Thingiverse

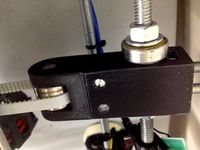

Laser Rotary by Jimf123

by Thingiverse

Last crawled date: 3 years, 1 month ago

Laser rotary

This rotary isn't for the stock K40 controller such as the M2nano. You will need to upgrade to a controller that can be configured for a rotary device. I use a Cohesion3D running Smoothieware and Lightburn Laser software. You will need to modify the steps per degree configuration value for correct rotary length movement. Other laser controllers such as Ruida will work also.

Videohttps://youtu.be/c_CwmfQNdzA

parts required

5/16x18 threaded rod (or 8mm)

four 608-2rs skate bearings

small m3 nuts and bolts to attach pulleys and stepper motor

six 5/16x18 lock nuts (or 8mm)

Nema17 stepper motor

HTD3 belt 105tooth 315mm length 9mm wide Gates Part# HTD3M-315

Four 30mm inside diameter rubber O-rings

I used the openscad parametric pulley to design the idler and HTD3 pulleyshttps://www.thingiverse.com/thing:16627

You can use any type belt that is approximately 315mm length and create matching pulleys. I used HTD3 type belt since that was found in my junk bin. Pulleys are 32 tooth. The stepper motor has mounting slots for tensioning the belt. If your belt is longer or shorter, just change the tooth amount to fit and re-print. Same with the idler pulley. If your O-ring is different size, make a idler to fit. You may want to experiment with using 2:1 reduction for more torque/resolution. 17 and 34 tooth pulleys are available for download.

If you want to laser tapered objects, print a pair of larger diameter idler pulleys. Adjust along the length of the threaded rod so the object is parallel to laser head.

The 5/16 threaded rod is slightly smaller diameter than the 8mm ID bearing. Wrap a couple of layers of tape around the threaded rod so the bearing fits tightly. Better yet, use 8mm threaded rod and lock nuts. You will need to modify the pulley/idler shaft diameter for 8mm. Get straight threaded rod to minimize wobble. You may need to add a washer between the bearing and pulley for more clearance.

The solidworks design files for the base is available if you want to re-mix. Fusion360 can import them for modification. The bearing pockets are 100mm apart. For really small diameter items, move them closer and use a shorter belt. You can purchase various size belts on ebay for a couple dollars. GT belts are common. 3mm and higher pitch pulleys are easier to print.

If you require a low profile rotary that works better for smaller K40 type lasers,https://www.thingiverse.com/thing:3068792

This rotary isn't for the stock K40 controller such as the M2nano. You will need to upgrade to a controller that can be configured for a rotary device. I use a Cohesion3D running Smoothieware and Lightburn Laser software. You will need to modify the steps per degree configuration value for correct rotary length movement. Other laser controllers such as Ruida will work also.

Videohttps://youtu.be/c_CwmfQNdzA

parts required

5/16x18 threaded rod (or 8mm)

four 608-2rs skate bearings

small m3 nuts and bolts to attach pulleys and stepper motor

six 5/16x18 lock nuts (or 8mm)

Nema17 stepper motor

HTD3 belt 105tooth 315mm length 9mm wide Gates Part# HTD3M-315

Four 30mm inside diameter rubber O-rings

I used the openscad parametric pulley to design the idler and HTD3 pulleyshttps://www.thingiverse.com/thing:16627

You can use any type belt that is approximately 315mm length and create matching pulleys. I used HTD3 type belt since that was found in my junk bin. Pulleys are 32 tooth. The stepper motor has mounting slots for tensioning the belt. If your belt is longer or shorter, just change the tooth amount to fit and re-print. Same with the idler pulley. If your O-ring is different size, make a idler to fit. You may want to experiment with using 2:1 reduction for more torque/resolution. 17 and 34 tooth pulleys are available for download.

If you want to laser tapered objects, print a pair of larger diameter idler pulleys. Adjust along the length of the threaded rod so the object is parallel to laser head.

The 5/16 threaded rod is slightly smaller diameter than the 8mm ID bearing. Wrap a couple of layers of tape around the threaded rod so the bearing fits tightly. Better yet, use 8mm threaded rod and lock nuts. You will need to modify the pulley/idler shaft diameter for 8mm. Get straight threaded rod to minimize wobble. You may need to add a washer between the bearing and pulley for more clearance.

The solidworks design files for the base is available if you want to re-mix. Fusion360 can import them for modification. The bearing pockets are 100mm apart. For really small diameter items, move them closer and use a shorter belt. You can purchase various size belts on ebay for a couple dollars. GT belts are common. 3mm and higher pitch pulleys are easier to print.

If you require a low profile rotary that works better for smaller K40 type lasers,https://www.thingiverse.com/thing:3068792

Similar models

thingiverse

free

Laser Rotary Lower Profile by Jimf123

...and 75tooth gt2 2mm pitch belt. this will give center to center length of exactly 50mm, the distance the two bearings are placed.

thingiverse

free

Belt Tensioner - Idle Pulley for Prusa Mendel I2 by Chris918

... old 608 bearing idler on the frame's threaded rod. it is acting as a washer on one side between the nut and the tensioner ;)

thingiverse

free

GT2 idler for 608 bearing M3 NEMA 17 stepper

...

idler for 6mm gt2 belt, designed to mount onto a nema 17 stepper motor and leave room for a 16 tooth pulley

step files included

thingiverse

free

K40 Rotary Attachment by funinthefalls

... use the plastic bearings in the stl file , but i do not reccomend it.

sorry for the lack of info, will post more as i build one.

thingiverse

free

K40 Adjustable Bed - 8mm Acme Rods by rpjamess1

...else is the same as the original remix.

requires 4x 688z bearings, 4x 8mm acme nuts, and 4x your length of 8mm acme threaded rod.

thingiverse

free

TRONXY X5S - Z motor sync by WT1704

...e platform on the stepper and 3 * m5 screws and nuts for the pulley

1 * m3 screw and nut to hold the tension stick with the block

thingiverse

free

Tronxy x5s single Z motor conversion by napo7

...the threaded rod version, but it can be cheaper and easier to source than leadscrew...

next version to come : with idler pulleys

thingiverse

free

Dual 608 bearing Y idler for Prusa i3 with 10mm threaded rod by Tech2C

...-slightly reduced the bearing rim.

you will need:

1x m8x30mm cap screw

1x m8 nut

2x 608 bearings

2x m4x20mm cap screws

2x m4 nuts

thingiverse

free

CR-10 Sleek X-Tensioner Revised by Splic3dBread

...ll need an m3 nut and m3 bolt not shorter than 20mm. you also may need to use the extended housing depending on your belt length.

thingiverse

free

Laser Engraver by Falcocarve

...ma 17 and pulleys

idler pulleys or barings with 5mm bore

8mm rods

wheels

8mm bolts and nuts

5mm bolts and nuts

wiring

electronics

Rotary

3ddd

$1

Medical Rotary table

...medical rotary table

3ddd

медицинский стол

medical rotary table

turbosquid

$18

Codex Rotary

...squid

royalty free 3d model codex rotary for download as stl on turbosquid: 3d models for games, architecture, videos. (1439894)

turbosquid

$12

Rotary drill

...y free 3d model rotary drill for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1394316)

3d_export

$6

The rotary module 3D Model

...the rotary module 3d model

3dexport

the rotary module

the rotary module 3d model armata2015 98145 3dexport

turbosquid

$40

Rotary Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Rotary Phone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

ROTARY medal

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Rotary conveyor

...veyor for download as 3ds, max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1300472)

3d_export

$5

Rotary Cylinder 3D Model

...rotary cylinder 3d model

3dexport

rotary cylinder pneumatic pressure torque

rotary cylinder 3d model fau 71217 3dexport

3ddd

$1

Medical Rotary Table M2

...medical rotary table m2

3ddd

медицинский , стол

medical rotary table m2

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

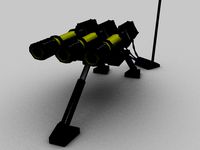

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below: