Thingiverse

Mold for 3inch compliant wheels

by Thingiverse

Last crawled date: 4 years, 2 months ago

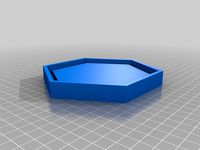

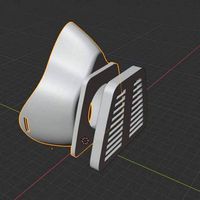

"Gietmal ribbelwiel 3 inch" is our newer design for a 3"wheel with a profiled rim. We designed this to be used with softer (shore 15) silicone, because anything stronger would probably be impossible to get out of the mold.

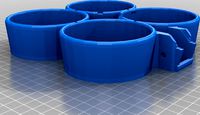

Many people asked us to include an example of a hub, we have now included a STL for an example hub ("hubje 3 inch ribbelwiel anderhalf hoog zonder gear"). This hub has a 4-hole pattern ready to accept M4 bolts with 16mm spacing (commonly used by GoBilda/Tetrix/REV

The original mold:

This is the mold FTC team 3954 made to pour our own compliant wheels from 2-component silicone. Our aim was to make the wheels lighter and add custom made hubs to suit our needs. It was a fun side project for a few of our "intake-engineers".

Printing the mold:

material, infill, no of layers or layer resolution does not matter much. As long as it is a smooth surface on the inside. The largest forces on the mold are when the wheel is pushed out afterwards.

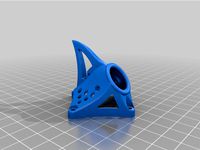

Designing your own hub:

Hub should have a 1 or 2 mm high, 6 mm diameter cylinder to plug the hole in the bottom. This cylinder is used to keep the hub centered in the mold. We designed it with a 4mm diameter hollow shaft, so we could use a long M4 bolt as an axle.

Hub should have a diameter of no more than 22mm to make sure silicone can flow freely around the hub.

Hub can be over 10mm high, but of course only 10mm will be covered in silicone. We designed ours with a 16T sprocket for #25 chain on top.

Hub MUST have holes or "inlets" to "capure" the silicone. we found out silicone does not stick to the PLA of the hub, so you must design a way to physically attach the silicone to the hub. We used a row of thin pillars around the outside of the hub.

Prepare for pouring silicone:

Make sure the molds are slick and free of printing artifacts (blobs/strings). Use a sharp hobby knife or a small file.

Spray the molds with anti adhesive for silicone. we used:https://polyestershoppen.nl/siliconenrubber/lossingsmiddel-voor-siliconen-305.html

Spread the anti-adhesive with a small paintbrush.

Mix the silicone and hardener and mix according to the instructions of supplier. MIX WELL! We added pink coloring (of course).

we used:https://polyestershoppen.nl/siliconenrubber/siliconen-gietrubber-1-1-shore-40-594.htmlhttps://polyestershoppen.nl/siliconenrubber/pigment-voor-siliconen-316.html

Each wheel takes roughly 20 mL of silicone, depending on the volume of the hub you designed.

Pouring the silicone:

"Pouring" silicone is hard, so we used a large syringe (60mL) to suck up the silicone (slowly) and inject it into the molds. Although the silicone may seem thick, is DOES flow quite well into the crevices of the hub AND it levels. So make sure your mold is level, otherwise the wheel will be thicker on one side.

We had a problem with lighter (less infill) hubs because they would "float" out of the center hole, so we prevented the hubs from floating with a small dead weight on top of each hub.

We did not use a vacuum chamber to de-air the silicone. We did find some small air pockets in our wheels but nothing serious. We did mix the silicone more gently at the end to prevent trapping more air in and we tapped the molds on the table a couple of times after they were filled to help free trapped air pockets.

Removing from the mold:

After the suggested curing time (supplier) you are ready for the last stage.

All surfaces in the mold are 6 degrees slanted to assure the wheel comes out easily.

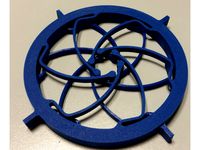

By pushing a 6mm pin (bolt) into the hole you should be able to push the hub out of the mold far enough to grab the silicone. Resist the temptation to push the whole wheel out this way, the silicone CAN tear or come loose from the hub, in both cases the wheel is worthless. just keep pushing and pulling until you can get hold of one of the spokes and pull the wheel free.

THERE you have it! Your own Compliant wheel!

Many people asked us to include an example of a hub, we have now included a STL for an example hub ("hubje 3 inch ribbelwiel anderhalf hoog zonder gear"). This hub has a 4-hole pattern ready to accept M4 bolts with 16mm spacing (commonly used by GoBilda/Tetrix/REV

The original mold:

This is the mold FTC team 3954 made to pour our own compliant wheels from 2-component silicone. Our aim was to make the wheels lighter and add custom made hubs to suit our needs. It was a fun side project for a few of our "intake-engineers".

Printing the mold:

material, infill, no of layers or layer resolution does not matter much. As long as it is a smooth surface on the inside. The largest forces on the mold are when the wheel is pushed out afterwards.

Designing your own hub:

Hub should have a 1 or 2 mm high, 6 mm diameter cylinder to plug the hole in the bottom. This cylinder is used to keep the hub centered in the mold. We designed it with a 4mm diameter hollow shaft, so we could use a long M4 bolt as an axle.

Hub should have a diameter of no more than 22mm to make sure silicone can flow freely around the hub.

Hub can be over 10mm high, but of course only 10mm will be covered in silicone. We designed ours with a 16T sprocket for #25 chain on top.

Hub MUST have holes or "inlets" to "capure" the silicone. we found out silicone does not stick to the PLA of the hub, so you must design a way to physically attach the silicone to the hub. We used a row of thin pillars around the outside of the hub.

Prepare for pouring silicone:

Make sure the molds are slick and free of printing artifacts (blobs/strings). Use a sharp hobby knife or a small file.

Spray the molds with anti adhesive for silicone. we used:https://polyestershoppen.nl/siliconenrubber/lossingsmiddel-voor-siliconen-305.html

Spread the anti-adhesive with a small paintbrush.

Mix the silicone and hardener and mix according to the instructions of supplier. MIX WELL! We added pink coloring (of course).

we used:https://polyestershoppen.nl/siliconenrubber/siliconen-gietrubber-1-1-shore-40-594.htmlhttps://polyestershoppen.nl/siliconenrubber/pigment-voor-siliconen-316.html

Each wheel takes roughly 20 mL of silicone, depending on the volume of the hub you designed.

Pouring the silicone:

"Pouring" silicone is hard, so we used a large syringe (60mL) to suck up the silicone (slowly) and inject it into the molds. Although the silicone may seem thick, is DOES flow quite well into the crevices of the hub AND it levels. So make sure your mold is level, otherwise the wheel will be thicker on one side.

We had a problem with lighter (less infill) hubs because they would "float" out of the center hole, so we prevented the hubs from floating with a small dead weight on top of each hub.

We did not use a vacuum chamber to de-air the silicone. We did find some small air pockets in our wheels but nothing serious. We did mix the silicone more gently at the end to prevent trapping more air in and we tapped the molds on the table a couple of times after they were filled to help free trapped air pockets.

Removing from the mold:

After the suggested curing time (supplier) you are ready for the last stage.

All surfaces in the mold are 6 degrees slanted to assure the wheel comes out easily.

By pushing a 6mm pin (bolt) into the hole you should be able to push the hub out of the mold far enough to grab the silicone. Resist the temptation to push the whole wheel out this way, the silicone CAN tear or come loose from the hub, in both cases the wheel is worthless. just keep pushing and pulling until you can get hold of one of the spokes and pull the wheel free.

THERE you have it! Your own Compliant wheel!

Similar models

thingiverse

free

Coaster Molds by BD3DCUSTOMS

...3dcustoms

thingiverse

4" coaster molds. pour some silicone into the mold pull the silicone out and you have a coaster mold.

thingiverse

free

Casting Flask Mold Box and Mold Cylinder by siderits

...e base of the box and cylinder is about 35mm.

the walls are canted out to make it easier to take the mold out of the casting box.

grabcad

free

Panda silicone mold

...esign if for a small panda model, can be 3d printed directly or mill the mold and pour silicone into it and use the silicone mold

thingiverse

free

silicone wedding band mold by 1337gallagher

...to cure overnight and trim excess. i use a similar mold for robotic wheels designed by team panic. the...

grabcad

free

3D printed silicone overmolding mold

...uot;hole" version is cast in urethane separately, then placed inside the 3d printed mold and flexible silicone is poured in.

thingiverse

free

Fingertech/Liteflite Foam Wheel Hubs 3mm

...it will wear down the foam. you can remove the wheel hub by simply pushing foam asde to expose the grub screw, then loosening it.

thingiverse

free

Senko Fishing Lure Bait by MrBoyle

...gether and clamp them tight. you might need to pour more silicone in through the top holes. make sure you use mold release spray.

thingiverse

free

Mold for Epoxy-Mixing Silicone Mat by KevinArne

...n't level. i recommend using carriage bolts with these knobs for the leveling feet: https://www.thingiverse.com/thing:4591644

thingiverse

free

G920 Wheel Board by DanA8

... make the look of the wheel better.

you will have to drill the holes out depending on your hub size and what wheel you are using.

thingiverse

free

Pouring snowman mold (Soapmen example and more!) by FilamentCorner

...download. just scale them down in a slicer for similar sized prints. update: we made a solid lotion bar...

3Inch

thingiverse

free

3inch Star by robosavvy

...3inch star by robosavvy

thingiverse

a 3inch star to hang on your christmas tree

thingiverse

free

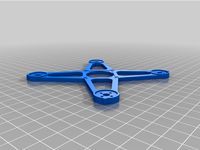

The ButterFly 3inch Frame by Tarkux

...the butterfly 3inch frame by tarkux

thingiverse

just a new tougher version of my 3inch 3d printable frame .

thingiverse

free

Plant support 3inch pot by InsaneFish

...plant support 3inch pot by insanefish

thingiverse

this is a plant support made to fit 3inch net pots. h: 145mm w: 68mm

thingiverse

free

3inch hex frame with canopy by Jandre_fpv

...e with canopy by jandre_fpv

thingiverse

3inch hex frame

3 inch props

1206 to 1507 motors

made for nano fpv cam

20x20 fc and esc.

thingiverse

free

3inch fpv drone frame

...3inch fpv drone frame

thingiverse

simple lightweight fpv drone frame

thingiverse

free

NACA Duct to 3inch Hose for duct & brakes

... & brakes

thingiverse

naca duct to 3inch hose for duct & brakes

as seen here:https://www.youtube.com/watch?v=nrv6kayzwkw

thingiverse

free

3inch hex frame with canopy by Jandre_fpv

... frame

1206 to 1507 motors

20x20 fc and esc

3 inch props

i do suggest you cut the frame out of carbon fiber

made for nano fpv cam

thingiverse

free

X-whoop 3inch by Xfoot

... 650-1050mah lipo

15mm lipo strap

top plate screws: hex m3 20-30mm screws

recommended: xt60 connector. xt30 is a bit to small.

thingiverse

free

3inch hose attachment by meetar

...y meetar

thingiverse

this connects a standard 80mm computer fan to a 3" hose, and fits makerbot m3 hex-head machine screws.

thingiverse

free

Donut 3inch ducts - new profile

...donut 3inch ducts - new profile

thingiverse

new duct profile. fast print.

print as the last picture, no supports are needed.

Compliant

3d_export

$5

coronavirus antivirus mask covid-19 compliant

...t;br>- filters needs to be buy.<br>- elastic to attach the mask<br>tell me if modifications needed<br>enjoy!

3ddd

$1

Capital Lighting Midtown 3 Light Bath Vanity Light

...60 watts (w) number of lights: 3 energy star compliant no shade material: fabric dimensions: overall: 13.5" h x...

3ddd

free

Adesso Architect 31 H Table Lamp with Empire Shade

...switch cul listed: no ul listed: no energy star compliant no dimensions: max overall: max: 742.95mm" h x 558.8mm"...

3d_export

$35

Ambient food display

...movement placement & cleaning easy<br>830l capacity<br>corrosion-resistant construction ensures longevity<br>fully compliant with australian safety standards and regulations<br>2 years bromic extra...

3d_export

$10

bola disc table

...efficacy: 57 lumens/watt<br>color rendition index: 95 cri<br>ada compliant<br>title 20 compliantlt;br>50k hour lifespan<br>cable length: 8’ (244cm)<br>designer<br>pablo studio<br>the pablo studio is...

3d_export

$25

Ambient food display 900 mm

...make movement, placement & cleaning easy<br>corrosion-resistant construction ensures longevity<br>fully compliant with australian safety standards and regulations<br>2 years bromic extra...

thingiverse

free

Compliant Pliers / Gripper

... to get into compliant mechanisms and test for fatigue on different materials. inspired by the fully compliant pliers by byu_cmr.

thingiverse

free

COMPLIANT HAND GRIP by maxbraindevices

...compliant hand grip by maxbraindevices

thingiverse

single piece compliant hand grip print in place

thingiverse

free

Compliant Iris by AJ_Daedalus

...s or glue or screws.

just print two of the similar parts and put it together.

i hope you will enjoy this satisfying mechanism :-)

thingiverse

free

(CMC) Compliant Mechanism Clip by ThusEnverHoxha

...(cmc) compliant mechanism clip by thusenverhoxha

thingiverse

a simple compliant mechanism clip

Mold

3ddd

$1

molding

...molding

3ddd

молдинг

molding

3ddd

$1

molding

...molding

3ddd

молдинг , резьба

molding

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

3d_export

$10

molding

...molding

3dexport

molding, casting, baguette, decoration

design_connected

$16

Mold

...mold

designconnected

eternit mold computer generated 3d model. designed by charlot, michel.

Wheels

archibase_planet

free

Wheel

...l steering control steering wheel

wheel ship steering wheel n060215 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_ocean

$14

Wheel

...wheel

3docean

car rim car wheel rim wheel

high poly car wheel design. 16,840 polys

3d_export

free

wheel

...wheel

3dexport

wheel

3d_export

free

wheel

...wheel

3dexport

wheel

3d_export

free

Wheel

...wheel

3dexport

wheel

3d_export

$5

wheel

...wheel

3dexport

wheel for car.

3d_export

$5

wheel

...wheel

3dexport

car wheel

3d_export

$5

wheel

...wheel

3dexport

car wheel

3d_export

$5

wheel

...wheel

3dexport

car wheel

3d_export

$5

wheel

...wheel

3dexport

car wheel