Thingiverse

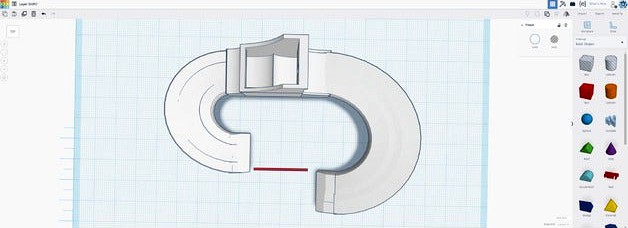

"Layer Shift" advanced cooling fan duct for A8 printer by _Grey_Area_

by Thingiverse

Last crawled date: 4 years ago

This is a modified design borrowing heavily from the Spaceship fan by Paul0.

It occurred to me that in the original design with the vents facing each other, the air from one vent would collide with the oncoming stream from the other. Thus the air would lose velocity and hang around longer, potentially cooling th nozzle (unwanted) and cooling the work less (also unwanted).

I wondered what would happen if the design were altered so that the streams perforrmed a "near miss"...each passing the other to one side, with the nozzle in the middle. Since the streams diverge, there is likely to be SOME air mixing in the space around the nozzle, but much less than in the "head on" version.

Initial tests would indicate that overhang and bridging performance is improved, as well as fine detail.

The angle of the vents in this version may not be optimal...which is why I've marked it a "work in progress". I'm still testing it (as are a few others) but I think we've seen enough to release it here without too much risk.

*note. The fan is large and on a standard A8 the left hand side almost grazes the Z axis lead screw when the carriage is returned to the home position. Please ensure you check there is room for the fan before homing your print carriage, in case your gap is smaller!

I just updated the description so that it says "fan duct" not "fan"...yes I know the two are different; I'm sure someone would have pointed that out at some point.

By the way the reason it's called "Layer Shift"...well, just look at it. It reminded me of some of the models I'v found split and disjointed when things go wrong...so once I'd seen that I couldn't think of it any other way.

It occurred to me that in the original design with the vents facing each other, the air from one vent would collide with the oncoming stream from the other. Thus the air would lose velocity and hang around longer, potentially cooling th nozzle (unwanted) and cooling the work less (also unwanted).

I wondered what would happen if the design were altered so that the streams perforrmed a "near miss"...each passing the other to one side, with the nozzle in the middle. Since the streams diverge, there is likely to be SOME air mixing in the space around the nozzle, but much less than in the "head on" version.

Initial tests would indicate that overhang and bridging performance is improved, as well as fine detail.

The angle of the vents in this version may not be optimal...which is why I've marked it a "work in progress". I'm still testing it (as are a few others) but I think we've seen enough to release it here without too much risk.

*note. The fan is large and on a standard A8 the left hand side almost grazes the Z axis lead screw when the carriage is returned to the home position. Please ensure you check there is room for the fan before homing your print carriage, in case your gap is smaller!

I just updated the description so that it says "fan duct" not "fan"...yes I know the two are different; I'm sure someone would have pointed that out at some point.

By the way the reason it's called "Layer Shift"...well, just look at it. It reminded me of some of the models I'v found split and disjointed when things go wrong...so once I'd seen that I couldn't think of it any other way.