Thingiverse

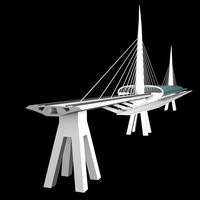

Led Bridge Lamp - bolted version by flash24

by Thingiverse

Last crawled date: 3 years ago

A remix of the Led Bridge Lamp by Opossums :

bolted version

foot parts printable on Flashforge Dreamer

The wonderfull Led Bridge Lamp made by designer Opossums

(see https://www.thingiverse.com/thing:1639224) makes me think of

the Eiffel Tower.

The original design features relatively large 'tabs', marked 'Left'

and 'Right' on the segment sides.

These tabs are the reason the side- and top-parts of the segment need

to be printed with supports.

I was looking for a design that could be printed without supports

and came up with this alternative version :

CURVED and STRAIGHT SEGMENTS :

No more supports needed, no post-printing cleanup work, less

material wasted.

Segment sides Left and Right are now identical, and so are top

panels A and B - resulting in a more simple design.

You WILL need a handfull of M2 bolts and (nylon lock) nuts to

inter-assemble the segments :

M2x10mm : 3 per segment

M2x6mm : 1 per curved segment

M2x20mm : 4 per foot

You will need a long, thin screwdriver to assemble the segments.

Segments can be assembled without glue (except for the LED

channels and top-to-side of course). If you use glue, the bolts

will keep the parts in place while the glue dries.

Base-plates 'mama' and 'papa' were redesigned to fit the M2 bolts

Straight segments were modified as well to match the bolted

assembly method.

The LED channel sides have been rounded - somehow this prints

cleaner on a Flashforge Dreamer at a cost of a little more PLA.

Try it out or use the original flat sided LED channels.

BRIDGE FOOT :

The Foot parts are too large for a Flashforge Dreamer printer-

platform so I resized the Foot Base, Center and Side parts.

The Foot Base now fits inside the Foot Center part

Foot parts Center, Cap and Height Extension can also be bolted

together using M2 bolts

New design of the Foot Side part to use less filament.

Added small tabs to the top of the Foot Side-panels.

These tabs fit in the bottom of the Foot Cap, so you don't

have to glue the Foot Sides to the Foot Center part.

As I did not need electronics in the Foot Base, I added a

ballast-tray and glued 2 layers of M8 nuts and some lead

airgun pellets in between those and so added some 500gr of weight

per foot.

Sketchup files are included so you can modify parts if you need

some sort of PCB-board on top of the Foot Base ballast tray,

or if you use a different size/type of power inlet or switch.

Enjoy!

Printed on Flashforge Dreamer in PLA, no supports, no raft.

First layer max. speed 10mm/s, 30% infill - standard print resolution.

bolted version

foot parts printable on Flashforge Dreamer

The wonderfull Led Bridge Lamp made by designer Opossums

(see https://www.thingiverse.com/thing:1639224) makes me think of

the Eiffel Tower.

The original design features relatively large 'tabs', marked 'Left'

and 'Right' on the segment sides.

These tabs are the reason the side- and top-parts of the segment need

to be printed with supports.

I was looking for a design that could be printed without supports

and came up with this alternative version :

CURVED and STRAIGHT SEGMENTS :

No more supports needed, no post-printing cleanup work, less

material wasted.

Segment sides Left and Right are now identical, and so are top

panels A and B - resulting in a more simple design.

You WILL need a handfull of M2 bolts and (nylon lock) nuts to

inter-assemble the segments :

M2x10mm : 3 per segment

M2x6mm : 1 per curved segment

M2x20mm : 4 per foot

You will need a long, thin screwdriver to assemble the segments.

Segments can be assembled without glue (except for the LED

channels and top-to-side of course). If you use glue, the bolts

will keep the parts in place while the glue dries.

Base-plates 'mama' and 'papa' were redesigned to fit the M2 bolts

Straight segments were modified as well to match the bolted

assembly method.

The LED channel sides have been rounded - somehow this prints

cleaner on a Flashforge Dreamer at a cost of a little more PLA.

Try it out or use the original flat sided LED channels.

BRIDGE FOOT :

The Foot parts are too large for a Flashforge Dreamer printer-

platform so I resized the Foot Base, Center and Side parts.

The Foot Base now fits inside the Foot Center part

Foot parts Center, Cap and Height Extension can also be bolted

together using M2 bolts

New design of the Foot Side part to use less filament.

Added small tabs to the top of the Foot Side-panels.

These tabs fit in the bottom of the Foot Cap, so you don't

have to glue the Foot Sides to the Foot Center part.

As I did not need electronics in the Foot Base, I added a

ballast-tray and glued 2 layers of M8 nuts and some lead

airgun pellets in between those and so added some 500gr of weight

per foot.

Sketchup files are included so you can modify parts if you need

some sort of PCB-board on top of the Foot Base ballast tray,

or if you use a different size/type of power inlet or switch.

Enjoy!

Printed on Flashforge Dreamer in PLA, no supports, no raft.

First layer max. speed 10mm/s, 30% infill - standard print resolution.

Similar models

thingiverse

free

Flashforge Dreamer printer foot by jamesarm97

...7

thingiverse

needed some rubber feet for the flashforge dreamer printer. print this (x4) in semiflex (preferred) or ninjaflex.

thingiverse

free

Led Arc Lamp by Niyada

...and

the surrounding area)

in one of the feet is a hole for a potentiometer, one for a power source and one for the led connectors

thingiverse

free

Led bridge lamp Universal Segment by Opossums

...ller? scale middle piece of the foot.

now includes straight segment.

thank you, 50 000 + viewers of the original led bridge lamp!

thingiverse

free

New Foot / Base for the great Led Bridge Lamp by Opossums by BplusO

...ed into the led light guides (instead of the led channels that create shafts that are too small when scaling) - here in 1:1 scale

thingiverse

free

LED Bridge Lamp Remix by Protopix

...he led guides and channels have been replaced with custom versions.

many thanks to opossums for his original bridge lamp designs!

thingiverse

free

LED Bridge Alternative Foot and Channels by BFerreira

...of two cabinets. the foots is designed to be similar to the bridge structure. i've also changed the channels...

thingiverse

free

FlashForge Dreamer spool holders by DaveMoi

...will need to print both the base and the screw-on spool holder bar. the center bar that interconnect the two holders is optional.

thingiverse

free

Remixed Channel parts for Opossum's Led bridge lamp by Tirpitz93

...t replace the light guides with the provided components.

i am printing mine in petg and assembling using dcm for a chemical weld.

thingiverse

free

Flashforge Door Lock Dreamer/Inventor by C_Birch81

... by it's self so this just pushes into place to lock the door open and as a tab to remove it when you need to close the door.

thingiverse

free

FlashForge Dreamer Side Vent cover by Willg77

...flashforge dreamer side vent cover by willg77

thingiverse

just in case, you have lost your side cover.

support need for print.

Flash24

thingiverse

free

Another Solder Holder by flash24

...another solder holder by flash24

thingiverse

simple solder holder

thingiverse

free

OTTO DIY - Foot Remix by flash24

...otto diy - foot remix by flash24

thingiverse

remix of the otto diy robot foot with toes.

thingiverse

free

IBC Clip by flash24

...elf (or other) to the metal top frame of an ibc container.

no supports, no raft, infill depending on weight of shelf : 30% or up.

thingiverse

free

Modular Plier Stand by flash24

... as you need and glue them together.

update oct. 29 2018

added 2 extra elements for those that want to fix the rack to a wall.

thingiverse

free

Simple Strong Book Stand by flash24

...able

book almost flat - in case you're standing (e.g. kitchen situation)

use m2x15 or m2x20 bolts and super glue to assemble.

thingiverse

free

Simple H0-scale Bridge Pillar - adjustable by flash24

... part, you may need to

minimize the depth of the m2 holes (10 mm. is probably deep enough) in

sketchup to print this part faster.

thingiverse

free

Funnel with OPEN-CLOSE Mechanism by flash24

... % infill.

update : made version 2 of part 2 : the thumb-end is now thinner, resulting in more 'reach' at the pencil-end.

thingiverse

free

V-dipole antenna construction set by flash24

..., they go straight into the choc blocks

you only need to solder 2 short wires between the so239 and the 2 choc blocks

enjoy !

thingiverse

free

Solenoid Valve Cover + LED slot by flash24

...is a new cover-version for a simple round 5mm. led.

pack of 20 pcs. 5mm. 12v led's here

pack of 50 black 5mm. led holder here

thingiverse

free

Another 18650 Charger Station by flash24

...

solder everything and test

evt. glue wires in place on the underside of the inner frame

glue exterior shell over the inner frame

Bridge

3d_export

free

bridge and destroyed bridge

...bridge and destroyed bridge

3dexport

bridge and destroyed bridge

3d_ocean

$19

Bridge

...bridge

3docean

3d bridge building

3d bridge

archibase_planet

free

Bridge

...bridge

archibase planet

bridge foot-bridge construction

bridge n130715 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3ddd

free

The Bridge

...the bridge

3ddd

мост

the bridge

3d_ocean

$7

Bridge

...bridge

3docean

bridge low polygon medi evil bridge old bridge

2048 * texture obj, fbx and blend format. game ready model.

archibase_planet

free

Bridge

...net

bridge foot-bridge construction

bridge ponte de tijolos n250515 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

$18

arch bridge-bridge-stairs

...arch bridge-bridge-stairs

3dexport

arch bridge-bridge-stairs<br>3ds max 2015

3d_export

$5

bridge

...bridge

3dexport

bridge - 3d model ( gsm : 3ds )

3d_export

$5

bridge

...bridge

3dexport

wood bridge all textures in 4k

3ddd

$1

Bridge

...bridge

3ddd

bridge , мост

мост для экстерьера

Led

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bolted

3d_export

$2

bolt

...

bolt - a fastener in the form of a rod with an external thread, usually with a hex head wrench, forming a connection with a nut.

3d_export

$5

bolted ring

...bolted ring

3dexport

bolted ring

3d_export

$5

royal bolt

...royal bolt

3dexport

royal bolt

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1681373)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680879)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680869)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680866)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1680860)

turbosquid

$10

Bolt

...lty free 3d model bolt for download as max, c4d, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1680480)

turbosquid

$13

bolt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Lamp

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp lantern

lamp - 3d model (*.3ds) for interior 3d visualization.

3d_ocean

$6

Lamp

...lamp

3docean

lamp

a high quality lamp.

Version

3ddd

$1

Diamond version

...nd , version , ванна

visionnaire - diamond bath

turbosquid

$50

LibraryMini Version

...free 3d model librarymini version for download as max and jpg on turbosquid: 3d models for games, architecture, videos. (1617724)

design_connected

$34

Barocco Version 01

...barocco version 01

designconnected

zanotta barocco version 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Barocco Version 02

...barocco version 02

designconnected

zanotta barocco version 02 computer generated 3d model. designed by progetti, emaf.

turbosquid

free

![Door [2 versions]](/t/13243146.jpg)

Door [2 versions]

...rbosquid

free 3d model door [2 versions] for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223985)

turbosquid

$2

seat version 0.1

...

royalty free 3d model seat version 0.1 for download as blend on turbosquid: 3d models for games, architecture, videos. (1432653)

3d_export

$10

magnolia grandiflora mature version

...magnolia grandiflora mature version

3dexport

magnolia grandiflora mature version

3d_export

$8

room assets and voxel version

...room assets and voxel version

3dexport

room assets and voxel version

turbosquid

$35

Zil Civilian version

... model zil civilian version for download as cgf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639420)

turbosquid

$3

Chair 3 versions

...3d model chair 3 versions for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1657530)