Thingiverse

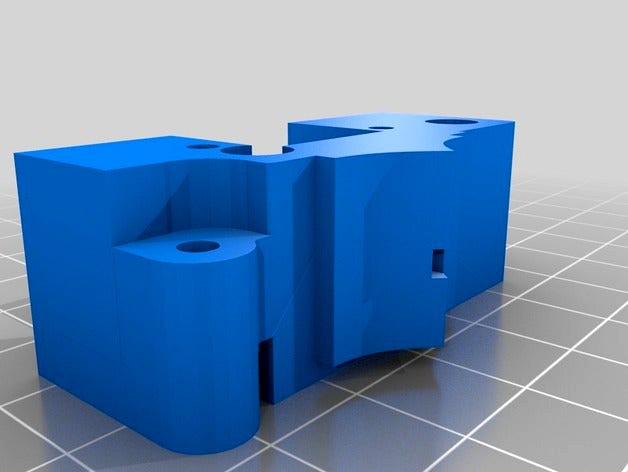

Lawsy's MK5 solidoodle extruder for ninjaflex E3D V6 edition by nebarnix

by Thingiverse

Last crawled date: 4 years, 5 months ago

Update #2: The hole is too small and does need to be enlarged. I drilled it out with a 3/32" bit. THIS YIELDED THE FIRST SUCCESSFUL PRINT IN NINJAFLEX (at 230C) =D =D =D!

I'm working on a new design to fix these problems, but there are mesh errors in the original file that are difficult to work with. Stay tuned....

Update #1: Cura produces errors but Slic3r prints great. The ball bearing needs to be the same diameter as the hobbed bolt in this design. Mine is too big and I had to melt material away slowly using a heated screwdriver.

An attempt to merge the ninjaflex feature with the E3D V6 extruder.

There are currently two issues -- the curvature of the roller bearing doesn't quite match and had to be dremmeled slightly

The hole is a little rectangular and filament friction is high. Small 1cm cubes of ninjaflex fail 20% in.

There is also a strange ridge which should not be in the model but appears in slicing and keeps the E3D from sliding into an already tight fit. I had to shave it down with an X-acto. The fit required large clamps, which is not ideal.

Consider this model, for the time being, extremely experimental.

I'm working on a new design to fix these problems, but there are mesh errors in the original file that are difficult to work with. Stay tuned....

Update #1: Cura produces errors but Slic3r prints great. The ball bearing needs to be the same diameter as the hobbed bolt in this design. Mine is too big and I had to melt material away slowly using a heated screwdriver.

An attempt to merge the ninjaflex feature with the E3D V6 extruder.

There are currently two issues -- the curvature of the roller bearing doesn't quite match and had to be dremmeled slightly

The hole is a little rectangular and filament friction is high. Small 1cm cubes of ninjaflex fail 20% in.

There is also a strange ridge which should not be in the model but appears in slicing and keeps the E3D from sliding into an already tight fit. I had to shave it down with an X-acto. The fit required large clamps, which is not ideal.

Consider this model, for the time being, extremely experimental.