Thingiverse

Monobot, the single servo robot

by Thingiverse

Last crawled date: 4 years, 3 months ago

How many motors do you need to make a robot which can move in 2 dimensions? Most need 2, either left-right differential like a tank, or one for going forward and one for steering, like cars. There are experiments to achieve steerable robots using just one actuator, notable ones are the 1STAR from UC Berkeley (which has 6 legs, the middle legs are elastic) and the Monospinner from ETH Zurich (which can even fly), but they require complex and delicate mechanisms and control systems.

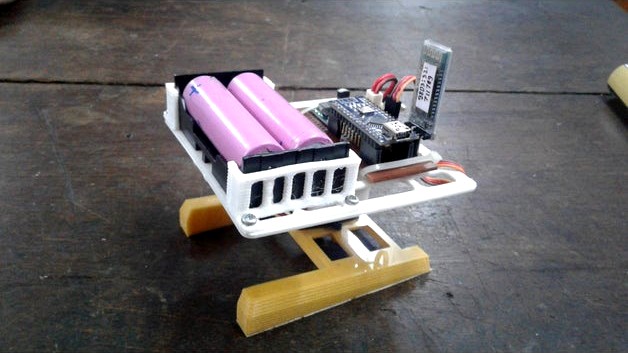

Introducing Monobot, the single servo robot. This robot has only 2 parts, the base and the foot, which are connected by a servo motor. But how could this robot move?

The key is center of mass, friction, and acceleration. The mass of the robot is located on the upper part ('the body') and is offset to the front, near the batteries. When the motor is accelerating to one direction, normal force (N) on one side of the foot is greater than the other, and since static friction limit (fsmax) is proportional to N, then one side will have more tendency to slip and 'steps' forward. By accelerating to left and right repeatedly, the robot will move forward... ideally. If the foot sides have dissimilar friction constant, because imperfect surfaces, the robot will veer off from straight line. But you can make the robot turn around in spot (which 1STAR cannot) by moving the motor to one direction slowly then suddenly reversing, so the body which has larger inertia will continue rotating that way, but the foot slips. You can see the demonstration in the video.https://www.youtube.com/watch?v=g27qqC4I8kU

Print the base, battery holder holder, and choose a foot (I used 5 degrees, haven't tried the others, but Blender Rigid Body simulation shows that higher angle gives faster movement), screw the servo horn to the foot using servo mounting screws, put your favourite controller (I used Arduino Nano and Bluetooth receiver), 2x 18650 batteries and battery holder, a 5V step down converter for the servo (I don't like powering servos through the nano's regulator), and there you are, a robot as simple as could be.

I suggest using high quality servo, preferably metal gear, since this robot will put high stress on the gears, motor, and motor driver from the repetitive direction reversing. I haven't broken any servo though.

Friction is important here. Slippery PLA only produce little movement, so I covered the foot with masking tape. I measured the coefficient of friction on wood, the result is about 0.4. Too high friction and the robot jumps around or topple.

Arduino code included.

How could you improve the performance of this robot?

Introducing Monobot, the single servo robot. This robot has only 2 parts, the base and the foot, which are connected by a servo motor. But how could this robot move?

The key is center of mass, friction, and acceleration. The mass of the robot is located on the upper part ('the body') and is offset to the front, near the batteries. When the motor is accelerating to one direction, normal force (N) on one side of the foot is greater than the other, and since static friction limit (fsmax) is proportional to N, then one side will have more tendency to slip and 'steps' forward. By accelerating to left and right repeatedly, the robot will move forward... ideally. If the foot sides have dissimilar friction constant, because imperfect surfaces, the robot will veer off from straight line. But you can make the robot turn around in spot (which 1STAR cannot) by moving the motor to one direction slowly then suddenly reversing, so the body which has larger inertia will continue rotating that way, but the foot slips. You can see the demonstration in the video.https://www.youtube.com/watch?v=g27qqC4I8kU

Print the base, battery holder holder, and choose a foot (I used 5 degrees, haven't tried the others, but Blender Rigid Body simulation shows that higher angle gives faster movement), screw the servo horn to the foot using servo mounting screws, put your favourite controller (I used Arduino Nano and Bluetooth receiver), 2x 18650 batteries and battery holder, a 5V step down converter for the servo (I don't like powering servos through the nano's regulator), and there you are, a robot as simple as could be.

I suggest using high quality servo, preferably metal gear, since this robot will put high stress on the gears, motor, and motor driver from the repetitive direction reversing. I haven't broken any servo though.

Friction is important here. Slippery PLA only produce little movement, so I covered the foot with masking tape. I measured the coefficient of friction on wood, the result is about 0.4. Too high friction and the robot jumps around or topple.

Arduino code included.

How could you improve the performance of this robot?

Similar models

thingiverse

free

Robotic drawing arm by Gabgau

...so any model will work. i put the file for the code and you got more specification in it, it's a mashup of a lot of projet...

thingiverse

free

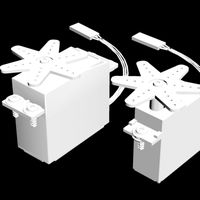

Grab for robotics and other (using 2x servo motor 9g) by fabiam93

... other (using 2x servo motor 9g) by fabiam93

thingiverse

simple grab for robotics. i used 2 servo motor in order to move 2 arms.

cg_trader

free

Coordination with servo motors

...rs. it works with sketchyphysics. to move use the arrow keys. technology coordination with servo motors vehicle part vehicle part

grabcad

free

Robot Gundam TR6's Body (first week version)

...d

because as a robot it needs servo motor to move its arm, i have to create an extra structure at its shoulder to put the motor.

thingiverse

free

Arduino Walker-Bot by MakerZoo

...ard but showed users how to wire up a joystick, power switch, batteries and servos to an arduino and then program it all to work.

thingiverse

free

BiCopter Stand and Motor plate for Servo control by k2345777

... stand and motor plate which can be moved by servo.

with arduino nano and gy-87(10 dof sensors) which soldering on the peg board.

thingiverse

free

RoBox , 3d printed walking robot, moving Arms, Head and meter. by RobotHut

...t all the same , so the new motor gear has the d slot all the way threw the gear so it can slip all the way onto the motor shaft.

thingiverse

free

Minimum Robot Steering/Speed Control by TimboInSpace

...on the battery platform. the unit doesn't have very much for clearance from the floor, so make sure it's mounted upright.

thingiverse

free

peon230 Battery Holder by unprovoked

... in the x and y direction.

i strongly recommend printing at 100%, since it is pretty minimal in dimensions as it is. i used pla.

thingiverse

free

Easy to build robot - Wendell the Robot by marc_cryan

...n inkscape.

parts -

plywood body

5 servo motors (2 are continuous)

arduino 1

batteries

a little servo board

thanks for looking!!

Servo

turbosquid

$30

Servo

...d model servo for download as obj, blend, dae, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1394011)

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

turbosquid

$1

Servo Moter

...quid

royalty free 3d model servo moter for download as blend on turbosquid: 3d models for games, architecture, videos. (1650816)

turbosquid

free

Motor/Servo

...osquid

royalty free 3d model motor/servo for download as obj on turbosquid: 3d models for games, architecture, videos. (1522522)

turbosquid

$60

Servo Skull

...

royalty free 3d model servo skull for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1318573)

3d_export

$5

Servo 3D Model

...rvo 3d model

3dexport

servo

servo 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl pasqualesiciliano 104590 3dexport

turbosquid

$50

Servo Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Servo Motor

...model servo motor for download as 3ds, max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1324153)

turbosquid

$29

Servo Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

machine servo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Robot

3d_ocean

$20

Robot

...robot

3docean

character metal robot robot robotic white

robot model for 3dsmax 2009 and greater

3d_ocean

$45

Robot

...robot

3docean

fighing machine robot

a fighting robot from the scrapyard.

3d_ocean

$18

Robot

...robot

3docean

machin robot science fiction

high poly robot.

3d_export

$7

Robot

...robot

3dexport

robot

3d_export

$5

robot

...robot

3dexport

robot

3d_export

free

Robot

...robot

3dexport

robot

turbosquid

$10

Robot/ Alien Robot

...

royalty free 3d model robot/ alien robot for download as max on turbosquid: 3d models for games, architecture, videos. (1442828)

3d_export

$5

robot

...robot

3dexport

robot in blender

3ddd

$1

robot

...robot

3ddd

робот

robot

3ddd

$1

Robot

...robot

3ddd

робот

robot

Single

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single fastener

...single fastener

3dexport

single fastener

3ddd

$1

Single FLOU

... sofa , трансформер

диван-трансформер single от итальянского производителя flou

3ddd

$1

bed single

...bed single

3ddd

постельное белье

bed single 190cm*90cm

3ddd

$1

Single Flou

...single flou

3ddd

качественная моделька дивана-трансформера single flou.

3d_ocean

$9

Single sofa

...le sofa

3docean

modern sofa single sofa sofa white sofa.comfortable sofa

single sofa,sofa,modern sofa,white sofa.comfortable sofa

3d_export

free

Single Knife

...single knife

3dexport

a single knife, presumably it was used as one of the throwing knives.

3d_export

free

couch - single

...couch - single

3dexport

low poly single couch with .psd file for personal customization

3d_ocean

$5

Single Sofa

...single sofa

3docean

single sofa made by fabric , wood frame & ss leg