Thingiverse

MonoPrice Select Mini Bed Expansion V2 (150mmx230mm) by iBigNTastyi

by Thingiverse

Last crawled date: 3 years ago

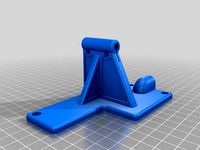

This is a revision of YourDrunkle's design. I've updated the bed holders to work with thumb-wheels. I've also included two versions of the thumb-wheel. Print 4x of whichever you choose. Photos above and the summary below are pulled directly from Yourdrunkle's design.

This is a modification to expand the MonoPrice Select Mini's print bed depth to 230mm on the cheap. I am able to utilize a printable area of 130mm x 220mm with just these modifications. The price once built was approximately $60 for me. This is nearly the same price as the unheated version of the "4th dimension modifications" "Maximus" kit but my build includes a heated bed. Note that you will need to upgrade the Select Mini's power supply to utilize the heater but I hope to be making a basic guide for that as well soon.

Some notes about this project:

No special tools (except a 3D printer) are needed for this project. I used a hacksaw to cut the aluminum, scissors, a drill with 1/8" and 5/32" drill bits, and a measuring device.

Most of the non-3D printer specific parts (8mm rod, belt, and the bed itself) were purchased from my local Ace Hardware.

I used a lot of Imperial sized (6-32) bolts instead of Metric (M3 or M4) bolts. Im in the US, so they are WAY cheaper locally. Seriously, like 1/3 to 1/2 the price. Sorry, I'd rather use metric too... M4 will PROBABLY work fine and allow use of the nut inserts.

Links to what I used:

Print Bed:https://www.amazon.com/gp/product/B01AAYY70Y/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Belt (note: this is WAY too much belt. You only need ~30cm and could save money by buying a smaller quantity):https://www.amazon.com/gp/product/B00F2IQNX8/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Rods:https://www.ebay.com/itm/300-350-400mm-8mm-Chromed-Rod-Parts-DIY-CNC-Linear-Rail-Shaft-for-3D-Printer/122850462999?hash=item1c9a754d17:m:m3bE2vd9IhcoeTMEq0XmC7Q

Everything else was locally purchased at Ace Hardware.

A REALLY REALLY BRIEF BUILD GUIDE:

Looking at your printer as it comes apart is crucial. This "guide" is very broad and skips a lot of stuff that you should be able to figure out on your own.

Printing

I printed everything with 100% infill and 0.1mm layers with PLA. Time will tell if the PLA holds up tot he heat from the print bed but I am confident. I am able to fit it all in 3 print files on the stock Select Mini. It took a long time but it is very rigid and looks good IMO.

Cutting Aluminum:

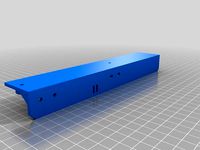

Cut aluminum to 150mm for the front and rear and approximately 2-5mm shorter than your rods for the left and right sides. Its ok for the aluminum to be a few mm short but not a few mm long.

Drilling:

Assemble and square the frame off of the printer. Ensure that the 8mm rods are against the aluminum and are the same spacing as on the printer. Use a 1/8" drill bit to drill through the holes in the 3D printer parts. Expand the holes shown in the pictures in the aluminum only. The expanded holes are to allow for some adjustability in the system.

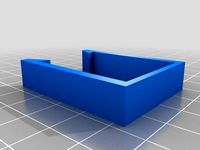

Assembly:

When the frame is initially assembled on the printer, do not tighten the 2 screws in the front and rear that were drilled oversized. Push the frame to the farthest back point of travel and tighten the front screw and vise versa. This prevent binding.

Installing the bed

When installing the bed, I placed the connector for the electronics toward the outside of the printer. It will bind if placed on the inside.

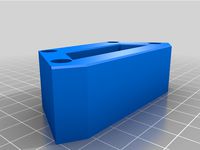

Installing the belt:

The belt loops through this frame differently than the stock printer. However, it still goes through the stepper motors the same way and the layout in the frame should be obvious. The ribs in the belt will sit in the ribs on the inside edge of the frame.

This is a modification to expand the MonoPrice Select Mini's print bed depth to 230mm on the cheap. I am able to utilize a printable area of 130mm x 220mm with just these modifications. The price once built was approximately $60 for me. This is nearly the same price as the unheated version of the "4th dimension modifications" "Maximus" kit but my build includes a heated bed. Note that you will need to upgrade the Select Mini's power supply to utilize the heater but I hope to be making a basic guide for that as well soon.

Some notes about this project:

No special tools (except a 3D printer) are needed for this project. I used a hacksaw to cut the aluminum, scissors, a drill with 1/8" and 5/32" drill bits, and a measuring device.

Most of the non-3D printer specific parts (8mm rod, belt, and the bed itself) were purchased from my local Ace Hardware.

I used a lot of Imperial sized (6-32) bolts instead of Metric (M3 or M4) bolts. Im in the US, so they are WAY cheaper locally. Seriously, like 1/3 to 1/2 the price. Sorry, I'd rather use metric too... M4 will PROBABLY work fine and allow use of the nut inserts.

Links to what I used:

Print Bed:https://www.amazon.com/gp/product/B01AAYY70Y/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Belt (note: this is WAY too much belt. You only need ~30cm and could save money by buying a smaller quantity):https://www.amazon.com/gp/product/B00F2IQNX8/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Rods:https://www.ebay.com/itm/300-350-400mm-8mm-Chromed-Rod-Parts-DIY-CNC-Linear-Rail-Shaft-for-3D-Printer/122850462999?hash=item1c9a754d17:m:m3bE2vd9IhcoeTMEq0XmC7Q

Everything else was locally purchased at Ace Hardware.

A REALLY REALLY BRIEF BUILD GUIDE:

Looking at your printer as it comes apart is crucial. This "guide" is very broad and skips a lot of stuff that you should be able to figure out on your own.

Printing

I printed everything with 100% infill and 0.1mm layers with PLA. Time will tell if the PLA holds up tot he heat from the print bed but I am confident. I am able to fit it all in 3 print files on the stock Select Mini. It took a long time but it is very rigid and looks good IMO.

Cutting Aluminum:

Cut aluminum to 150mm for the front and rear and approximately 2-5mm shorter than your rods for the left and right sides. Its ok for the aluminum to be a few mm short but not a few mm long.

Drilling:

Assemble and square the frame off of the printer. Ensure that the 8mm rods are against the aluminum and are the same spacing as on the printer. Use a 1/8" drill bit to drill through the holes in the 3D printer parts. Expand the holes shown in the pictures in the aluminum only. The expanded holes are to allow for some adjustability in the system.

Assembly:

When the frame is initially assembled on the printer, do not tighten the 2 screws in the front and rear that were drilled oversized. Push the frame to the farthest back point of travel and tighten the front screw and vise versa. This prevent binding.

Installing the bed

When installing the bed, I placed the connector for the electronics toward the outside of the printer. It will bind if placed on the inside.

Installing the belt:

The belt loops through this frame differently than the stock printer. However, it still goes through the stepper motors the same way and the layout in the frame should be obvious. The ribs in the belt will sit in the ribs on the inside edge of the frame.

Similar models

thingiverse

free

MonoPrice Select Mini Bed Expansion (150mmx230mm) by YourDrunkle

...ame way and the layout in the frame should be obvious. the ribs in the belt will sit in the ribs on the inside edge of the frame.

thingiverse

free

Arcade1Up SwitchBracket_v2 for Monoprice Select Mini by Hilux74

... the edges of bumbumbum's arcade1up switchbracket v2 so it will fit the print bed area of the monoprice select mini printer

thingiverse

free

Monoprice Select Mini V2 3mm Glass Bed Z-Spacer by MMDeveloper

...or those needing 3.5mm of offset.

i personally use this one https://www.amazon.com/dp/b075xj5zp1/ref=cm_sw_r_cp_apa_eslhabesgrx0p

thingiverse

free

Monoprice Select Mini Z-Axis Rod Stabilizers by mdsajjad

... printing instrument, on our hack-a-day project page here: https://hackaday.io/project/14823-maximum-3d-printer-bang-for-the-buck

thingiverse

free

Monoprice Select Mini Z-Axis Rod Stabilizers by USWaterRockets

... printing instrument, on our hack-a-day project page here: https://hackaday.io/project/14823-maximum-3d-printer-bang-for-the-buck

thingiverse

free

Monoprice Select Mini extended bed brackets by mfink70

...dard size bed mounts. these fit and are usable but you may lose some bed space.

8/30/17: cleaned up a few things with the mounts.

thingiverse

free

Select Mini X Gantry Supports w/ Bed Rewiring Mod Access Duct by jprochazka

...o be printed on the monoprice select mini. the main problem is retaining rigidity after cutting the model into multiple models.

thingiverse

free

Monoprice MP Select Mini - Z End Stop Spacer by arielrossell

... simpler and "easier to install" z end stop spacer, so you can use a piece of glass on the bed of the mp select mini.

thingiverse

free

Cork insulation for Monoprice Select Mini 3D Printer by noen

...x11" letter sized sheet of paper and use it to cut out your foam and cork. attach together and insert under the bed, enjoy!

thingiverse

free

Monoprice Select Mini Filament Guide by tommytwothousand

...monoprice select mini filament guide by tommytwothousand

thingiverse

here is a filament guide for the monoprice select mini!

150Mmx230Mm

thingiverse

free

MonoPrice Select Mini Bed Expansion (150mmx230mm) by YourDrunkle

...ame way and the layout in the frame should be obvious. the ribs in the belt will sit in the ribs on the inside edge of the frame.

thingiverse

free

CTC Adjustable Glass Bed Corner Clamp by m4t42

...exactly the same shape/size as the aluminium build plate (150mmx230mm. they should allow plates up to 156mm x 236mm....

Ibigntastyi

thingiverse

free

Aurora A3 Flexible Filament Guide by iBigNTastyi

...ns, i finally created a product that works. it's a very tight fit, as seen in the photo, but i've tested it and it works.

thingiverse

free

AC knob for 06 Toyota Tundra by iBigNTastyi

...inted in the designed orientation with supports. the bottom comes out kind of ugly, but that's ok since it won't be seen.

thingiverse

free

Whirlpool/KitchenAid Dishwasher Upper Rack Adjuster W10530376 by iBigNTastyi

...get by until a replacement shows up, and i don't expect it to last long in the high heat conditions of dishwasher operations.

thingiverse

free

Simple Airsoft Suppressor by iBigNTastyi

...omment if you would like to see any changes.

fyi, it doesn't suppress the airsoft gun at all. not functional, but looks cool.

Monoprice

thingiverse

free

Display frame for Monoprice MP10

...display frame for monoprice mp10

thingiverse

display frame for monoprice mp10

thingiverse

free

Bridge covers Monoprice MP10

...bridge covers monoprice mp10

thingiverse

bridge covers monoprice mp10

thingiverse

free

Monoprice Coin by Peyton_Guyot

...monoprice coin by peyton_guyot

thingiverse

print this!

thingiverse

free

Voxel Monoprice spool holder by avalero

...voxel monoprice spool holder by avalero

thingiverse

voxel monoprice spool holder

thingiverse

free

Monoprice select mini knob by BramRausch

...monoprice select mini knob by bramrausch

thingiverse

this is a replacement knob for the monoprice select mini.

thingiverse

free

Monoprice 3d printer hook by dmitriyf

...monoprice 3d printer hook by dmitriyf

thingiverse

this is an attachment to monoprice select 3d printer v2

thingiverse

free

monoprice ultimate spool mount by death4u

...older by danmannert to monoprice ultimate 3d printer. it clips into the slot on the top of the printer for the optional enclosue.

thingiverse

free

Monoprice Mini Delta Foot

...a foot for a monoprice mini delta. it helps to increase airflow under the printer. it also helps to reduce the volume of the fan.

thingiverse

free

Monoprice Select Mini Fan Guard

...y fan protection. this is an essential upgrade.

used it on the monoprice select mini pro (from www.3dprinthings.be).

perfect fit!

thingiverse

free

Monoprice Cable Tie Mount

... but had to cut down the straps a bit to make them work. designed a quick mount that fits the full strap, item 6457 on monoprice.

Expansion

turbosquid

$42

Expansion tank

...d model expansion tank for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1207393)

3d_export

$50

Expansion Joint 3D Model

...expansion joint 3d model

3dexport

expansion joint 3d model stargazer 4537 3dexport

turbosquid

$25

Titanic Expansion Joint

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

thermostatic expansion valve

...thermostatic expansion valve

3dexport

3d model stl of fusion 360.

3d_ocean

$15

Dungeon Tileset01 Expansion 1

...m/dungeon-tileset01-base/4625640 including stairs, tiles to make large rooms and a new texture that works with the tiles in th...

turbosquid

$20

Cartoon Corgi Banana Costume Expansion Pack

...artoon corgi banana costume expansion pack for download as ma on turbosquid: 3d models for games, architecture, videos. (1445388)

3ddd

$1

Hichory chair Ingold Oval Expansion

...kitchen-furniture/1911-collection/i510089-ingold-oval-expansion-top-mahogany-and-185-11-ingold-3-leg-pedestal-base.aspx

turbosquid

$299

Sci-Fi Dark Space Game Kit plus Expansion Pack

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Swedish wall

...swedish wall 3dexport swedish wall, expansion wall bars, stairs for children, horizontal bar for...

3d_export

$10

External HDD 3D Model

...hard disk drive external seagate usb storage hdd portable expansion data mobile external hdd 3d model nkfrds 47740...

Select

3ddd

$1

TUBADZIN SELECT

...max 2014, 2011.

fbx 2014, 2013, 2011,

obj

_____________________________________http://www.tubadzin.pl/en/collection/324

3ddd

$1

Плитка Selection

... supergres , плитка

плитка selection - supergres ceramiche

turbosquid

$15

Christmas Selection

...royalty free 3d model christmas selection for download as fbx on turbosquid: 3d models for games, architecture, videos. (1696333)

turbosquid

$39

Vases selection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SELECTIVE RACKING SYSTEM

...yalty free 3d model selective racking system for download as on turbosquid: 3d models for games, architecture, videos. (1282512)

turbosquid

$10

Hansgrohe ShowerTablet Select

...ee 3d model hansgrohe showertablet select for download as max on turbosquid: 3d models for games, architecture, videos. (1336955)

turbosquid

$29

Chill selectional sofa

...odel chill selectional sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1465691)

3ddd

free

Lunaria - Nova, ASA Selection

... asa selection , dried flowers

ветка лунарии в вазе nova, asa selection

3ddd

$1

inno SELECT SLIM chair

...inno select slim chair

3ddd

inno

high detailed inno select slim chair

turbosquid

$29

Select Chaise Lounge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

Bed

...bed

3ddd

bed , постельное белье , постель

bed

3d_export

$7

bed adairs bed

...rs bed

3dexport

bed adairs bed in modern style. if you want a smoother surface, please turn on turbosmooth in the modifier list.