Thingiverse

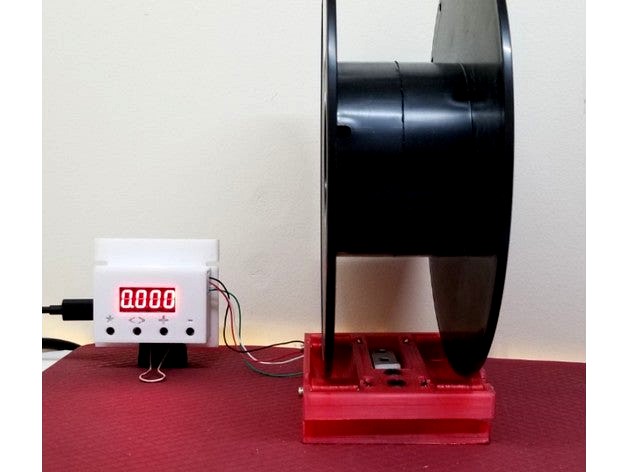

Low profile Spool holder with Scale by ksihota

by Thingiverse

Last crawled date: 2 years, 11 months ago

Updates01/06/2021

I replaced the Top Spool Holder with a slight variation that requires a little less support material when printed on end. Makes no real difference for those printing flat.

31/05/2021

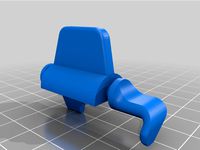

I added a small safety feature to the top holder to test out. Its two small posts that screw into the side of the upper piece. They provide some side support in case the spool tips on its side. I used a small M3 threaded rod to tie the posts at the top, through the centre hole of the spool. This should also hold the spool from rolling off the holder. Of course the holder has to be held in place so that it does not slide. You could also just insert a short piece of coat hanger wire with one end bent at a 90 degree angle. If it slips out of the other side holder, put a small bend in the other side to provide a little friction, so it won't slide out easily.

I have not tested this other than to put it on while doing my last few prints. I haven't tried it while the filament has been caught or tangled. It was just an idea that I thought I would try.

Summary

This is a component designed to work with my custom filament dryer. Its size and construction is constrained by the parameters dictated by the dryer component it must fit within.

It can be used as a stand alone spool holder with scale or as a simple spool holder without the scale. Instead of using bearings I printed low profile bushings that ride on 5mm shafts. I used M5x25 button head screws, as the head holds the shaft in place. Smaller diameter shafts could be used as long as the bushings spin freely. The width of the holder is enough to handle between 60-70mm wide spools.

The scale portion requires a couple of components that can be found on AliExpress or amazon. I purchased mine on AliExpress for about $12 CAD (module and sensor) including shipping. On amazon they will run about double the price. I was unable to locate the control module on amazon.ca (it might be available in different countries.)

I used a 2KG load cell and an electronic module that includes the HX711 amplifier. An Arduino can also be used instead of the pre-built module. If you use an Arduino you will need a HK711 module with your sensor. There is information on the web on how to hook up and program an Arduino to report the weights provided by the load sensor. I just found the pre-built module easier to set up as it does not require any extra parts and is powered by a standard micro USB adapter.

AD Module: (AliExpress)

HX711 Load Cell AD Weight Pressure Sensor AD Module with Display 24-bit Weighing Instrument Electronic Scale

Sensor: (AliExpress or amazon)

Digital Load Cell Weight Sensor 2KG

The instructions for using the electronics (AD Module) are not very clear so I made up my own and included them here as a PDF.

If you are just using the spool holder without weight sensor you will require the top piece and the bushings. If you are using the sensor (filament scale) you will also require the base.

I have included a small case for the control module as well, but it is not integrated with the spool stand as the unit is meant to fit inside my filament dryer.

The plastic base is quite smooth so you will need to apply something to the base to keep the spool holder from sliding during a print. I have mine sitting on a silicone pad but you could probably just stick on some silicone feet to help keep it in place. There are also screw holes that can be used to fasten the unit onto a larger base.

Two M5x12 and two M4x12 countersunk head screws are used to fasten the load sensor to the base and top frames. The case uses a couple of M3x12 screws.

Depending on your setup, you may notice some spring in the scale which will vary your weight display. There will also be an increase in tension on the spool during printing which will display as a higher weight on the display. As the spool releases the tension, the number on the display will decrease. At the end of a print you can release any tension in the filament to get a more accurate reading. If your bushings are not running smoothly expect this tension to be quite a bit higher than when the spool rolls easily. On my original designs my tension varied from about 50g to 200g. On my latest builds the tension remains around 10g to 25g. I suppose that if you used an Arduino you could figure out the tension threshold (point where the tension indicates the filament is caught) and program a safe pause for the printer.

I have included 2 different bushing sizes. If you find that the 18mm binds on the edges you can replace it with the 17mm.

Keep a close eye on your spool, initially, to make sure that it rolls easily. If your bushings do not roll properly or the edge of the spool is damaged, the spool may roll or get pulled off the holder. Have something in place to ensure this does not happen or protects the spool and surrounding items from damage.

I replaced the Top Spool Holder with a slight variation that requires a little less support material when printed on end. Makes no real difference for those printing flat.

31/05/2021

I added a small safety feature to the top holder to test out. Its two small posts that screw into the side of the upper piece. They provide some side support in case the spool tips on its side. I used a small M3 threaded rod to tie the posts at the top, through the centre hole of the spool. This should also hold the spool from rolling off the holder. Of course the holder has to be held in place so that it does not slide. You could also just insert a short piece of coat hanger wire with one end bent at a 90 degree angle. If it slips out of the other side holder, put a small bend in the other side to provide a little friction, so it won't slide out easily.

I have not tested this other than to put it on while doing my last few prints. I haven't tried it while the filament has been caught or tangled. It was just an idea that I thought I would try.

Summary

This is a component designed to work with my custom filament dryer. Its size and construction is constrained by the parameters dictated by the dryer component it must fit within.

It can be used as a stand alone spool holder with scale or as a simple spool holder without the scale. Instead of using bearings I printed low profile bushings that ride on 5mm shafts. I used M5x25 button head screws, as the head holds the shaft in place. Smaller diameter shafts could be used as long as the bushings spin freely. The width of the holder is enough to handle between 60-70mm wide spools.

The scale portion requires a couple of components that can be found on AliExpress or amazon. I purchased mine on AliExpress for about $12 CAD (module and sensor) including shipping. On amazon they will run about double the price. I was unable to locate the control module on amazon.ca (it might be available in different countries.)

I used a 2KG load cell and an electronic module that includes the HX711 amplifier. An Arduino can also be used instead of the pre-built module. If you use an Arduino you will need a HK711 module with your sensor. There is information on the web on how to hook up and program an Arduino to report the weights provided by the load sensor. I just found the pre-built module easier to set up as it does not require any extra parts and is powered by a standard micro USB adapter.

AD Module: (AliExpress)

HX711 Load Cell AD Weight Pressure Sensor AD Module with Display 24-bit Weighing Instrument Electronic Scale

Sensor: (AliExpress or amazon)

Digital Load Cell Weight Sensor 2KG

The instructions for using the electronics (AD Module) are not very clear so I made up my own and included them here as a PDF.

If you are just using the spool holder without weight sensor you will require the top piece and the bushings. If you are using the sensor (filament scale) you will also require the base.

I have included a small case for the control module as well, but it is not integrated with the spool stand as the unit is meant to fit inside my filament dryer.

The plastic base is quite smooth so you will need to apply something to the base to keep the spool holder from sliding during a print. I have mine sitting on a silicone pad but you could probably just stick on some silicone feet to help keep it in place. There are also screw holes that can be used to fasten the unit onto a larger base.

Two M5x12 and two M4x12 countersunk head screws are used to fasten the load sensor to the base and top frames. The case uses a couple of M3x12 screws.

Depending on your setup, you may notice some spring in the scale which will vary your weight display. There will also be an increase in tension on the spool during printing which will display as a higher weight on the display. As the spool releases the tension, the number on the display will decrease. At the end of a print you can release any tension in the filament to get a more accurate reading. If your bushings are not running smoothly expect this tension to be quite a bit higher than when the spool rolls easily. On my original designs my tension varied from about 50g to 200g. On my latest builds the tension remains around 10g to 25g. I suppose that if you used an Arduino you could figure out the tension threshold (point where the tension indicates the filament is caught) and program a safe pause for the printer.

I have included 2 different bushing sizes. If you find that the 18mm binds on the edges you can replace it with the 17mm.

Keep a close eye on your spool, initially, to make sure that it rolls easily. If your bushings do not roll properly or the edge of the spool is damaged, the spool may roll or get pulled off the holder. Have something in place to ensure this does not happen or protects the spool and surrounding items from damage.

Similar models

thingiverse

free

Filament Weight measure using HX711 Load Cell with Spool holder by ADMC

...ink to load cell weight sensor hx711 module:https://www.aliexpress.com/item/32949395083.html?spm=a2g0s.9042311.0.0.27424c4d4utje7

thingiverse

free

Filament Spool Scale and Usage Meter by sb43201

...lcd display with i2c x1

12x12 push button micro switch with cap x2

602zz bearing x4

m4x16 machine screw x2

m5x16 machine screw x2

thingiverse

free

Weight display based on Arduino Uno and LCD shield by egil

...and add as library in the arduino ide.

i have included a very simple piece of arduino code to implement a basic weight display.

grabcad

free

Degraw 40 Kg Tension Load Cell

...ino scale - everything needed for accurate force measurement

https://www.amazon.ae/degraw-tension-load-hx711-combo/dp/b07f922rzc

thingiverse

free

Filament Holder W/Scale by dieki

...l, changing the reading.

nonetheless in my experiments i've found it to be accurate +/- 40g, which is more than good enough.

thingiverse

free

Anycubic i3 Mega Filament Sensor holder by BrezZZz

...ent sensor for the original sensor. if you want to use this, the spool holder needs to be sit above the screws in the metalframe.

thingiverse

free

Ender3 side spool support but with with weight sensor (load cell)

...n also input this url in the plugin manager to install it: https://github.com/dieki-n/octoprint-filament-scale/archive/master.zip

thingiverse

free

Load Cell Spool Holder by Knickohr

...we can calculate the lenght of the remaining filament on the spool.

https://youtu.be/juuyldff6k8

update :

added an filament guide

thingiverse

free

3D Printed Filament Spool by Marcielo

...ent holder in the end and start of the spool, you can also use zip tie.

the two parts screw together, no need for glue or screws.

thingiverse

free

Filament Scale by mcgeehd

... weight

library dependencies (for platformio) are:

hx711 by bogde

esp8266_ssd1306 by daniel eichhorn

onebutton by matthias hertel

Ksihota

thingiverse

free

Predator Extruder Feed Sleeve by ksihota

... need to be sanded slightly to fit properly

if you use it, leave me a comment to indicate if it works or if it needs adjustments.

thingiverse

free

Operation Game Pieces by ksihota

...y as well as a single stl with all the parts.

i am not sure what the names are really supposed to be so i just named them myself.

thingiverse

free

1995 Volvo 850 seatbelt release button by ksihota

...riginal by filling in the centre underside. this makes for a stronger part and makes the print cleaner when printing on its edge.

thingiverse

free

Ryobi One+ Hybrid Leaf blower switch by ksihota

... canada. it is a one+ model. i have included a full picture of it for reference. the switch is a side toggle, not a slide switch.

thingiverse

free

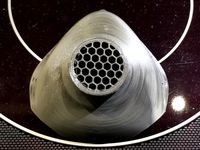

Simple Face Shield by ksihota

... for intended use.

if you do try and like the design but find the size is not right let me know and i can resize it if necessary.

thingiverse

free

Filastruder Electronics Case by ksihota

...f the filastruder case where the switches and temp controller used to reside.

let me know if you find any issues with the design.

thingiverse

free

Unusual filter masks by ksihota

...thing down the nose. maybe an old sock?

obviously the filter aspect would require some redesigning, but it can be done if needed.

thingiverse

free

Hard Shell Filter Mask by ksihota

...hile printing you may have better success. of course by printing in tpu the print would also take quite a bit longer than in pla.

thingiverse

free

Ryobi Backpack Leaf Blower Nozzles by ksihota

...as a little wider and not quite as high.

i have not yet tested either nozzle ends yet. i will add comments about their use later.

thingiverse

free

MPMD E3D V6 Effector by ksihota

...base

rod connectors:

3 60mm m3 threaded rods (nuts and washers)

or

6 30mm m3 nuts bolts and washers

assorted wires and connectors

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Profile

3ddd

$1

Profile

... лофт , профиль , свип

описание ниже

3d_export

$5

profile anchor

...profile anchor

3dexport

profile anchor

3d_export

$5

profile fastener

...profile fastener

3dexport

profile fastener

3ddd

$1

Profil Doors

...

3ddd

profil doors , дверь

двери и наличник profil doors модели 7х и 15х, цвет капучино.

3ddd

$1

Profile chair

...rofile

http://www.casefurniture.co.uk/contemporary-furniture-products/contemporary-chairs-benches-stools/profile-chair/

3ddd

$1

Profil Doors

...dd

двери , profildoors

дверь profil doors

серия - vg

модель - 4vg

цвет - чёрный матовый

3d_export

$5

profile hand wheel

...profile hand wheel

3dexport

profile hand wheel

3d_export

$5

profile rotation handle

...profile rotation handle

3dexport

profile rotation handle

3d_ocean

$6

Low Profile Radiator

...low profile radiator

3docean

heat heater hot pipe radiator temperature thermostat warm

a low profile version of the radiator

3d_export

$10

Aluminum profile 3D Model

...aluminum profile 3d model

3dexport

aluminum profile window sample corner

aluminum profile 3d model 3dstocker 27361 3dexport

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Scale

turbosquid

$20

Weight scale or Bathroom Scale

...ght scale or bathroom scale for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1664576)

turbosquid

$19

Scale

...e

turbosquid

royalty free 3d model scale for download as fbx on turbosquid: 3d models for games, architecture, videos. (1411722)

turbosquid

$5

Scales

...s

turbosquid

royalty free 3d model scales for download as ma on turbosquid: 3d models for games, architecture, videos. (1393439)

turbosquid

$40

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$17

Scales

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

of scales

...s have a flat point of support. the samples are rendered in the standard cinema 4d renderer. enjoy your use and creative success.

3d_export

$5

scale knob

...scale knob

3dexport

scale knob

3d_export

$20

cartoon weight scale or bathroom scale

...cartoon weight scale or bathroom scale

3dexport

texture size:512px number of texture:1 texture format: png