Thingiverse

Laser measuring device for the sharpening angle of knives by Zefram_Cochrane

by Thingiverse

Last crawled date: 3 years, 1 month ago

Laser measuring device for the sharpening angle of knives

Since Thingiverse does not offer proper formatting solutions for texts or the possibility to enter formulas I recommend all those who want to learn more about the background to visit my website.: www.science-feles.de.

I would be very happy about a Tip.

Introduction

In addition to the steel alloy, the grinding angle of the blade is decisive for the sharpness and service life of a knife blade. The smaller the angle, the thinner the blade can be ground and the sharper it is. However, this significantly reduces the time in which the knife is sharp. The material removal is higher, it is easier to break pieces from the blade and it becomes chipped and the fine phase bends and must be straightened again. The greater the angle, the longer the service life, greater is the robustness but significantly less is the sharpness of the blade.The sharpening angle depends exclusively on the alloy of the steel and is selected by the manufacturer of the knife based on this. Steel with a high carbon content will have a correspondingly smaller grinding angle than a stainless steel blade. Each knife has an individually calculated angle that must be maintained.

My measuring principe

When light hits a smooth surface with low surface roughness, such as a metallic knife blade, the light beam is reflected back in a directional reflection based on the law of reflection. The angle of incidence (δ) of the incident light beam is equal to the angle of reflection (δ') of the reflected beam. Both lie on the same plane of incidence.

If the knife is lying on its back with the blade pointing upwards and a laser beam shines exactly perpendicular to the blade, the light beam is split. It is reflected depending on the sharpeningangle of the blade. If it is a double beveled knife edge, two reflection points will be created mirror symmetrically. With single beveled knife edges, one reflection point will be asymmetrical to the other. The width of the two projected points indicates whether the blade was ground evenly, flat, concave or convex. Ideally, only two clearly defined points should be visible.

Trigonometry

The distance between the reflection point and the mirror axis provides information about the grinding angle of the knife. The greater the distance, the greater the angle.

To calculate the angle, we need two pieces of information. The exact distance between the reflection points to the mirror axis, and the perpendicular distance from the reflection surface to the knife blade. Using these two values (a and b), the side c can be calculated via the Pythagorean theorem (Fig). By means of the cosine rule the angle α at the reflection point R (Fig 2) between the sides c and b can be calculated. The actual grinding angle of the knife is equal to the angle bisector here. I made a small sheet in Excel to simplify the calculations.

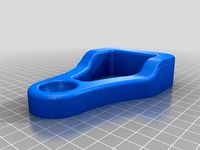

Printing the measurement setup

I have designed and 3D-printed a holder for simple kitchen knives with a small blade in order to be able to reproducibly determine the grinding angle with exact values. For this, the blade is simply clamped, the laser inserted and the reflection projected onto a sheet of paper. I use a simple and cheap violet laser with a diameter of 13.3 mm. Then, only the distance between the sheet of paper and the blade as well as projection points must be measured and entered into the formula.

I'm still working on the design of the holder so that larger knives can fit in it.

Ceterum censeo martem esse abeundum.

Since Thingiverse does not offer proper formatting solutions for texts or the possibility to enter formulas I recommend all those who want to learn more about the background to visit my website.: www.science-feles.de.

I would be very happy about a Tip.

Introduction

In addition to the steel alloy, the grinding angle of the blade is decisive for the sharpness and service life of a knife blade. The smaller the angle, the thinner the blade can be ground and the sharper it is. However, this significantly reduces the time in which the knife is sharp. The material removal is higher, it is easier to break pieces from the blade and it becomes chipped and the fine phase bends and must be straightened again. The greater the angle, the longer the service life, greater is the robustness but significantly less is the sharpness of the blade.The sharpening angle depends exclusively on the alloy of the steel and is selected by the manufacturer of the knife based on this. Steel with a high carbon content will have a correspondingly smaller grinding angle than a stainless steel blade. Each knife has an individually calculated angle that must be maintained.

My measuring principe

When light hits a smooth surface with low surface roughness, such as a metallic knife blade, the light beam is reflected back in a directional reflection based on the law of reflection. The angle of incidence (δ) of the incident light beam is equal to the angle of reflection (δ') of the reflected beam. Both lie on the same plane of incidence.

If the knife is lying on its back with the blade pointing upwards and a laser beam shines exactly perpendicular to the blade, the light beam is split. It is reflected depending on the sharpeningangle of the blade. If it is a double beveled knife edge, two reflection points will be created mirror symmetrically. With single beveled knife edges, one reflection point will be asymmetrical to the other. The width of the two projected points indicates whether the blade was ground evenly, flat, concave or convex. Ideally, only two clearly defined points should be visible.

Trigonometry

The distance between the reflection point and the mirror axis provides information about the grinding angle of the knife. The greater the distance, the greater the angle.

To calculate the angle, we need two pieces of information. The exact distance between the reflection points to the mirror axis, and the perpendicular distance from the reflection surface to the knife blade. Using these two values (a and b), the side c can be calculated via the Pythagorean theorem (Fig). By means of the cosine rule the angle α at the reflection point R (Fig 2) between the sides c and b can be calculated. The actual grinding angle of the knife is equal to the angle bisector here. I made a small sheet in Excel to simplify the calculations.

Printing the measurement setup

I have designed and 3D-printed a holder for simple kitchen knives with a small blade in order to be able to reproducibly determine the grinding angle with exact values. For this, the blade is simply clamped, the laser inserted and the reflection projected onto a sheet of paper. I use a simple and cheap violet laser with a diameter of 13.3 mm. Then, only the distance between the sheet of paper and the blade as well as projection points must be measured and entered into the formula.

I'm still working on the design of the holder so that larger knives can fit in it.

Ceterum censeo martem esse abeundum.

Similar models

3dwarehouse

free

Knife Sharpening Jig

...knife sharpening jig

3dwarehouse

super accurate knife sharpening jig to make knives razor sharp

3dwarehouse

free

knife blade with full tang

...4mm thick blade nearly 1' wide, 4 3/4' long, 8 3/8' overall. careful, it's sharp. #blade #clip_point #knife #tang

thingiverse

free

Knife Sharpening Guide | Arca Acuta by smgill

...ure to read the instructions in the section headed, "how do i use it?" i hope this is as useful to you as it was to me.

3dwarehouse

free

Flamberge

...the medieval times. #blade #bladed #blades #edge #edged #flamberge #knife #knives #long #sharp #sharpened #sword #weapon #weapons

thingiverse

free

Angle Guide for Shapening Steel by CNCKitchen

...arpening steels with a diameter of 14mm.

this will help you to hold the perfect blade angle when sharpening your precious knifes.

grabcad

free

Laser liner - UMAREX

...r - umarex

grabcad

- a simple device to measure distances , areas and volumes based on ultrasonic beam and laser beam reflection

grabcad

free

Knife Sharpener

...bles-with-a-fastened-wire-clamp-on-the-knife-blade-1

the model is available as a step file (.stp) of the complete assembly only.

cg_trader

$10

Yinxiang Knife

...nifes knive knives weapon coldweapon whitearm blade steel sharp chrome bladed weapon cutting handle various models various models

3dwarehouse

free

compass range finder MK1

...se

finds the range of two targets and calculates the distance between them using the pyth therum #laser #measuring #range_finder

thingiverse

free

Sharpening Guide for 6" Ryobi Bench Grinder by n7jti

...of the shaft and hold my blade level with the ground and grind on the wheel on that line. (pictures added) works like a champ!

Zefram

thingiverse

free

Arduino Holder by zefram

...older by zefram

thingiverse

holder for the smaller arduino boards, leonardo, uno etc... stl and step files are in the downloads.

thingiverse

free

Scanner Booth by zefram

...scanner booth by zefram

thingiverse

scanner booth made from laser cut acrylic sheets and 3d printed abs blocks.

thingiverse

free

Zefram Cochrane by stanojoski

...first contact. i looked for it but didn't find it, so here it is.. i tried my best. i hope you love it and share your prints.

thingiverse

free

Liberator by zefram

...akes 7. the finished model is 435mm (17 inches) long. the biggest part is about 110mm, so should fit on a lot of common printers.

thingiverse

free

Playstation Eye Cover by zefram

...playstation eye cover by zefram

thingiverse

a plastic cap that covers the playstation eye camera when it is not in use.

thingiverse

free

Square Gears for 3D Printing by zefram

...square gears for 3d printing by zefram

thingiverse

copy of square gears, made into an stl file for printing.

thingiverse

free

Boe-Bot Stand by zefram

...giverse

stand to support the parallax boe-bot robot, while you are testing programs, holds the robot with wheels off the ground.

thingiverse

free

Tamiya Paint Stand Extension by zefram

...nd extension by zefram

thingiverse

this is an extension for the tamiya paint stand, it adds a tier to hold an additional 5 pots.

thingiverse

free

Travel Tic-Tac-Toe by zefram

...c-tac-toe by zefram

thingiverse

a tic-tac-toe game where you can't lose the pieces!

stl and step files are in the downloads.

thingiverse

free

Knurled Center Knob for Napier Deltic Engine Model by zefram by ryonsherman

...ram's napier deltic engine model inspired by the build by 3gng.

the gear includes a knurled knob to allow for easy operation.

Cochrane

3d_export

$50

ironclad frigate cochrane 3d

...ironclad frigate cochrane 3d

3dexport

design_connected

$7

Cale & Brady

...cale & brady

designconnected

q collection cale & brady stools computer generated 3d model. designed by anthony cochran.

3d_export

$60

Norton Commando 850 3D Model

...hopper rebel jukebox cochran young james british harley indian twin cc speed

norton commando 850 3d model gonzo_3d 21370 3dexport

thingiverse

free

Zefram Cochrane by stanojoski

...first contact. i looked for it but didn't find it, so here it is.. i tried my best. i hope you love it and share your prints.

thingiverse

free

Electronic housing for Cochrane ringlight by Zefram_Cochrane

...the lab: cochrane lab designs.

housing for the electronics of my microscope ringlight. https://www.thingiverse.com/thing:4842732

thingiverse

free

Cochrane Ringlight for microscopes by Zefram_Cochrane

...e illumination of the sample to be able to improve the contrast by targeted shadow casting.

ceterum censeo martem esse abeundum.

thingiverse

free

Cochrane 60 mm hotend cooler for Ender 3 with BlTouch by Zefram_Cochrane

...y smaller resulting in a smoother measuring point.

the clamp on the right side is reinforced

ceterum censeo martem esse abeundum.

thingiverse

free

Microscope eyepiece protection cap by Zefram_Cochrane

... the lab: cochrane lab designs.

visit my website for more information: www.science-feles.de.

i would be very happy about a tip.

thingiverse

free

Funway 1 "Project Board"

...has been unchanged for several years now (last item listed in project milestones is november 2016) https://funwayelectronics.com/

grabcad

free

Ryan Cochran

...ryan cochran

grabcad

gcxszf

Knives

3d_export

$5

knives

...knives

3dexport

3 knives

archibase_planet

free

Knives

...knives

archibase planet

knife knives kitchen ware

knives gipfel n170211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Knive

...quid

royalty free 3d model knive for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1278438)

turbosquid

$30

knives

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Knives

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

KNIVE

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Knives

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

knives

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

knive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

knives

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Sharpening

turbosquid

$5

Sharpener

...

turbosquid

royalty free 3d model sharpener for download as on turbosquid: 3d models for games, architecture, videos. (1603397)

3d_export

$5

sharpener

...r is made in the compass 3d program, the rendering is made in the keyshot program. the model is saved in the stl, fbd, stl format

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Sharpener

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Device

3ddd

$1

device

...device

3ddd

device

3ddd

$1

device

...device

3ddd

device

turbosquid

$25

Device

...royalty free 3d model device for download as ma, max, and obj on turbosquid: 3d models for games, architecture, videos. (1431298)

archive3d

free

Device 3D Model

...device 3d model

archive3d

equipment device

device- 3d model for interior 3d visualization.

archive3d

free

Device 3D Model

... model

archive3d

device

device n050608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Device 3D Model

...e 3d model

archive3d

device gear

device - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$24

ICG Device

...turbosquid

royalty free 3d model icg device for download as on turbosquid: 3d models for games, architecture, videos. (1692389)

3d_export

$5

rope tighten device

...rope tighten device

3dexport

rope tighten device

3d_export

$5

front clamping device

...front clamping device

3dexport

front clamping device

archive3d

free

Device 3D Model

...e3d

device kitchen ware

device n130208 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Angle

design_connected

$25

Angle

...angle

designconnected

flou angle sleep furniture computer generated 3d model. designed by rodolfo dordoni.

3ddd

$1

FLOU / Angle

...flou / angle

3ddd

flou

кровать flou angle. все карты процедурные.

3ddd

free

Кровать ANGLE flou

...le , flou , постельное белье

кровать angle flou

design_connected

$16

Calin Angle

...calin angle

designconnected

ligne roset calin angle computer generated 3d model. designed by mourgue, pascal.

3d_export

$5

angle grease nipple

...angle grease nipple

3dexport

angle grease nipple

3ddd

$1

Двуспальная кровать Angle

...ngle. двуспальную кровать с подъемным механизмом angle оценят и те, кто любит практичность: кровать имеет объемый ящик для белья.

turbosquid

$10

Angle Wardrobe

...e 3d model angle wardrobe for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1301544)

turbosquid

$9

Angle Stool

...y free 3d model angle stool for download as max, skp, and skp on turbosquid: 3d models for games, architecture, videos. (1694318)

3d_export

free

angle bracket

...t 3d model part. it is the combination of a bra and ket (bra+ket = bracket) which represents the inner product of two functions.

turbosquid

$6

Angles Pouf

...e 3d model angles pouf for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1577097)

Measuring

3d_export

$5

measuring instrument

...measuring instrument

3dexport

measuring instrument

3d_export

$10

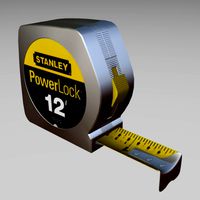

measuring tape

...ng tape

3dexport

measuring tape 3dmodel includes all materials , texture and lighting ,3dmax , 3ds , obj , dw. rendererd by vray

turbosquid

$15

Tape Measure

...uid

royalty free 3d model tape measure for download as blend on turbosquid: 3d models for games, architecture, videos. (1700720)

turbosquid

$5

Tape measures

...quid

royalty free 3d model tape measures for download as max on turbosquid: 3d models for games, architecture, videos. (1319446)

turbosquid

$5

Measuring Cups

... 3d model measuring cups for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1289678)

turbosquid

$3

Measuring Spoons

...d model measuring spoons for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1289679)

turbosquid

$55

Tape Measurer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Tape Measure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Tape Measure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

Tape Measurer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.