Thingiverse

Kiteboard deep concave with OPENSCAD mod files. by fluidity

by Thingiverse

Last crawled date: 3 years, 1 month ago

The final STL file is for DELTA printing, most other printers won't go high enough unless you make it really small. This is a 1/10 scale 1400mm x 400mm board.

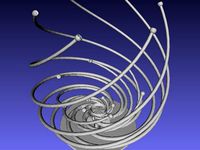

I developed the surface with tweaks to my vase building program. The base cylinder is wider at the ends and deformed to sway left the closer it gets to the middle in height. As a consequence, the vertical surface slice I have chosen has a little less concave towards the ends (easier turning). Also, I've got two scales of sinewave playing out over the radius and height so that the ends have a small amount of progressive rocker.

Running the *.SCAD programs in sequence(instal openscad first) gives options to fine tune thickness, rocker, concave and outline. The handle would be a nice print in ninjaflex.

ourwaveA2.scad gives fine tuning of the outline by combining an ellipse inner guide shape with a radiused addition all around the outside of the ellipse. While a pointier true ellipse shape would probably give a smoother ride, the selected compromise gives a visually pleasing shape with a more compact, back of car shape. Rocker is gentle for upwind capability but is still there to make it more friendly riding waves downwind.

My next step is to do DXF slices and print them out in A1, or get them CNC cut to form my templates for the test build with strip-built wood under surface. Once they are glued to each other over the formers, I will finish one side with basalt, graphics and surface tissue before flipping and adding a bit of volume, handle, binding and fin screw fixings and overcoating with more composite fabrics. If you've got the CNC equipment to try this out then please bookmark this design and post your progress! Hopefully I'll have one ready to ride in about a month! Note that the rounded ends make this the equivalent of a slightly shorter square ended board.

"Kiteboard outlines.pdf" is for printing in a huge A0 sheet of paper. The bulkhead forms should be glued in line at 100mm spacings. The partial outline can be printed twice and rotated 180 degrees and overlapped or folded between the center handle holes to trace the other end.

I developed the surface with tweaks to my vase building program. The base cylinder is wider at the ends and deformed to sway left the closer it gets to the middle in height. As a consequence, the vertical surface slice I have chosen has a little less concave towards the ends (easier turning). Also, I've got two scales of sinewave playing out over the radius and height so that the ends have a small amount of progressive rocker.

Running the *.SCAD programs in sequence(instal openscad first) gives options to fine tune thickness, rocker, concave and outline. The handle would be a nice print in ninjaflex.

ourwaveA2.scad gives fine tuning of the outline by combining an ellipse inner guide shape with a radiused addition all around the outside of the ellipse. While a pointier true ellipse shape would probably give a smoother ride, the selected compromise gives a visually pleasing shape with a more compact, back of car shape. Rocker is gentle for upwind capability but is still there to make it more friendly riding waves downwind.

My next step is to do DXF slices and print them out in A1, or get them CNC cut to form my templates for the test build with strip-built wood under surface. Once they are glued to each other over the formers, I will finish one side with basalt, graphics and surface tissue before flipping and adding a bit of volume, handle, binding and fin screw fixings and overcoating with more composite fabrics. If you've got the CNC equipment to try this out then please bookmark this design and post your progress! Hopefully I'll have one ready to ride in about a month! Note that the rounded ends make this the equivalent of a slightly shorter square ended board.

"Kiteboard outlines.pdf" is for printing in a huge A0 sheet of paper. The bulkhead forms should be glued in line at 100mm spacings. The partial outline can be printed twice and rotated 180 degrees and overlapped or folded between the center handle holes to trace the other end.

Similar models

thingiverse

free

Kiteboarding fin by brammezz

... prefer to ride very small fins on my thigh rocker, wakestyle kiteboards or when the water is nice and glassy.

32,67mm x 150mm

thingiverse

free

Improved parametric propeller by Robotbeat

...int out straight on the print bed, and it works fine.

try it out! it may take a while to compile in openscad or the customizer.

thingiverse

free

Kiteboard (deep concave) test profile with supports. by fluidity

...00mm board.

i have kiteboard fins listed among my thingiverse creations too.

best printed on a nice high printer like my rostock.

thingiverse

free

Covid Vaccine Trophy by nescro147

...r covid vaccine. in my print, i dropped the virus-cell through the print bed before slicing to give it a flat surface for gluing.

thingiverse

free

Small Beads by pmoews

...program makes spacers.

templates are included in the programs and the openscad code includes instructions for making other beads.

thingiverse

free

Paddles for use with Goodminton or Jazzminton birdies by arpruss

...do the handles in two other ways:

cut out the flat handle piece and then round it by sanding

3d print the inflated handle pieces.

thingiverse

free

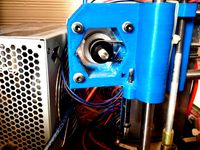

Prusa i3 X-end-motor with Z adjuster, by Chema by ChemaFuji

...

this is the x-end-motor with a customization to put a m3 screw to make fine tuning of z heigh home position.

added scad files!!

grabcad

free

Wakeboard

...ability level: advanced-expert

rocker type: three-stage

core material: carbonfiber, foamcore

base type: slider/grind base

fins: 4

thingiverse

free

Mjolnir remix for handle strength by pchanizzle

...andle. the hammerhead i left basically the same but i put a trapezoid shape in the socket for a little more gluing surface area.

thingiverse

free

kiteboard handle by moon3jp

...kiteboard handle by moon3jp

thingiverse

kiteboard handle

Kiteboard

3d_export

$22

GoPro Hero2 Camera GoPro 3D Model

...go-pro go pro camera hd underwater waterproof hero kitesurf kiteboard surf sport adventures rc mini gopro hero2 camera gopro...

thingiverse

free

kiteboard handle by moon3jp

...kiteboard handle by moon3jp

thingiverse

kiteboard handle

thingiverse

free

Kiteboard Fin by atunguyd

...kiteboard fin by atunguyd

thingiverse

kiteboard fin based on original design by edditiv

thingiverse

free

Kiteboard fin by tomembke

...kiteboard fin by tomembke

thingiverse

i bought an used kiteboard without fins so ive printed some.

thingiverse

free

Kiteboard mount by andyteler1

...kiteboard mount by andyteler1

thingiverse

kiteboard mount. its works really good!https://www.youtube.com/watch?v=ozt1wvi6sii

thingiverse

free

Twintip kiteboard fin washer by hullabaloo

...tip kiteboard fin washer by hullabaloo

thingiverse

twintip kiteboard fins washers. pretty standard. print 4 pcs for 1 kiteboard.

thingiverse

free

Kiteboarding fin by brammezz

... prefer to ride very small fins on my thigh rocker, wakestyle kiteboards or when the water is nice and glassy.

32,67mm x 150mm

thingiverse

free

Kiteboarding Nozzle by ariasr

...kiteboarding nozzle by ariasr

thingiverse

air compressor adapter for inflating kites

thingiverse

free

Kiteboard Snowboard Board Holder Wallmount by PreMaker

...kiteboard snowboard board holder wallmount by premaker

thingiverse

kiteboard / snowboard stackable wallmount

thingiverse

free

Fin kiteboard by MarcoMT

...fin kiteboard by marcomt

thingiverse

fin kitesurf

size in mm: 120 x 10 x 4.5

Fluidity

3ddd

$1

CORVO by NURUS (turkey)

...and manufacture. corvo, the combination of structural form and fluidity offers its user...

3ddd

$1

NAIAD AMBER

...shown here in a deep amber finish. the generous fluidity and curves give this lamp a true artisan feel....

3d_export

$65

MQ-9 Reaper USAF

...in mid to high poly to maintain its polygon fluidity and its accuracy. additional props are included in the...

thingiverse

free

Surfski race rudder, 132mm deep. by fluidity

...surfski race rudder, 132mm deep. by fluidity

thingiverse

this fin is intended as a plug to sand cast an aluminium fin from.

thingiverse

free

Voronoi wavetube by fluidity

...s after a couple of hours of fiddling with settings on meshlab.

if any of you print it, i'd love to see a picture please! :-)

thingiverse

free

Vibration absorbing mounts by fluidity

...umber ones at a lower height(design is 10mm high) for more stretch, print the shorter ones higher or scaled up for more firmness.

thingiverse

free

Spike hangar. by fluidity

...s one which is much more functional. there won't be any issues for any reasonably tuned printer, the overhangs are all small.

thingiverse

free

Spiral helical hangar. by fluidity

...ater...

now with the openscad source. uses only a scaled and rotated sphere (elipsoid) and a differenced disc to form the base.

thingiverse

free

Chainmail experiment #3, spheremail. by fluidity

...xis. not as elegant as my other ones but i wanted to explore this particular idea and see how it looked finished, how it felt :-)

thingiverse

free

Sarah's Snowman. by fluidity

... underneath and i'll tidy the openscad file up for publishing so you can do different animations of it or change the footing.

Concave

design_connected

$9

Ridge Concave

...ridge concave

designconnected

chista ridge concave computer generated 3d model.

turbosquid

free

Concave Assymetry

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

CONCAVE BRASS_TABLE LAMP

...p

3ddd

thesofaandchair

concave brass_table lamp_mr-conc-lmp-001-001

размеры w:50cm / d:50cm / h:79cm

лампочки 2 x e27 max. 60w

turbosquid

$9

Stone pebble concave decorative

...3d model stone pebble concave decorative for download as max on turbosquid: 3d models for games, architecture, videos. (1511691)

turbosquid

$3

Her concave ring 1

...3d model her concave ring 1 for download as obj, 3dm, and stl on turbosquid: 3d models for games, architecture, videos. (1514535)

turbosquid

$5

Bed bench concave.3dm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Estanteria Zero Uno Concave

... zero uno concave for download as mat, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1378980)

turbosquid

$17

Ulu Concave Stool by Jonathan Adler

...u concave stool by jonathan adler for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1192743)

3ddd

$1

Ulu Concave Stool / Jonathan Adler

... столик , круглый

столик из полированной латуни от jonathan adler

3d_export

$18

concave bob grooming real-time hairstyle unreal engine 4

...to use: - for both personal and commercial projects watch the video below for some extra information and real-time demonstration.

Deep

3ddd

$1

Кровать Deep

...вать deep

3ddd

novamobili , deep

производитель: италия

фабрика : novamobili

модель: deep

3d_export

$5

deep-sea mine

...deep-sea mine

3dexport

deep-sea mine

turbosquid

$18

Deep fryer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Bookshelf deep

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

deep fat

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

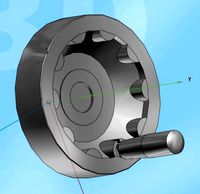

deep joint hand wheel

...deep joint hand wheel

3dexport

deep joint hand wheel

3ddd

free

Sonya Rugs / Deep Sunset

... круглый

ковёр deep sunset от sonya winner studiohttp://www.sonyawinner.com/deep-sunset

turbosquid

$15

Zaza sofas Deep

...id

royalty free 3d model zaza sofas deep for download as max on turbosquid: 3d models for games, architecture, videos. (1286690)

turbosquid

$10

DEEP SPACE JET

...ty free 3d model deep space jet for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1612277)

turbosquid

$99

Deep sea helmet

...free 3d model deep sea helmet for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1616360)

Openscad

thingiverse

free

OpenSCAD sphere

...openscad sphere

thingiverse

basic project for openscad.

thingiverse

free

Openscad Football by KySyth

...openscad football by kysyth

thingiverse

openscad not tested

thingiverse

free

Openscad Apple by KySyth

...openscad apple by kysyth

thingiverse

openscad apple = not tested

thingiverse

free

Plugs with openscad by benengel

...plugs with openscad by benengel

thingiverse

plugs with openscad and fontawesome

thingiverse

free

Openscad spirals by mafmuf

...openscad spirals by mafmuf

thingiverse

just fooling around with openscad.

thingiverse

free

Practice on OpenScad by ajensen906

...practice on openscad by ajensen906

thingiverse

a very crude practice on openscad

thingiverse

free

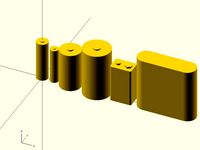

Batteries in OpenSCAD by roman_hegglin

...batteries in openscad by roman_hegglin

thingiverse

common batteries as modules for openscad.

thingiverse

free

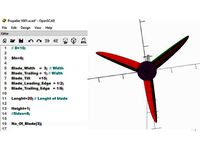

OpenScad Propeller by KySyth

...se

trying to make a propeller with openscad = not tested

this is some of the results

added the openscad file but still need work

thingiverse

free

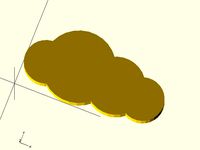

Openscad Cloud by Twanne

...openscad cloud by twanne

thingiverse

openscad cloud.

size can be adjusted

thingiverse

free

Geomag for OpenScad by vicnet

...geomag for openscad by vicnet

thingiverse

openscad file to design geomag things.

Mod

design_connected

$13

MOD. 4233 - MOD. 4234 Table Lamp

...mod. 4233 - mod. 4234 table lamp

designconnected

arcahorn mod. 4233 - mod. 4234 table lamp computer generated 3d model.

design_connected

$11

MOD.1095

...mod.1095

designconnected

mod.1095 computer generated 3d model. designed by sarfatti, gino.

3ddd

$1

fireplaces mod Spec

...fireplaces mod spec

3ddd

камин

fireplaces mod spec 180x90x125h

3ddd

free

Flos Mod. 2129

... mod

фабрика: flos

модель: mod. 2129

описание: подвесной светильник, металл, белый, черный.

сайт: www.flos.com

turbosquid

$34

Mod Lamp.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

MOD A 001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Maars Mod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Mod 70..

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

MOD Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Mod-Lite

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Files

archibase_planet

free

File

...file

archibase planet

locker box archive

fp suspension file wh - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

File

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Filing cabinet

...locker office paper storage store work

a simple but neatly-made filing cabinet, which ads a touch of relism to any office render.

turbosquid

$8

Filing cabinets

...id

royalty free 3d model filing cabinets for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371140)

turbosquid

$8

File Cabinet

...squid

royalty free 3d model file cabinet for download as fbx on turbosquid: 3d models for games, architecture, videos. (1572208)

turbosquid

$16

Filing Cabinet

...ree 3d model filing cabinet for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1310873)

turbosquid

$2

File Cabinet

... free 3d model file cabinet for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1357577)

turbosquid

$12

Nail File

...e 3d model nail file for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1588508)

turbosquid

$5

File Organiser

...model file organiser for download as blend, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1636447)

turbosquid

$1

Flat file

...e 3d model flat file for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1209808)