GrabCAD

Mighty Micro version 3.1

by GrabCAD

Last crawled date: 1 year, 11 months ago

-Fixed submission scale to the correct mm rather than inches

-Basically the same as my other entry with polish and stack-up fixes.

"The winning electromechanical pressure switch design will accomplish the following:

- Diaphragm activated momentary switch, normally open and normally closed options." Y

- Design enables efficient automation process and eliminate manual assembly with minimal changeover to alternate configurations. Y

- Differential, vacuum and positive pressure options. Y

- Electrical Connection options: Both male quick connect (4,7 X 0,5 mm) and Pin configurations Y

- Automated calibration enabled to adjust pressure set point at testing. Y

- Ports interface for 8mm flexible tubing diameter maximum. Y

- Pressure ranges: 15 to 40 Pa (low) and 30 to 160 Pa (high). Theoretically Y

- Maximum body size envelope: 25 X 25 X 7mm.

- Preferred body size envelope: 14 X 14 X 7mm. Main body is within 14x14x7 mm volume. All other parts withing 25x25x7mm minus 8mm air nozzle violates 7mm limit but only because it was specified in requirements. Nozzle can be shrunk to any dimension or replaced

- Highlights core manufacturing technologies (injection molding, stamping, assembly, tooling, machining, insert molding, and automation). With a bonus of heat-staking.

- Utilizes accelerating manufacturing technologies and materials. Y

- Cost effective design with least amount of materials. Y

Development of a diaphragm operated vacuum/pressure micro-switch.

Switch allows setting sensitivity and normally open or closed operation for either vacuum or pressure via adjustment screws.

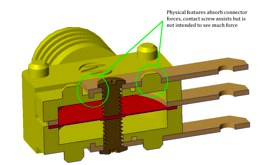

Diaphragm is made of "Metal Rubber" elastomer that has been doped to be conductive. (https://en.wikipedia.org/wiki/Metal_rubber) Which can have a resistance a low as 1/10 of an ohm. The common quick connect makes direct contact with the rim of this diaphragm.

Reduced parts count to 6 unique components (8 physical) two of which are screws down from 13 shown in drawing. Eliminated rivets in favor of heat stake fastening all components including what i assume is a % glass-fill body.

End notes:

Weight of product is not possible as I don't have the density of the materials that Microtechnologies Inc. has decided on.

Model still needs draft and radii put in before molding, these also effect weight. I left these out because they are much easier to add than to take out when model tweaks are desired.

Screws and air nozzle are mainly place holders and should be replaced with what Microtechnologies Inc. uses commonly.

Diaphragm thickness will need adjusted once better data is available on elastic properties of "Metal Rubber".

Switch would fit well into some sort of snap mount cradle. Plug everything into place air etc then snap switch in place.

-Basically the same as my other entry with polish and stack-up fixes.

"The winning electromechanical pressure switch design will accomplish the following:

- Diaphragm activated momentary switch, normally open and normally closed options." Y

- Design enables efficient automation process and eliminate manual assembly with minimal changeover to alternate configurations. Y

- Differential, vacuum and positive pressure options. Y

- Electrical Connection options: Both male quick connect (4,7 X 0,5 mm) and Pin configurations Y

- Automated calibration enabled to adjust pressure set point at testing. Y

- Ports interface for 8mm flexible tubing diameter maximum. Y

- Pressure ranges: 15 to 40 Pa (low) and 30 to 160 Pa (high). Theoretically Y

- Maximum body size envelope: 25 X 25 X 7mm.

- Preferred body size envelope: 14 X 14 X 7mm. Main body is within 14x14x7 mm volume. All other parts withing 25x25x7mm minus 8mm air nozzle violates 7mm limit but only because it was specified in requirements. Nozzle can be shrunk to any dimension or replaced

- Highlights core manufacturing technologies (injection molding, stamping, assembly, tooling, machining, insert molding, and automation). With a bonus of heat-staking.

- Utilizes accelerating manufacturing technologies and materials. Y

- Cost effective design with least amount of materials. Y

Development of a diaphragm operated vacuum/pressure micro-switch.

Switch allows setting sensitivity and normally open or closed operation for either vacuum or pressure via adjustment screws.

Diaphragm is made of "Metal Rubber" elastomer that has been doped to be conductive. (https://en.wikipedia.org/wiki/Metal_rubber) Which can have a resistance a low as 1/10 of an ohm. The common quick connect makes direct contact with the rim of this diaphragm.

Reduced parts count to 6 unique components (8 physical) two of which are screws down from 13 shown in drawing. Eliminated rivets in favor of heat stake fastening all components including what i assume is a % glass-fill body.

End notes:

Weight of product is not possible as I don't have the density of the materials that Microtechnologies Inc. has decided on.

Model still needs draft and radii put in before molding, these also effect weight. I left these out because they are much easier to add than to take out when model tweaks are desired.

Screws and air nozzle are mainly place holders and should be replaced with what Microtechnologies Inc. uses commonly.

Diaphragm thickness will need adjusted once better data is available on elastic properties of "Metal Rubber".

Switch would fit well into some sort of snap mount cradle. Plug everything into place air etc then snap switch in place.

Similar models

grabcad

free

Mighty Micro Switch

...".

switch would fit well into some sort of snap mount cradle. plug everything into place air etc then snap switch in place.

grabcad

free

SGCHL Pressure Switch

...le printed circuit board.

automated calibration enabled to adjust pressure set point at testing.

electrical conductive diaphragm.

grabcad

free

Differential Pressure Switch NC/NO with Pressure Adjustment (PCB / Faston Options)

... technologies and materials. => fully compliant

- cost effective design with least amount of materials. => fully compliant

grabcad

free

Differential Pressure Switch NC/NO with Pressure Adjustment

...maining components to assemble (automatically or manually) are 3.

the weight is estimate at about 4,1 g (1,1g plastic, 3g metal)

grabcad

free

Vacuum and positive pressure switch

...ing)

1 x contact c (stamping)

2 x male quick connector (stamping)

1 x cover (injection molding)

1 x diaphragm (injection molding)

grabcad

free

PRESSURE SWITCH NO

...pressure switch no

grabcad

air pressure diaphragm switch, normally open (solidworks file is sw20)

grabcad

free

Pressure Switch - Cylinder

...e flow is regulated by a screw, which also enables closing options.

the switch consists of seven parts (including the m2 screw).

grabcad

free

PRESSURE SWITCH NC

...pressure switch nc

grabcad

air pressure diaphragm switch, normally closed (solidworks model is sw20)

grabcad

free

CircleFlip

...e flow is regulated by a screw, which also enables closing options.

the switch consists of seven parts (including the m2 screw).

grabcad

free

Pressure Switch

...be tight. used technology:

- main body (two parts) - by injection molding

- connect/terminal, adjust connect, terminal - stamping

Mighty

turbosquid

$15

Mighty monster

...osquid

royalty free 3d model mighty monster for download as on turbosquid: 3d models for games, architecture, videos. (1614059)

turbosquid

$40

Mighty Wurlitzer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Mighty Hammer Kraken

...ree 3d model mighty hammer kraken for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1611798)

turbosquid

$59

Cartoon Mighty Unicorn

...rtoon mighty unicorn for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1502497)

3d_export

$50

Mighty Warrior

...mighty warrior

3dexport

fantasy warrior. model for printing. an excellent figure that you put on the shelf and admire it.

turbosquid

$15

(sword) Mighty Sword

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$119

Hyundai Mighty 03 2

...d model hyundai mighty 03 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1284284)

cg_studio

$30

Apple Wireless Mighty Mouse3d model

....3ds .c4d .dxf .fbx .obj - apple wireless mighty mouse 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Mighty Thistle (The Legend of Zelda: Breath of the Wild)

...he legend of zelda: breath of the wild) for download as blend on turbosquid: 3d models for games, architecture, videos. (1280910)

3d_export

$5

guybrush threepwood mighty pirate

... the game. the model can be used for 3d printing or can be topology for modeling and rigging. comes with fbx, obj and blend files

Micro

3ddd

$1

Micro

...micro

3ddd

автобус

turbosquid

$80

MICRO

...ty free 3d model micro for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1700743)

3ddd

$1

JBL Micro Wireless

... micro , колонка , плеер

jbl micro wireless

turbosquid

$10

Suppressor Micro

...quid

royalty free 3d model suppressor micro for download as on turbosquid: 3d models for games, architecture, videos. (1380433)

turbosquid

$20

Micro Meter

...osquid

royalty free 3d model micro meter for download as fbx on turbosquid: 3d models for games, architecture, videos. (1350448)

turbosquid

$7

NIghtstand Micro

...d

royalty free 3d model nightstand micro for download as max on turbosquid: 3d models for games, architecture, videos. (1248117)

3ddd

$1

Micro wind turbine

...micro wind turbine

3ddd

турбина

micro wind turbine for your green building projects

turbosquid

$29

Micro Speakers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Micro Servo.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Micro cells

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Version

3ddd

$1

Diamond version

...nd , version , ванна

visionnaire - diamond bath

turbosquid

$50

LibraryMini Version

...free 3d model librarymini version for download as max and jpg on turbosquid: 3d models for games, architecture, videos. (1617724)

design_connected

$34

Barocco Version 01

...barocco version 01

designconnected

zanotta barocco version 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Barocco Version 02

...barocco version 02

designconnected

zanotta barocco version 02 computer generated 3d model. designed by progetti, emaf.

turbosquid

free

![Door [2 versions]](/t/13243146.jpg)

Door [2 versions]

...rbosquid

free 3d model door [2 versions] for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223985)

turbosquid

$2

seat version 0.1

...

royalty free 3d model seat version 0.1 for download as blend on turbosquid: 3d models for games, architecture, videos. (1432653)

turbosquid

$12

Chip Version 03

...lty free 3d model chip version 03 for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1241145)

3d_export

$10

magnolia grandiflora mature version

...magnolia grandiflora mature version

3dexport

magnolia grandiflora mature version

3d_export

$8

room assets and voxel version

...room assets and voxel version

3dexport

room assets and voxel version

turbosquid

$35

Zil Civilian version

... model zil civilian version for download as cgf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639420)

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)