GrabCAD

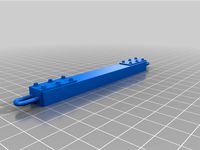

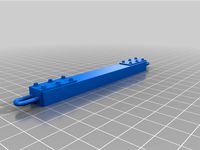

LGB Dual Uncoupler Ramp

by GrabCAD

Last crawled date: 10 months ago

This is a set of files which I have designed to replicate the LGB style uncoupler. This allows twin-hook stock to be uncoupled without the need for a permanent uncoupler (these have always caused issues).

You will need to replace the fishplates with rail camps - I used TL45 clamps as they are shorter than Massoth. This allows the sleepers to be slid together, bringing the two ramps closer, producing an uncoupling 'sweet spot'.

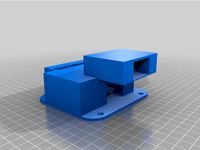

The kit includes a crank rod set to allow one drive motor to actuate both ramps, this will require the 'Uncoupler Ramp Actuator Driver' which has connections both ends.

This can be used with an existing LGB uncoupler (LGB 10560) or the whole set can be used for both ramps - the print files include 'Uncoupler Ramp Body LGB' which is a copy of the LGP body, and Uncoupler Ramp Body which has been shortened by 8mm to bring the ramps closer together.

Print settings used:

ABS (Can be PLA if used indoors)

0.06mm layer height (to make the ramps nice and smooth - can be 0.1mm)

100% Infil

Supports - some are hard to remove, espeicially inside the Ramp.

I used 'breakaway' support which seemed to work best.

All parts are (should be) oriented the correct way for printing.

Body - print flat side down, with supports. The support material can be a pain to get out of the small pockets on the underside.

Rear Mount / Front Mount / Actuators / Link arms / Arm mount / Link Rods - flat side down.

Ramp - Ideally this would be printed with the hinge pins at the top. However this leaves a rough surface on the top slide of the ramp - can be removed with much sanding, not to my taste.

I have printed this with the hinge pins down, with support. Getting support out of the inside is a PITA. Watch out for the hinge pins.

Inner - print with centre hole facing up. Filing of the actuator pin is required. You will also need to file the end stop nearest the open hinge - this is to set the ramp angle. This has been left it 0.1mm too big to allow filing to fit. If not filed and set properly, the ramp will not sit fully down.

Big thanks to phils2um for the original idea and R&D work.

You will need to replace the fishplates with rail camps - I used TL45 clamps as they are shorter than Massoth. This allows the sleepers to be slid together, bringing the two ramps closer, producing an uncoupling 'sweet spot'.

The kit includes a crank rod set to allow one drive motor to actuate both ramps, this will require the 'Uncoupler Ramp Actuator Driver' which has connections both ends.

This can be used with an existing LGB uncoupler (LGB 10560) or the whole set can be used for both ramps - the print files include 'Uncoupler Ramp Body LGB' which is a copy of the LGP body, and Uncoupler Ramp Body which has been shortened by 8mm to bring the ramps closer together.

Print settings used:

ABS (Can be PLA if used indoors)

0.06mm layer height (to make the ramps nice and smooth - can be 0.1mm)

100% Infil

Supports - some are hard to remove, espeicially inside the Ramp.

I used 'breakaway' support which seemed to work best.

All parts are (should be) oriented the correct way for printing.

Body - print flat side down, with supports. The support material can be a pain to get out of the small pockets on the underside.

Rear Mount / Front Mount / Actuators / Link arms / Arm mount / Link Rods - flat side down.

Ramp - Ideally this would be printed with the hinge pins at the top. However this leaves a rough surface on the top slide of the ramp - can be removed with much sanding, not to my taste.

I have printed this with the hinge pins down, with support. Getting support out of the inside is a PITA. Watch out for the hinge pins.

Inner - print with centre hole facing up. Filing of the actuator pin is required. You will also need to file the end stop nearest the open hinge - this is to set the ramp angle. This has been left it 0.1mm too big to allow filing to fit. If not filed and set properly, the ramp will not sit fully down.

Big thanks to phils2um for the original idea and R&D work.

Similar models

thingiverse

free

Pachinko TypeB Ball Loader Actuator

...nues to work.

if i need a replacement, i'll print it in abs / asa

the picture is of the printed piece mounted in the machine.

thingiverse

free

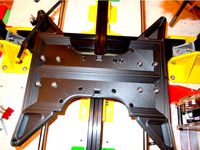

FLSUN CUBE XCarriage Upgrades Interchangeable Hotend Mounts

... on it's back. print the hotend mounts upside down as well.

added z axis support for 608 bearings at the very end of the rod.

thingiverse

free

Hinge Pin for ScreenBar DIY

...

however, low printing temperatures can degrade the layer's adhesion and easily break.

you can also lie down and use support.

thingiverse

free

Customizable Spool Drawer with Printed Pin by nemebean

...be mounted off-center let me use the drawer anyway), and the particular drawer i printed for a spool of ttyt3d silk pla filament.

thingiverse

free

Handy sleeve adapter for stock sleeve by bafangit

... full cylinder one-piece version, please download ethanfel's excellent design here: https://www.thingiverse.com/thing:4852035

thingiverse

free

Kuppelstange LGB by lokservice

...kuppelstange lgb by lokservice

thingiverse

coupling rod of lgb locomotives with pin link couplers

thingiverse

free

Tevo Tarantula 8mm Rod Y-Axis and Printed Bed Support by evil_k

....thingiverse.com/thing:1580899

other brackets on bottom of tevo tarantula by thingirob: https://www.thingiverse.com/thing:1457449

thingiverse

free

OpenRC F1 Stackable Steering Pin by Cackedy

...th.

sept 21, 2018

i added a 2017 version of the steering pin. i haven't tested it yet. but i assume it should work just fine.

thingiverse

free

PET Bottle Opener (both sides) by asimomagic

...way to use it.

-support is already included, so you can print with no support.

[post printing]

-remove the support by pushing it.

thingiverse

free

Pegboard snap-fit pin

...rease strength and ease of printing, but there is an option to print straight up and down as well (which would require supports).

Uncoupler

thingiverse

free

Uncoupling Wand (Handentkuppler) by wassi

...uncoupling wand (handentkuppler) by wassi

thingiverse

simple uncoupling wand tool for n - h0 scale

thingiverse

free

Hornby OO Uncoupler by Davehaslanded

...aslanded

thingiverse

a simple uncoupler for standard hornby track. simply print as is. only needs 0.4mm shell and sparce infill.

thingiverse

free

Mount for servo based magnetic uncoupler by FenEndPit

...h bore and allows the plunger part to slide easily. a small 6mm diameter rare-earth magnet is attached to the top of the plunger.

thingiverse

free

G-scale Train Knuckle Coupler

...ector sits over the coupler and prevents uncoupling. it is flexible enough to not affect the swiveling movement of the couplers.

thingiverse

free

Ultimaker sound damping feet by Berend

...er sound damping feet by berend

thingiverse

another experiment to silence my ultimaker by uncouple it from it's environment.

thingiverse

free

Replacement Coupler for Playmobil Trains by af12689

...pport.

the third photo is a comparison between the printed part and the original playmobil coupler (which has a worn out spring).

thingiverse

free

Throttle Holder, Throttle Pocket for Model Railroad Controls by kharstin

...iphone 7. it also has pockets for train waybills, uncoupler tools, pencils and...

thingiverse

free

Modular Chain link by Phanto

... size and length. it is designed so it can be easily coupled and uncoupled by hand with negligible risk of accidental decoupling.

thingiverse

free

slider for 5th voice on Hohner Morino VS

...rdions as well, but the position of the lever may need to be changed then.

besides the stl files i also included sketchup source.

thingiverse

free

Ruger Mini-14 5 Round Magazine Coupler by macobaco

...back of the coupler and press the metal tab on the magazine floor plate then slide out the coupler.

don't shoot your eye out.

Lgb

turbosquid

$10

LGB Paveway II

...uid

royalty free 3d model lgb paveway ii for download as fbx on turbosquid: 3d models for games, architecture, videos. (1655466)

3ddd

$1

GRAMERCY HOME - CAPRICE TABLE LAMP TL051-1-LGB

...lgb

3ddd

gramercy home

gramercy home

caprice table lamp

tl051-1-lgb

ширина 51 см

глубина 28 см

высота 98 см

www.gramercy-home.ru

cg_studio

$9

GBU/16 Laser Guided Bomb3d model

...laser guided bomb3d model cgstudio gbu/16 laser guided bomb lgb war missile jet .3ds .ma .lwo .max .obj .xsi...

3ddd

$1

Ceramica Cielo Le Giare Vaso sospeso

...sospeso 3ds max 2012+fbx+obj+pdf ceramica cielohttp://www.ceramicacielo.com/ vaso sospesohttp://www.ceramicacielo.it/it/sanitari/vaso-sospeso-lgvs/ bidet sospesohttp://www.ceramicacielo.it/it/sanitari/bidet-sospeso-lgb/ ...

thingiverse

free

LGB 63193 by 2009marius15

...lgb 63193 by 2009marius15

thingiverse

the rebuild of the lgb 63193

thingiverse

free

Kuppelstange LGB by lokservice

...kuppelstange lgb by lokservice

thingiverse

coupling rod of lgb locomotives with pin link couplers

thingiverse

free

Reflektor LGB Lampe by lokservice

...reflektor lgb lampe by lokservice

thingiverse

reflektor für lgb lampe mit öffnung nach unten

thingiverse

free

LGB RhB Krokodil Toolbox by 5p0o

...lgb rhb krokodil toolbox by 5p0o

thingiverse

spare toolbox for a lgb rhb krokodil

thingiverse

free

LGB Wheel Block/Stop by 8thscale

...lgb wheel block/stop by 8thscale

thingiverse

this fits lgb rail, similar to #5025.

thingiverse

free

Re-railer for LGB track by 5p0o

...re-railer for lgb track by 5p0o

thingiverse

re-railer for lgb track. to be placed on a straight track and screwed on.

Ramp

turbosquid

$3

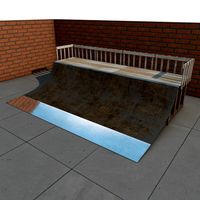

Kicker Ramp - Skate Ramp

...ramp - skate ramp for download as 3ds, obj, c4d, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1153575)

turbosquid

$2

Ramp

...squid

royalty free 3d model ramp for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1494204)

turbosquid

$5

ramp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Ramp 3D Model

...ramp 3d model

3dexport

ramp jump carjump carramp car

ramp 3d model ryisnelly100 83186 3dexport

turbosquid

$10

Ramp and Barrels

...d

royalty free 3d model ramp and barrels for download as fbx on turbosquid: 3d models for games, architecture, videos. (1263040)

turbosquid

$19

Skate Ramp

...ty free 3d model skate ramp for download as dxf, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1187602)

turbosquid

$19

Skate Ramp

...ee 3d model skate ramp for download as dxf, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1187673)

turbosquid

$80

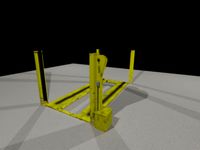

Hydralic Ramps

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$45

ramp door_center

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Ramp.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.