Thingiverse

MIFO - Semi-automatic Film Processor by michaelfowler

by Thingiverse

Last crawled date: 2 years, 11 months ago

MIFO - Semi-automatic Film Processor

(Why MIFO? Why JOBO? - Find the answer to Both)

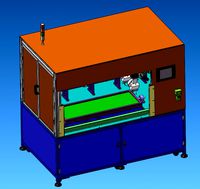

Well Here it is, a semi-automatic temperature controlled water bath

film processor. I have included gears for Nikor (Stainless Steel)

and Patterson tanks. If there is a different tank out there (other than JOBO)

Get a hold of me with your tank diameter and I will make a Gear for it.

Unit Running - https://vimeo.com/544118649/3395e64be6

Unit and Timer Running - https://vimeo.com/544118570/4d8968fa8f

A ZIP file of all the necessary files and all the individual files for the project are

available off my box server here (including full size pics):https://app.box.com/s/0mdurfhsfmk2tij5mmiolwlv1nqgumg4

Take the Top off and it makes a great tray to fill and empty the tanks, hold chemicals etc.

Any Sous Vide cooker out there can be used to control the water bath temperature.

I would probably go this route:https://www.amazon.com/dp/B07BKSH4KY/ref=cm_sw_em_r_mt_dp_CXAGTRDGARRX90T2P758?_encoding=UTF8&psc=1

Pretty nice features for the price. I happened to already have the Joule.

BONUS -You can also cook the BEST STEAK you have ever had. - REALLY!

I used the same motor form the Poorman's JOBO project

HERE: https://www.thingiverse.com/thing:4709155

Here is the link to the Motor:https://www.amazon.com/dp/B00BX54O8A/ref=cm_sw_em_r_mt_dp_09O8FbJGXP10R

Alternative Motor -https://www.amazon.com/dp/B072N84JX7/ref=cm_sw_em_r_mt_dp_D0QA1W1X2WK0DBC7AVA8

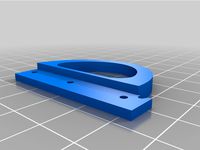

O-rings (1-1/8 x 1 x 1/8") on the tank support and the holes in the tank rollers

are also off center slightly to give some up/down agitation to the tank.

3 Small bumps on the rollers indicate the high side of the roller.

Smaller O-rings or grommets cut in half are used as "Stops" on the rods to keep

things from sliding around.

RODS - 5/8" aluminum rods but I would think stainless or even carbon fiber would work.

My rods were 12 5/8" long

There is also a Motor hook on a 1/8" Bungee to prevent the motor from accidently taking a bath

and can be moved the the opposite side of the tote to keep the gears meshed.

But anything other than light pressure will cause the motor to bind.

The tank should run TOWARDS you and the bite of the gears alone will keep them together.

Tank support rollers are printed slightly small ID - use 80 grit sand paper to make them fit

and spin freely on the rods you use.

The tote used for the project is a Muscle Rack 5 Gallon tote

11.8"Wx16.1"Lx8.1"H - Model PT5HD

Once you have built the rail assembly you can properly determine where to cut the

tote edges - I used a Dremel with a cut off wheel.

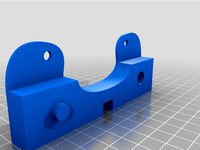

Need to print List and Settings.

Printer settings

.20 - 20% infill unless Noted

(If placed properly No supports are needed.)

Two -

Tank ends

Tank end to rod end supports

Rod end Holders

Bumpers - Print 100% infill with MAX cooling

One-

Drive Arm

Rod Spacer Sliding

Rod Spacer Upright

Motor Drive Gear

Motor Cover

Motor hook ( Print with MAX cooling)

Various

The number you need of Tank Rollers - Normally 4

Gear to match your Tank (May need a wrap or two of electrical tap for a good fit).

Timer - If Desired

All Three pieces Front Back and switch support

4 Small Sheet metal screws to hold the timer box together

A small piece of 1/8 bungee cord.

A 12 volt 1 amp power supply

Timer schematics and code as well as part lists are available off my box server here.https://app.box.com/s/0mdurfhsfmk2tij5mmiolwlv1nqgumg4

There is a separate read me in the Countdown timer Nano folder also.

It contains specific info on the Timer build.

(Why MIFO? Why JOBO? - Find the answer to Both)

Well Here it is, a semi-automatic temperature controlled water bath

film processor. I have included gears for Nikor (Stainless Steel)

and Patterson tanks. If there is a different tank out there (other than JOBO)

Get a hold of me with your tank diameter and I will make a Gear for it.

Unit Running - https://vimeo.com/544118649/3395e64be6

Unit and Timer Running - https://vimeo.com/544118570/4d8968fa8f

A ZIP file of all the necessary files and all the individual files for the project are

available off my box server here (including full size pics):https://app.box.com/s/0mdurfhsfmk2tij5mmiolwlv1nqgumg4

Take the Top off and it makes a great tray to fill and empty the tanks, hold chemicals etc.

Any Sous Vide cooker out there can be used to control the water bath temperature.

I would probably go this route:https://www.amazon.com/dp/B07BKSH4KY/ref=cm_sw_em_r_mt_dp_CXAGTRDGARRX90T2P758?_encoding=UTF8&psc=1

Pretty nice features for the price. I happened to already have the Joule.

BONUS -You can also cook the BEST STEAK you have ever had. - REALLY!

I used the same motor form the Poorman's JOBO project

HERE: https://www.thingiverse.com/thing:4709155

Here is the link to the Motor:https://www.amazon.com/dp/B00BX54O8A/ref=cm_sw_em_r_mt_dp_09O8FbJGXP10R

Alternative Motor -https://www.amazon.com/dp/B072N84JX7/ref=cm_sw_em_r_mt_dp_D0QA1W1X2WK0DBC7AVA8

O-rings (1-1/8 x 1 x 1/8") on the tank support and the holes in the tank rollers

are also off center slightly to give some up/down agitation to the tank.

3 Small bumps on the rollers indicate the high side of the roller.

Smaller O-rings or grommets cut in half are used as "Stops" on the rods to keep

things from sliding around.

RODS - 5/8" aluminum rods but I would think stainless or even carbon fiber would work.

My rods were 12 5/8" long

There is also a Motor hook on a 1/8" Bungee to prevent the motor from accidently taking a bath

and can be moved the the opposite side of the tote to keep the gears meshed.

But anything other than light pressure will cause the motor to bind.

The tank should run TOWARDS you and the bite of the gears alone will keep them together.

Tank support rollers are printed slightly small ID - use 80 grit sand paper to make them fit

and spin freely on the rods you use.

The tote used for the project is a Muscle Rack 5 Gallon tote

11.8"Wx16.1"Lx8.1"H - Model PT5HD

Once you have built the rail assembly you can properly determine where to cut the

tote edges - I used a Dremel with a cut off wheel.

Need to print List and Settings.

Printer settings

.20 - 20% infill unless Noted

(If placed properly No supports are needed.)

Two -

Tank ends

Tank end to rod end supports

Rod end Holders

Bumpers - Print 100% infill with MAX cooling

One-

Drive Arm

Rod Spacer Sliding

Rod Spacer Upright

Motor Drive Gear

Motor Cover

Motor hook ( Print with MAX cooling)

Various

The number you need of Tank Rollers - Normally 4

Gear to match your Tank (May need a wrap or two of electrical tap for a good fit).

Timer - If Desired

All Three pieces Front Back and switch support

4 Small Sheet metal screws to hold the timer box together

A small piece of 1/8 bungee cord.

A 12 volt 1 amp power supply

Timer schematics and code as well as part lists are available off my box server here.https://app.box.com/s/0mdurfhsfmk2tij5mmiolwlv1nqgumg4

There is a separate read me in the Countdown timer Nano folder also.

It contains specific info on the Timer build.

Similar models

thingiverse

free

Jobo CPE-2 Roller block 1500 tanks by Andrewit

...e block for 2500 tanks.

print 2 of these and glue together.

you may want to drill out top holes with a 6mm drill to fit rollers.

thingiverse

free

Jobo CPA Tank Support Roller Blocks by CrazyMonkeyBen

...k supports any of the 2500 or 2800 series film or paper tanks, while the taller block supports any of the 1500 series film tanks.

thingiverse

free

JoBo 2520 developing tank support by Lichtagent

...p really helps to hinder it from wandering around).

i hope you'll have much fun and find it as useful as i do...

cheers chris

thingiverse

free

Replacement knob for Jobo Film Processor by pwmd

...ng the on/off or motor speed knobs. rotate 90 degrees in slicer so that the "top" of the knob is flat on the print bed.

thingiverse

free

Jobo CPE2 Roller Supports for 25XX/28XX and 15XX tanks

...

note that these functional equivalent models are not licensed for commercial production and are only for your own personal use.

thingiverse

free

Motorized Roller Shade Replacement Parts for 30 mm Tubes by henryarnold

...e motor:http://www.amazon.com and then search for "b01dzq43ai"

bofu is the brand of this motor and remote kit.

thingiverse

free

Poormans Jobo - Film Tank Agitator - Rock/Bullet Tumbler by michaelfowler

...was 1 amp off a old router) wall transformer - motor case has a provision for a small rubber grommet

1x - a small spst - junk box

thingiverse

free

Just an Indestructible Spool Mount (No Acronym!) by MrRobot6502

... two rollers, push the steel rods through the rollers and put a bearing on each end. drop the rollers into the slots in the base.

grabcad

free

Impact Double Ended Spigot with 1/4-20 and 3/8 Male Threads

... ended spigot with 1/4"-20 and 3/8" male threads

https://www.amazon.com/double-ended-spigot-male-threads/dp/b00phxn8rc

thingiverse

free

Wormgear DC Motor Bracket by TheTapeWaster

...com/15rpm-shaft-torque-turbine-geared/dp/b00edmih7e/ref=sr_1_1?ie=utf8&qid=1517090219&sr=8-1&keywords=worm+gear+motor

Michaelfowler

thingiverse

free

Graflex Grafmatic 45 Film holder handle by michaelfowler

...graflex grafmatic 45 film holder handle by michaelfowler

thingiverse

replacement handle for a grafmatic 45 film holder

thingiverse

free

110/16MM Development Reel (Nikor Tank) by michaelfowler

...nd

other sizes are here

minox - https://www.thingiverse.com/thing:4831142

17.5mm hit - https://www.thingiverse.com/thing:4831135

thingiverse

free

HIT (17.5mm) Development Reel (Nikor Tank) by michaelfowler

...d end

other sizes are here

110/16mm - https://www.thingiverse.com/thing:4831133

minox- https://www.thingiverse.com/thing:4831142

thingiverse

free

MINOX (9.2mm) Development Reel (Nikor Tank) by michaelfowler

...

other sizes are here

110/16mm - https://www.thingiverse.com/thing:4831133

17.5mm hit - https://www.thingiverse.com/thing:4831135

thingiverse

free

Poormans Jobo - Film Tank Agitator - Rock/Bullet Tumbler by michaelfowler

...was 1 amp off a old router) wall transformer - motor case has a provision for a small rubber grommet

1x - a small spst - junk box

Processor

3d_ocean

$4

Processor

...oly model of mine. you can always change the logo with your own. the zip includes the 3ds 2008 max file, and textures for dire...

turbosquid

$2

processors

...bosquid

royalty free 3d model processors for download as max on turbosquid: 3d models for games, architecture, videos. (1597730)

3d_export

$10

Food processor

...food processor

3dexport

a food processor that you can use in the kitchen

turbosquid

$3

Food processor

...d

royalty free 3d model food processor for download as blend on turbosquid: 3d models for games, architecture, videos. (1191492)

3ddd

$1

processor Kenwood KM080

...processor kenwood km080

3ddd

kenwood , кухонный комбайн

processor kenwood km080

turbosquid

$29

guitar processor

...model guitar processor for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1402391)

archive3d

free

Processor 3D Model

...uipment

digital sound processor sh-ge90 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$39

Food Processor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Microchip quantum processor, micro-processor with board electronic CPU

...ocessor with board electronic cpu for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1448752)

archive3d

free

Music processor 3D Model

...music processor distortion ds100 n010511 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Semi

turbosquid

$65

semi

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

Semi 3D Model

...semi 3d model

3dexport

semi

semi 3d model modelix 59728 3dexport

3d_ocean

$19

Semi Truck

...y rim seat semi truck speed truck tyre wheel

detailed 3d model of semi truck. all materials are included. model is ready for use.

design_connected

$10

Semi Lights

...semi lights

designconnected

gubi semi lights computer generated 3d model. designed by bonderup, claus.

3ddd

$1

Gubi Semi Pendant

...gubi semi pendant

3ddd

gubi

gubi semi pendant

turbosquid

$110

Tesla Semi

...bosquid

royalty free 3d model tesla semi for download as obj on turbosquid: 3d models for games, architecture, videos. (1404184)

turbosquid

$99

Tesla Semi

...bosquid

royalty free 3d model tesla semi for download as max on turbosquid: 3d models for games, architecture, videos. (1706688)

turbosquid

free

Semi Truck

...rbosquid

free 3d model semi truck for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1397814)

turbosquid

$400

Semi Truck

...

royalty free 3d model semi truck for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1503399)

turbosquid

$50

SEMI-92

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Automatic

archibase_planet

free

Automat

...automat

archibase planet

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$17

Automatic wire bending machine wire automatic bending machine

...atic wire bending machine wire automatic bending machine

3dexport

automatic wire bending machine, wire automatic bending machine

archive3d

free

Automat 3D Model

...ive3d

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$20

Design of automatic laminator

...design of automatic laminator

3dexport

design of automatic laminator

3d_export

$6

Automatic soldering machine

...automatic soldering machine

3dexport

automatic soldering machine

turbosquid

$20

automatic rifle

...id

royalty free 3d model automatic rifle for download as fbx on turbosquid: 3d models for games, architecture, videos. (1163137)

turbosquid

$9

automatic gun

...yalty free 3d model automatic gun for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1226948)

turbosquid

$5

Automatic Knife

...lty free 3d model automatic knife for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1378253)

turbosquid

$15

Automatic Stamp

...d model automatic stamp for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1569569)

turbosquid

$1

flashlight for automat

...flashlight for automat for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1314717)

Film

3d_export

$65

filming

...filming

3dexport

simple rendering of the scene file

design_connected

$16

Oka Film

...oka film

designconnected

nkuku oka film computer generated 3d model.

turbosquid

$80

Film Actress2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Film Reel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Film Projector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Film Strip

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Film clapper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Photographic Film

...n texture

- realistic highly detailed and animation ready photographic film - adjustable photographic tape (by curve) - textured

turbosquid

$4

film reel

...rbosquid

royalty free 3d model film reel for download as c4d on turbosquid: 3d models for games, architecture, videos. (1212542)

3d_export

$65

film base

...film base

3dexport

simple rendering of the scene file