Thingiverse

Lewihe Play 3D bowden layer fan blower by magonegro

by Thingiverse

Last crawled date: 3 years ago

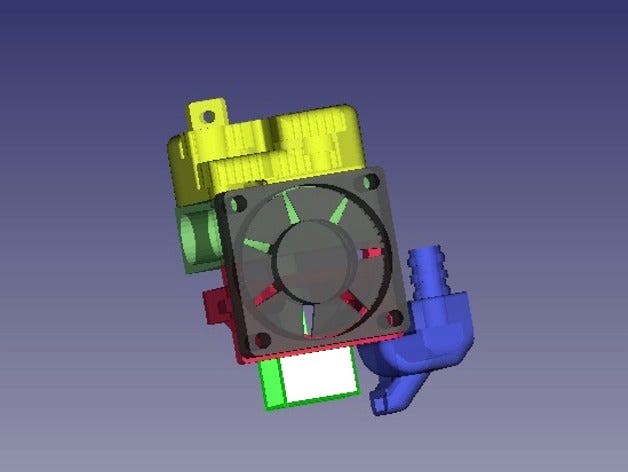

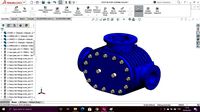

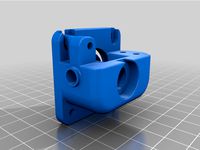

Pics shows how this part fits in the whole design (blue part). The part that fits the LM6UU bearings is the Play3D original part. Other parts conform my custom design for the Play3D's X-Carriage.http://www.thingiverse.com/thing:1547122http://www.thingiverse.com/thing:1527259http://www.thingiverse.com/thing:1639559

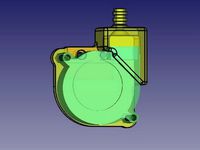

and also used this awesome 40mm fan model for reference: http://www.thingiverse.com/thing:32246

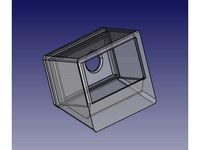

My previous design of a layer fan for this extremely small hotend used a 30mm fan but this one is much better. I know this little fans very well, and as I thought it started to have troubles after just a month of printing (24/7). I mean it started to be noisy, and thus, prone to fail soon. I have thinking about this for two weeks and I have decided to bring in a new solution. Well, I can't put in that little room a larger fan, but I can use a cheap vinyl or silicone tube from anywhere out of the printer where I have free space, using this tube as an air conduct I can manage to use a durable and powerful 50mm blower instead of a #&$#%# little fan, and have lots of air pressure when needed. Besides this, the air coming from the exterior part of the printer is cooler and works better. This little part of just 44x24mm will do the job. Just use a ~8mm inner diameter tube, attach it to the part, fix it with some ties and job done. At first I thought about using a PTFE tube and pneumatic fittings but that was an expensive solution and less flexible. Use your own solution to attach the blower where you want, or use the one included. Print the part in ABS with buildplate support only, don't use complete support as it will completely clog the air flow, and you won't be able to remove the inner support, remember this is a hollow part. Bridging should be ok. V2 new version recommended.

TODO: Nothing. Performs as expected.

UPDATE (29-JUN-2016):V2 enhanced M3 bolt support. Reinforced latch. I ended breaking the bolt support when tightening. Shortened back 4mm the bolt support length, 30mm M3 bolts weren't enough. Some minor design changes. This a final version (if that exists). Previous versions will not be maintained.

UPDATE (28-JUN-2016): V2 added. Increased screw length to use a 30mm M3 regular screw. Added a latch to avoid pitching, this also helps ABS printing acting as as extra cooling pillar. Removed unnecessary material that could interfere with bed clips. Rounded and refined design. Increased air output hole to enhance airflow. Added a small duct to aim better the airflow. Part still requires buildplate support ONLY, and only due to the tube connector, any other overhang angle is 45º or more. Will put pics when I have the time. First version works fine but some improvements should be done. You don't need to update your printed part if it works well for your setup, but if you do you won't regret. Anyway no more updates expected for this part beyond this V2.

UPDATE (22-JUN-2016): Updated model and STL for a inner ~8mm tube, The only one I could find nearby as I ended all my 6mm tube stocks. Lengthened a bit the part to accomodate the 8mm inner / 10mm outer diameter tube. Anyway performing even better than previous model as the airflow is enhanced by the greater diameter of the tube.

and also used this awesome 40mm fan model for reference: http://www.thingiverse.com/thing:32246

My previous design of a layer fan for this extremely small hotend used a 30mm fan but this one is much better. I know this little fans very well, and as I thought it started to have troubles after just a month of printing (24/7). I mean it started to be noisy, and thus, prone to fail soon. I have thinking about this for two weeks and I have decided to bring in a new solution. Well, I can't put in that little room a larger fan, but I can use a cheap vinyl or silicone tube from anywhere out of the printer where I have free space, using this tube as an air conduct I can manage to use a durable and powerful 50mm blower instead of a #&$#%# little fan, and have lots of air pressure when needed. Besides this, the air coming from the exterior part of the printer is cooler and works better. This little part of just 44x24mm will do the job. Just use a ~8mm inner diameter tube, attach it to the part, fix it with some ties and job done. At first I thought about using a PTFE tube and pneumatic fittings but that was an expensive solution and less flexible. Use your own solution to attach the blower where you want, or use the one included. Print the part in ABS with buildplate support only, don't use complete support as it will completely clog the air flow, and you won't be able to remove the inner support, remember this is a hollow part. Bridging should be ok. V2 new version recommended.

TODO: Nothing. Performs as expected.

UPDATE (29-JUN-2016):V2 enhanced M3 bolt support. Reinforced latch. I ended breaking the bolt support when tightening. Shortened back 4mm the bolt support length, 30mm M3 bolts weren't enough. Some minor design changes. This a final version (if that exists). Previous versions will not be maintained.

UPDATE (28-JUN-2016): V2 added. Increased screw length to use a 30mm M3 regular screw. Added a latch to avoid pitching, this also helps ABS printing acting as as extra cooling pillar. Removed unnecessary material that could interfere with bed clips. Rounded and refined design. Increased air output hole to enhance airflow. Added a small duct to aim better the airflow. Part still requires buildplate support ONLY, and only due to the tube connector, any other overhang angle is 45º or more. Will put pics when I have the time. First version works fine but some improvements should be done. You don't need to update your printed part if it works well for your setup, but if you do you won't regret. Anyway no more updates expected for this part beyond this V2.

UPDATE (22-JUN-2016): Updated model and STL for a inner ~8mm tube, The only one I could find nearby as I ended all my 6mm tube stocks. Lengthened a bit the part to accomodate the 8mm inner / 10mm outer diameter tube. Anyway performing even better than previous model as the airflow is enhanced by the greater diameter of the tube.

Similar models

thingiverse

free

Lewihe Play real 30mm layer fan duct by magonegro

...to not interfere with some configurations of the hotend. similar as previous design, just as using a saw to...

thingiverse

free

Blower fan attachment for compact effector by mandrav

...c.

so i created this little attachment that allows me to use a standard 50mm blower fan which produces a much better flow of air.

thingiverse

free

Parametric E3D clone Cooling Fan and (double) Part Blower V2 by nmaggioni

...iant of my previous mount, featuring a different design and improved airflow.

hinged design for side fans

slightly better airflow

thingiverse

free

Tevo Tarantula Pro Radial Fan Fang

...the hot end because the stock bolts are not long enough. you will also need 4 - m3 x 12 for mounting the 40mm fan to the adapter.

thingiverse

free

Hotend 30mm fan shroud by lucascorato

...ed part. i have supplied two versions for the hotends i currently use: magma and parisotto. feel free to remix to fit your needs!

thingiverse

free

Blower Fan holder for 2040 extrusion by peddiparth

...829733 is what i used.

i uploaded the openscad file so that you can make this design better and share it back with the community.

thingiverse

free

USB Air Blower v2.0 by fabiolutz

...project check: https://diyers.com.br/index.php/en/2018/07/25/usb-air-blower/

for more diy projects, access: https://diyers.com.br

thingiverse

free

General 50x15mm blower adapter by magonegro

... use your own solution, you just need two m3 screws...

sorry, no time at this moment for a wider description. (too many projects)

thingiverse

free

![[CR6-SE] blower fan duct 40x20mm by michaelbourque](/t/8365203.jpg)

[CR6-SE] blower fan duct 40x20mm by michaelbourque

...9t

also may i suggest you print this too and upgrade the front facing fan to a 40x10mm: https://www.thingiverse.com/thing:4774334

thingiverse

free

Fan Grill 30mm by Kaibob

...verse

fan grill for almost every 30mm fan.

v2 has more space between the rings to allow a bigger airflow. better use this one :)

Lewihe

thingiverse

free

Blade Holder for Lewihe Play by oppuigdengolas

...blade holder for lewihe play by oppuigdengolas

thingiverse

a cutter blade holder for lewihe play.

thingiverse

free

Soporte Ramps by lewihe

...soporte ramps by lewihe

thingiverse

soporte para electrónic ramps.

support for ramps electronics.

thingiverse

free

Printed wallet women by lewihe

...printed wallet women by lewihe

thingiverse

printed wallet women

thingiverse

free

Printable spool holder by lewihe

...printable spool holder by lewihe

thingiverse

devandadera imprimible.

printable spool holder.

thingiverse

free

Duct fan 40x40 by lewihe

...duct fan 40x40 by lewihe

thingiverse

soporte ventilador con conducto para refrigeración de capa

duct fan layer

thingiverse

free

Custom bed support - PLAY 3D by Lewihe by Jotaperamez

...he by jotaperamez

thingiverse

custom bed support for play 3d by lewihe to earn print area and to get be able to use a 12 cm bed.

thingiverse

free

SAV 3D-OLEd . Case by lewihe

...sav 3d-oled . case by lewihe

thingiverse

case for sav 3d-oled by http://www.electrofunltd.com/

thingiverse

free

Remixed layer fan magonegro + lewihe by Jotaperamez

...remixed layer fan magonegro + lewihe by jotaperamez

thingiverse

ready to print

thingiverse

free

Rueda niveladora by lewihe

...ara base de impresión. sustituye a las tuercas de m-3 de nivelación.

leveling wheel for printer dock. replaces nuts leveling m-3.

thingiverse

free

Soporte SAV Mk-I by lewihe

...soporte sav mk-i by lewihe

thingiverse

soporte para electrónica sav mk-i

support for sav mk-i electronics

Magonegro

thingiverse

free

Remixed layer fan magonegro + lewihe by Jotaperamez

...remixed layer fan magonegro + lewihe by jotaperamez

thingiverse

ready to print

thingiverse

free

Case for Thermometer by magonegro

...them and wanted a convenient case to keep them in place, allowing also to keep inside the case the temperature probe if you want.

thingiverse

free

Nema17 manual wheel by magonegro

...otor with a m3 nut & bolt. i did this because i was in a hurry and wanted a simple and sturdy thing for my double axis motor.

thingiverse

free

Cubic vacuum pen holder by magonegro

...egro

thingiverse

this my idea for my new pen holder. i think its cool! just scale it up to your likes. freecad sources included.

thingiverse

free

Logos for Rio2016 rotating geared logo by magonegro

...iverse

this is a customizer to make your own personal text logos for this thing; http://www.thingiverse.com/thing:1693420

enjoy!

thingiverse

free

Rectangular tube endcap by magonegro

...ap in seconds !!

you can also download the .scad script and use it standalone with openscad just in case the customizer is stuck.

thingiverse

free

Tube endcap by magonegro

...tation and comments.

here you have another of my customizers for squared endcaps: http://www.thingiverse.com/thing:1654153

enjoy.

thingiverse

free

A5 Cardboard support by magonegro

...atever you want. it is intended to keep readable the cardboard on a office table, a dinner table or a showcase.

happy reading!!

thingiverse

free

Blade generator for sandpaper handler by magonegro

...d, flat, cylindrical or ortho. any lenght you want.

press the customizer button, launch customizer app and make your own blade.

thingiverse

free

Double spiral pencil/toothpick holder by magonegro

...odel so scaling is not a problem. scale it to your needs. requires support for printing. recommended print in pla-like materials.

Blower

3d_export

$5

ball blower

...ball blower

3dexport

ball blower

3d_export

$10

engine blower assambly

...engine blower assambly

3dexport

engine blower assambly

3d_export

$5

air pipe blower

...air pipe blower

3dexport

air pipe blower

3d_export

$5

air hand blower

...air hand blower

3dexport

air hand blower

3d_export

$5

Blower Boom 3D Model

...blower boom 3d model

3dexport

boom blower

blower boom 3d model bkl1989 63079 3dexport

turbosquid

$44

blower-dxf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Old Blower

...l old blower for download as ma, max, gltf, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1638848)

3d_export

$7

zy series centrifugal blower

...zy series centrifugal blower

3dexport

zy series centrifugal blower

3d_export

$5

root blower compressor

...oot blower compressor

3dexport

you will get both .stl and .sldprt format of root blower compressor from here at very cheap rate.

turbosquid

$5

V8 engine with blower

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Play

3ddd

$1

play center

...play center

3ddd

площадка

play center

3ddd

free

Mecplast play

...mecplast play

3ddd

mecplast , play , кресло

archive3d

free

Play 3D Model

...ine playing machine game machine

play n210909 - 3d model (*.3ds) for interior 3d visualization.

archive3d

free

Play 3D Model

...ame-playing machine game machine

play 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Dedon play

...p://www.dedon.de/en/collections/detail/collection/play-with-dedon-143/sidechair-1146/play-64.html#armchair-2059/play-64

3d_export

$5

Kitchen knife for play

...kitchen knife for play

3dexport

kitchen knife for play

design_connected

$18

Lazy PLAI

...lazy plai

designconnected

b & b italia lazy plai lounge chairs computer generated 3d model. designed by patricia urquiola.

turbosquid

$1

playing cards

...quid

royalty free 3d model playing cards for download as max on turbosquid: 3d models for games, architecture, videos. (1614013)

3ddd

$1

пластилин Play-Doh

...пластилин play-doh

3ddd

пластилин

пластилин play-doh

archive3d

free

Play 3D Model

...l

archive3d

child's play toy

play n121009 - 3d model (*.3ds) for interior 3d visualization.

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Layer

design_connected

$9

Layer

...layer

designconnected

gallotti & radice layer tables computer generated 3d model. designed by luca nichetto.

3ddd

$1

Calligaris LAYERS

...calligaris layers

3ddd

calligaris , layers

стол фабрики calligaris модель layers

3ddd

$1

Eglo Layer

...eglo layer

3ddd

eglo , layer

люстра eglo layer (89593) h=1100 l=655

3d_export

$5

pipe layer

...pipe layer

3dexport

3d_export

$25

mandala layer

... modelled in cinema 4d r23 hope you like it! also check out my other models, just click on my username to see a complete gallery.

turbosquid

$29

cloth layers

... 3d model cloth layers for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1441919)

turbosquid

$29

Layer desk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

layered traffic

...layered traffic

3dexport

simple rendering of the scene file

turbosquid

$400

testis with covering layers

...ee 3d model testis with covering layers for download as blend on turbosquid: 3d models for games, architecture, videos. (1431659)

turbosquid

$210

Thoracic wall layers

...alty free 3d model thoracic wall layers for download as blend on turbosquid: 3d models for games, architecture, videos. (1674521)