Thingiverse

Leadscrew Upgrade X Ends for Wilson / Prusa i3 by unknown_lamer

by Thingiverse

Last crawled date: 4 years, 7 months ago

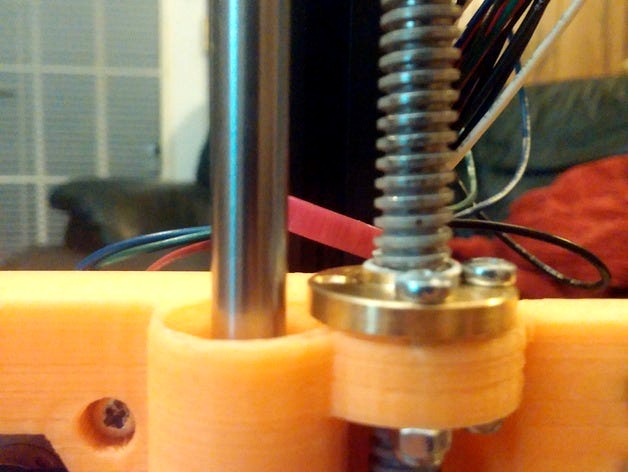

These new X-ends integrate the changes from the Wilson II into the Wilson TS X-end, adjusting the geometry to match the Wilson TS and resized for 8mm linear rods and an 8mm leadscrew with a brass nut (I got mine from folgertech, the cheap THSL-8... seem to all use the same nut). These should fit the standard Prusa i3 geometry since the Wilson TS uses the same geometry (if I am incorrect, please leave a comment so that I can update the title and avoid misleading anyone).

This uses the tensioner and x-carriage from the Wilson TS. In addition to supporting a leadscrew, I also integrated the new strain reliefs on the motor end, and the ridges for preventing the tensioner from pitching / cut out to add more travel to the idler end.

This does lose about 3mm of travel on the motor side, but adds more on the idler end. The end stop switch can likely be moved inward another 3mm to avoid losing any travel on the motor end (change x-end-motor.scad:endstop_sw_offs_adjust), but I realized that after printing and left the position alone in the STLs since I know the current version works.

The openscad source code is available at https://git.hcoop.net/?p=clinton/wilson.git;a=summary and is licensed under the GPLv3+. These changes could possibly be integrated back into the upstream Prusa i3 as well.

I had to print http://www.thingiverse.com/thing:1347181 because my leadscrews are taller than the top rod holders, and I had z-wobble issues (my m5 rods had similar issues before I cut them below the top rod holders, but I didn't want to cut the leadscrews since I may build a taller printer later). My frame is a bit too tall for its own good (470mm linear rods), so there might not be any problem with the leadscrews poking out of the top rod holders on a normal height Wilson TS.

Note: although my layer quality is better, my printer is slower with this because the leadscrews are stiffer and when they vibrate they seem to make the x-axis shake back and forth more (= ringing become excessive at 45mm/s instead of 60mm/s). I also extended my x- and z- axes by 100mm and 8mm smooth rods don't seem stiff enough at these lengths anyway (450mm z, 470mm x) so YMMV if you didn't make your Wilson way too large. I am working on a 10mm variant of these that will be combined with the Prusa i3 z-axis parts with a new extrusion_frame option.

This uses the tensioner and x-carriage from the Wilson TS. In addition to supporting a leadscrew, I also integrated the new strain reliefs on the motor end, and the ridges for preventing the tensioner from pitching / cut out to add more travel to the idler end.

This does lose about 3mm of travel on the motor side, but adds more on the idler end. The end stop switch can likely be moved inward another 3mm to avoid losing any travel on the motor end (change x-end-motor.scad:endstop_sw_offs_adjust), but I realized that after printing and left the position alone in the STLs since I know the current version works.

The openscad source code is available at https://git.hcoop.net/?p=clinton/wilson.git;a=summary and is licensed under the GPLv3+. These changes could possibly be integrated back into the upstream Prusa i3 as well.

I had to print http://www.thingiverse.com/thing:1347181 because my leadscrews are taller than the top rod holders, and I had z-wobble issues (my m5 rods had similar issues before I cut them below the top rod holders, but I didn't want to cut the leadscrews since I may build a taller printer later). My frame is a bit too tall for its own good (470mm linear rods), so there might not be any problem with the leadscrews poking out of the top rod holders on a normal height Wilson TS.

Note: although my layer quality is better, my printer is slower with this because the leadscrews are stiffer and when they vibrate they seem to make the x-axis shake back and forth more (= ringing become excessive at 45mm/s instead of 60mm/s). I also extended my x- and z- axes by 100mm and 8mm smooth rods don't seem stiff enough at these lengths anyway (450mm z, 470mm x) so YMMV if you didn't make your Wilson way too large. I am working on a 10mm variant of these that will be combined with the Prusa i3 z-axis parts with a new extrusion_frame option.