to have an X and Y length of 125mm. This is not ideal as the official lengths are 120mm. But in order to print, we have to cheat a little and squeeze out a little more space. Reference the Cura photos. You most likley will not be able to fit a skirt or brim, so if you can print without. Please remember to put your settings back (X:120mm Y:120mm) when you are done. Alternately you can print the brackets on a larger printer.

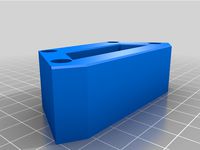

3.) None of the parts require supports if oriented correctly in your slicer. The bracket should be printed as shown in the photo and the wheels face down.

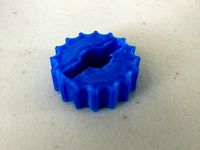

4.) Thumb wheel assembly: The nuts will tightly fit within the hub of the wheels. You might have to tap them in a little to get them to seat properly. It is HIGHLY recommended that you super glue these in place. Please allot enough time for the glue to dry or the wheel will not be usable. You've been warned. Once the glue has dried, run an M2 screw through the nut a few times to make sure the inner threads of the nut are clear of dried glue. It might take some doing to clean it out but it's not too hard. I don't recommend heating the nuts and melting them in place since this tends to leave them not flush. If the nuts aren't flush with the face of the bed, it will make the wheels very difficult to turn.

5.) Place the wheels into the slots of the brackets. The nut should be facing down.

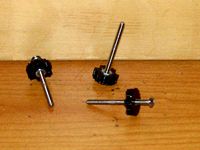

6.) Attach screws to heat bed: The 4 M2 screws must be securely fastened to the heat bed so that they DO NOT TURN. This is accomplished with the nylon lock nuts or lock washers. Also secure existing cup washers as shown in the pictures. Use M2 washers on the top of the bed to prevent the screw head from falling through the screw hole.

7.) Screw brackets to the gantry. Remove the screws that hold the bed gantry to the y-axis rods. You can do this without harming anything. Just don't move the bed a bunch after you have unscrewed. Place the bracket on the bed and using the same screws, screw the bracket to the bed. Repeat for the other bracket. Please be careful that you install the correct brackets on the front and back.

8.) Assemble the heat bed: Place the heat bed on top of the brackets. The screws should line up with the center of the wheels. If they do not loosen them and re-align until they do. Place the existing 4 springs around the screws and make sure they seat into the depression of the brackets. Press down with the face of your hand on the heat bed until the screws seat with the top of the nuts in the thumb wheels. Turn each thumb wheel counter clockwise until the screw catches in the nut and it holds. At this point your heat bed should be securely fastened.

9.) Install the z-axis spacer: Lower the bed with the thumb wheels as low as they will go. Because the brackets add 12mm to the z-axis height, we have to adjust for this. 3 spacers are available for printing: 0mm offset, 3mm offset, and 4mm offset. The 0mm offset should be used by those that have not added a surface such as glass to the heat bed. BuildTak users, tape users, etc should use the 0 mm offset spacer. If you are using glass or another substrate choose the appropriate width (3mm or 4mm) for your application. Place the spacer as shown in the picture. The spacer clearly labels the correct orientation. It should snap into place.

10.) Level the bed: It is important to note that with this mod there is no play in the bed if the nozzle dives into it. PLEASE USE CARE WHEN HOMING THE NOZZLE AS TO NOT RUIN BOTH YOUR NOZZLE AND HEAT BED. With the bed lowered as low as it can go, home the printer. Be prepared to shut the printer off if you feel the nozzle is pressing to hard on the bed. From this point you should be able to adjust the thumb wheels to level the bed. Again, there is no play in the bed as there used to be. If the nozzle goes too low, it will dig into the bed causing damage. Be sure your leveling is spot on.

11.) THAT'S IT!

I hope you enjoy this mod. It makes leveling a snap and goes a lot quicker than using the Allen wrench. If anyone out there needs a different sized spacer, let me know. I can crank a new design out pretty fast.

As always, if you have any questions or concerns, post in the comments section and I'll get back to you.

DISCLAIMER: I am not responsible for any damage you cause to your printer if you choose to install this mod, whether you follow my directions or not. Install at your own risk. Pay close attention to the height of the bed prior to homing the printer so you don't do damage.

One last thing: If you are successful with this mod, please share a picture here. I would greatly appreciate it.

Happy Leveling!

A new Version 2 Thumbwheel Leveling System is available here:

https://www.thingiverse.com/thing:3280396

It's much better than this one!

Please consider trying the newer version above as it works much better and is more reliable.

Update February 14, 2018

I've changed this from a work in progress to final. I do not plan on making any other changes to this system unless someone indicates a problem. Several have been successful with this system so I am making the move. Thanks to those that gave it a try in the beta stage!

Update: February 11, 2018

It was brought to my attention that the regular back bracket was missing the countersunk holes for the springs. I've updated the files and recommend everyone update that bracket with the newer file. The bracket without the countersunk is still usable if you use one of the the spring cup washers on the bottom.

Update: February 11, 2018

I've added a version of the front bracket with the magic number layer heights embossed in it. You can choose the original version or the magic number version as you please. No need to print both.

Update: February 10, 2018

I've added a back bracket with an integrated wire harness for those that choose to do the heat bed wire modification. You can use the same wheels with this bracket. It has a slot to hold a zip tie if you wish to secure your wires for strain relief. You choose which bracket you want to use. No need to print both.

Monoprice Select Mini Thumbwheel Leveling System

This is a thumb wheel leveling system I designed for the Monoprice Select Mini 3D Printer. This system is designed to be completely printable on the MP Select Mini and installed without any drilling or modification to the existing hardware. In doing this, the mod takes up some Z-height that you will lose for taller prints. The advantage of this system is that it is easily installed and removed if a larger Z-height is required.

Note: This is a prototype (Beta) leveling system that I may still tinker with based on recommendations and required improvements

Please follow the installation instructions below in order to be successful with this mod. DO NOT attempt to print until you have installed the correctly sized provided spacer

Also, I HAVE NOT tested the z-spacers with a glass bed. Do so at your own risk

Parts List:

4 M2 X 25mm screws to secure to the heat bed. I am currently using M2 X20mm screws and it does work, but you have more flexibility with the longer screws. DO NOT use M3 screws and DO NOT use the current screws used to hold the heat bed. They will not work. Must be M2. I used hex head M2 screws because that's what I had on hand, but you can use whichever head style you like. Countersunk style heads would probably be the best.

4 M2 nylon lock nuts or lock washers. I prefer the lock nuts as they are more secure

4 M2 nuts. 8 if you choose to go the lock washer route.

8 M2 washers to prevent the M2 screws from falling through the heat bed screw holes.

Existing printer springs, cup washers and screws that secure the bed to the y-axis rods

InstallationPlease reference the photos provided when putting together your system.

1.) Print all parts before assembly. DO NOT INSTALL ANY PARTS until you have printed out both the front and back brackets, the thumb wheels, and the necessary spacer.

2.) In order to print the brackets on the MP Select Mini, you will have to adjust your printer settings in Cura (or your particular slicer) to have an X and Y length of 125mm. This is not ideal as the official lengths are 120mm. But in order to print, we have to cheat a little and squeeze out a little more space. Reference the Cura photos. You most likley will not be able to fit a skirt or brim, so if you can print without. Please remember to put your settings back (X:120mm Y:120mm) when you are done. Alternately you can print the brackets on a larger printer.

3.) None of the parts require supports if oriented correctly in your slicer. The bracket should be printed as shown in the photo and the wheels face down.

4.) Thumb wheel assembly: The nuts will tightly fit within the hub of the wheels. You might have to tap them in a little to get them to seat properly. It is HIGHLY recommended that you super glue these in place. Please allot enough time for the glue to dry or the wheel will not be usable. You've been warned. Once the glue has dried, run an M2 screw through the nut a few times to make sure the inner threads of the nut are clear of dried glue. It might take some doing to clean it out but it's not too hard. I don't recommend heating the nuts and melting them in place since this tends to leave them not flush. If the nuts aren't flush with the face of the bed, it will make the wheels very difficult to turn.

5.) Place the wheels into the slots of the brackets. The nut should be facing down.

6.) Attach screws to heat bed: The 4 M2 screws must be securely fastened to the heat bed so that they DO NOT TURN. This is accomplished with the nylon lock nuts or lock washers. Also secure existing cup washers as shown in the pictures. Use M2 washers on the top of the bed to prevent the screw head from falling through the screw hole.

7.) Screw brackets to the gantry. Remove the screws that hold the bed gantry to the y-axis rods. You can do this without harming anything. Just don't move the bed a bunch after you have unscrewed. Place the bracket on the bed and using the same screws, screw the bracket to the bed. Repeat for the other bracket. Please be careful that you install the correct brackets on the front and back.

8.) Assemble the heat bed: Place the heat bed on top of the brackets. The screws should line up with the center of the wheels. If they do not loosen them and re-align until they do. Place the existing 4 springs around the screws and make sure they seat into the depression of the brackets. Press down with the face of your hand on the heat bed until the screws seat with the top of the nuts in the thumb wheels. Turn each thumb wheel counter clockwise until the screw catches in the nut and it holds. At this point your heat bed should be securely fastened.

9.) Install the z-axis spacer: Lower the bed with the thumb wheels as low as they will go. Because the brackets add 12mm to the z-axis height, we have to adjust for this. 3 spacers are available for printing: 0mm offset, 3mm offset, and 4mm offset. The 0mm offset should be used by those that have not added a surface such as glass to the heat bed. BuildTak users, tape users, etc should use the 0 mm offset spacer. If you are using glass or another substrate choose the appropriate width (3mm or 4mm) for your application. Place the spacer as shown in the picture. The spacer clearly labels the correct orientation. It should snap into place.

10.) Level the bed: It is important to note that with this mod there is no play in the bed if the nozzle dives into it. PLEASE USE CARE WHEN HOMING THE NOZZLE AS TO NOT RUIN BOTH YOUR NOZZLE AND HEAT BED. With the bed lowered as low as it can go, home the printer. Be prepared to shut the printer off if you feel the nozzle is pressing to hard on the bed. From this point you should be able to adjust the thumb wheels to level the bed. Again, there is no play in the bed as there used to be. If the nozzle goes too low, it will dig into the bed causing damage. Be sure your leveling is spot on.

11.) THAT'S IT!

I hope you enjoy this mod. It makes leveling a snap and goes a lot quicker than using the Allen wrench. If anyone out there needs a different sized spacer, let me know. I can crank a new design out pretty fast.

As always, if you have any questions or concerns, post in the comments section and I'll get back to you.

DISCLAIMER: I am not responsible for any damage you cause to your printer if you choose to install this mod, whether you follow my directions or not. Install at your own risk. Pay close attention to the height of the bed prior to homing the printer so you don't do damage.

One last thing: If you are successful with this mod, please share a picture here. I would greatly appreciate it.

Happy Leveling!

Similar models

thingiverse

free

3mm Thumb Bed Level Adjusters

...ps://github.com/prusaowners/prusaowners/wiki/bed_leveling_without_wave_springs

video: https://www.youtube.com/watch?v=hdv73adibqm

thingiverse

free

print bed thumb wheel by tanasibob

...lt with a washer to seat it properly... make this one of your first mods, you will not be sorry (if you dont have auto leveling.)

thingiverse

free

Anycubic Photon S - Sovol Flexi Plate X Sensor Spacer - Sovol3D by warezchewy

...ore you install the magnetic plate. then go ahead and install your magnetic plate, then zero z out and level the plate if needed.

thingiverse

free

Tevo Tornado / CR-10 Bed Spacer Spring Replacement by ratmandu

... the ability to level your bed with the screws.

this should help improve y-axis slop by removing any lateral movement of the bed.

thingiverse

free

Ender 3 and Ender 5 bed leveling spring spacer with capture nut

... the spacers and then put the bed back on your carriage and put on the bed leveling wheels. you will now have a much stiffer bed.

thingiverse

free

Prusa i3 heat bed nut holder by J_Seppala

...int out nicely and the nut should have a snug fit to hold the nut in place. i printed these with pla and for me they work nicely.

thingiverse

free

FT-5 Mechanical Bed Leveling : Dial Gauge Bracket by Ishampadron

...etailpage_o07_s00?ie=utf8&psc=1

if there are any issues with the design or adjustments that need to be made please notify me.

thingiverse

free

Anet A8 / A6 Bed Level Thumbwheel use with wing nut by reba256

...hat can be used with the wing nut, but they were too tight. the wing nut did not fit in to the thumb wheel. so i made my own one.

thingiverse

free

Bed Level Thumb-wheel by Jb3designer

...cise.

in adittion, to complete the kit, you need these elements too:

4x screw m3x30

4x springs

8x nut m3 (optional)

4x washer m3

thingiverse

free

Wingnut Thumb Screw for Maker Select V2 by Deliciousfewd

...design takes into account clearance for the y carriage to travel and should just make it easier on your fingers to level the bed.

Ahutton1972

thingiverse

free

F-15 Logo by ahutton1972

...f-15 logo by ahutton1972

thingiverse

this is a f-15 logo.

thingiverse

free

Storm Door Bracket by ahutton1972

...i printed at 100% infill and on its side to orient the layers outward.

if you print one, post a picture. i'd love to see it!

thingiverse

free

Headphone Holder for 34mm Width IKEA Table by ahutton1972

... in two parts. you can glue them together if you wish or not. if you make one, please post a picture as i would love to see it!

thingiverse

free

Monoprice Select Mini Control Panel Relocation by ahutton1972

...ile.

if you have any comments or suggestions, please feel free to comment here or on the mp select mini users group on facebook.

thingiverse

free

Monoprice Select Mini Filament Spool Spinner by ahutton1972

...-code command in the g-code file at the appropriate layers. use your slicer to figure out which layers are right for your print.

thingiverse

free

MP Select Mini Beefy Bed Wire Harness by ahutton1972

...t interfere with the gantry. if it does, use a smaller zip tie.

i used m3 screws and nuts to secure the wire harness to the bed.

Thumbwheel

thingiverse

free

Thumbwheel by Workshopshed

...thumbwheel by workshopshed

thingiverse

a three cornered thumbwheel i made to put on some m6 bolts

thingiverse

free

Thumbwheel by schneik80

...umbwheel by schneik80

thingiverse

6 mm thumbwheel as a replacement part for a broken wheel on a floor standing projector screen.

thingiverse

free

Small Thumbwheel by johnpanter

...small thumbwheel by johnpanter

thingiverse

14mm thumbwheel for a m3 screw or bolt.

thingiverse

free

Thumbwheel M3 by neeoo

...thumbwheel m3 by neeoo

thingiverse

thumbwheel for standard m3 nut.

external dimension only 11,8mm.

thingiverse

free

Tarantula Thumbwheel by Fabio22italy

...tarantula thumbwheel by fabio22italy

thingiverse

tiny thumbwheel for bed leveling, perfect for original tevo tarantula.

thingiverse

free

M3 thumbwheel by tnw513

...m3 thumbwheel by tnw513

thingiverse

based on "just another m3 thumbwheel!".

height: 8mm

thingiverse

free

Thumbwheel direction guide by SirexwasP

...thumbwheel direction guide by sirexwasp

thingiverse

a thumbwheel direction guide to assist newcomers with bed levelling.

thingiverse

free

M3 Knob Thumbwheel by LittleDangerous

...m3 knob thumbwheel by littledangerous

thingiverse

this knob/thumbwheel is designed for m3 hex head bolts.

thingiverse

free

Thumbwheel Reminder by Thundrfuk

...always forget which way to turn those bed thumbwheels! this just goes in the corner of the 2020 extrusion as a simple reminder.

thingiverse

free

Directional Thumbwheel by demoneye999

...ed - larger text!

added some text to the thumbwheel just so it's easier to remember which direction lowers/highers the bed :)

Monoprice

thingiverse

free

Display frame for Monoprice MP10

...display frame for monoprice mp10

thingiverse

display frame for monoprice mp10

thingiverse

free

Bridge covers Monoprice MP10

...bridge covers monoprice mp10

thingiverse

bridge covers monoprice mp10

thingiverse

free

Monoprice Coin by Peyton_Guyot

...monoprice coin by peyton_guyot

thingiverse

print this!

thingiverse

free

Voxel Monoprice spool holder by avalero

...voxel monoprice spool holder by avalero

thingiverse

voxel monoprice spool holder

thingiverse

free

Monoprice select mini knob by BramRausch

...monoprice select mini knob by bramrausch

thingiverse

this is a replacement knob for the monoprice select mini.

thingiverse

free

Monoprice 3d printer hook by dmitriyf

...monoprice 3d printer hook by dmitriyf

thingiverse

this is an attachment to monoprice select 3d printer v2

thingiverse

free

monoprice ultimate spool mount by death4u

...older by danmannert to monoprice ultimate 3d printer. it clips into the slot on the top of the printer for the optional enclosue.

thingiverse

free

Monoprice Mini Delta Foot

...a foot for a monoprice mini delta. it helps to increase airflow under the printer. it also helps to reduce the volume of the fan.

thingiverse

free

Monoprice Select Mini Fan Guard

...y fan protection. this is an essential upgrade.

used it on the monoprice select mini pro (from www.3dprinthings.be).

perfect fit!

thingiverse

free

Monoprice Cable Tie Mount

... but had to cut down the straps a bit to make them work. designed a quick mount that fits the full strap, item 6457 on monoprice.

Select

3ddd

$1

TUBADZIN SELECT

...max 2014, 2011.

fbx 2014, 2013, 2011,

obj

_____________________________________http://www.tubadzin.pl/en/collection/324

3ddd

$1

Плитка Selection

... supergres , плитка

плитка selection - supergres ceramiche

turbosquid

$15

Christmas Selection

...royalty free 3d model christmas selection for download as fbx on turbosquid: 3d models for games, architecture, videos. (1696333)

turbosquid

$39

Vases selection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SELECTIVE RACKING SYSTEM

...yalty free 3d model selective racking system for download as on turbosquid: 3d models for games, architecture, videos. (1282512)

turbosquid

$10

Hansgrohe ShowerTablet Select

...ee 3d model hansgrohe showertablet select for download as max on turbosquid: 3d models for games, architecture, videos. (1336955)

turbosquid

$29

Chill selectional sofa

...odel chill selectional sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1465691)

3ddd

free

Lunaria - Nova, ASA Selection

... asa selection , dried flowers

ветка лунарии в вазе nova, asa selection

3ddd

$1

inno SELECT SLIM chair

...inno select slim chair

3ddd

inno

high detailed inno select slim chair

turbosquid

$29

Select Chaise Lounge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Leveling

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)

turbosquid

$3

Level Ball

...

royalty free 3d model level ball for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1515558)

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport