Thingiverse

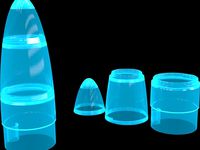

Model Rocket - B & C Engine Size by NEATman

by Thingiverse

Last crawled date: 3 years ago

UPDATE - I've added "Rocket 2 - Payload.stl" It's the same size rocket, but with a payload section at the top. It also has a new lighter weight motor retention system, made from a cleverly bent large paper clip to keep the weight down. To assemble, straighten a large standard paper clip. Bend the "U" at one end, insert downward, from the nose cone end toward the tail end. Then bend the paperclip out sideways, and add the knee bend and loop at the end. It acts like a torsion spring to retain the rocket motor.

I tried unsuccessfully to properly print out the rockets that were here on thingiverse, so my son and I designed our own in solidworks. I think it was mostly due to learning the limitations of our TOM, and not a problem with the existing designs. You will notice that this is a "all at once" print, where you print the fins, tubes and nose cone all at the same time. There are connecting ribs between the parts so that the fin section will stabilize the other tall thin parts - you'll notice in one of the pictures that the print failed near the end when the tall skinny tubes were tilting around on the ABP conveyor belt.

It is currently just a simple design, but I hope to design a version that will include a mount for a "Spy-pen" camera to take video, and possibly one that will launch gliders when the nosecone is ejected, perhaps a propeller retrieval option for the nosecone - and any other wild ideas my 4 & 7 year olds come up with...

This was printed on a Thing-O-Matic, with a MK6 extruder, ABP (which made the first attempt unstable), the layer height is .35mm, feedrate of 30, and we used white ABS so the kids could color the sections with markers.

Update-

I have added a STL without the connecting ribs - just make sure you have a solid foundation - the incomplete print in the pictures was because the conveyor belt on my ABP was too "floppy" when the parts got that tall.

I tried unsuccessfully to properly print out the rockets that were here on thingiverse, so my son and I designed our own in solidworks. I think it was mostly due to learning the limitations of our TOM, and not a problem with the existing designs. You will notice that this is a "all at once" print, where you print the fins, tubes and nose cone all at the same time. There are connecting ribs between the parts so that the fin section will stabilize the other tall thin parts - you'll notice in one of the pictures that the print failed near the end when the tall skinny tubes were tilting around on the ABP conveyor belt.

It is currently just a simple design, but I hope to design a version that will include a mount for a "Spy-pen" camera to take video, and possibly one that will launch gliders when the nosecone is ejected, perhaps a propeller retrieval option for the nosecone - and any other wild ideas my 4 & 7 year olds come up with...

This was printed on a Thing-O-Matic, with a MK6 extruder, ABP (which made the first attempt unstable), the layer height is .35mm, feedrate of 30, and we used white ABS so the kids could color the sections with markers.

Update-

I have added a STL without the connecting ribs - just make sure you have a solid foundation - the incomplete print in the pictures was because the conveyor belt on my ABP was too "floppy" when the parts got that tall.

Similar models

grabcad

free

Rocket Nose Cone

...rocket nose cone

grabcad

nosecone for .940 diameter rocket tube.

thingiverse

free

Paper Rocket Fins and Nose Cone by Tony72

...paper rocket fins and nose cone by tony72

thingiverse

fin and nose cone for a paper rocket made around 15mm id pvc pipe.

thingiverse

free

Version 2 Ellipsoidal Threaded Rocket Nose Cone by MaximSachs

...ers can be modified in the catia model.

improved by adding threads between the sections to increase the strength of the joints.

thingiverse

free

Extended BT20 Nosecone by Dave_W6DPS

...just extended the nosecone.

this should work with any bt20 (18mm id) body tube.

i print with the nose up, and have had no issues.

thingiverse

free

Orbis Rocket Parts by Mr_Disintegrator

...ar gift wrap works great, light and helps make to easy to find the rocket.

try an a8-3 for first flight, b6-4 for second flight.

thingiverse

free

1/10 Scale Nike Smoke Model Rocket by mech-G

... double-perimeter fins can add weight to the rear of the rocket, so pay attention to the cg/cp relationship to ensure stability.

thingiverse

free

Layered Success 16" tall 2" Dia Rocket Nose Cone by 2ROBOTGUY

...one. 16" tall 2" dia for a 2" mailing tube. please watch video for more information

https://youtu.be/bz-t8f2igue

thingiverse

free

Model Rocket Nose Cones by Aslansmonkey

... was loose in the nose. hence the "tight" versions. just be prepared for the tight versions to possibly be too tight.

thingiverse

free

Ellipsoidal Rocket Nose Cone by MaximSachs

...mm.

many design parameters can be modified in the catia model.

the new updated version: http://www.thingiverse.com/thing:294783

grabcad

free

nosecone

...nosecone

grabcad

nose cone for amateur rocket

Neatman

thingiverse

free

Cat Head Guitar Pick by NEATman

...cat head guitar pick by neatman

thingiverse

playing the guitar, impressing cat loving fans all over the world...

thingiverse

free

Sony MP3 Player Mount by NEATman

... neatman

thingiverse

this is a mount for a sony mp3 player. it attaches with an expandable mount that fits into the power port.

thingiverse

free

GM/Chevy Antenna Wrench by NEATman

...ntenna wrench by neatman

thingiverse

this is a simple knob style wrench for installing and removing a 90's style gm antenna.

thingiverse

free

Maker Crab Pin for Dover Mini Maker Faire by NEATman

...e blue crab is the giant sculpture outside of the dover nh children's museum, and he is the unofficial mascot of the museum.

thingiverse

free

Air Rocket Glider by NEATman

...h our website at airrocketworks.com and also through the maker shed here: http://www.makershed.com/products/air-rocket-glider-kit

thingiverse

free

"Towel" Plane Parts, Servo/Motor Mounts & Drop Mechanism by NEATman

...ne and radio transmitter to keep the plane out of harms way.

i have added the solidworks files for all of the parts of the plane.

Rocket

3d_export

$5

rocket

...rocket

3dexport

rocket 3d model low poly

3d_export

$5

rocket

...rocket

3dexport

rocket low poly 3d model cartoon

archibase_planet

free

Rocket

...rocket

archibase planet

rocket toy

rocket tintin's n290813 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_export

$5

Rocket

...rocket

3dexport

the rocket is made from a cylinder made in blender 3.0

turbosquid

$6

Rocket Baby Rocket Stool

...el rocket baby rocket stool for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502645)

turbosquid

$15

rocket

...ket

turbosquid

royalty free 3d model rocket for download as on turbosquid: 3d models for games, architecture, videos. (1340796)

turbosquid

$10

Rocket

...ket

turbosquid

royalty free 3d model rocket for download as on turbosquid: 3d models for games, architecture, videos. (1247547)

3d_export

$5

scifi rocket

...scifi rocket

3dexport

scifi rocket

turbosquid

$199

rockets

...turbosquid

royalty free 3d model rockets for download as max on turbosquid: 3d models for games, architecture, videos. (1233135)

turbosquid

$30

Rocket

...

turbosquid

royalty free 3d model rocket for download as fbx on turbosquid: 3d models for games, architecture, videos. (1290260)

B

3ddd

$1

B&B

...b&b

3ddd

b&b italia

statue b&b italy

3ddd

$1

B&B Italia

...b&b italia

3ddd

b&b italia

b&b; italia

3ddd

$1

b&b italia

...b&b italia

3ddd

b&b italia

b&b; italia

3ddd

$1

B&B LAZY

...b&b lazy

3ddd

b&b italia

b&b; lazy

3ddd

$1

B&B Italy

...b&b italy

3ddd

b&b italia

диван b&b; italy

3ddd

$1

b&b RAY

...b&b ray

3ddd

b&b italia , угловой

диван b&b; ray

3ddd

$1

B&B Beverly

... b&b italia , beverly

cтул beverly от b&b.; текстуры в архиве

3ddd

$1

B&B ITALIA

...lia , журнальный , круглый

стол b&b; italia

3ddd

$1

шезлонг B&B

...шезлонг b&b

3ddd

b&b italia , шезлонг

шезлонг b&b; terminal 1

3ddd

$1

B&B J.J

...b&b j.j

3ddd

b&b italia , журнальный

b&b;

j.j

45x40x49 cm

C

3ddd

$1

Gustavsberg Skandic 160 c-c

...gustavsberg skandic 160 c-c

3ddd

gustavsberg , смеситель

3dmax 2009

3ddd

$1

Кресло Victoria C

...кресло victoria c

3ddd

victoria c , стул

victoria c

design_connected

$25

Mobius C

...mobius c

designconnected

zenith mobius c computer generated 3d model. designed by schamburg, marc.

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

molteni & c

turbosquid

$10

Raids house C&C Tiberian sun

... raids house c&c tiberian sun for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1188376)

turbosquid

$10

Civilian Asylum C&C Tiberian sun

...ilian asylum c&c tiberian sun for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1188365)

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

стул molteni & c

3ddd

free

kamina&c

...kamina&c

3ddd

kamina-c , табурет барашек

sheep chair by kamina-c

design_connected

$29

Extrasoft C

...extrasoft c

designconnected

living divani extrasoft c computer generated 3d model. designed by lissoni, piero.

design_connected

$4

Mono C

...mono c

designconnected

scp mono c tables computer generated 3d model. designed by konstantin grcic.

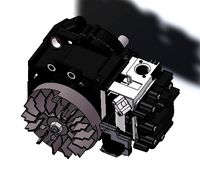

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$49

ENGINE

...

turbosquid

royalty free 3d model engine for download as max on turbosquid: 3d models for games, architecture, videos. (1206116)

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)

Size

3d_export

$7

shoes size from 5 inch size to 11 inch

...shoes size from 5 inch size to 11 inch

3dexport

shoes design women model sizing from 5 inch to 11 inch

turbosquid

$15

Closet-small size

...

royalty free 3d model closet-small size for download as max on turbosquid: 3d models for games, architecture, videos. (1186088)

turbosquid

$5

Full size Futon

...id

royalty free 3d model full size futon for download as max on turbosquid: 3d models for games, architecture, videos. (1339638)

turbosquid

$4

mid size sword

...d

royalty free 3d model mid size sword for download as blend on turbosquid: 3d models for games, architecture, videos. (1160246)

turbosquid

$3

Mid size hammer

...

royalty free 3d model mid size hammer for download as blend on turbosquid: 3d models for games, architecture, videos. (1160647)

turbosquid

$19

Beaker 3 Sizes

...yalty free 3d model beaker 3 sizes for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1645955)

turbosquid

$20

Full Sized Bed

...d model full sized bed for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1547542)

turbosquid

$45

King Size Bed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Queen size bed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Bed - Full Size

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.