Thingiverse

Lead screw cleaning guide CR-10 and other TR8x8

by Thingiverse

Last crawled date: 4 years, 2 months ago

Manually written Gcode cleaning files for the cr-10

Required:

Old credit card or similar

Tissues

Isopropanol or other high conc alcohol

replacement lubricant (teflon based only) (I used muc off dry lube)

Test the 380mm gcode script (or modify it for however long your Z axis actually is. You can find out your total by moving z on your printers control box, Note if you have changed extruder, hotend or bed this will be different for stock. Mine was 400 now its 380.

If needed edit one of the gcode scripts to say change 330 to 100 for a Z=100max printer.

Run the script on the printer, be prepared to kill it if anything goes wrong. It will cycle up, home and repeat.

Get a tissue, dab a single strip along it with alcohol generously, then wrap the alcohol wet tissue around one long edge of the card and hold it into your leadscrew. It should move up.

After getting use to it, push snugly on the screw to make sure the card is fully engaged with the slot. If too much gunk builds up, slide the card along so the gunk now goes on a clean part of the tissue.

Unwrap the card, move the tissue so a clean part is over the edge, rewrap it and repeat both above and below your moving gantry until your screws are reasonably clean.

They will never be fully silver, dont waste your time trying, its going to be messy in weeks again.

when done wrap a finger around your leadscrew (whilst the gcode is still running) and drip lube onto the inner joint (wrinkle) of your finger, it should run down your finger and into the screw. Do this in medium amounts and if any looks like its going to drip into a motor grab a tissue and stop it.

Edit: Uploaded block.stl as thingiverse requires an stl be attached

Required:

Old credit card or similar

Tissues

Isopropanol or other high conc alcohol

replacement lubricant (teflon based only) (I used muc off dry lube)

Test the 380mm gcode script (or modify it for however long your Z axis actually is. You can find out your total by moving z on your printers control box, Note if you have changed extruder, hotend or bed this will be different for stock. Mine was 400 now its 380.

If needed edit one of the gcode scripts to say change 330 to 100 for a Z=100max printer.

Run the script on the printer, be prepared to kill it if anything goes wrong. It will cycle up, home and repeat.

Get a tissue, dab a single strip along it with alcohol generously, then wrap the alcohol wet tissue around one long edge of the card and hold it into your leadscrew. It should move up.

After getting use to it, push snugly on the screw to make sure the card is fully engaged with the slot. If too much gunk builds up, slide the card along so the gunk now goes on a clean part of the tissue.

Unwrap the card, move the tissue so a clean part is over the edge, rewrap it and repeat both above and below your moving gantry until your screws are reasonably clean.

They will never be fully silver, dont waste your time trying, its going to be messy in weeks again.

when done wrap a finger around your leadscrew (whilst the gcode is still running) and drip lube onto the inner joint (wrinkle) of your finger, it should run down your finger and into the screw. Do this in medium amounts and if any looks like its going to drip into a motor grab a tissue and stop it.

Edit: Uploaded block.stl as thingiverse requires an stl be attached

Similar models

grabcad

free

Z-Axis Leadscrew Top Mount

...

grabcad

z-axis leadscrew top mount for 3d printer such as cr-10, cr-10s, etc.

you can find them on amazon, ebay or aliexpress.

grabcad

free

Z-Axis Leadscrew Bearing Block

...

grabcad

z-axis leadscrew top mount for 3d printer such as cr-10, cr-10s, etc.

you can find them on amazon, ebay or aliexpress.

thingiverse

free

CR-10 S Bowden Drive with guide and filament sensing by doogielabs

... this incorporates the z-screw filament guide, as well as the sensor / switch that informs the printer that filament has run out.

thingiverse

free

Geeetech i3 Z-Axis Top-Caps for 200mm Stepper/Leadscrews by BrendaEM by BrendaEM

...ns.

v2, is updated model, as in picture. i am sorry for any problems.

my patreon page:https://www.patreon.com/brendaem

--brendaem

thingiverse

free

CR-10 Z-Axis Leadscrew Top Mount by samsonmking

...s are not perfect and the system requires some compliance - make sure you loosen the screws on your leadscrew nut a couple turns.

thingiverse

free

Multi Use Robotic Arm SCARA Equivalent MURASE by pghauff

... for the r axis.

a modified sanguinolo 3d printer computer is used but any ramps system would run the robot with minor soldering.

thingiverse

free

Z_knob by StikkaDesign

...z_knob by stikkadesign

thingiverse

knob to manually move the z axis your t8 leadscrew

thingiverse

free

Wilson II Z axis alignment tool by ant0ny

...leadscew nut in place attach a couple of these to assist in lining up the leadscrew and motor before tightening the motor screws.

thingiverse

free

Mechanical Dual Z bracket for CR-10 (Mini) by alex2504

...mechanical dual z bracket for cr-10 (mini) by alex2504

thingiverse

bracket for adding a second z axis leadscrew to a cr-10.

thingiverse

free

Z axis leadscrew stepper rotation position indicator by OndrejP_SK

...e device attaches to the coupler and i can quickly check if the leadscrews are in the same starting position after homing z axis.

Tr8X8

thingiverse

free

RebeliX X2 TR8x8 by olihenbeznadeje

...ake the rebelix x2 printer to trapezoidal screws tr8x8.

other parts are the same as in github.https://github.com/reprap4u/rebelix

thingiverse

free

Cyclone PCB TR8x8 Y-Carriage by dakahler

...w instead of a threaded rod. see here for more info:

https://groups.google.com/d/msg/cyclone-pcb-factory/fxtsmkxq6hy/ayeqjqxccgaj

thingiverse

free

lead screw anti backlash nut Tr8x8 P2 by Fips11

...lead screw anti backlash nut tr8x8 p2 by fips11

thingiverse

nope

thingiverse

free

Cyclone PCB TR8x8 X-Carriage by dakahler

...sg/cyclone-pcb-factory/fxtsmkxq6hy/ayeqjqxccgaj

see my new, reinforced x carriage here: https://www.thingiverse.com/thing:2380780

thingiverse

free

TR8x8 Lead Screw Anti-backlash nut by buffcleb

...open nut... i'll leave the design here but you can probably just print the mount and the replaceable nut and get good results

thingiverse

free

Threaded TR8x8 lock collar by JanoMyburgh

...he collar with tightening knob negates the need to an extra tool during for tension installations and it can double as a jog knob

thingiverse

free

Lewihe Play base for TR8x8 leadscrew and nut by magonegro

... updated the .stl also.

(update 24-may-2016): added a little fillet to ease the use of inferior bolts to adjust bed's height.

thingiverse

free

Ecrou anti backlach TR8X8 Pack Expert+ by 3DLD

...tion il faudra 6 vis m4x12

compatible avec https://www.thingiverse.com/thing:3068012 et https://www.thingiverse.com/thing:3079634

thingiverse

free

TR8x8 lead screw to 8mm Nema23 Coupler by buffcleb

...1486386187&sr=8-1&keywords=20mm+m3&linkcode=sl1&tag=wwwbethnchris-20&linkid=6b1551d6a6653efa95aeeaf57d07466f)

thingiverse

free

Prusa i3 MK2 lead screw cover with alignment gauge by davtr

...by printed markers on cover surface. both tr8x4 and tr8x8 provided. tr8x8 is original mk2 lead screw. see also...

Cr

turbosquid

$15

Creazioni CR-673 CR-4461

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Ravak CR 055.00

...ravak cr 055.00

3ddd

ravak , смеситель

ravak cr 055.00

turbosquid

$100

CR-002

...

turbosquid

royalty free 3d model cr-002 for download as stl on turbosquid: 3d models for games, architecture, videos. (1686037)

3ddd

$1

Ravak CR 012.00

...ravak cr 012.00

3ddd

ravak , смеситель

смеситель ravak cr 012.00

3ddd

free

Консоль CR Currin

...ь , cr currin

консоль cr currin

ширина - 1675 мм

глубина - 510 мм

общая высота - 810 мм

3ddd

$1

CR 39444

...0

диаметр: 100

тип патрона: gu5,3 gu10

количество ламп: 1

мощность: 35w

цвет: золото хрусталь

материал: металл хрусталь exclusive

3d_ocean

$89

Honda CR-Z

...www.youtube.com/watch?v=rrbb4d4lypk ` he honda cr-z‘s exterior styling is formed around a “one-motion wedge” concept with a lo...

3ddd

$1

Creazoni / STEFY CR-8901

...creazoni / stefy cr-8901

3ddd

creazoni

creazioni stefy cr-8901

turbosquid

$60

Chain-CR-001

...squid

royalty free 3d model chain-cr-001 for download as stl on turbosquid: 3d models for games, architecture, videos. (1680536)

turbosquid

$99

Honda CR-Z

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

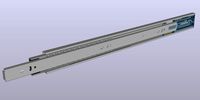

Guide

turbosquid

$15

Guide drawer

...squid

royalty free 3d model guide drawer for download as dwg on turbosquid: 3d models for games, architecture, videos. (1261387)

turbosquid

$1

Road Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Guide-board 3D Model

...ion sign guide sign

guide-board n170112 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

turbosquid

$2

soap cutter guide

...

royalty free 3d model soap cutter guide for download as stl on turbosquid: 3d models for games, architecture, videos. (1694030)

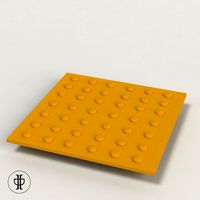

turbosquid

$15

Blind Guiding tiles

...free 3d model blind guiding tiles for download as 3dm and dae on turbosquid: 3d models for games, architecture, videos. (1156598)

turbosquid

$69

Japanese Tour Guide

...d model japanese tour guide for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1614288)

turbosquid

$10

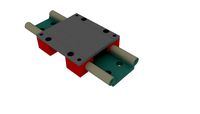

CNC Linear Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Tank Model Guide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Road Guide 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$9

Guide Books 3

...sformed separately and each have unique texture map on front and back cover. to make your work easier this model comes in thre...

Cleaning

turbosquid

$29

Clean Bow

...osquid

royalty free 3d model clean bow for download as blend on turbosquid: 3d models for games, architecture, videos. (1257234)

turbosquid

$25

Jacuzzi Clean

...quid

royalty free 3d model jacuzzi clean for download as max on turbosquid: 3d models for games, architecture, videos. (1461249)

turbosquid

$32

Bobcat Clean

... free 3d model bobcat clean for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1393706)

turbosquid

$1

Zanbato - Clean

...ree 3d model zanbato - clean for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328531)

turbosquid

$10

Cleaning Products

...model cleaning products for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559247)

turbosquid

$25

cleaning kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Cleaning pads

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Cleaning Bucket

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

cleaning bucket

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cleaning Equipment

...ng equipment for download as max, 3ds, dae, dxf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1693554)

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

Screw

3d_export

$5

screw

...screw

3dexport

screw

turbosquid

$29

Screw driver and screws

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$2

Screw

... steel twist wood screw

screw 3d model in 2 different materials real world scale rendered with mental ray file formats: .max .obj

3d_ocean

$4

Screw

...n

3d bolt male mechanic metal nut parts prop propeller schraube schraubenmutter screw steel twist

screw 3d model, clean modeling.

turbosquid

$2

screw

...crew

turbosquid

royalty free 3d model screw for download as on turbosquid: 3d models for games, architecture, videos. (1198271)

turbosquid

free

Screw

...screw

turbosquid

free 3d model screw for download as obj on turbosquid: 3d models for games, architecture, videos. (1240851)

3d_ocean

$2

Frame Screw

...frame screw

3docean

construction screw

a frame screw and plug.

turbosquid

$27

screw

...w

turbosquid

royalty free 3d model screw for download as max on turbosquid: 3d models for games, architecture, videos. (1334064)

turbosquid

$20

SCREW

...

turbosquid

royalty free 3d model screw for download as sldas on turbosquid: 3d models for games, architecture, videos. (729733)

turbosquid

$1

Screws

...

turbosquid

royalty free 3d model screws for download as max on turbosquid: 3d models for games, architecture, videos. (1640360)

Lead

turbosquid

$25

Lead Sled

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

pencil leads

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Lead Pipe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Leagoo Lead 7

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

leaded Glass

...glass

3ddd

стекло витраж

стаки не свернуты длч удобства подгонки под размеры.материалы легко меняються по вкусу.

текстуры+мах 10.

turbosquid

$15

LAS LEAD ARMCHAIRS

...del las lead armchairs for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1443555)

turbosquid

$19

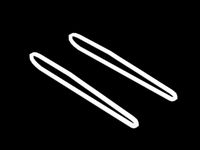

2 Black Lead Pencils

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Mechanical Pencil Lead Refill

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Antique lead crystal vase

...free 3d model antique lead crystal vase for download as blend on turbosquid: 3d models for games, architecture, videos. (1405722)

turbosquid

$60

Lead Bricks for Radiation Shielding

...icks for radiation shielding for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1622529)

Other

design_connected

$16

ST12 Other

...signconnected

photo-realistic 3d models of the st12 other stool from e15 for 3d architectural and interior design presentations.

turbosquid

$26

Oar and Other

...quid

royalty free 3d model oar and other for download as fbx on turbosquid: 3d models for games, architecture, videos. (1473409)

turbosquid

$5

chair with other

...id

royalty free 3d model chair with other for download as ma on turbosquid: 3d models for games, architecture, videos. (1171468)

3ddd

$1

parfume and other

...parfume and other

3ddd

тумбочка

create by sametyuzer

turbosquid

$79

The Others Collection

...others collection for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1480228)

turbosquid

$25

Other Man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

other car.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Other Mothers Hand

... 3d model other mothers hand for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1663825)

turbosquid

$8

other sport wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

pool and other elements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.