Thingiverse

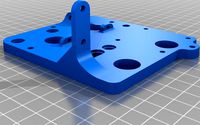

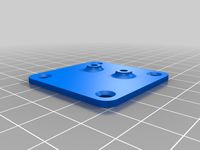

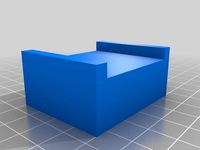

MicroSwiss Direct Drive CR10-V2 Conversion by Siganberg

by Thingiverse

Last crawled date: 3 years, 5 months ago

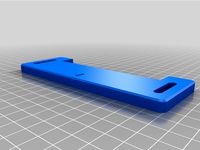

Update: Version 2 is thicker and I use PLA+ to print it to get more rigid especially on the area where BL Touch is mounted.

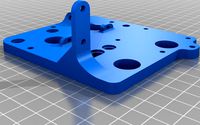

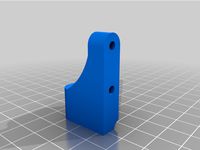

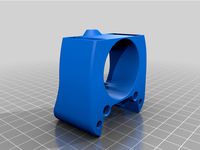

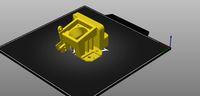

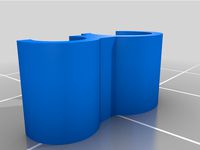

Custom Mount of MicroSwiss Direct Drive Extruder. The housing design leverage the existing front cover since it already has a nice duct air cooler and to achieve close to original looks of CR-10 V2.

Materials needed.

Printed in PETG material with .2mm resolution.

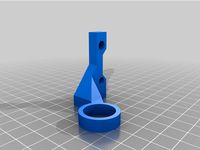

You need one M3x8mm screw to mount the backing housing to the plate.

You also need to replace the X-axis timing belt. The existing one will be shorter for the MicroSwiss mount. Here's the link for the timing belt: https://amzn.to/3fiKZpd

Instructions on how to install:

Assemble first the heater block. These include the extruder head and heater and sensor.

Alight the heater block to the new back housing. Slide the PTFE tube from the top all the way through the heater block.

Install the back housing by sliding the top side of the PTFE tube to the MicroSwiss plate, align it with the hole, and then push up.

Use the 2 screws for the heater block to mount it to the backplate.

Use an additional 1 M3x8mm screw to secure the back housing. This screw and the heating black pressing the back housing is enough to hold it in place.

Route the heater and sensor wire to the channel of the back housing.

Put the front housing and screw the 2 fans. This will join and hole the housing completely.

Mount the BL-Touch (if you have one)

Follow the rest of the MicroSwiss instruction to connect the rest of the wires.

For Creality firmware adjustment, we need to adjust the extruder step and the BL-Touch.

For me, these are the adjustment I did.

Extruder Step: 138.00

BL Touch Offset: X45.00 Y-13.00 Z-2.70 - Mostly you need to figure your own Z offset. You can use the same X and Y offset as mine.

Note: For Printing TPU or flexible material, I highly suggest not to use the Filament guide and just go straight to the direct drive extruder as PTFE create a lot of friction on flexible materials.

The command I use adjusting using octopi Terminal:

M851 Z-2.70 //-- Adjust Z BL-Touch Offset

M92 E138 //-- Adjust Extruder Step

G28 //-- Home Extruder

G29 //-- Perform BL Touch Calibration

M500 //-- Save

M501 //-- Restore/Retrieve current Settings

Custom Mount of MicroSwiss Direct Drive Extruder. The housing design leverage the existing front cover since it already has a nice duct air cooler and to achieve close to original looks of CR-10 V2.

Materials needed.

Printed in PETG material with .2mm resolution.

You need one M3x8mm screw to mount the backing housing to the plate.

You also need to replace the X-axis timing belt. The existing one will be shorter for the MicroSwiss mount. Here's the link for the timing belt: https://amzn.to/3fiKZpd

Instructions on how to install:

Assemble first the heater block. These include the extruder head and heater and sensor.

Alight the heater block to the new back housing. Slide the PTFE tube from the top all the way through the heater block.

Install the back housing by sliding the top side of the PTFE tube to the MicroSwiss plate, align it with the hole, and then push up.

Use the 2 screws for the heater block to mount it to the backplate.

Use an additional 1 M3x8mm screw to secure the back housing. This screw and the heating black pressing the back housing is enough to hold it in place.

Route the heater and sensor wire to the channel of the back housing.

Put the front housing and screw the 2 fans. This will join and hole the housing completely.

Mount the BL-Touch (if you have one)

Follow the rest of the MicroSwiss instruction to connect the rest of the wires.

For Creality firmware adjustment, we need to adjust the extruder step and the BL-Touch.

For me, these are the adjustment I did.

Extruder Step: 138.00

BL Touch Offset: X45.00 Y-13.00 Z-2.70 - Mostly you need to figure your own Z offset. You can use the same X and Y offset as mine.

Note: For Printing TPU or flexible material, I highly suggest not to use the Filament guide and just go straight to the direct drive extruder as PTFE create a lot of friction on flexible materials.

The command I use adjusting using octopi Terminal:

M851 Z-2.70 //-- Adjust Z BL-Touch Offset

M92 E138 //-- Adjust Extruder Step

G28 //-- Home Extruder

G29 //-- Perform BL Touch Calibration

M500 //-- Save

M501 //-- Restore/Retrieve current Settings

Similar models

thingiverse

free

Ender3 Direct Drive Mount with support for BL Touch and Dual Gear Extruder by furconc

... the stock plastic extruder or an upgraded metal single-gear extruder.

no extra hardware should be needed to install this part.

thingiverse

free

Dual gear extruder direct mount with BL Touch mount

... mounts together in shapr3d and printed in petg.

you will need to add spacers under the bl touch to adjust this to your hotend.

thingiverse

free

BMG Wind / BMG Aero Mounting Plate for Artillery Genius / Sidewinder X1 with BL-Touch & V6 Heater Block by bl00me

... slots of the back from square nuts to normal hexagonal nuts.

you will need three m4x12 screws and thre m4 nuts for installation.

thingiverse

free

BL Touch Holder for MicroSwiss Direct Drive Ender 3 pro by Lindegaard

...microswiss direct drive kit, offsets the blt 60 degrees, enabling you to take the standard ender shroud off without removing blt.

thingiverse

free

Sovol SV01 & SV03 Hemera Mounting plate by GreameGB

...otor current needs to be set to 940)

(filament sensor for some reason i had to set filament sensor inverting to "true")

thingiverse

free

Sovol SV01 & SV03 Hemera Mounting plate by GreameGB

...otor current needs to be set to 940)

(filament sensor for some reason i had to set filament sensor inverting to "true")

thingiverse

free

Tevo Tornado Titan extruder Direct Drive w/BL Touch by cosworth99

... direct drive w/bl touch by cosworth99

thingiverse

remixed to add a bl touch. with my tornado, z offset is about -0.8 with this.

thingiverse

free

BLTouch Mount for Ender 3 with Microswiss Direct Drive Extruder by lawrence1024

...1024

thingiverse

use this mount to connect your bltouch to the solid aluminum block that comes with the microswiss extruder kit.

thingiverse

free

EZABL Mount for CR-10 With Microswiss Direct Drive by jamiej831

...g a microswiss direct drive extruder and all metal hotend. cutout to be use with a fang mounting plate.

offsets:

x: -64.5

y: -8

thingiverse

free

E3D BigBox - Minimalist BL Touch Mount by hugofitz

...proof washers to stop it falling off! simple

probe offset from nozzle

y = 0mm

x = 38mm

z = adjustable using m1.5 washers as shims

Siganberg

thingiverse

free

Shapeoko 2 Controller Case by Siganberg

...shapeoko 2 controller case by siganberg

thingiverse

enclosure case for andruino and grblshield

thingiverse

free

Naza GPS Top Shell by Siganberg

...naza gps top shell by siganberg

thingiverse

https://www.youtube.com/watch?v=eajpznhnz7q

thingiverse

free

Tarot 16mm Boom Drill Guide by Siganberg

... boom drill guide by siganberg

thingiverse

drill guide for drilling screw hole on 16mm carbon fiber boom with tarot motor mount.

thingiverse

free

Flip32+ and PDB Standoff by Siganberg

...http://witespyquad.gostorego.com/mini-power-distribution-board.html

mounting hold distance of pdb and fc are 30mm on all corners.

thingiverse

free

PwnCNC V3 Hose Adapter for Rockler by Siganberg

...e.

i created 2 versions. one require support material during printing and the other one can be printed without support material.

thingiverse

free

Ammo can Lipo Field Charger by Siganberg

...cal ammo can

2 multistart 16000mah 4s lipo

parallel board

xt60 male and female

4s balancer port male and female

silicond wires.

thingiverse

free

Connex GroundStation Accessories by Siganberg

...

lipo holder.

holder for multistart 4s 5200mah

use m5 screw and nuts

dual hanger

hold radio tx and goggle

use m5 screw and nuts

thingiverse

free

OneFinity CNC X-Gantry Lock by Siganberg

...https://youtu.be/mzpnqy9dufo

if you found this useful, tips are always welcome. :d

https://paypal.me/fmarasigan?locale.x=en_us

thingiverse

free

5.8Ghz Helical Antenna with Dowel Template for Turning by Siganberg

...to the center pin as close as possible to the reflector but not touching/grounding it.https://www.youtube.com/watch?v=gagbcynj004

thingiverse

free

Wireless transfer file to 3D Printer by Siganberg

...mputer browser to drag and drop files that i need to print.

i just added some dummy stl so i can make it available to the public.

Microswiss

thingiverse

free

Microswiss Ender 3 by Joferval

...microswiss ender 3 by joferval

thingiverse

microswiss direct drive adapter for ender 3

thingiverse

free

Precision Piezo Orion Microswiss clamp by Moriquendi

...nted parts required to use the orion with a microswiss hotend.

i have not personally tested these parts with a microswiss hotend.

thingiverse

free

VORON printhead for MicroSwiss hotend by phil245

...3d v6 hotend but i do have the microswiss so i set to making it fit.

i hope this helps someone, if it does please post a make.

thingiverse

free

BLTouch adjuster for Ender 3 with MicroSwiss hotend

... adjuster for ender 3 with microswiss hotend

thingiverse

bl touch (creality version) adjuster for ender 3 with microswiss hotend

thingiverse

free

Microswiss X Axis Endstop for DirectDrive by ericthetazman

... by ericthetazman

thingiverse

i made this to account for new position of x endstop with microswiss direct drive on my longer lk4

thingiverse

free

microswiss dd cr10s pro by deshi

...thingiverse

modified for the ender 3 microswiss dd to fit cr10s pro.

had to raise bed 5mm set x axis off set to -35 and y to -25

thingiverse

free

CR-10S fan nozzle for microswiss hotendf by jfmvoers

...hotendf by jfmvoers

thingiverse

cooling nozzle for a creality cr10s with microswiss hotend.also fits on other creality printers.

thingiverse

free

Satsana Ender 3 v2 MicroSwiss 5010 by Annikamint

...giverse.com/thing:4787797/files

and

https://www.thingiverse.com/thing:4647053 to fit on ender 3 v2 with microswiss and 5010 fan

thingiverse

free

ender 3 v2 bltouch microswiss by Mampo112

...sured 1.4mm shorter than creality stock hotend.

use m3 screws to fit it.

thats my first post in thingiverse

sorry my poor english

thingiverse

free

CR10 / Ender2 Microswiss Fang by 2bedom

...all metall 300°c microswiss hotend.

(https://store.micro-swiss.com/products/all-metal-hotend-kit-for-cr-10)

the fang fits good ..

Cr10

3d_export

$21

Hall tree and Clothing Rack CR10

... real object. 3. lights and cameras are included in the scenes renders using vray * renders are made in 3ds max 2018 using vray 5

thingiverse

free

Clips for Ender 3, CR10, CR10S

.... maybe others, but only been tested with these.

these clips makes a tight fit, so that the cable and bowden tube stays in place.

thingiverse

free

X-axis endstop offset for cr10 cr10s Ender 3

...x-axis endstop offset for cr10 cr10s ender 3

thingiverse

x-axis endstop offset for cr10 cr10s ender 3

thingiverse

free

Filament Sensor CR10

...or cr10

thingiverse

remix of the sensor with fixation in order to face directly the extruder and ptfe tube

cr10, cr10s ender3...

thingiverse

free

Fan V4 CR10/CR10S Ender3 Versione 4 by creativesolutions-lab

...fan v4 cr10/cr10s ender3 versione 4 by creativesolutions-lab

thingiverse

fan v4 cr10/cr10s versione 4

thingiverse

free

CR10 Feet by Leighton417

...cr10 feet by leighton417

thingiverse

this is a cr10 feet for people who have short table width.

thingiverse

free

Dremel Attachment for CR10, Ender 3, Cr10s by Conn22_43

...verse

a bracket to hold a dremel onto any ender 3, cr10 bracket. i printed it in petg, but it can be made in any rigid material.

thingiverse

free

CR10S-Plus Hotend by scorpio_man30ro

...cr10s-plus hotend by scorpio_man30ro

thingiverse

cr10s-plus hotend

thingiverse

free

Leveling knob CR10 by JMJacques

...leveling knob cr10 by jmjacques

thingiverse

leveling knob cr10

thingiverse

free

Soporte Superior sensor filamento CR10 v2 - CR10 v3 by Guimir

...3 by guimir

thingiverse

soporte sensor de filamento guia superiror tipo cr10 v3 para convertir la cr10 v2 en extrusión directa.

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

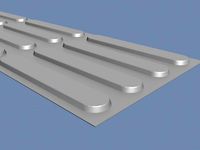

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

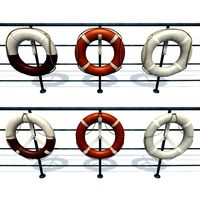

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)