Thingiverse

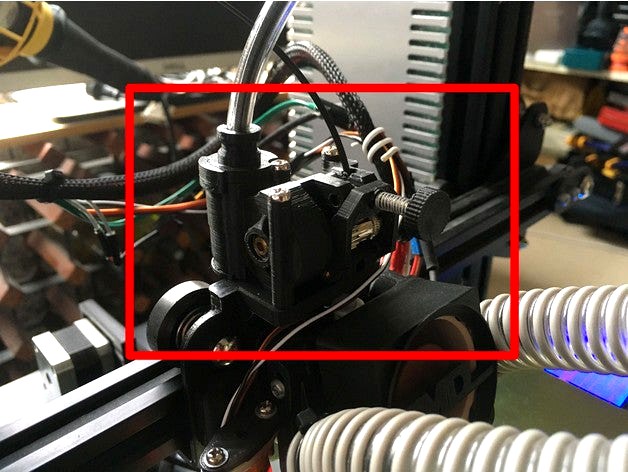

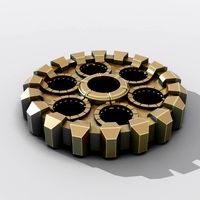

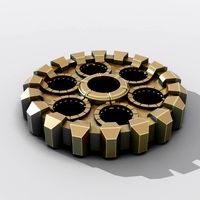

Mods for Remote Direct Extruder with Bondtech Gears (30:1 Gear Ratio)

by Thingiverse

Last crawled date: 4 years, 2 months ago

First off, If you don't know what you are doing then don't do this mod. This is a remix of https://www.thingiverse.com/thing:4009262 with changes I made to make things work well with my setup. I will only include parts that I have changed/added.

First off, go read everything from https://www.thingiverse.com/thing:4009262 and plan what you want to do.

Changes

Some parts did not fit tight, so i redid them.

Some parts were made smaller/lighter.

Some parts were made more chunky.

And some extra stuff to bring it all together.

Also print it in black!

Details

Moved the extruder motor to the left of the printer next to all the other motors and changed how it is mounted (now mounted from the bottom

Added a knob for the front screw (super glue this)

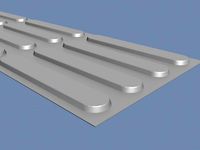

Screw washer now fits my screws

The good quality fake bond tech I used came with slightly smaller bearings so added an outer ring to make it fit the housing

Cover for the worm drive shaft made the screw not reach so modified it so it reaches

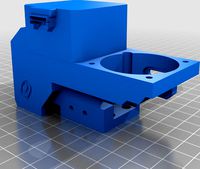

Cover got the motor side made more chunky for added strength

Motor shaft cover made taller to match the overall height of the original with different mounting system

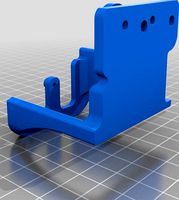

Flex shaft Mount Ring (x2) to guide flex shaft around the printer.

Flex shaft Mount Top mount for top of printer

Flex shaft Mount Side mount for side of printer

Firmware

I am using a SKR mini 1.3 with TMC2209 with Marlin 2 branch bugfix-2.0.x.

My esteps were different to the original. Also my linear advanced needed retuning.

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 1026.56 }

#if AXIS_IS_TMC(E0)

#define E0_CURRENT 400

#define E0_MICROSTEPS 4

#define E0_RSENSE 0.11

#define E0_CHAIN_POS -1

#endif

Tips

Print parts strong where possible, I mostly used 4 perimeters and 12% gyroid infill.

When doing test prints and calculating esteps turn off linear advance. Once this is all good, redo linear advance, I found my numbers to be very different to the stock extruder.

Always print printer parts in black ;)

First off, go read everything from https://www.thingiverse.com/thing:4009262 and plan what you want to do.

Changes

Some parts did not fit tight, so i redid them.

Some parts were made smaller/lighter.

Some parts were made more chunky.

And some extra stuff to bring it all together.

Also print it in black!

Details

Moved the extruder motor to the left of the printer next to all the other motors and changed how it is mounted (now mounted from the bottom

Added a knob for the front screw (super glue this)

Screw washer now fits my screws

The good quality fake bond tech I used came with slightly smaller bearings so added an outer ring to make it fit the housing

Cover for the worm drive shaft made the screw not reach so modified it so it reaches

Cover got the motor side made more chunky for added strength

Motor shaft cover made taller to match the overall height of the original with different mounting system

Flex shaft Mount Ring (x2) to guide flex shaft around the printer.

Flex shaft Mount Top mount for top of printer

Flex shaft Mount Side mount for side of printer

Firmware

I am using a SKR mini 1.3 with TMC2209 with Marlin 2 branch bugfix-2.0.x.

My esteps were different to the original. Also my linear advanced needed retuning.

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 1026.56 }

#if AXIS_IS_TMC(E0)

#define E0_CURRENT 400

#define E0_MICROSTEPS 4

#define E0_RSENSE 0.11

#define E0_CHAIN_POS -1

#endif

Tips

Print parts strong where possible, I mostly used 4 perimeters and 12% gyroid infill.

When doing test prints and calculating esteps turn off linear advance. Once this is all good, redo linear advance, I found my numbers to be very different to the stock extruder.

Always print printer parts in black ;)

Similar models

thingiverse

free

Extruder motor Cali Cat by petieken

...ft with a flat face. on my printer it fitted just right. there was a bit of resistance, which made me confident it wont fall off.

thingiverse

free

Extruder Motor Spacer for 3DFused Direct Drive mount by Critterninja

...ere, just a 3mm thick spacer, set to the same shape of the standard 42x42mm motor and a hole in the middle to fit over the shaft.

thingiverse

free

Tronxy X3 extruder mount. by DracenKnights

...ents from my steppers and some other motor mounts on here to build the rest of the design myself.... credit where credit is do...

thingiverse

free

CR-10 BMG/Regular extruder mount

... settings.

please note that v9 is for bmg only and v11 is for both bmg and regular extruder and you need some m3 scrows and nuts.

thingiverse

free

Ender 3 X-Axis belt idler - Using extruder upgrade parts by LaDane

...were things i had laying around after i upgraded the extruder, and some of them were left overs from when i assembled my ender 3.

thingiverse

free

Robo R2 BMG Extruder mount by Waggster

...ng the red and blue wires over on the extruder motor connector. you just lift the white tab and the pin pulls out.. really easy.

thingiverse

free

Dremel Flex Shaft mount for Ender/CR-Series printers by Aces88

...l flex shaft mount for ender/cr-series printers by aces88

thingiverse

i couldn't find a mount that i liked so i made my own.

thingiverse

free

M2 Extruder Motor Mount by Thedudevt

... the side hole as well. motor mount has the larger hole spacing for the mounting screws which matches my older gen linear guide.

thingiverse

free

Pi Zero W - Mount by scloutier

...cover just so it would be easier to print without support.

original:

i just added some screw mounting ears. should fit #8 screws

thingiverse

free

Orballo Steel X Axis by m3lvm

... the alignment of the bearing.

i will be modifying the cable chain mount to compensate for a new bearing mount on the lead screw.

Bondtech

thingiverse

free

x5s bondtech

...x5s bondtech

thingiverse

this allow using a bondtech dual drive on x5s machines

thingiverse

free

Bondtech mount by Nicoande99

...bondtech mount by nicoande99

thingiverse

custom bondtech mount for my velleman k8200 3d printer.

thingiverse

free

Trex2+ Bondtech adpter by fong504

...trex2+ bondtech adpter by fong504

thingiverse

bondtech makerbot 2 clone adapter for the trex2+.

thingiverse

free

Bondtech PTFE tube Holder

...bondtech ptfe tube holder

thingiverse

adjusted a bit to fit my bondtech clone.

thingiverse

free

Bondtech DDX by sebbzor

...of the ddx incase you want to build adapters for it. original stepfile can be found on bondtechs website, all credits go to them.

thingiverse

free

Support BONDTECH Anet_A8 By SergioFPV by SergioFPV

...support bondtech anet_a8 by sergiofpv by sergiofpv

thingiverse

support bondtech anet_a8

thingiverse

free

CR-10S-Bondtech-Mosquito_Mount_Bl_Touch by enoblk

...cr-10s-bondtech-mosquito_mount_bl_touch by enoblk

thingiverse

cr-10s-bondtech-mosquitomount-_bl_touch

thingiverse

free

Bondtech Flying mount by Yakandu

...du

thingiverse

lightweight flying extruder mount for the bondtech bmg with design centred around filament path.

this is a remix.

thingiverse

free

Bondtech Oiler by bamhm182

...t a piece of sponge and put it in the hole. oil it up and you're good to go! been using it for a few months with no problems.

thingiverse

free

RatRig V-Core Pro Bondtech Carriage (Prusa MK3S Bondtech Extruder)

...dtech can be mounted 1:1 :)

i have the mk3s with bondtech and mosquito magnum. i'll try out if my ratrig arrives...

have fun!

Ratio

3ddd

$1

Ratio MGX

...ratio mgx

3ddd

mgx

ratio mgx

3ddd

$1

Made In Ratio - Alpha Chair

...made in ratio - alpha chair

3ddd

made in ratio

the alpha chair by made in ratio.

fully unwrapped uvs.

3ddd

$1

Made In Ratio - Cowrie Chair

...e chair

3ddd

cowrie , made in ratio

cowrie chair by made in ratio.

fully unwrapped uvs.

turbosquid

$2

Dna Golden Ratio

...id

royalty free 3d model dna golden ratio for download as ma on turbosquid: 3d models for games, architecture, videos. (1455580)

turbosquid

$19

Kukri Extrema Ratio

...d model kukri extrema ratio for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1229281)

turbosquid

$6

Barrel with golden ratio

...el with golden ratio for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1433745)

3d_export

free

ring golden ratio

...er to complete cycle of the form.<br>proportion of the elements are come from the golden ratio to make it more fascinating.

turbosquid

$3

Monitor 16:9 ratio

...

royalty free 3d model monitor 16:9 ratio for download as fbx on turbosquid: 3d models for games, architecture, videos. (1698852)

turbosquid

$65

Extrema Ratio Knife Bayonet

...extrema ratio knife bayonet for download as jpg, png, and obj on turbosquid: 3d models for games, architecture, videos. (1169845)

3ddd

$1

Cowrie Chair by Made In Ratio

...*************************

в файле один стул и 4 дополнительных материала, в которых он реально продаётся: oak, ash, ebony, walnut

Remote

archibase_planet

free

Remote

...remote

archibase planet

tv remote remote controller remote

remote - 3d model for interior 3d visualization.

archibase_planet

free

Remote

...e

archibase planet

remote control remote controller remote

remote n140512 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$1

Remote

...

turbosquid

royalty free 3d model remote for download as obj on turbosquid: 3d models for games, architecture, videos. (1487515)

3d_export

$5

Tv Remote

...tv remote

3dexport

tv remote

3d_ocean

$7

Remote controller

... control switcher tv remote

remote controller for tv, sound systems etc easy to edit textures photo real rendered with mental ray

turbosquid

$39

remote

...free 3d model remote for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1387531)

turbosquid

$5

remote

...free 3d model remote for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1401849)

archive3d

free

Remote 3D Model

...l

archive3d

tv remote remote controller remote

remote - 3d model for interior 3d visualization.

turbosquid

$11

Remote

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

remote

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mods

design_connected

$13

MOD. 4233 - MOD. 4234 Table Lamp

...mod. 4233 - mod. 4234 table lamp

designconnected

arcahorn mod. 4233 - mod. 4234 table lamp computer generated 3d model.

design_connected

$11

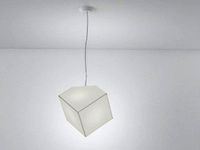

MOD.1095

...mod.1095

designconnected

mod.1095 computer generated 3d model. designed by sarfatti, gino.

3ddd

$1

fireplaces mod Spec

...fireplaces mod spec

3ddd

камин

fireplaces mod spec 180x90x125h

3ddd

free

Flos Mod. 2129

... mod

фабрика: flos

модель: mod. 2129

описание: подвесной светильник, металл, белый, черный.

сайт: www.flos.com

turbosquid

$34

Mod Lamp.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

MOD A 001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Maars Mod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Mod 70..

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

MOD Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Gears

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels 3docean engine engineering gear gears industry machinery mechanical toothwheel wheel pair of gear wheels...

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

30

3d_export

free

30 x 30 extrusion

... x 30 x 40.sldprt<br>30 x 30 x 50.sldprt<br>30 x 30 x 606.sldprt<br>the sketch.sldprt<br>30 x 30 x 40.stl

3d_export

$15

rocks 30

...rocks 30

3dexport

rocks 3d model 30

3ddd

$1

Bed 30

...bed 30

3ddd

постельное белье

bed 30.i hope you like it

design_connected

$7

Edge 30

...edge 30

designconnected

artemide edge 30 computer generated 3d model. designed by mendini, alessandro.

design_connected

$18

30-0073

...30-0073

designconnected

christopher guy 30-0073 armchairs computer generated 3d model. designed by n/a.

design_connected

$13

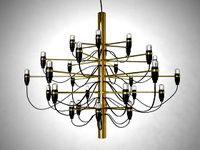

2097-30

...2097-30

designconnected

flos 2097-30 pendant lights computer generated 3d model. designed by gino sarfatti.

3d_export

$17

Yakovlev Yak-30

...yakovlev yak-30

3dexport

yakovlev yak-30

turbosquid

$50

Decor 30

...urbosquid

royalty free 3d model decor 30 for download as stl on turbosquid: 3d models for games, architecture, videos. (1678263)

turbosquid

$20

Curtains 30

...osquid

royalty free 3d model curtains 30 for download as max on turbosquid: 3d models for games, architecture, videos. (1333840)

turbosquid

$6

Bedcloth 30

...osquid

royalty free 3d model bedcloth 30 for download as max on turbosquid: 3d models for games, architecture, videos. (1522756)

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)