Thingiverse

Low Profile Chuck for Carving Corzetti Stamp Blanks by icenyne

by Thingiverse

Last crawled date: 3 years ago

Having been holed up for much of 2020, I ended up making homemade pasta of various types. One interesting and somewhat unknown form is corzetti, embossed coins of pasta originating in Liguria in the middle ages. (see https://en.wikipedia.org/wiki/Corzetti) The stamps are carved from wooden dowels about 2 inches in diameter.

Commercial corzetti stamp sets are not inexpensive, particularly ones carved with custom designs. The appeal of making personalized and themed corzetti for friends and family was too great to settle for the few (even custom) designs available, so I had to make my own stamps, which easily justified the purchase of a 3018 CNC machine. The goal was to make Christmas gifts for family and friends by the end of year... (The goal was reached, I made about a dozen sets, but this thing is about continuing to make them and make them more easily.)

I started inexpensively with 2" diameter disks from Amazon carved on the CNC. These worked great but they lack the integrated cutter of the traditional corzetti stamps and a nice handle. So, I needed to use 2" diameter dowel for starting blanks. (This prompted getting the Shopsmith ER10 I'd picked up 4 years ago running, but that's another whole story...)

The 3018 CNC only has 40mm of vertical travel. The corzetti stamp pieces end up being about 2-3 inches tall, so how do you face the ends and then carve them in a travel space that small? Simply: you change out the bed on the CNC for a wood one (using the CNC itself to cut the bearing and nut holes, of course). The new bed has a hole to accommodate the dowel and a 3D printed jig to hold it in place while faced and carved.

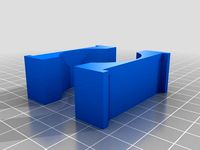

Unfortunately, variations in blank diameter require re-centering the bit nearly every time and the jigs don't hold the blank's square to the CNC bit very well, even after 4 iterations of jigs (pic of latest pip vise inspired clamp is attached)...

Having seen self-centering chucks and collets on Thingiverse, I really wanted something for holding the corzetti blanks. Collets were out because my lathe skills yield too much variation in diameter; PLA is not all that flexible. So, it had to be a chuck, hence this remix of these two things:https://www.thingiverse.com/thing:624625 for generating the scrollhttps://www.thingiverse.com/thing:2670620 for jaws and jaw guides

Finally got a working faceplate.

Still a work in progress but I have a working chuck, so work on this has stopped.

STL files came from: https://www.tinkercad.com/things/3Gy7omUSfS6

Update 23/02//2021: After trying to carve some disks, it became apparent that the jaws were too short: they were bowing up in the center and would not hold the 6mm thick wood disks I have very well. I lengthened the jaws and it seems to hold much more firmly since all the scroll teeth are engaged and the jaws occupy the full length of the guides in the faceplate. It's still a pain to hold the disk while tightening the chuck, so the jaws may be updated later...

Commercial corzetti stamp sets are not inexpensive, particularly ones carved with custom designs. The appeal of making personalized and themed corzetti for friends and family was too great to settle for the few (even custom) designs available, so I had to make my own stamps, which easily justified the purchase of a 3018 CNC machine. The goal was to make Christmas gifts for family and friends by the end of year... (The goal was reached, I made about a dozen sets, but this thing is about continuing to make them and make them more easily.)

I started inexpensively with 2" diameter disks from Amazon carved on the CNC. These worked great but they lack the integrated cutter of the traditional corzetti stamps and a nice handle. So, I needed to use 2" diameter dowel for starting blanks. (This prompted getting the Shopsmith ER10 I'd picked up 4 years ago running, but that's another whole story...)

The 3018 CNC only has 40mm of vertical travel. The corzetti stamp pieces end up being about 2-3 inches tall, so how do you face the ends and then carve them in a travel space that small? Simply: you change out the bed on the CNC for a wood one (using the CNC itself to cut the bearing and nut holes, of course). The new bed has a hole to accommodate the dowel and a 3D printed jig to hold it in place while faced and carved.

Unfortunately, variations in blank diameter require re-centering the bit nearly every time and the jigs don't hold the blank's square to the CNC bit very well, even after 4 iterations of jigs (pic of latest pip vise inspired clamp is attached)...

Having seen self-centering chucks and collets on Thingiverse, I really wanted something for holding the corzetti blanks. Collets were out because my lathe skills yield too much variation in diameter; PLA is not all that flexible. So, it had to be a chuck, hence this remix of these two things:https://www.thingiverse.com/thing:624625 for generating the scrollhttps://www.thingiverse.com/thing:2670620 for jaws and jaw guides

Finally got a working faceplate.

Still a work in progress but I have a working chuck, so work on this has stopped.

STL files came from: https://www.tinkercad.com/things/3Gy7omUSfS6

Update 23/02//2021: After trying to carve some disks, it became apparent that the jaws were too short: they were bowing up in the center and would not hold the 6mm thick wood disks I have very well. I lengthened the jaws and it seems to hold much more firmly since all the scroll teeth are engaged and the jaws occupy the full length of the guides in the faceplate. It's still a pain to hold the disk while tightening the chuck, so the jaws may be updated later...

Similar models

thingiverse

free

lathe faceplate spacer by jn1

...errors,

i superglue the magnets into the pockets. one is always press fit, the other two are always loose enough to require glue.

grabcad

free

CNC ADAPTERS and COLLET CHUCK

...cnc adapters and collet chuck

grabcad

cnc adapters and collet chuck

grabcad

free

360 degree ER32 Indexer (1 degree Increments)

...lar positioning part (especially the engraved text and graticules) are best machined with a cnc mill or laser. drawings included.

thingiverse

free

Nut Cap for 3 Jaw Chuck by malakid

...or precision work. i made this nut cap for bmanx2000's 3 jaw drill chuck 1/4 inch.

https://www.thingiverse.com/thing:2625085

thingiverse

free

jaw faceplates for holding round things in a Sherline CNC vise by ecloud

...ameter as necessary, depending on what you want to hold in the vise. it's for milling the flat side of a cylindrical object.

thingiverse

free

Lathe 3-Jaw Chuck Spacer for Short Stock - Spider by kencaid

...with a part against it.

this shape is rather bizarre when viewed out of context but it works quite well on a 6" 3-jaw chuck.

grabcad

free

CNC chuck jaw

...cnc chuck jaw

grabcad

cnc chuck jaw

grabcad

free

K02-63 4 Jaw Self Centering Chuck

...jaw self centering chuck

grabcad

i used this inexpensive 63mm od chuck to make a tap holder for my bt30 spindle milling machine.

grabcad

free

3 jaw chuck

...ck model. diameter and height is correct. pitch on jaws is correct.

i am an amateur doing these drawings to test ideas for work.

thingiverse

free

miniVICE X-Series - Modular miniature holder, painting and hobby system by chito

...aws top regular

combo collet v2:

25mm - 40mm and 45mm - 60mm

65mm rubberband

chuck jaws top regular

would love feedback on these

Corzetti

thingiverse

free

Corzetti Stamp by chumsize

...it of olive oil before use to make removal of pasta from stamp easier.

11jul14 - updated with cleaner shape / larger bottom stamp

thingiverse

free

Corzetti Press by yoyorks

...ess by yoyorks

thingiverse

updated ajtripoli's design to remove the logo so people can add their custom logo.

scale to 2540%

Chuck

design_connected

$29

Chuck Sofa

...chuck sofa

designconnected

one kings lane chuck sofa computer generated 3d model.

3d_export

$9

chuck automatic quartering dividing chuck 11 specifications in total

...ring dividing chuck 11 specifications in total

3dexport

[chuck] automatic quartering dividing chuck (11 specifications in total)

3d_export

$5

Lathe chuck

...lathe chuck

3dexport

[list]

turbosquid

$39

CHUCK KEY

...

royalty free 3d model chuck key for download as ige and obj on turbosquid: 3d models for games, architecture, videos. (1425798)

turbosquid

$9

Lathe Chuck

...model lathe chuck for download as 3ds, obj, fbx, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1363582)

3d_export

$35

Chuck key 3D Model

...ort

chuck key drill bit electric cable tool power powerdrill construction toolkit

chuck key 3d model harrynicholas 15496 3dexport

turbosquid

$9

Covered Chuck Wagon

...royalty free 3d model covered chuck wagon for download as fbx on turbosquid: 3d models for games, architecture, videos. (1555993)

turbosquid

$15

Drill Chuck Key

...odel drill chuck key for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1649253)

3d_export

$100

double angle collet chuck

... collet chuck which we can fit on cnc,vmc or any other machine where we need to clamp precisely part clamp and machine or messure

turbosquid

$100

Lumion Skills by Chuck - Yellow Kitchen

...l lumion skills by chuck - yellow kitchen for download as skp on turbosquid: 3d models for games, architecture, videos. (1345751)

Stamp

3d_export

$8

stamp

...p with documents. made for a newspaper illustration. made in blender 2.92 and rendered in cycles sent as .blend .obj stl and .jpg

turbosquid

$6

stamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Stamp Wood

...bosquid

royalty free 3d model stamp wood for download as c4d on turbosquid: 3d models for games, architecture, videos. (1407102)

turbosquid

$2

rubber stamp

...alty free 3d model rubber stamp for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1653332)

turbosquid

$2

rubber stamp

...alty free 3d model rubber stamp for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1653226)

3d_export

$10

stamping process

...stamping process

3dexport

3d_export

$7

Stamp 3D Model

...stamp 3d model

3dexport

stamp

stamp 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl john.ru 104009 3dexport

turbosquid

$13

Rubber Stamp

... free 3d model rubber stamp for download as jpg, psd, and max on turbosquid: 3d models for games, architecture, videos. (1401488)

turbosquid

$15

Automatic Stamp

...d model automatic stamp for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1569569)

turbosquid

$5

Rubber stamp

... 3d model rubber stamp for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1379470)

Blanks

3d_ocean

$5

Blank Keyboard

...yboard

3docean

3d blank computer computing gaming keyboard office

3d blank keyboard for usage in your scenes with 5709 poly count

3ddd

$1

Камин Max Blank

...мин max blank

3ddd

max blank , камин

камин от компании max blank. текстуры присутствуют.

3d_export

$5

Blank for creating a robot

...blank for creating a robot

3dexport

a blank for creating a female robot, or an anthropomorphic creature.

turbosquid

$35

Blank Board

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

blank mug

...d model blank mug for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1535630)

turbosquid

$1

Blank Scroll

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Blank Book

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Blank dumbbell 3D Model

...blank dumbbell 3d model

3dexport

blank dumbbell sport fitnes

blank dumbbell 3d model loadname 87617 3dexport

turbosquid

$25

Step ladder blank

...y free 3d model step ladder blank for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1569325)

turbosquid

$29

Blank Golf Ball

...3d model blank golf ball for download as ma, obj, fbx, and ma on turbosquid: 3d models for games, architecture, videos. (1407306)

Carving

turbosquid

$5

Carving

...turbosquid

royalty free 3d model carving for download as max on turbosquid: 3d models for games, architecture, videos. (1538595)

3d_export

free

carved chair

...carved chair

3dexport

carved chair with colored gems

turbosquid

$19

Carving

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Carving 3D Model

...g 3d model

archive3d

carving fretwork

carving n280707 - 3d model for interior 3d visualization.

3d_export

$10

Carveli flip

...carveli flip

3dexport

archive3d

free

Carving 3D Model

...

wood engraving carving

carving n070508 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

Carved Wreath

...h

turbosquid

free 3d model carved wreath for download as stl on turbosquid: 3d models for games, architecture, videos. (1335068)

archive3d

free

Carving 3D Model

...ure picturesque element

carving n200608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

Carved Table

...osquid

royalty free 3d model carved table for download as ma on turbosquid: 3d models for games, architecture, videos. (1621203)

turbosquid

$3

Decor carving

...quid

royalty free 3d model decor carving for download as stl on turbosquid: 3d models for games, architecture, videos. (1214819)

Profile

3ddd

$1

Profile

... лофт , профиль , свип

описание ниже

3d_export

$5

profile anchor

...profile anchor

3dexport

profile anchor

3d_export

$5

profile fastener

...profile fastener

3dexport

profile fastener

3ddd

$1

Profil Doors

...

3ddd

profil doors , дверь

двери и наличник profil doors модели 7х и 15х, цвет капучино.

3ddd

$1

Profile chair

...rofile

http://www.casefurniture.co.uk/contemporary-furniture-products/contemporary-chairs-benches-stools/profile-chair/

3ddd

$1

Profil Doors

...dd

двери , profildoors

дверь profil doors

серия - vg

модель - 4vg

цвет - чёрный матовый

3d_export

$5

profile hand wheel

...profile hand wheel

3dexport

profile hand wheel

3d_export

$5

profile rotation handle

...profile rotation handle

3dexport

profile rotation handle

3d_ocean

$6

Low Profile Radiator

...low profile radiator

3docean

heat heater hot pipe radiator temperature thermostat warm

a low profile version of the radiator

3d_export

$10

Aluminum profile 3D Model

...aluminum profile 3d model

3dexport

aluminum profile window sample corner

aluminum profile 3d model 3dstocker 27361 3dexport