Thingiverse

Model Diesel Engine Starter Anti-clockwise power turn using Clock Mainspring by ProtomakerSprint

by Thingiverse

Last crawled date: 3 years, 1 month ago

WORK IN PROGRESS!!! Files may change any time!!!!

I am looking for a YouTube Real Model Diesel Engine Starter tester as I do not have the budget to buy one for testing. Contact me on YouTube if you have a YouTube channel to video a real life test using a Model Diesel Engine.

https://youtu.be/cluPJf9axIo?t=1028

NOW IMPROVED and Updated.:=

Model Diesel Engine Starter improved:-https://youtu.be/cluPJf9axIo

The "Pawl_Model_Diesel_Engine.stl" ( print with supports and in Nylon, co-polyester or similar springy filament ), it has a plastic spring so should be 3D printed in a suitable plastic. I tried a basic test in PLA but after testing the spring in PLA it stopped being springy enough to latch the pawl.

Springy Test Diesel Engine Starter Pawl: using co-polyester-https://youtu.be/dP1HzwIn5rs

I had problems with PLA not maintain it's spring so here I test CPE HG100 Red Hood Transparent co-polyester 1.75mm 3D Printer Filamenthttps://shop.3dfilaprint.com/cpe-hg100-red-hood-transparent-co-polyester-175mm-3d-printer-filament-13288-p.asp

Filaprint Premium 3D Printer Filaments and Resinshttp://www.3dfilaprint.com/

Great if you just want to try filament types out like the sample I use

i.e:

CPE HG100 Red Hood Transparent co-polyester 1.75mm 3D Printer Filament

Filaprint Premium sampleshttps://shop.3dfilaprint.com/filament-samples-251-c.asp

CPE HG100 Red Hood Transparent co-polyester 1.75mm 3D Printer Filament

Nozzle Temperate 255-275° C, I use 260° C

Bed Temperature 70-80° C I use 75° C

No Fan. although I didn't use a part fan one may be recommended.

I have a Borosilicate glass Build plate with Elmer's Disappearing Purple Glue stick on.

This part is 3D Printed with supports

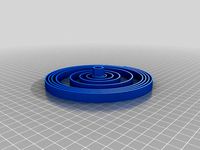

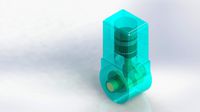

Model Diesel Engine Starter Anti-clockwise power turn using Clock Main spring

I do not have a Model Diesel Engine to fully test this in real life.*

This is a wind up unit for kick starting Model Diesel Engines.

The power of this one is "Anti-clockwise" turn using Clock Mainspring, when facing the Model Engine.

This should save having to use:-

Battery's and electric Model Diesel Engine starters.

Hands or fingers taking risks and causing danger.

The Clock Mainspring I used :-

The French & German Hole End Clock Mainspring

Height 13 mm Diameter 40mm Force 0.50

Northern Watch & Clock Supplies

eBay seller : nwcs84

eBay Item : 263496692717

After cleaning the supports out of the "Pawl_Model_Diesel_Engine.stl"

There are holes in the:-

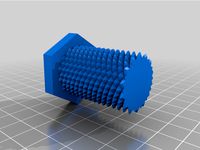

Shaft Ratchet Clock Mainspring Model Diesel Engine Starter

and the

Body Clock Mainspring Big Shaft Model Diesel Engine Starter

for M3 x 10 (or 15mm) Button Head bolts to catch on to the holes in the ends of the Main spring use with 4mm washers to keep spring on.

The body parts are designed for M3 bolts * to screw, (these can be drilled to 4mm if some adjustment is required), into the Lid part with a hole of 2.5mm to make threads in of 3mm

The shaft two other bolts are M4*

button head Allen bolts

There are two washers for each of the shaft ends, smooth surface towards each other and oiled.

Small spring required for the main ratchet pawl.

Please see the video's on YouTube this should explain things:-

https://youtu.be/cluPJf9axIo

Note these videos show the Clockwise power model, I think that is the incorrect direction:-

Watch it working dry run. I do not have a Model Diesel Engine to fully test this in real life:-

https://youtu.be/cluPJf9axIo?t=1020

The "Rubber Turner Clock Mainspring Big Shaft Model Diesel Engine Starter.stl" is for a

RC plane starter insert 30mm x 36mm 20mm inner hole I Have not carried out a test fit so some redesign may be needed. This has holes to bolt on to the Ratchet Lid part..

DANGER be very careful the spring does not come out.

Have safety precautions ready.

Turning_Lid_Model_Diesel_Engine.stl = 100% infill for ratchet teeth strength

Pawl_Model_Diesel_Engine.stl = 100% infill for pawl tooth strength

Shaft_Ratchet_Model_Diesel_Engine.stl = 100% infill for ratchet arms strength and supports everywhere because arms are printed off the print bed

.

.

I am looking for a YouTube Real Model Diesel Engine Starter tester as I do not have the budget to buy one for testing. Contact me on YouTube if you have a YouTube channel to video a real life test using a Model Diesel Engine.

https://youtu.be/cluPJf9axIo?t=1028

NOW IMPROVED and Updated.:=

Model Diesel Engine Starter improved:-https://youtu.be/cluPJf9axIo

The "Pawl_Model_Diesel_Engine.stl" ( print with supports and in Nylon, co-polyester or similar springy filament ), it has a plastic spring so should be 3D printed in a suitable plastic. I tried a basic test in PLA but after testing the spring in PLA it stopped being springy enough to latch the pawl.

Springy Test Diesel Engine Starter Pawl: using co-polyester-https://youtu.be/dP1HzwIn5rs

I had problems with PLA not maintain it's spring so here I test CPE HG100 Red Hood Transparent co-polyester 1.75mm 3D Printer Filamenthttps://shop.3dfilaprint.com/cpe-hg100-red-hood-transparent-co-polyester-175mm-3d-printer-filament-13288-p.asp

Filaprint Premium 3D Printer Filaments and Resinshttp://www.3dfilaprint.com/

Great if you just want to try filament types out like the sample I use

i.e:

CPE HG100 Red Hood Transparent co-polyester 1.75mm 3D Printer Filament

Filaprint Premium sampleshttps://shop.3dfilaprint.com/filament-samples-251-c.asp

CPE HG100 Red Hood Transparent co-polyester 1.75mm 3D Printer Filament

Nozzle Temperate 255-275° C, I use 260° C

Bed Temperature 70-80° C I use 75° C

No Fan. although I didn't use a part fan one may be recommended.

I have a Borosilicate glass Build plate with Elmer's Disappearing Purple Glue stick on.

This part is 3D Printed with supports

Model Diesel Engine Starter Anti-clockwise power turn using Clock Main spring

I do not have a Model Diesel Engine to fully test this in real life.*

This is a wind up unit for kick starting Model Diesel Engines.

The power of this one is "Anti-clockwise" turn using Clock Mainspring, when facing the Model Engine.

This should save having to use:-

Battery's and electric Model Diesel Engine starters.

Hands or fingers taking risks and causing danger.

The Clock Mainspring I used :-

The French & German Hole End Clock Mainspring

Height 13 mm Diameter 40mm Force 0.50

Northern Watch & Clock Supplies

eBay seller : nwcs84

eBay Item : 263496692717

After cleaning the supports out of the "Pawl_Model_Diesel_Engine.stl"

There are holes in the:-

Shaft Ratchet Clock Mainspring Model Diesel Engine Starter

and the

Body Clock Mainspring Big Shaft Model Diesel Engine Starter

for M3 x 10 (or 15mm) Button Head bolts to catch on to the holes in the ends of the Main spring use with 4mm washers to keep spring on.

The body parts are designed for M3 bolts * to screw, (these can be drilled to 4mm if some adjustment is required), into the Lid part with a hole of 2.5mm to make threads in of 3mm

The shaft two other bolts are M4*

button head Allen bolts

There are two washers for each of the shaft ends, smooth surface towards each other and oiled.

Small spring required for the main ratchet pawl.

Please see the video's on YouTube this should explain things:-

https://youtu.be/cluPJf9axIo

Note these videos show the Clockwise power model, I think that is the incorrect direction:-

Watch it working dry run. I do not have a Model Diesel Engine to fully test this in real life:-

https://youtu.be/cluPJf9axIo?t=1020

The "Rubber Turner Clock Mainspring Big Shaft Model Diesel Engine Starter.stl" is for a

RC plane starter insert 30mm x 36mm 20mm inner hole I Have not carried out a test fit so some redesign may be needed. This has holes to bolt on to the Ratchet Lid part..

DANGER be very careful the spring does not come out.

Have safety precautions ready.

Turning_Lid_Model_Diesel_Engine.stl = 100% infill for ratchet teeth strength

Pawl_Model_Diesel_Engine.stl = 100% infill for pawl tooth strength

Shaft_Ratchet_Model_Diesel_Engine.stl = 100% infill for ratchet arms strength and supports everywhere because arms are printed off the print bed

.

.

Similar models

thingiverse

free

Ratchet and Pawl for Tetrix by gcrocker

...se

remixed this ratchet & pawl to be used with a tetrix axle collar and fit along tetrix channel (with a 1/4"-20 bolt).

thingiverse

free

Ratchet and Pawl by entomophile

...erse

this is a locking 12 step ratchet and pawl mechanism i designed for a project i am working on. http://youtu.be/l4cxz2uywvq

thingiverse

free

Plastic Pawl for CY / RC Starter - eg415 (DDM)

...for my losi dbxl.

used for printing exclusively nylon material with the addition of carbon. i assure you tested everything works.

thingiverse

free

waterjet clock rev 4 by engunneer

...ront gear on the right shaft is connected to the ratchet and pawl mechanism and can be used for winding the weight back up again.

thingiverse

free

Luger P08 Mainspring Assembly by kobing

...an be inserted into the body. for the spring, i stretched a compressed 11/32"x 1-27/32" spring that i bought on amazon.

grabcad

free

Ratchet Tool pawl spring

...ratchet tool pawl spring

grabcad

part 7 of assembly of a ratchet tool

grabcad

free

Inverse dual ratchet drive

... suppressing mates, that is a cop out! ) sorry about the 2012 sw files, i hate that feature of sw and may junk it because of it.

3d_export

$5

Rachet Pawl Mechanism

...semblies that are used to transmit intermittent rotary motion, or to permit a shaft to rotate in one direction but not the other.

thingiverse

free

3D Tourbillon Clock Torque Modification by miked3

...cmaster carr:

95893a550, for ratchet pawls and clock face

95893a510, for tourbillon and going barrel

95893a560, for lower housing

grabcad

free

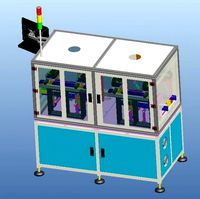

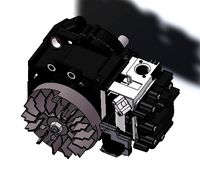

Engine Starter Test Rig

...engine starter test rig

grabcad

test bench for diesel and petrol engine starter

Mainspring

thingiverse

free

1911 mainspring housing

...1911 mainspring housing

thingiverse

stl file repaired for print

thingiverse

free

1911 Arched Mainspring housing by PrintedFirearm

...edfirearm

thingiverse

3d printable mainspring housing for a 1911 pistol. find out more on my blog http://www.printedfirearm.com

thingiverse

free

Luger P08 Mainspring Assembly by kobing

...an be inserted into the body. for the spring, i stretched a compressed 11/32"x 1-27/32" spring that i bought on amazon.

thingiverse

free

Toy's mainspring handle attachment by takfjt

...toy's mainspring handle attachment by takfjt

thingiverse

this is a attachment for a handle of the capsule plarail.

thingiverse

free

Clock Mainspring Winder - Clock Repair by ihsjepsen

...read rod would probably work.

crank handle: 1/4 20 bolt and nut. use thread locker on the nut to keep it from

loosening.

thingiverse

free

3D Printed Watch Mainspring for Smaller Print Beds (UNTESTED) by Jake

...that it might not fit and might not work!

p.s. if anyone knows why i can't post comments on thingiverse, please let me know!

thingiverse

free

Paint Mixer Attachment for Sherline Mill by wackyvorlon

...to help with mixing up a bottle of watch mainspring grease. step file is included so you can modify...

3d_sky

free

Playground equipment

...firm ksil: sandbox art. rocking chair-4242, art of the mainspring 4102, swing art. 4153, swing art. 4155, carousel art....

thingiverse

free

Robo Chick by CodeNameX

...of avenger... this thing is... a toy of chick (mainspring movement) . it was selled in daiso japan. thats...

Protomakersprint

thingiverse

free

Marlin Inside Symbol by ProtomakerSprint

...marlin inside symbol by protomakersprint

thingiverse

marlin inside symbol

thingiverse

free

Octoprint Raspberry Pi Logo by ProtomakerSprint

...octoprint raspberry pi logo by protomakersprint

thingiverse

octoprint raspberry pi logo

thingiverse

free

Pie Shaped Piece curved wedge by ProtomakerSprint

...pie shaped piece curved wedge by protomakersprint

thingiverse

pie shaped piece curved wedge

thingiverse

free

Ribbon Cable Holder 2040 by ProtomakerSprint

...ribbon cable holder 2040 by protomakersprint

thingiverse

just ribbon cable holder 2040

e.g. pi camera cable holder

thingiverse

free

Humidity Removal Unit by ProtomakerSprint

...ld do.

humidity removal unit 3d print playlist on youtubehttps://www.youtube.com/playlist?list=pluqt0stixuddi0rbgkrowhanr9h22nuva

thingiverse

free

PCB Runner clips by ProtomakerSprint

... having quite a good grip.

ideal if need to adjust pcb edge distance away from something else.

single and doubles, adjust to fit.

thingiverse

free

SD Card Holder by ProtomakerSprint

...ndard +10 microhttps://youtu.be/jpvzpjpw_cu

remix of : sd card holderhttps://www.thingiverse.com/thing:2722882 by theswedishbear

thingiverse

free

Save the NHS by ProtomakerSprint

...op the new plans to dismantle our nhs. please share it.https://you.38degrees.org.uk/petitions/stop-the-plans-to-dismantle-our-nhs

thingiverse

free

Flux Thermal Paste Dispenser 3D Print by ProtomakerSprint

... raft

baised on dispenser for syringe of flux or solder paste by mordaha on thingiverse:https://www.thingiverse.com/thing:4549023

thingiverse

free

Motorola Moto G 3rd generation Tripod Mount by ProtomakerSprint

...g 3rd generation tripod mount

should suite any bigger backed phones

a video of this being 3d printed

https://youtu.be/qwuess8shqc

Clockwise

3d_export

$9

Clock Hands 3D Model

...second hour face analog time antique dial longcase grandfather clockwise minutes seconds hours timekeeper old clock hands 3d model...

3d_export

$7

automatic coater

...of decorative edge banding. two coating mechanism, one is clockwise rotation, the other is counter clockwise rotation. the positive...

3d_export

$10

compass

...rose. north corresponds to 0°, and the angles increase clockwise so east is 90° degrees, south is 180°, and...

3d_export

$15

record player

...a base that accommodates the circular plate, which rotates clockwise driven by an electric motor, with a central pin...

thingiverse

free

Two way clockwise and counter clockwise bolt with nuts by Arashrk

...rint one.

here is the video mentioned: https://youtu.be/cdfmi5ahbji

print on lowest layer hight as possible for smoother action.

thingiverse

free

Clockwise DITR-0105 Holder by meesix

...05 holder by meesix

thingiverse

this is a simple holder for the clockwise ditr-0105 which locks onto 20x20 aluminium extrusions.

thingiverse

free

D6 - Clockwise 6 Sided Dice by Cyrrus

...d6 - clockwise 6 sided dice by cyrrus

thingiverse

d6 - clockwise 6 sided dice

thingiverse

free

Wind Turbine Blade Hub clockwise rotation by bacheporo

...nd turbine blade hub clockwise rotation by bacheporo

thingiverse

this blade hub is mirrored so that the blades rotate clockwise.

thingiverse

free

6" clockwise Prop 5mm hole Quadracer by Xxtreme

...6" clockwise prop 5mm hole quadracer by xxtreme

thingiverse

6" clockwise prop 5mm hole for quadracer

thingiverse

free

RC plane two, three and zero blade propeller spinner - clockwise and counter-clockwise by pintokitkat

...0 (which i'm choosing as my modelling software of choice these days).

i'll sort them all out and clean them up in time.

Starter

turbosquid

$12

Starter old

...royalty free 3d model starter old for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1293428)

turbosquid

free

Cream Starter

...free 3d model cream starter for download as fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1408178)

turbosquid

$2

Fire Starter

...ree 3d model fire starter for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1371386)

turbosquid

$11

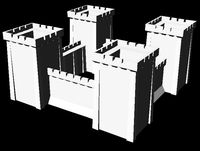

starter castle.dxf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Fluorescent Starter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Philips starter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Starter Spider

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

starter wheel for the brushcutter

...d model starter wheel for the brushcutter for download as stl on turbosquid: 3d models for games, architecture, videos. (1586931)

turbosquid

$1

man Head starter

...yalty free 3d model man head 3d starter for download as blend on turbosquid: 3d models for games, architecture, videos. (1575541)

turbosquid

$11

starter castle.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Diesel

3ddd

$1

Diesel chair

...diesel chair

3ddd

diesel

моя интерпретация кресла diesel.

polys: 88 895

3d_export

$15

diesel generator

...diesel generator

3dexport

generator diesel

3ddd

$1

Diesel by Moroso

...й

diesel by moroso

размеры: 400х400х h750http://www.architonic.com/pmsht/bar-stud-stool-diesel-by-moroso_proref/1076262

3ddd

$1

Кровать Diesel

... diesel

кровать moroso "diesel"

размеры: 2140х1900х1000

материал оббивки: ткань

turbosquid

$12

Diesel

...d model diesel for download as ma, c4d, max, ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1705708)

3ddd

$1

Diesel / Mic

...diesel / mic

3ddd

diesel , foscarini

cage mic nero

diesel.foscarini.com

3ddd

free

Diesel / Stud

... foscarini

фабрика: diesel (with foscarini)

коллекция: stud

модели: stud grande, stud piccola

www.diesel.foscarini.com

3ddd

$1

Diesel - Cloudscape

...diesel - cloudscape

3ddd

diesel

100 х 100 х 104 см.

3ddd

$1

DIESEL CAGE LIGHT

...diesel cage light

3ddd

diesel , cage

diesel cage light by foscarini

3ddd

$1

Diesel / Cage Mic

...carini , diesel , подвесной

design: diesel 2011

Anti

3d_export

$5

Anti stress kit

...anti stress kit

3dexport

anti stress kit wall sign

turbosquid

$5

Anti-aircraft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Anti stapler 3D Model

...anti stapler 3d model

3dexport

staples anti stapler анти степлер

anti stapler 3d model seemoonlight 69602 3dexport

archive3d

free

Anti-aircraft 3D Model

...litary equipment

anti-aircraft m730a1 n020711 - 3d model (*.3ds) for exterior 3d visualization.

3d_export

$5

anti-vandal unit nofer

...anti-vandal unit nofer

3dexport

anti-vandal unit nofer

turbosquid

$30

Anti-tank Obstacle

...

royalty free 3d model anti-tank obstacle for download as fbx on turbosquid: 3d models for games, architecture, videos. (1438196)

turbosquid

$3

Anti gravity drone

...

royalty free 3d model anti gravity drone for download as obj on turbosquid: 3d models for games, architecture, videos. (1311361)

turbosquid

$1

Anti airplane Missile

...yalty free 3d model anti airplane missile for download as fbx on turbosquid: 3d models for games, architecture, videos. (1274540)

turbosquid

$1

Anti-Terrorist Barrier

...e 3d model anti-terrorist barrier for download as jpg and obj on turbosquid: 3d models for games, architecture, videos. (1348463)

3d_ocean

$8

Sunsilk Anti Dandruff

...i dandruff sunsilk bottle sunsilk pack sunsilk product sunsilk shampoo

sunsilk anti dandruff is sunsilk shampoo 3d model product.

Clock

3d_ocean

$4

Clock

...clock

3docean

clock hand kitchen clock time watch

a clock

archibase_planet

free

Clock

...clock

archibase planet

clock table clock alarm-clock

clock orange - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock table clock alarm-clock

clock yellow - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock alarm-clock

clock n100707 - 3d model for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock table clock

clock - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock striking clock

clock - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock wall clock

clock 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock wall clock

clock 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

clock wall clock

clock 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Clock

...clock

archibase planet

alarm clock alarm-clock

clock - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Turn

turbosquid

$60

TURN TURN

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$11

Turn

...turn

designconnected

seletti turn computer generated 3d model. designed by zambelli, alessandro.

3ddd

$1

Jorger Turn

... turn , смеситель

коллекция смесителей фирмы jorger, серия turn

3ddd

$1

joerger turn

...

joerger , смеситель

http://www.joerger.de/

коллекция turn

артикул 623,30,300

design_connected

$9

Turning desk

...turning desk

designconnected

atelier areti turning desk computer generated 3d model. designed by kerschbaumer, gwendolyn.

3ddd

$1

E-Turn

... скамейка

современная скамейка фирмы kundalini.

модель e-turn.

дизайнер brodie neil.

размеры: h 42 cm l 185 cm w 54 cm

design_connected

$16

Re-turned

...

photo-realistic 3d models of the re-turned table accessories from beller for 3d architectural and interior design presentations.

turbosquid

$15

turning torso

...quid

royalty free 3d model turning torso for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1525931)

turbosquid

$15

Turn Ring

...rbosquid

royalty free 3d model turn ring for download as max on turbosquid: 3d models for games, architecture, videos. (1482401)

turbosquid

$6

RETURN OR TURN

...uid

royalty free 3d model return or turn for download as max on turbosquid: 3d models for games, architecture, videos. (1215382)

Power

turbosquid

$100

power

...ower

turbosquid

royalty free 3d model power for download as on turbosquid: 3d models for games, architecture, videos. (1421990)

3d_export

$5

Power

...power

3dexport

3d_export

$5

power outlets

...power outlets

3dexport

power outlets

3ddd

$1

lion power

...lion power

3ddd

лев , статуя

lion power gold sculpture

3ddd

$1

Sea Power

...

компас , море , часы

часы с компасом sea power

3ddd

free

Meridiani / Power

...power

3ddd

meridiani , круглый

стол power производитель meridiani, диаметр 120,высота 67

3d_export

$5

Power Surge

...power surge

3dexport

the power surge is a all mesh carnival ride to lower in game part count and lag

turbosquid

$8

Airport Ground Power Unit (AXA Power )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Power Houser

...rbosquid

royalty free 3d model power houser for download as on turbosquid: 3d models for games, architecture, videos. (1333800)

3d_export

$5

power outlet

...power outlet

3dexport

power outlet<br>format file maya 2018, 3d max 2017, obj, fbx

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$49

ENGINE

...

turbosquid

royalty free 3d model engine for download as max on turbosquid: 3d models for games, architecture, videos. (1206116)

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)

Using

3ddd

$1

US flag

...us flag

3ddd

флаг

us flag

3d_export

free

Among us

...among us

3dexport

among us red

3d_export

free

Among Us

...among us

3dexport

this 3d-model of a character from the game "among us". it can be used as a toy or decoration.

3d_export

$6

among us

...among us

3dexport

doll from among us in red

3d_export

$5

amoung us

...amoung us

3dexport

amoung us character. was created by cinema 4d 19

3d_export

$5

Humvee us

...humvee us

3dexport

humvee us 3d model good quality for animation

3d_export

$15

among us

...among us

3dexport

turbosmooth modifier can be used to increase mesh resolution if necessary

3d_export

$25

mailbox us

...mailbox us

3dexport

low poly model mailbox us. modeling in the blender, texturing in substance painter

design_connected

$13

Use Me

...use me

designconnected

sitland use me computer generated 3d model. designed by paolo scagnellato.

3d_export

$5

Among Us

...rt

the among us model comes in a variety of colors that can be customized by anyone, and even works with little in the animation